fernando meneses

12_design and make a 3D mold (~ft2), and produce a fiber composite part in it

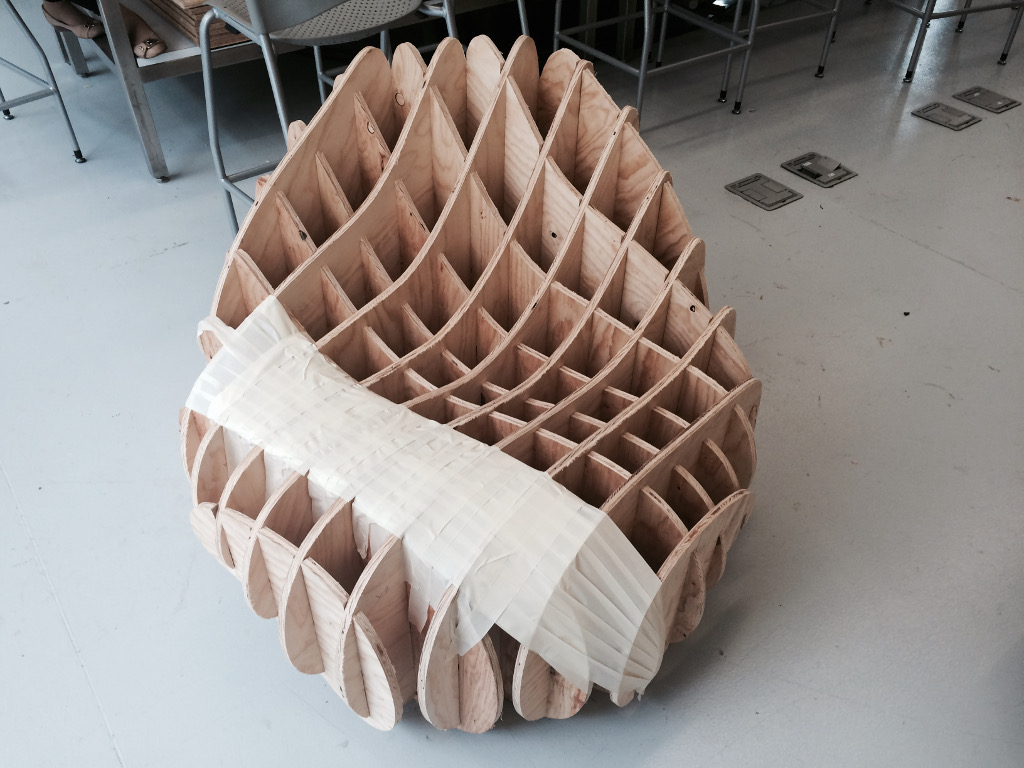

For this activity I will use the geometries of the week to do something big.

The idea is to have a surface that allows the continuity of the geometry.

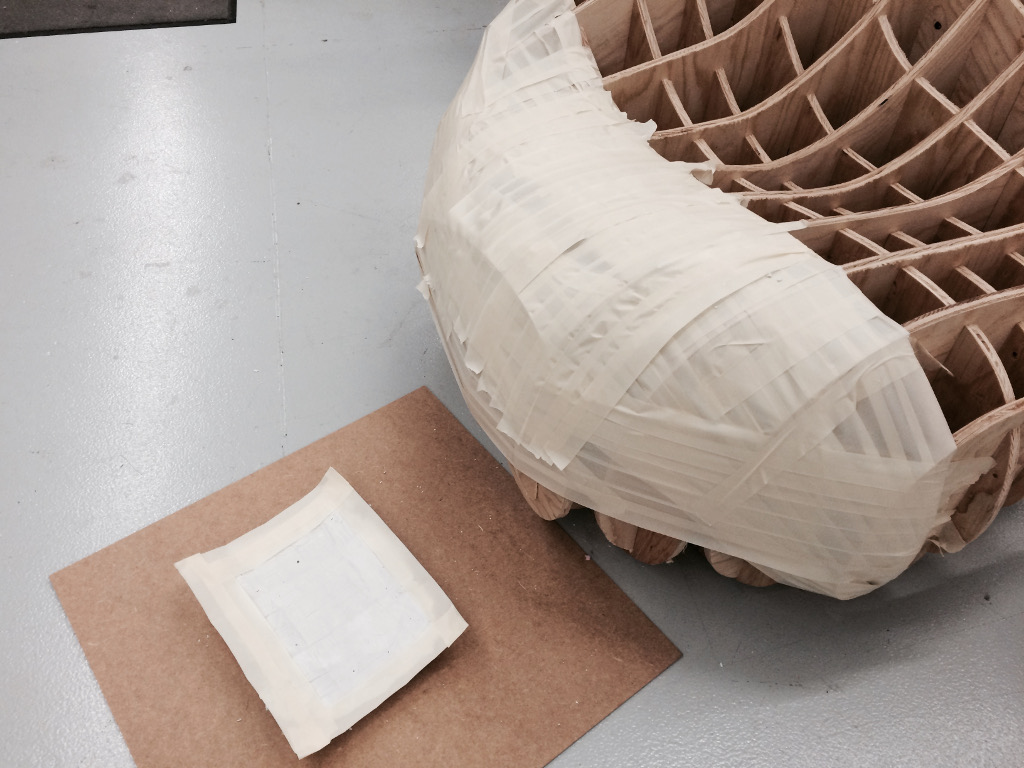

The first step is to divide the way surfaces that can be disassembled.

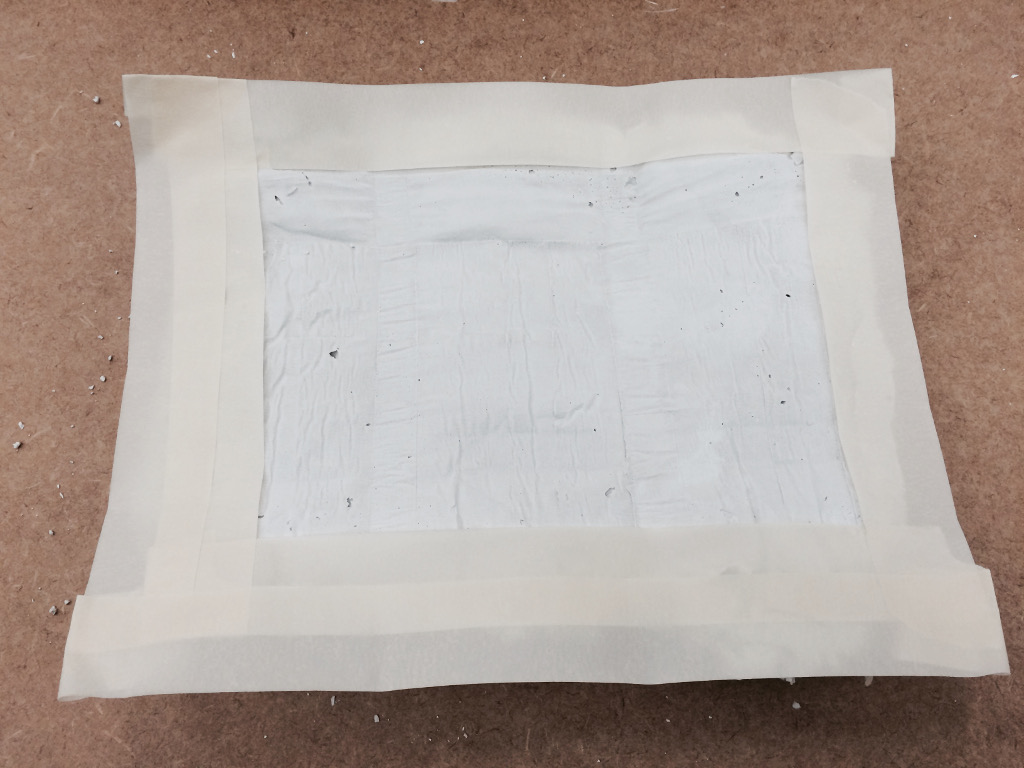

The process, make a plaster mold, polish the surface and then making fiberglass parts.

plaster mold process

_conclusions

In this activity it was possible to explore the use of composite materials, to explore something out of silicone, try making a compound based on plaster, gypsum is very easy to work, but if you hit it hard you can break in this case, put a small layer board can help the resistance, it is the technique used in the drywall.

Also explore a little bit with fiberglass, is a little more dangerous than the plaster, but resistance is much better, I think that the compounds are a good opportunity for particular projects. In this exercise presents a test, but the idea would be to use the chair as a template and create an entire surface of the chair.

_files

geometry.3dm

_

Original source: http://academy.cba.mit.edu/classes/composites/index.html

Contact: fernando.meneses@udem.edu / fernandomeneses@nodolab.com / f / in / g+ / b / v / mx / w