wk.14-Mechanical design, machine design

My contribution...

In general terms, I was in charge of the web page development, of the digital model check and development of the new digital elements if necessary, I tested the base digital model and I in company of the fab-team, i modeled all the new pieces and constructed the fabrications file for the differents machines "laser cutter, Shopbot machine, and 3d printer machine".

Downloading the files

The "fab team" begins this adventure with the obtaining the files for the fabrication process of each of the machine pieces, with this, the team saw some initial errors of the digital models, that affect in somehow the prototype process.

And most of settings...

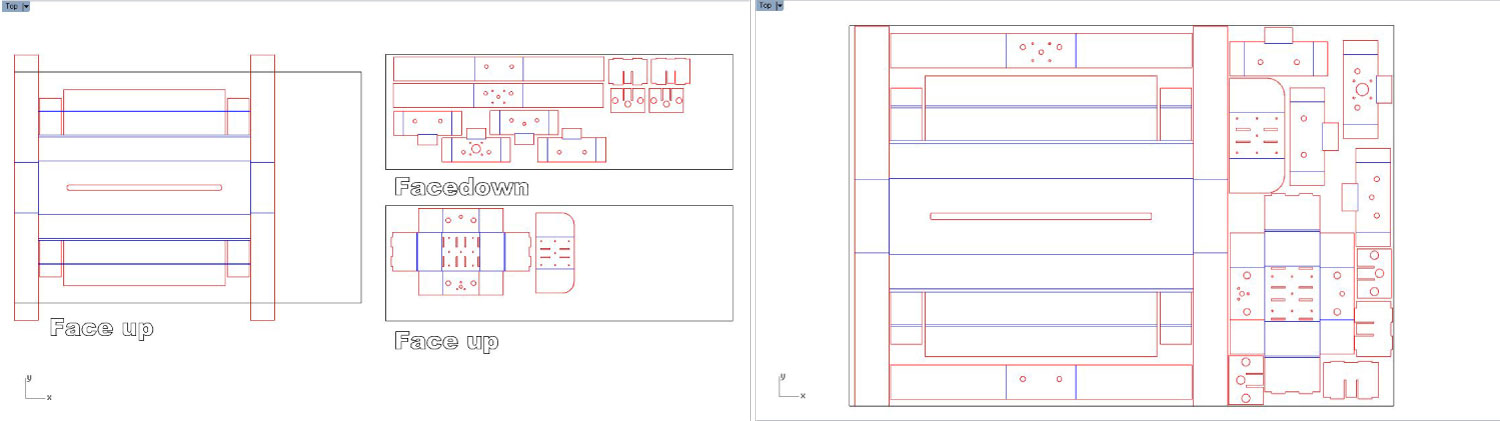

With the previous, we check the cut vectors in relationship with the digital models that is shown, and in this case also we found some errors as double line, and open vectors (nonoptimal for the laser cutting process), for this here we did the first modifications in the digitals files.

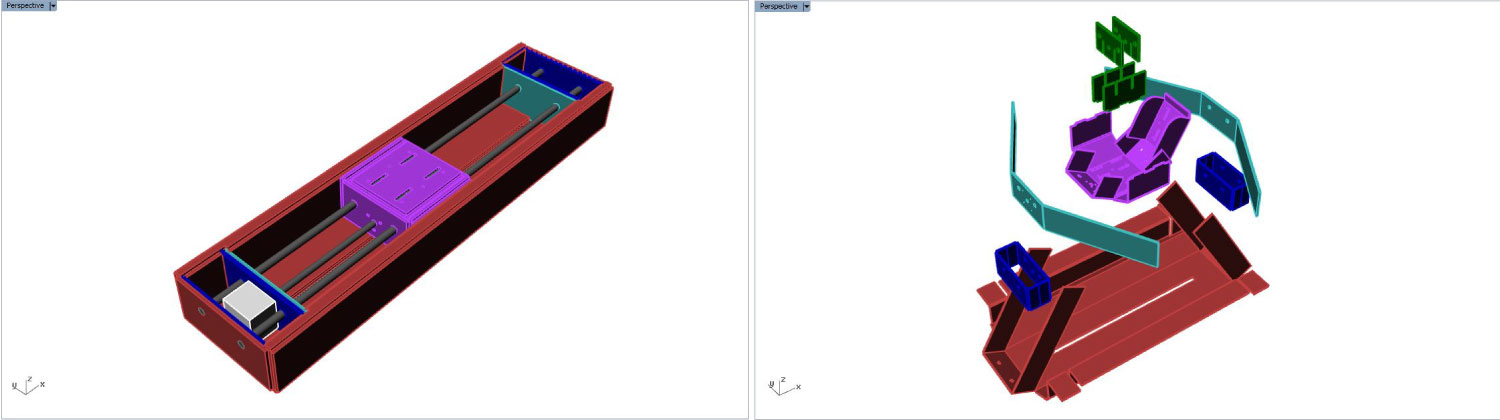

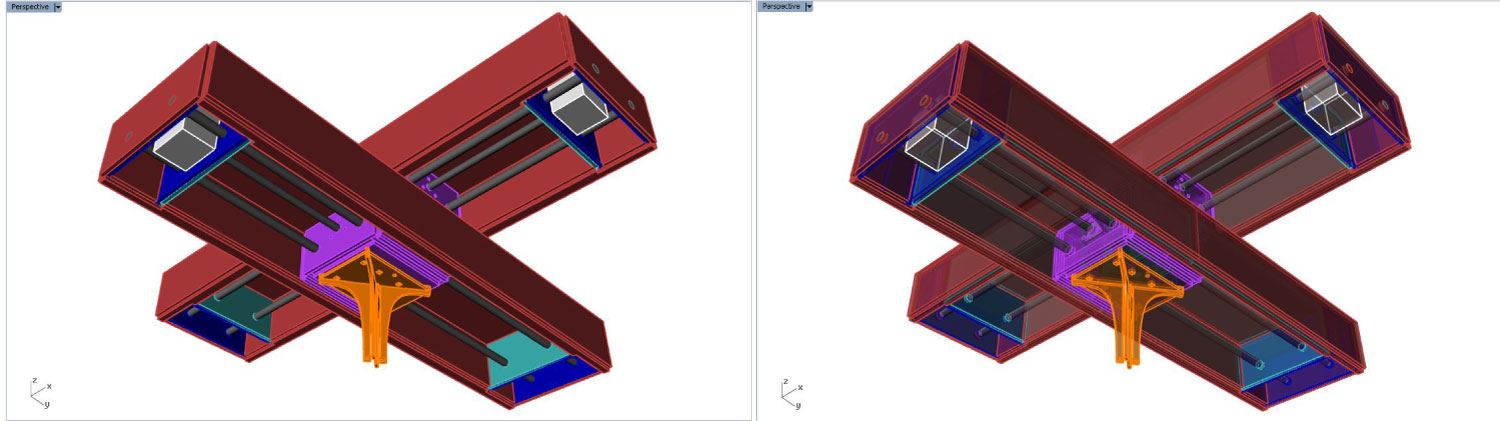

Definitely... We did reconstruction our cardboard model

And either for the tolerance, modeling in the human process, or divine causes, the cardboard prototype gave us serious problems to the hour of the assembling, for this we decided modeling ours digital prototype... of course based in "some details" of the downloading digital model (also for understanding much better the system).

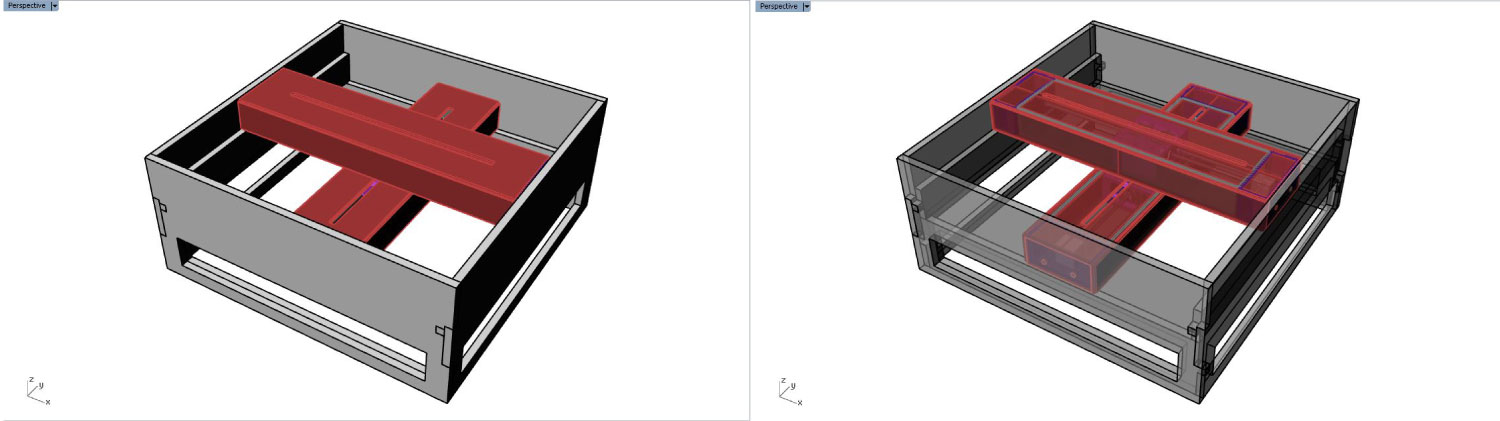

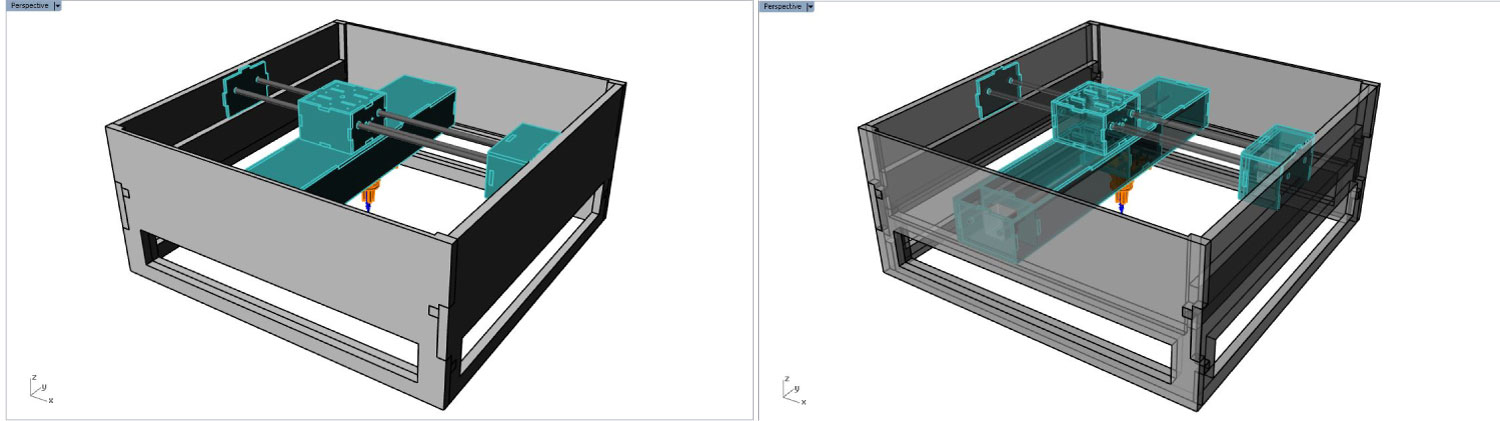

"Formwork for the machine"

By all the previous "inconvenients", and in towards improving our prototype, we designed a formwork in MDF-RH of 15 mm (remaining fab-material) for stiffening the CNC machine, and thinking in the better functioning system.

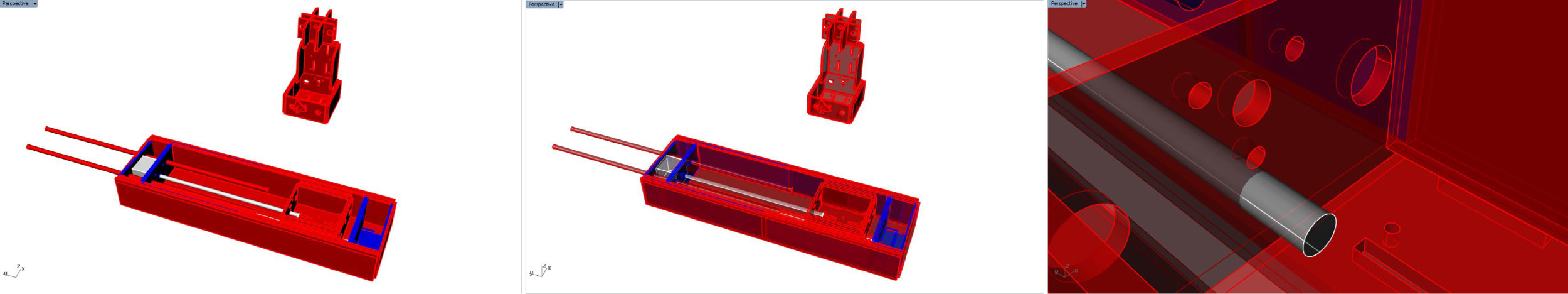

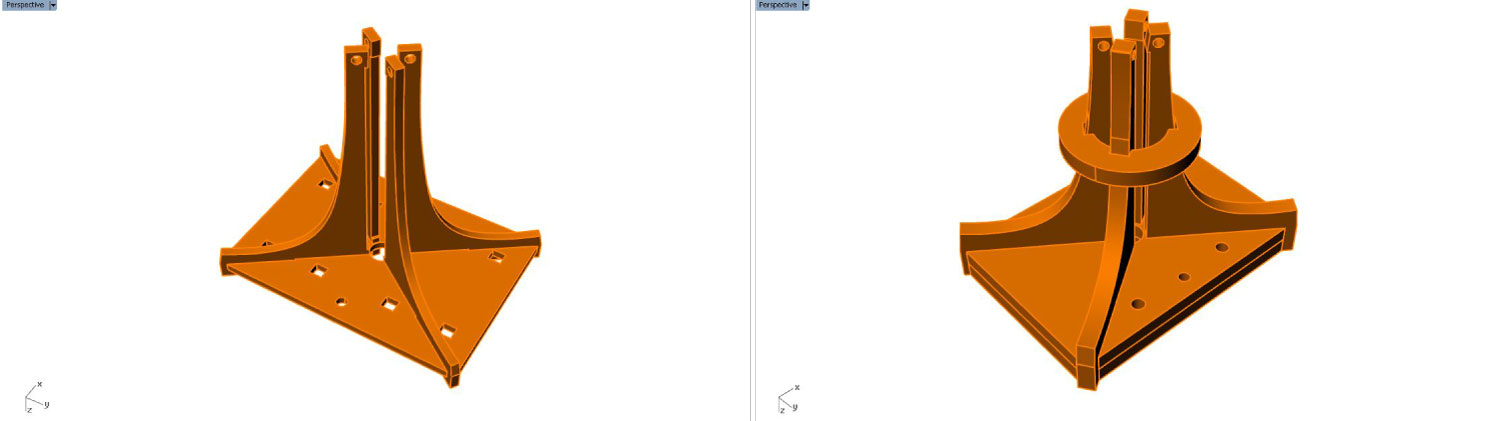

Bottom of the model

In this case we show the bottom part of the digital model, and how probably this is in the physical model.

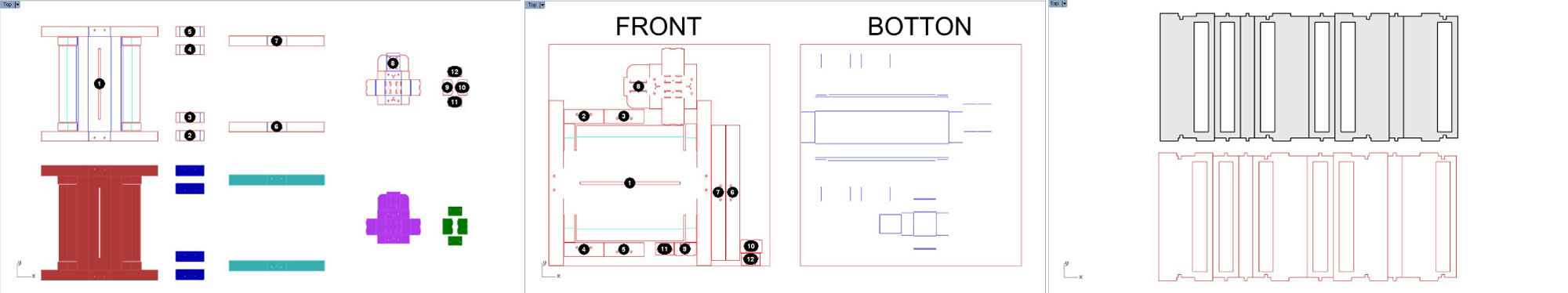

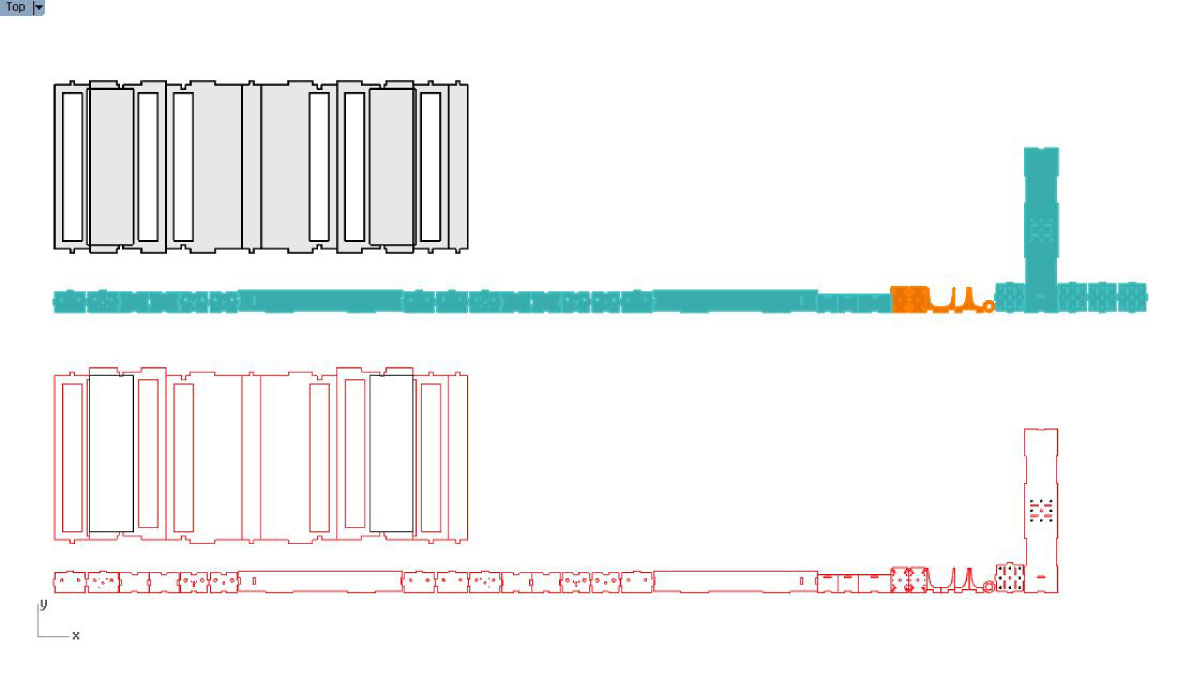

Cut vectors of the model

This is are the images of the nesting and vectors extractions for the machining process, the first two for the laser cutting machine, and the last for the Shopbot 2D cut process.

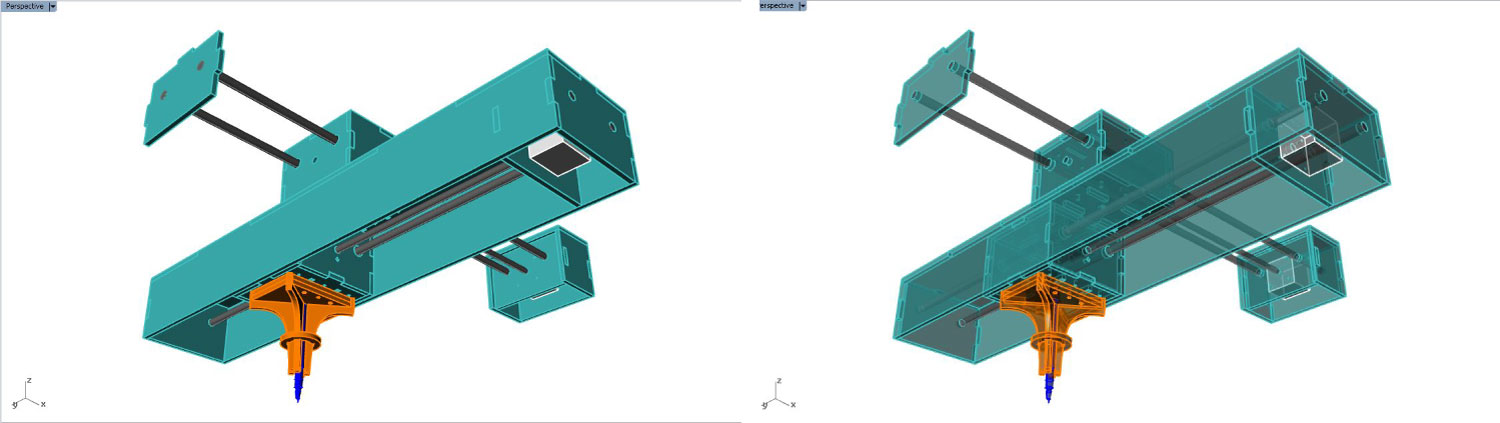

But...!!! We think that we can giving further improve machine.

After of the cardboard system testing, we again decided make the CNC in a rigid material, that in the remaining material inventory of the lab, was MDF of 5 mm, and we got ready to create a new CNC model, but always based in the downloading model

Here more details of new our MDF model.

In the same way that the previous explications, in this image, They are shown parts in machine inside and functioning system.

Other of our parts

Also we designed "as you see in the previous sketches" the pencil case, because we decided that our machine is a plotter prototype.

Manufacturing vectors of the model.. (of the MDF model).

This are the digital files "vectors" for the cut process in the shopbot machine.