wk.06-Electronics design

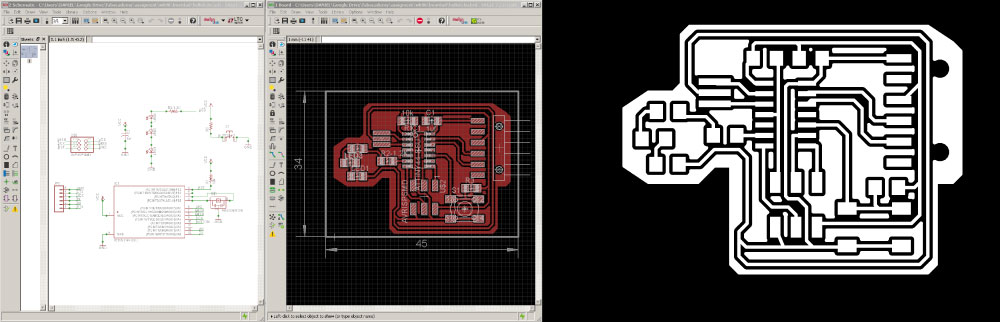

Circuit design

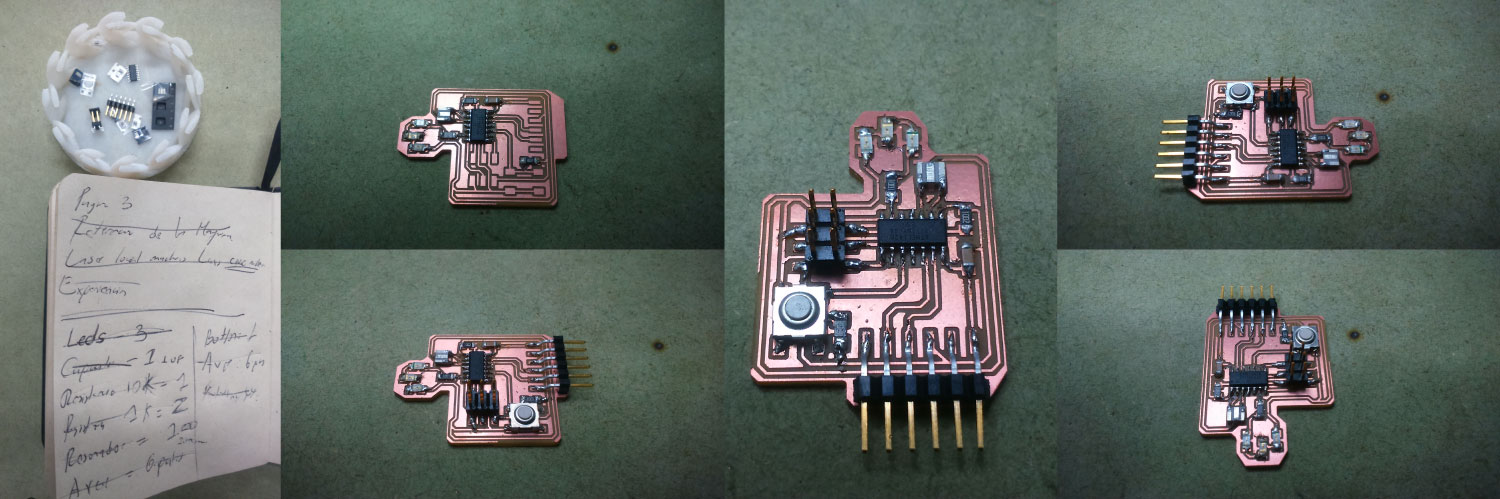

I began the assignment with the board design in the Eagle CAD software, taking as reference the "hello-eco" circuit, where i proposed a three leds series that light by pressing a button.

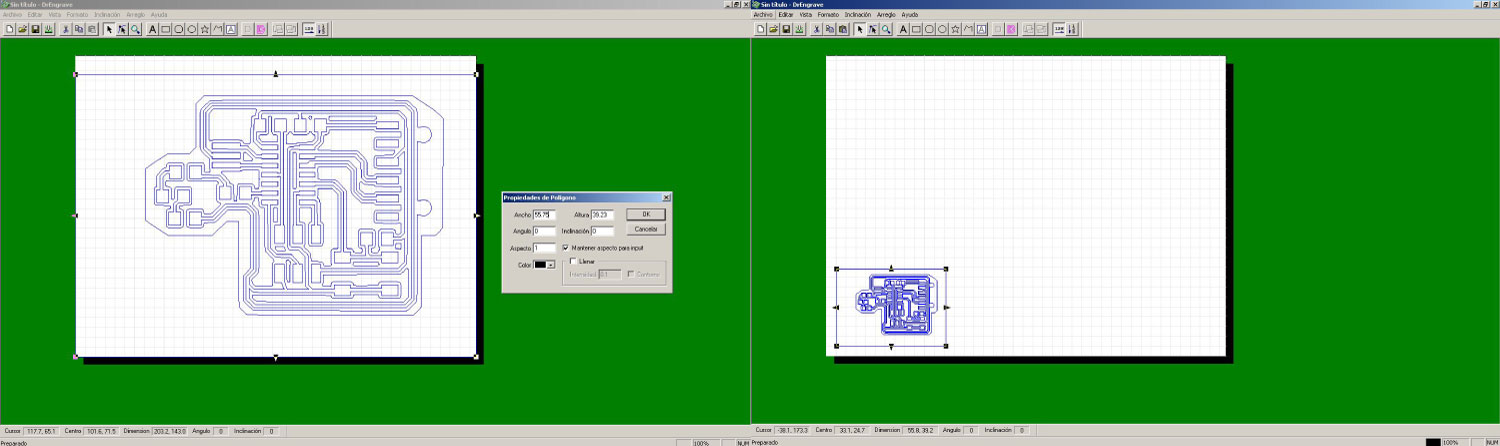

Creating the milling process in the Dr.Engrave software

Done the board design, i proceed with the creation of the cut process, this with the same parameters used in the electronic productions assignment, where the first image show the import of the .bpm file and the size configurations, (width=55.75, height=39.23).

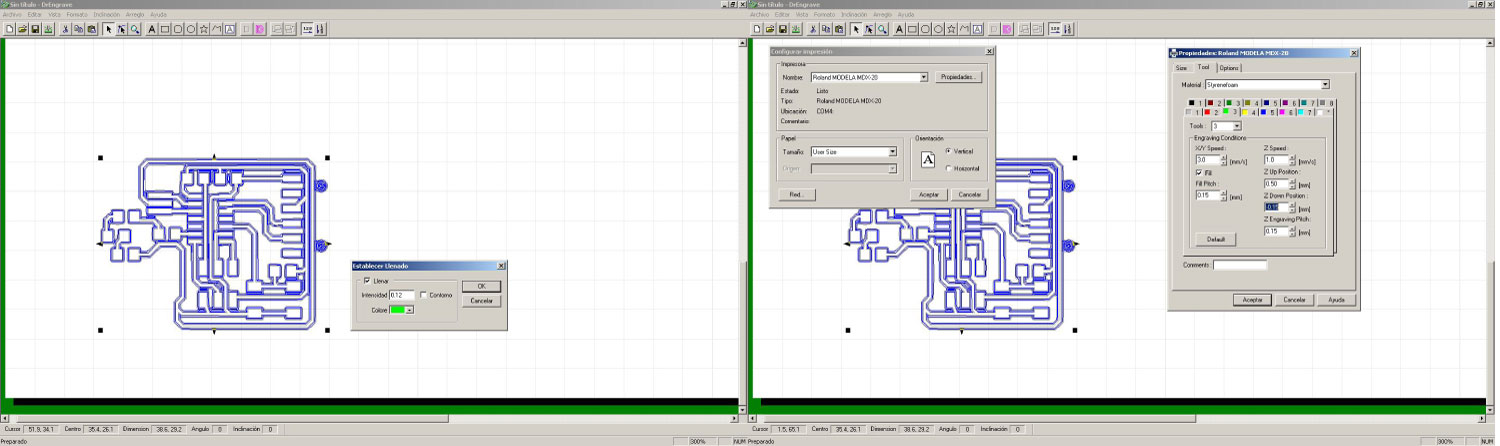

In this picture, I configure specifically the parameters of the milling routes and the thickness or definition of the "fill" parameter also the speed settings and machine movements (xy speed=3.0mm/s - fill pitch=0.15mm - z speed=1.0mm/s -z up position=0.50mm - z down position=-0.15mm, z engraving pitch=0.15mm), this because i used the 1/64 bit.

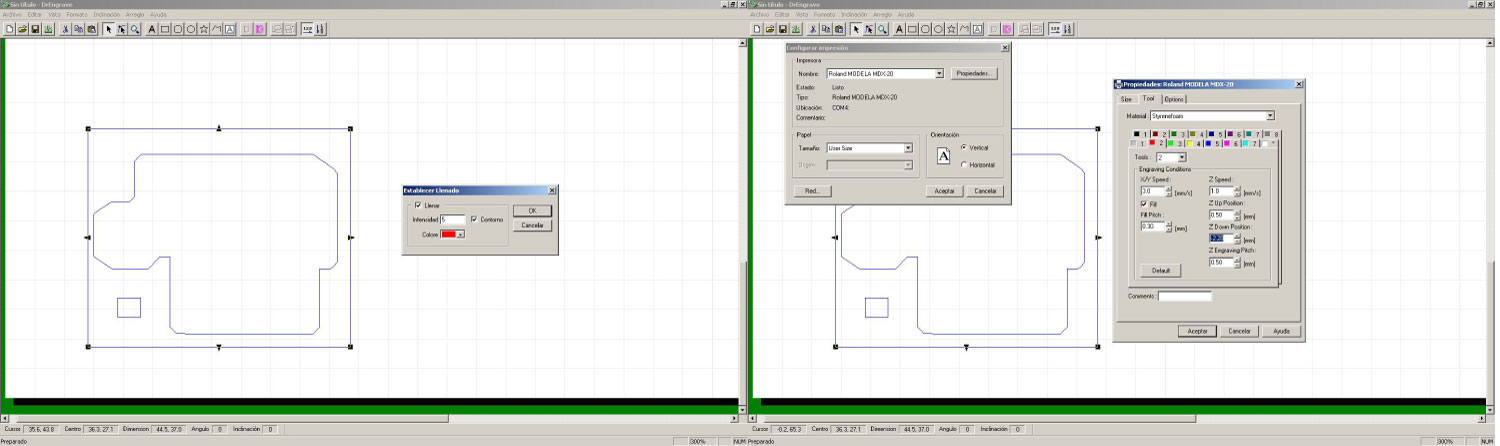

The last configuration step, is the cut process of the piece edges, this by the setting of the fill parameter in "5" and in the speed and movement parameters (xy speed=3.0mm/s - fill pitch=0.3mm - z speed=1.0mm/s -z up position=0.50mm - z down position=-2.20mm, z engraving pitch=0.5mm), this because i used the 1/32 bit.

Component list and welding process

Defined and manufactured the board in the Modela MDX 15/20 machine, i proceed with the consecution of the components for the welding process: