W11 ¦ Output Devices

Assignment for week 11

- Add an output device to a microcontroller board you've designed and program it to do something

- Link to this week’s homeworkpage

Stepper motor and hall sensor

This week I wanted to use the opportunity to program a Stepper motor for my final project. I added a Hall sensor the board as well. I intend to use the Hall sensor for positioning.

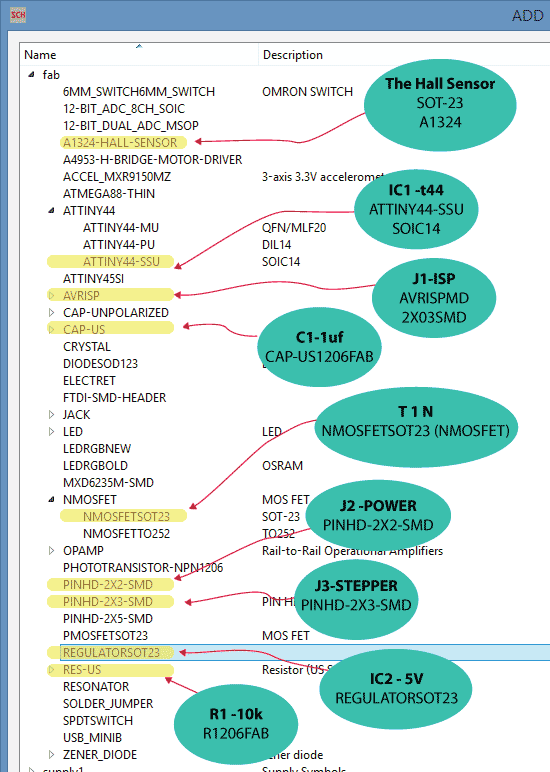

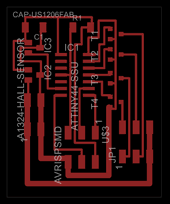

- These are the parts I used for the board.

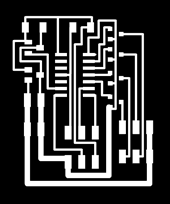

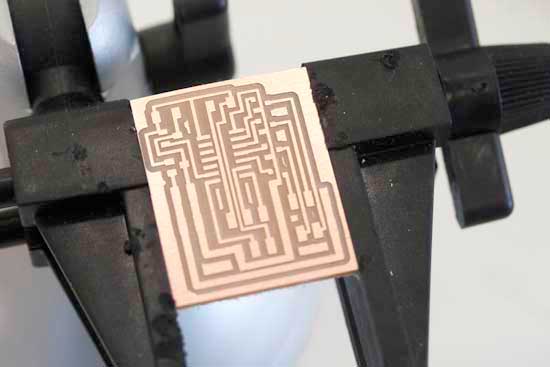

- The traces.

- Drawing in Eagle went well. I simply used my newfound knowledge of altering the image in Photoshop after having exported it.

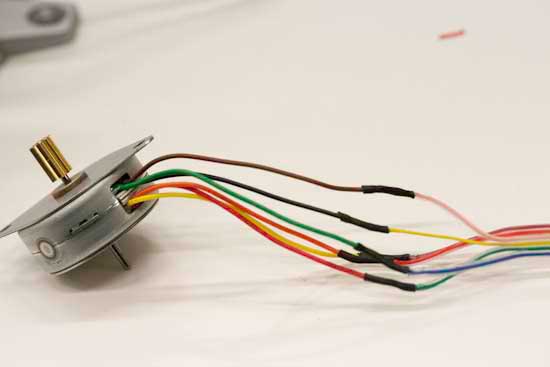

- In the lab I found a unipolar stepper motor. Here is the data-sheet

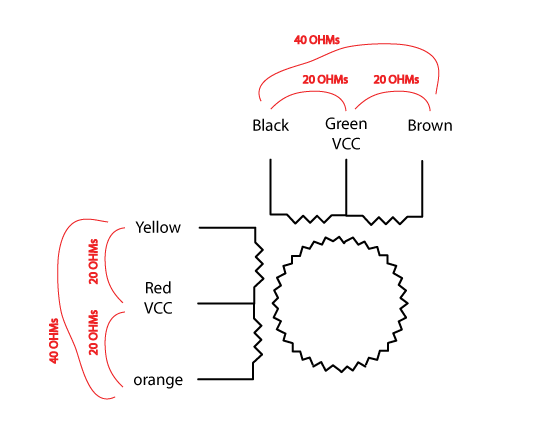

- The motor has six wires. To find out how to connect them I measured the current running through each combination.

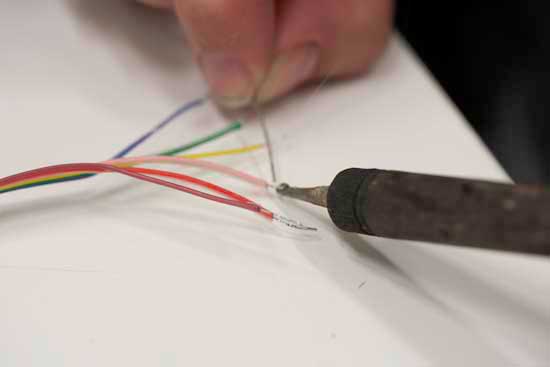

- Best is to pre-solder each wire and then solder the two ends together.

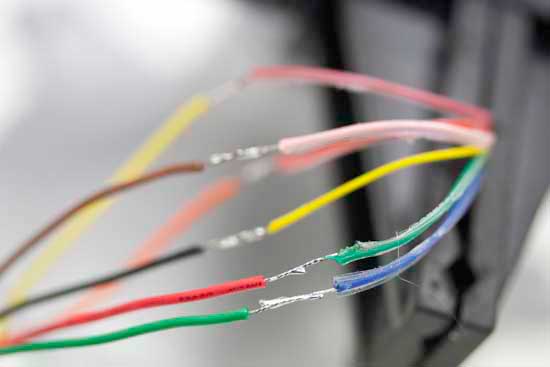

- It was bit confusing to find out where which wire should go. I started by attaching the six pin shoe to the cable, I then used the digital multimeter to find out which wire was what.

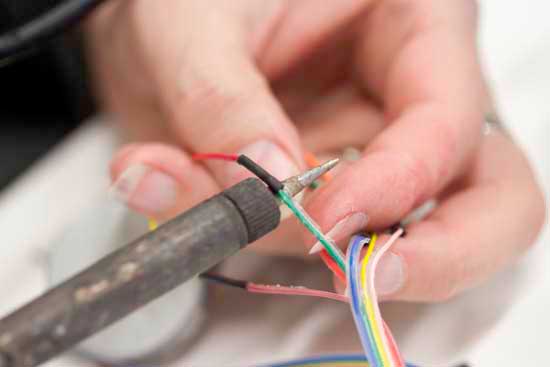

- Using heat-shrink to insulate the wires.

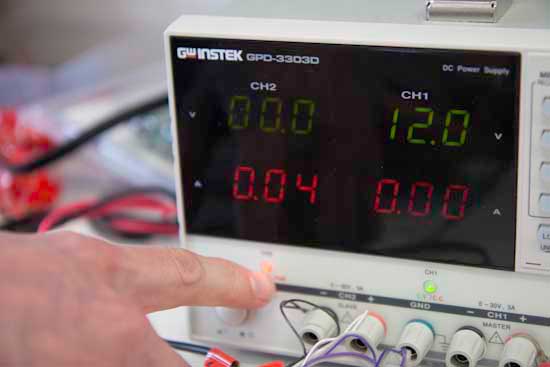

- The motor connected to power.

- I learned how to use the power supply to test whether the 4 pin power connector shoe was correctly attached to the battery wires. By taking down the current to 0.04 Amps but keeping the Volts at 7 I would not damage anything if it was the wrong way around.

Programming

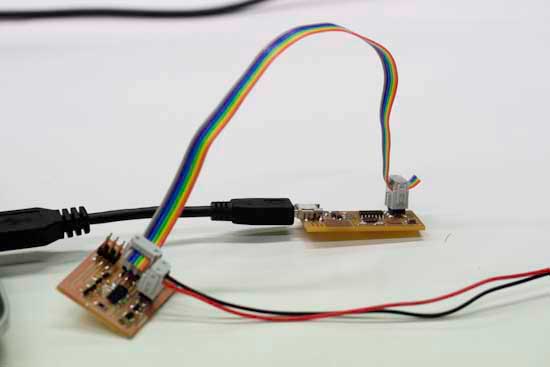

- Programming the board using Neil’s makefile went well. I intended to serial connect this board using the ISP connection. But I found out that the motor connection and the programming header are too close so I can not physically fit two six pin connector shoes next to each other.

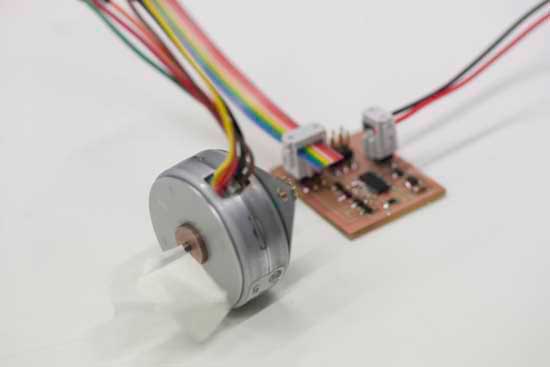

- I got the motor to run bacwards and forwards alright.

Here is where my problems started. I now wanted to combine the Hall sensor program with the Stepper Motor program. That did not go smoothly. I have no prior experience in programming and even though I have been watching programming courses online I was no closer to understanding what needed doing to get these two programmes into one! For me this is like trying to compose a symphony only knowing ONE note.

I started by writing sudo code explaining to myself what needed doing. I then made an honest attempt to combine Neil´s two programs and adding my own requirements for my final project. After a long day of frustration I took a step back, had a good think about this and decided that I needed to program this in the Arduino environment. There I would at least stand a chance.

Here is my sudo code:

Programming in the Arduino environment

Working within the Arduino environment was more to my liking. Here is the code I managed to put together in the end:

/*

==============================================================================================

Stepper Motor & Hall Sensor -

Sigga Helga

FabAcademy Mai, 2015

I am using ATtiny 44 AVR microcontroller with 8MHz internal clock and programming it with FABISP.

The TX (transmited from computer)= MOSI (MasterOutSlaveIn) is on PA6 and translates as Pin 5 in arduino

The RX (Received from computer)= MISO (MasterInSlaveOut) is on PA5 and translates as Pin 6 in arduino

I am using Stepper motor: PF35T-48L4

The data sheet:http://www.jameco.com/jameco/products/prodds/171601.pdf

It is a unipolar motor with six wires, the step angle is 7.5 degrees

Stepper is attached as follows:

Coil 1 = PAO=Brown is PIN 0, PA1=Black is PIN 1,

Coil 2 = PA2=Yellow is PIN 2, PA3=orange is PIN 3,

Red and Green are connected to power

This program controls one motor. I have many motors connected and I am talking to many microcontroller all listening in on the same line

I am sending 2 bites of info, first is the ID of the motor, second is the new location.

When the microcontoller reconizes it's ID it acts on the order, otherwise it ignors it.

==============================================================================================

*/

#include

#define ID 1

#define stepsPerPosition 12 //if the motor has 7,5 degree steps that means 360/7,5 = 48 and each "step_cw" function consists of 4 steps hence 48/4 =12 for full circle

#define totalPositions 40

#define myHomePosition 1

int motorPin1 = 0; //Brown

int motorPin2 = 1; //Black

int motorPin3 = 2; //Yellow

int motorPin4 = 3; //Orange

#define delayTime 5

int hallSensorPin = A7; //Hall Sensor reads magnetic field. Using this to find the "home" positstion

int myCurrentPosition = myHomePosition; // position 0 does not excist....0;

int myTargetPosition = 0;// position 0 does not excist....0

SoftwareSerialWithHalfDuplex mySerial(6, 5, false, false); // RX, TX for reciving and transmitting data

//=====================SETUP======================================================================

void setup() {

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

pinMode(motorPin3, OUTPUT);

pinMode(motorPin4, OUTPUT);

pinMode(hallSensorPin, INPUT);

mySerial.begin(9600);

mySerial.println("hello you"); // debug line - prints "hello You" each time you reset the program

}

//====================MAIN LOOP====================================================================

void loop(){

if (myTargetPosition ==0) {

findHomePosition();

myTargetPosition=1;

}

if(mySerial.available() >= 2 ){ // if 2 bytes or more arrived through the seraial communication line

int targetID = mySerial.read();

int newTargetPosition = mySerial.read();

if (targetID == ID ){

myTargetPosition = newTargetPosition; // make my

}

}

if (myCurrentPosition != myTargetPosition){

moveOnePositionCW();

}

}

//==================DEFINING FUNCTIONS=============================================================

void whichDirectionToGo (){

if (myTargetPosition > myCurrentPosition) {

moveOnePositionCW;

}

else if (myTargetPosition < myCurrentPosition) {

moveOnePositionCCW;}

}

void moveOnePositionCW (){ //clockwise direction

myCurrentPosition++;

if (myCurrentPosition == totalPositions+1) // if I am one over myTotalPositions I am back to square one (the counting for totalPositions starts at zero hence the plus 1.

{myCurrentPosition = 1;

}

for (int i = 0; i < stepsPerPosition; i++) { //each "step_cw" consist of 4 steps, so if the motor has 7,5 degree steps that means 360/7,5 = 48 and 48/4 =12

step_cw();

}

}

void moveOnePositionCCW(){ //counterClockWise direction

myCurrentPosition--;

if (myCurrentPosition == 0 ) // if I am one over myTotalPositios (-1)I reset the counter to start counting again

{myCurrentPosition = totalPositions;

}

for (int i = 0; i < stepsPerPosition; i++) {

step_ccw();

}

}

void findHomePosition() {

int hallSensorValue = analogRead(hallSensorPin);

while ((hallSensorValue > 450) && (hallSensorValue < 550)) {

moveOnePositionCW();

delay (1);

hallSensorValue = analogRead(hallSensorPin);

// while (1){ //Debugger- sends the Hall Sensor's reading to the console window

mySerial.write(hallSensorValue);

}

myCurrentPosition = myHomePosition;

}

//Forward steps- Clock wise = cw

void step_cw() {

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

digitalWrite(motorPin3, HIGH);

digitalWrite(motorPin4, LOW);

delay(delayTime);

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, HIGH);

digitalWrite(motorPin3, LOW);

digitalWrite(motorPin4, LOW);

delay(delayTime);

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

digitalWrite(motorPin3, LOW);

digitalWrite(motorPin4, HIGH);

delay(delayTime);

digitalWrite(motorPin1, HIGH);

digitalWrite(motorPin2, LOW);

digitalWrite(motorPin3, LOW);

digitalWrite(motorPin4, LOW);

delay(delayTime);

}

//Backward steps - Counter clock wise = ccw

void step_ccw() {

digitalWrite(motorPin1, HIGH);

digitalWrite(motorPin2, LOW);

digitalWrite(motorPin3, LOW);

digitalWrite(motorPin4, LOW);

delay(delayTime);

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

digitalWrite(motorPin3, LOW);

digitalWrite(motorPin4, HIGH);

delay(delayTime);

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, HIGH);

digitalWrite(motorPin3, LOW);

digitalWrite(motorPin4, LOW);

delay(delayTime);

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

digitalWrite(motorPin3, HIGH);

digitalWrite(motorPin4, LOW);

delay(delayTime);

}

Here is a vido showing the motor in action moving to the right postion. The video was actually shot in week 14 when I had also mangaged to establed networking communication between the microcontroller and a website sitting on a server, using a node.js bridge: