18. Mechanical Design and Machine Designs¶

Group Work Page¶

This week I worked on CNC Foam cutting Machine.

-

Example Our task for this week Assignment:

-

Design and 3D print the machine’s parts.

Download Files¶

Software¶

Fusion .

Cura .

Machines¶

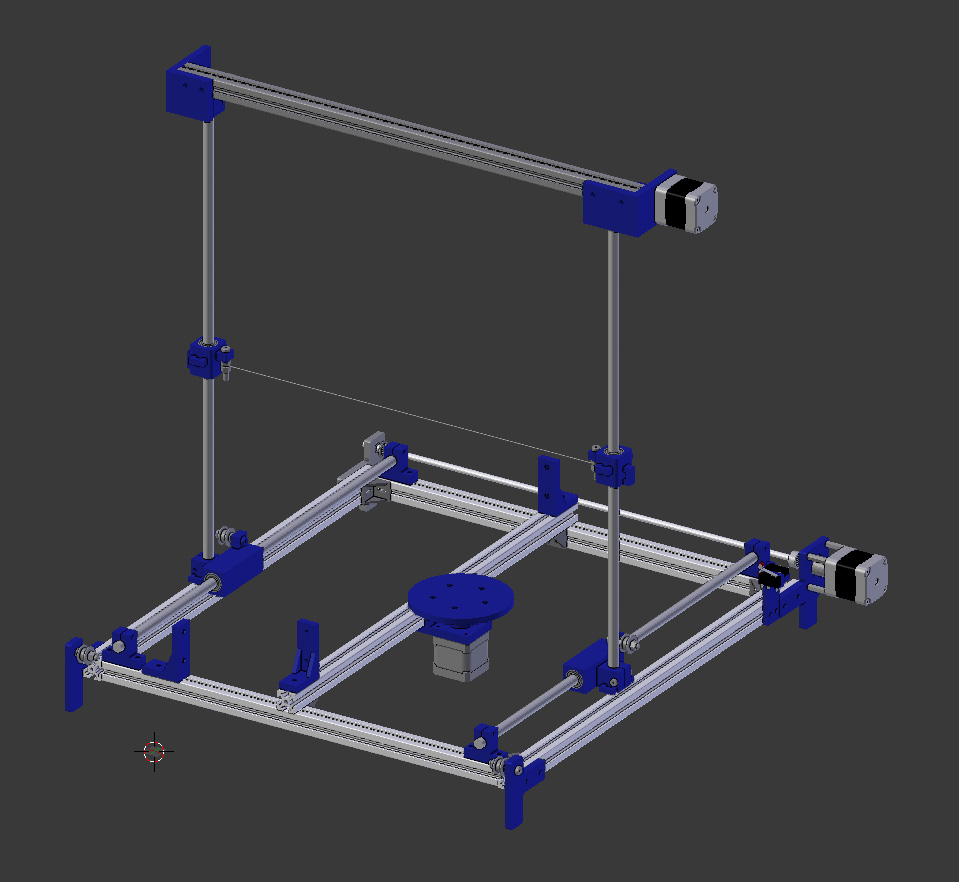

Orginal Design¶

Overall, in terms of construction and rigidity the design is probably not that good, but In my opinion making a function machine with minimum parts possible and still to be able to get the job done._

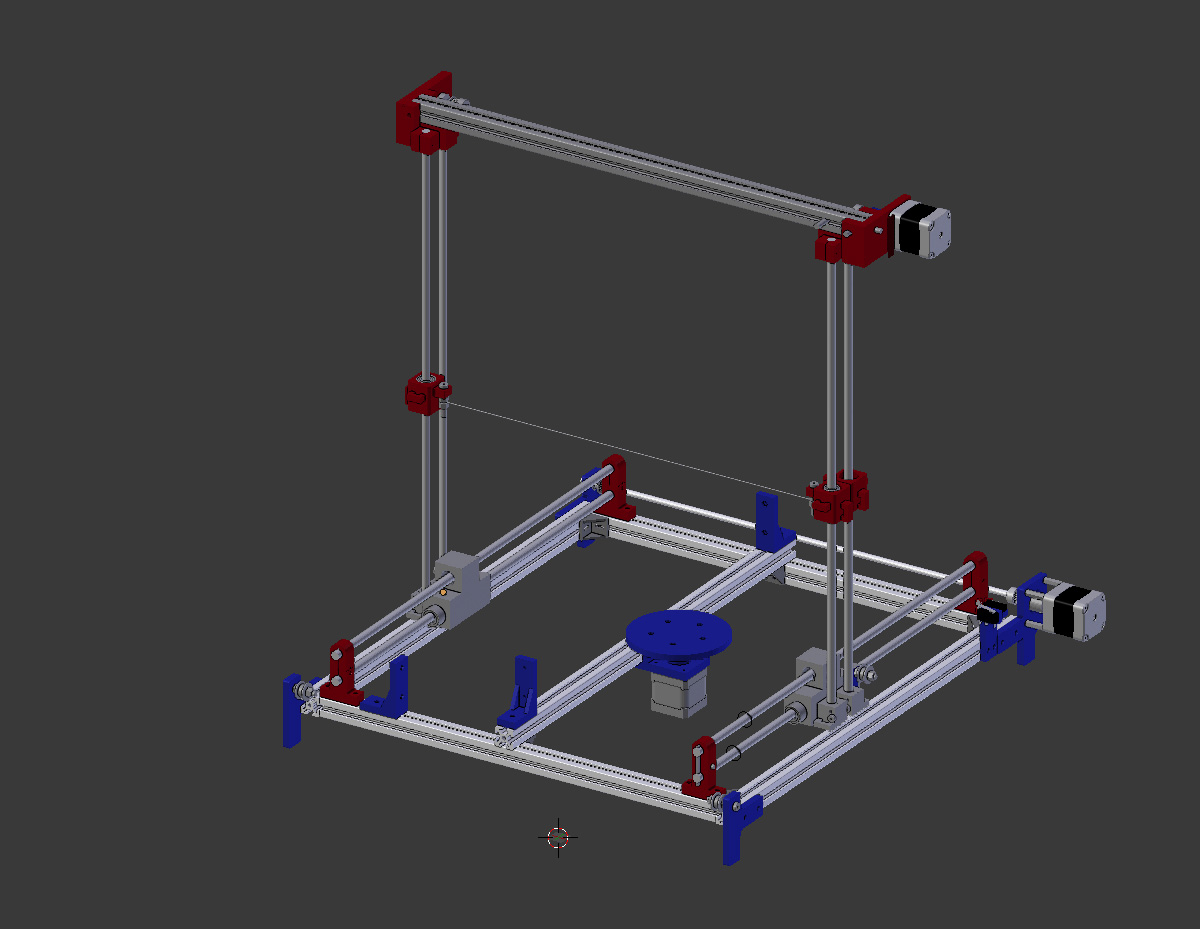

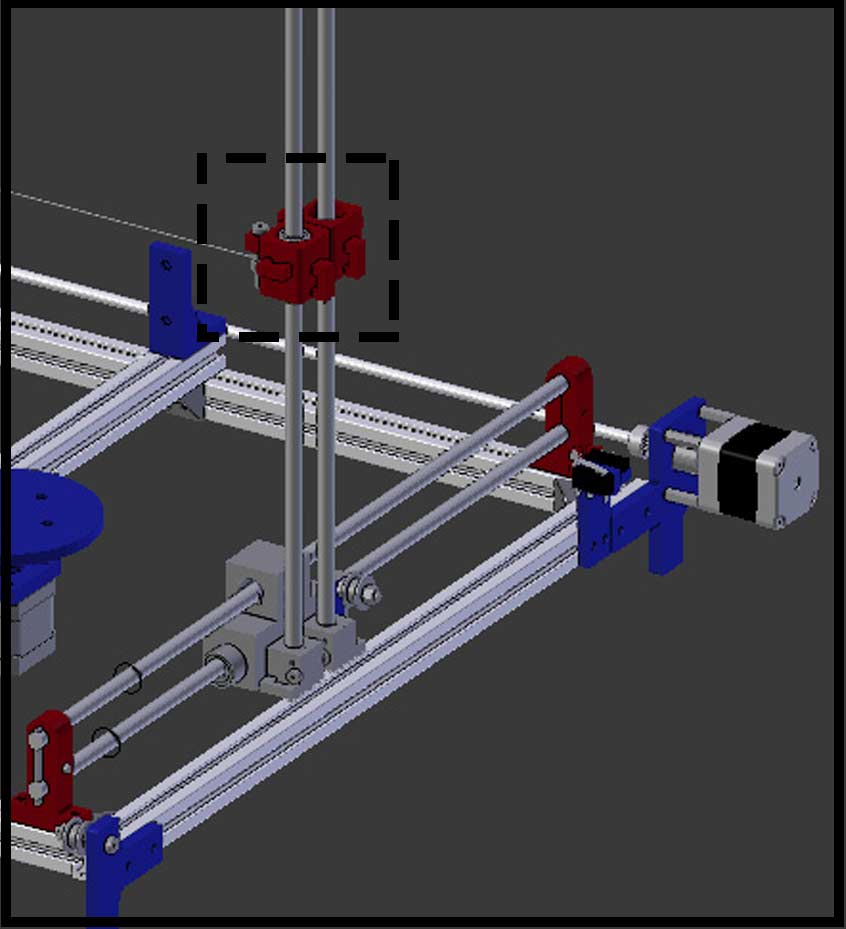

Modified Design :

in this design we wanted the machine to be more rigid so we have made those changes :

First we have added one more linear rail for each moving axis in each side .

Second we have edited the 3D models in order to fit the new design .

Third we have used a flexible Coupler instead of the shaft Coupler (printed one) .

Finally we have replaced the linear rod from 10mm to 8mm and the bearings also .

And you can see the changes we have made in the picture below, the red parts !! .

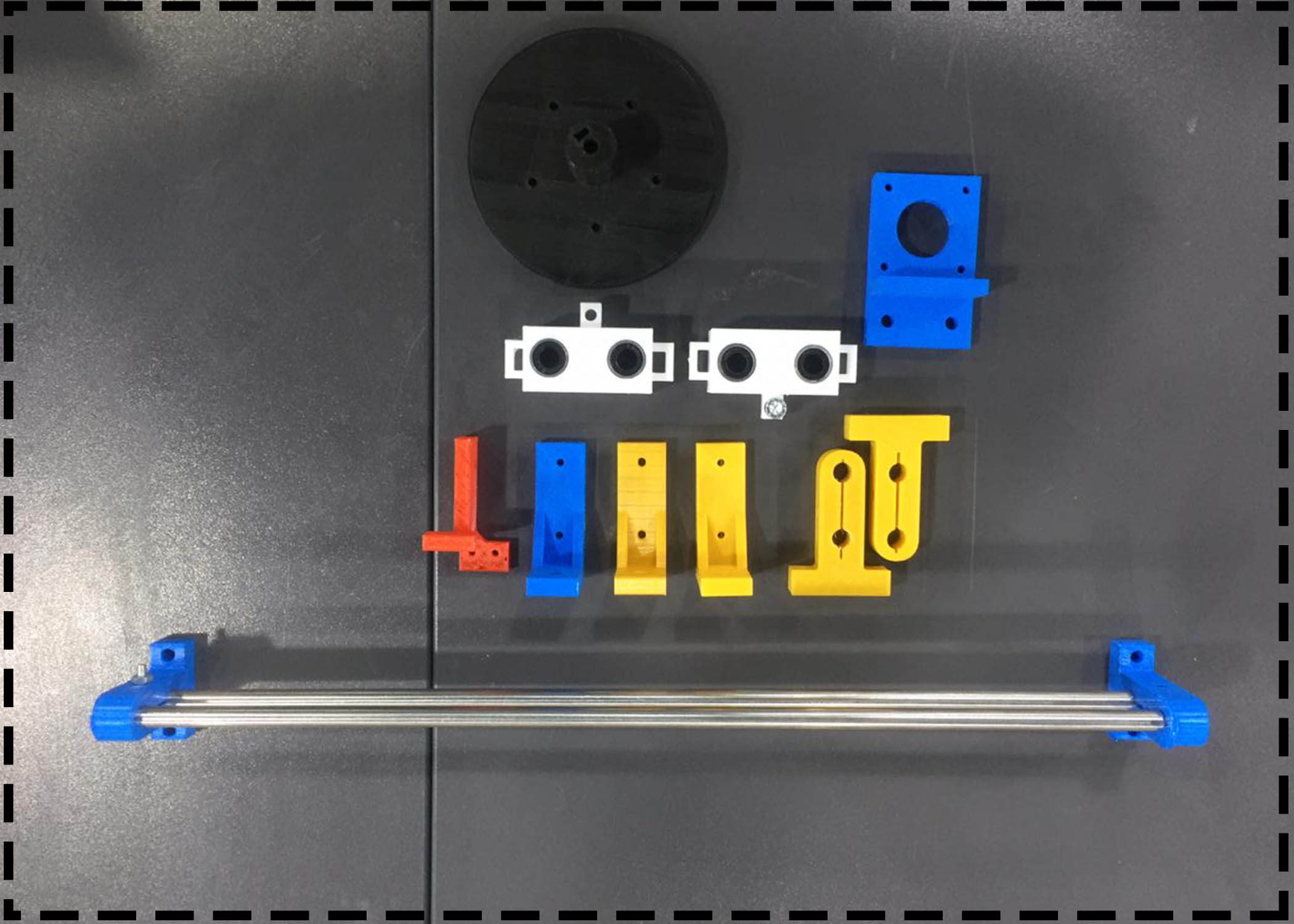

Parts¶

Part 1 :

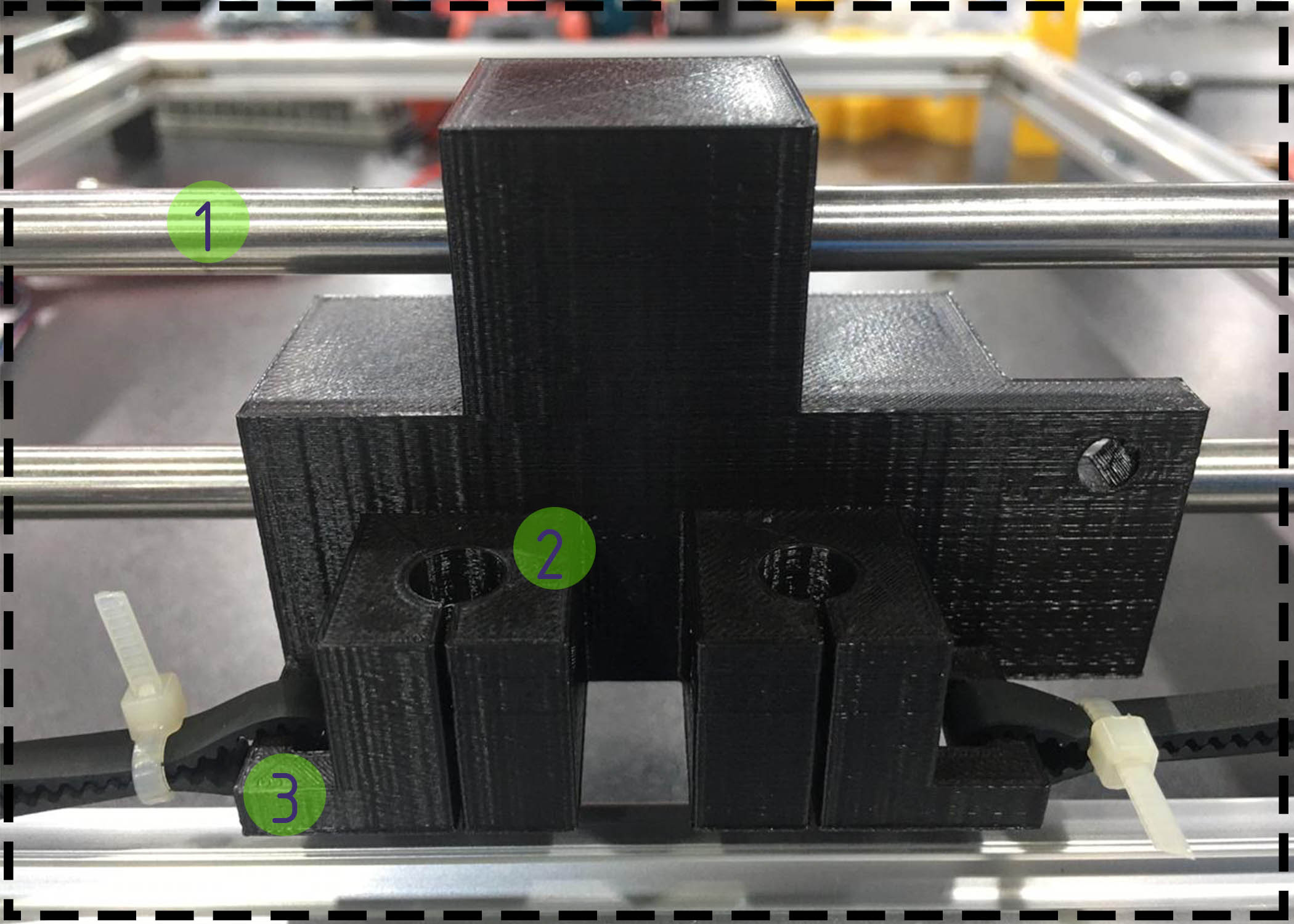

Sliding block ‘X axis’

It is place in the Machine :

File to print :

Function :

It has multi functions :

One of it is to advance the Machine axises (Vertically and Horizontally) from the vibration of the Motors.

1 - Accommodate the two X-axis linear bearings.

2 - It holds the two Y-axis Rods.

###### checking the fit between 3D printed parts and ordered metallic mechanical parts :

Print Settings¶

Shell

Wall Thickness: 0.7 mm

Top/Bottom Thickness: 0.75 mm

Infill

Infill Density: 18%

Infill Pattern: Grid

Material

Printing Temperature: 200 °C

Build Plate Temperature: 60 °C

Speed

Print Speed: 45 mm/s

Travel

Enable Retraction: Yes

Travel speed : 150

Cooling

Enable Print Cooling: Yes

Fan Speed: 100%

Build Plate Adhesion

Build Plate Adhesion Type: Skirt

Hero Shot¶

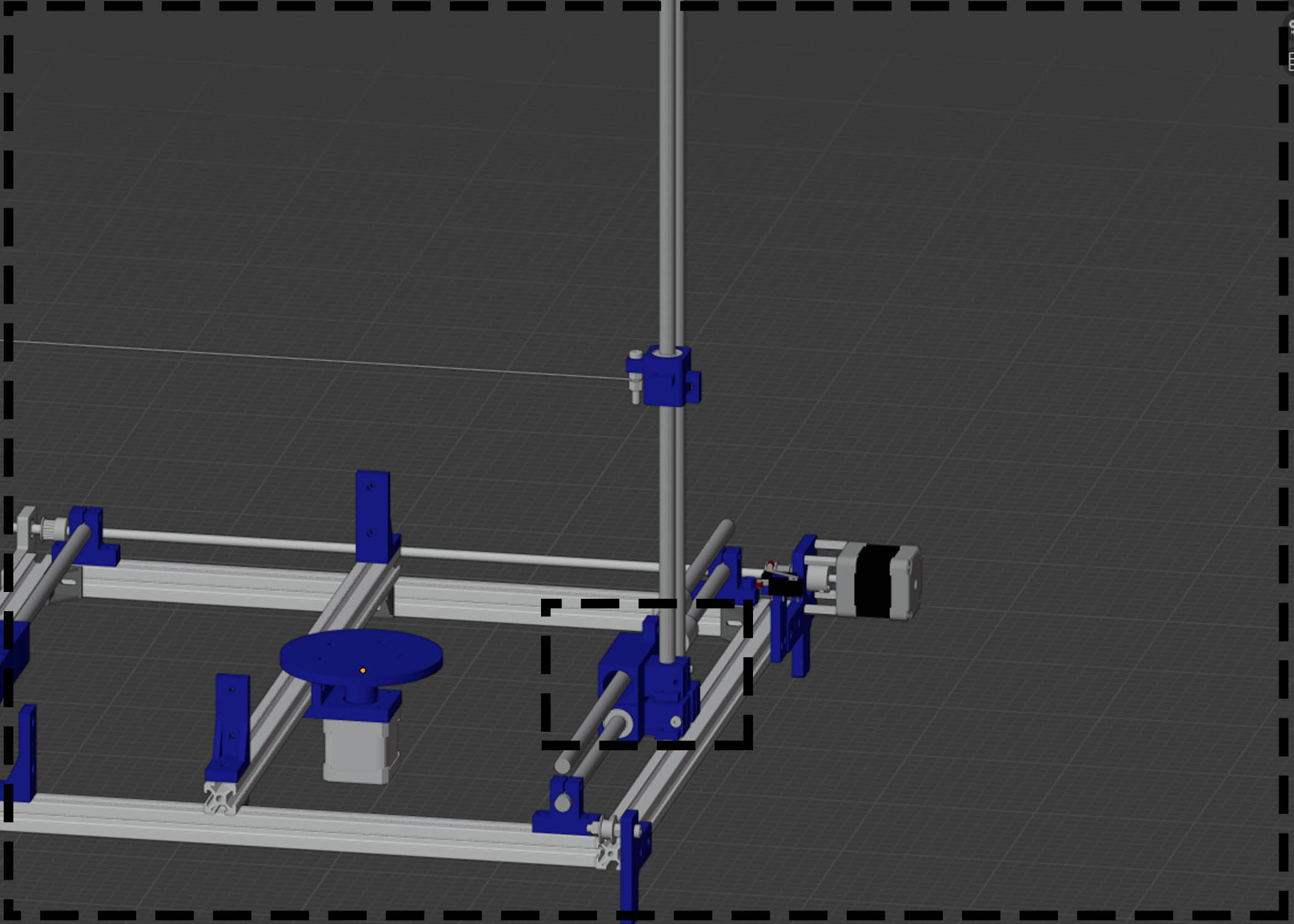

Part 2¶

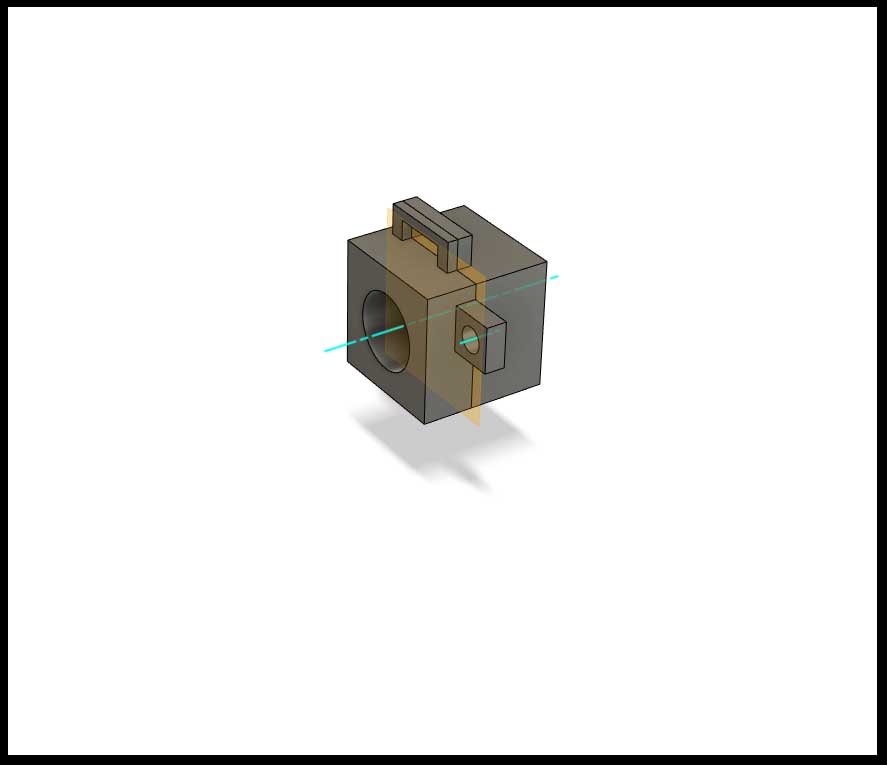

Sliding block ‘Y axis’

File to print :

Function : 1- Hold the hot wire and move it around the ‘Y axis’. 2- Accommodate the two Y-AXIS linear bearings and Rods. 3- Attaching the Y-AXIS belts.

Print Settings :

Shell

Wall Thickness: 0.7 mm

Top/Bottom Thickness: 0.75 mm

Infill

Infill Density: 18%

Infill Pattern: Grid

Material

Printing Temperature: 200 °C

Build Plate Temperature: 60 °C

Speed

Print Speed: 45 mm/s

Travel

Enable Retraction: Yes

Travel speed : 150

Cooling

Enable Print Cooling: Yes

Fan Speed: 100%

Build Plate Adhesion

Build Plate Adhesion Type: Skirt

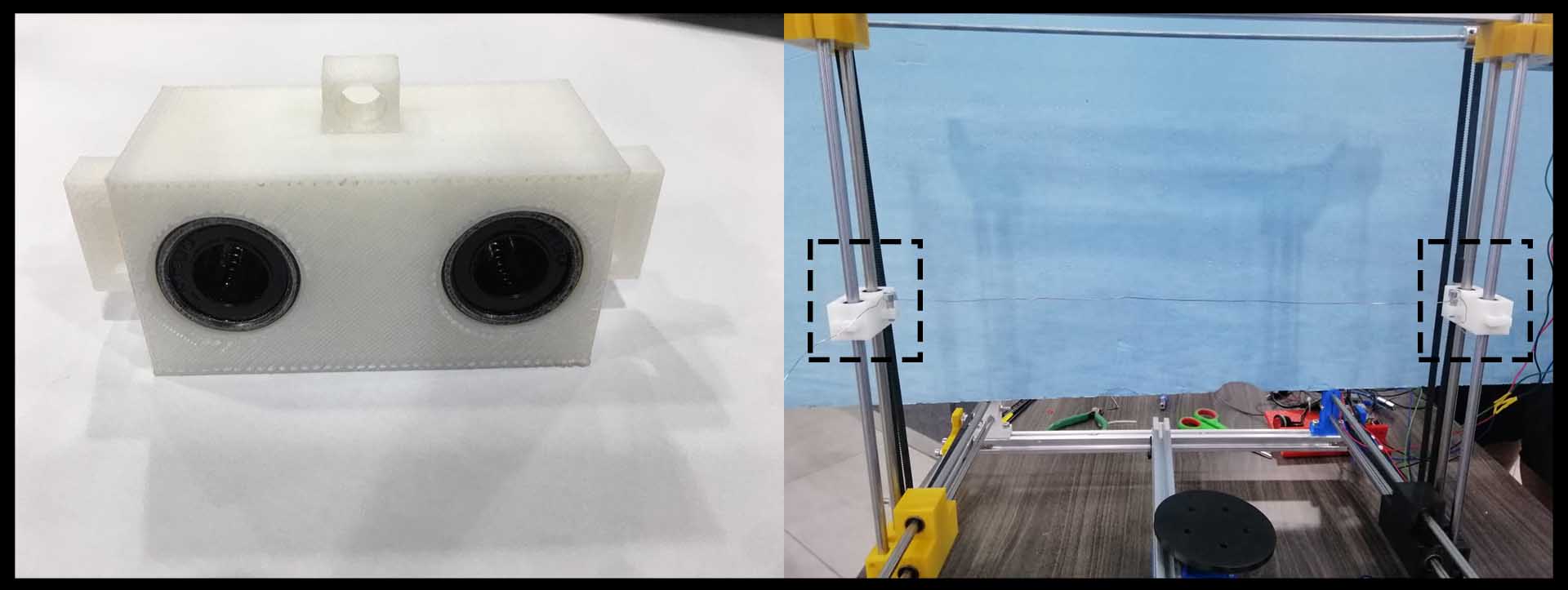

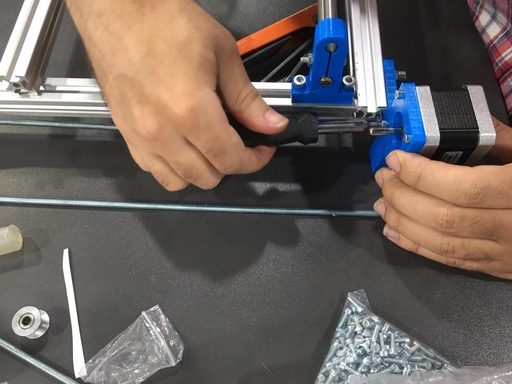

Arduino CNC Machine Foam Cutting Assembling :

Here you can see how we assembled the machine :

First we started with the profile :

Next we started to hold the motors :

And here you can see the final Assemble :