17. Wildcard Week¶

For this week i want to make a bio material for the final project dynamic part (Blades).

Files¶

1- Mold

2- Blades

Sourse :

First : I have to choose which bio material i want to include in my final project functions :

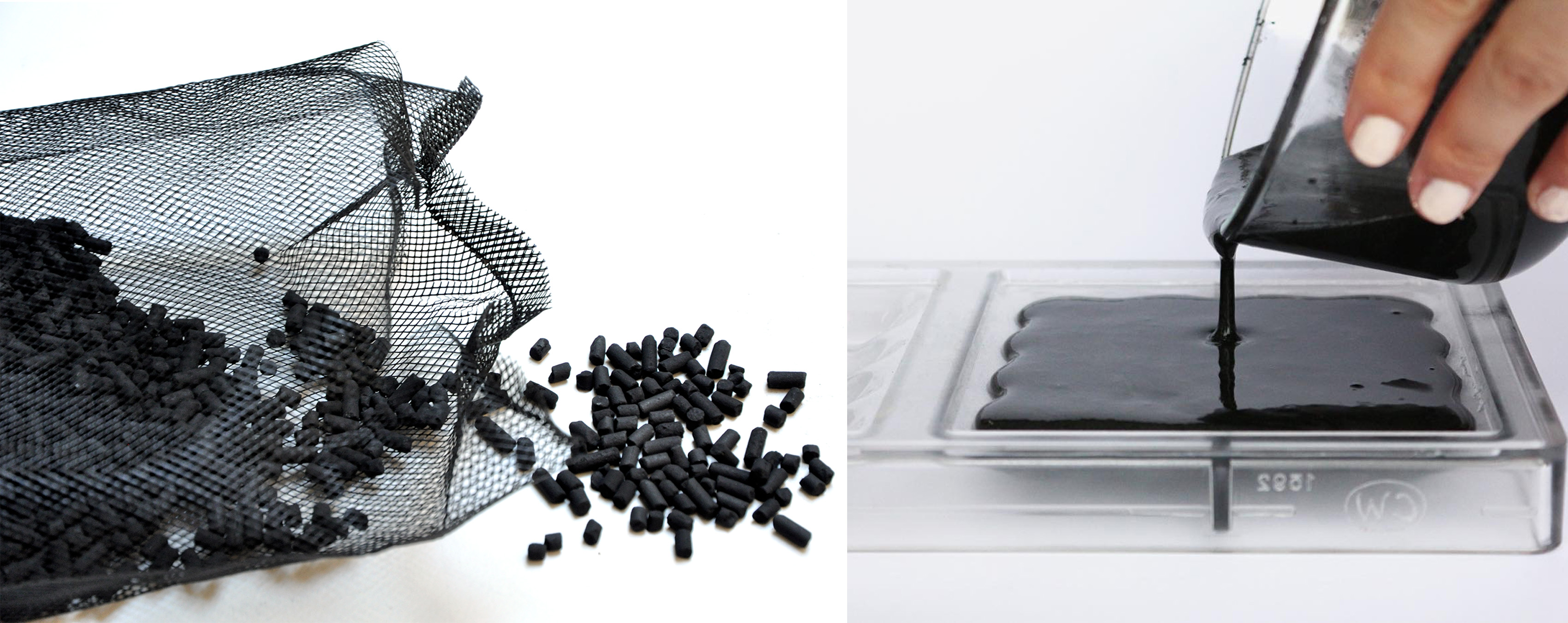

The function is to purify the Air from toxic dust in it, so for this function i choosed ( Activated Charcoal ) as a filter

Activated charcoal is one material that seems especially applicable to Fab Lab makers, because of its ecologically sound and purifying properties. It is essentially a form of incredibly microporous carbon, processed from natural carbon-rich materials by applying various gases or chemicals to ‘burn’ in tiny holes and thus exponentially increasing its surface area. The result ? A material that can efficiently filter out all manner of impurities and toxins. A super-sponge, if you will. Bioplastics present themselves as an excellent and similarly sustainable substrate for activated charcoal with a wide range of uses.

so the bio material has multiable variables such as:

| Variable |

|---|

| Flexibility |

| Texture |

| Conductivity |

| Resistance |

I want it flexible and smooth:

So for this i have to test different recipes and quantities to get the result i want.

Materials¶

| Name | quantity |

|---|---|

| Activated Charcoal | 500g |

| Gelatine | 300 g |

| Glycerin | 300 g |

| petri dish | 10 |

| Pot | 2 |

| stove | 1 |

| scale | 1 |

| Acrylic heet | 100*60 |

First Round :

First one was not good enough and the results were too bad because of :

1 - i mixed the material without boiling the water, i just add hot water to the mixture and mix it without getting it boiled together.

2- It turned out that the bio material has differnet quantities from country to another so for the first time i have used a recipes from Mixeco and definitely it wont work in jordan because it has a totally different weather.

Second Round :

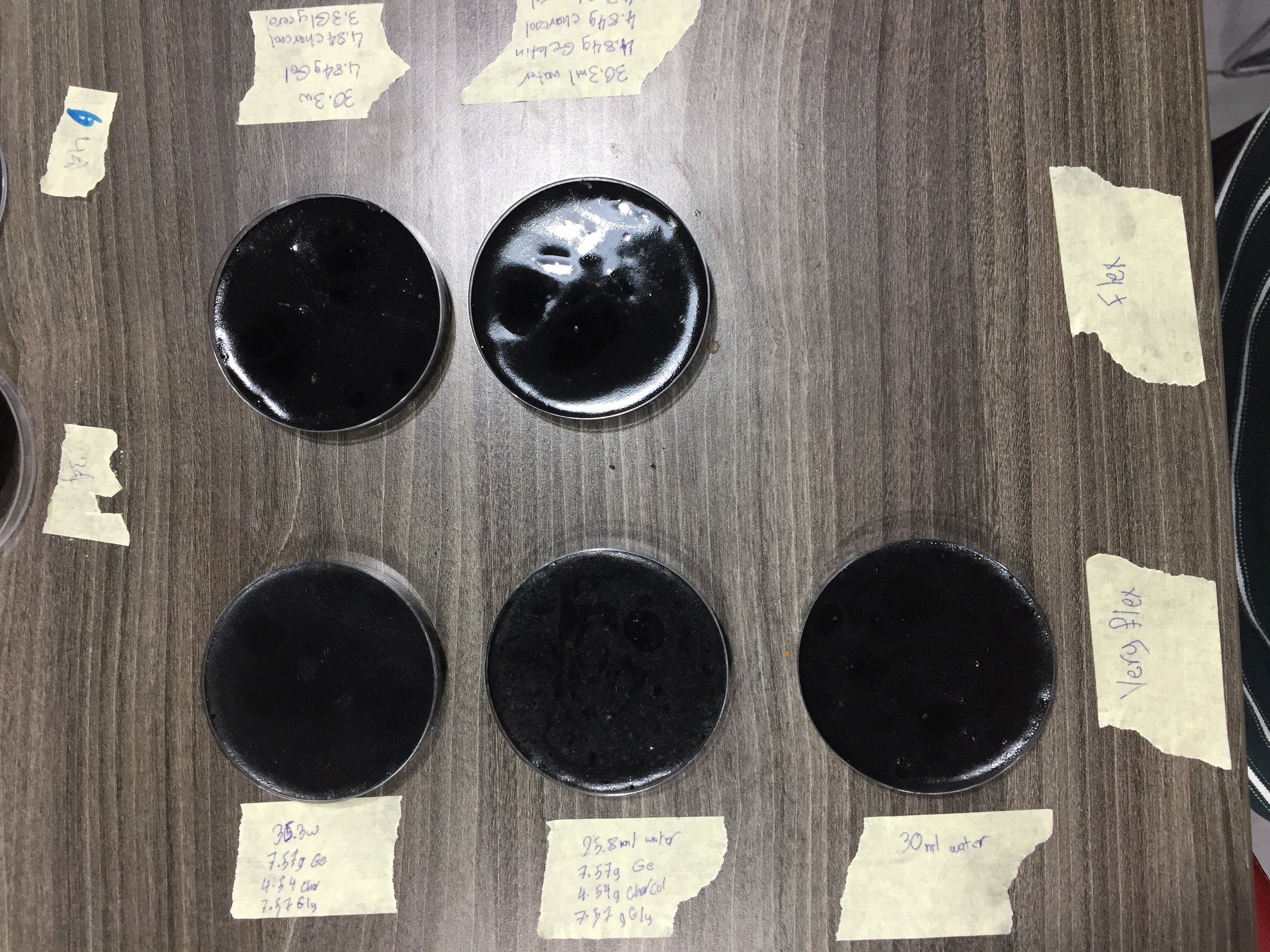

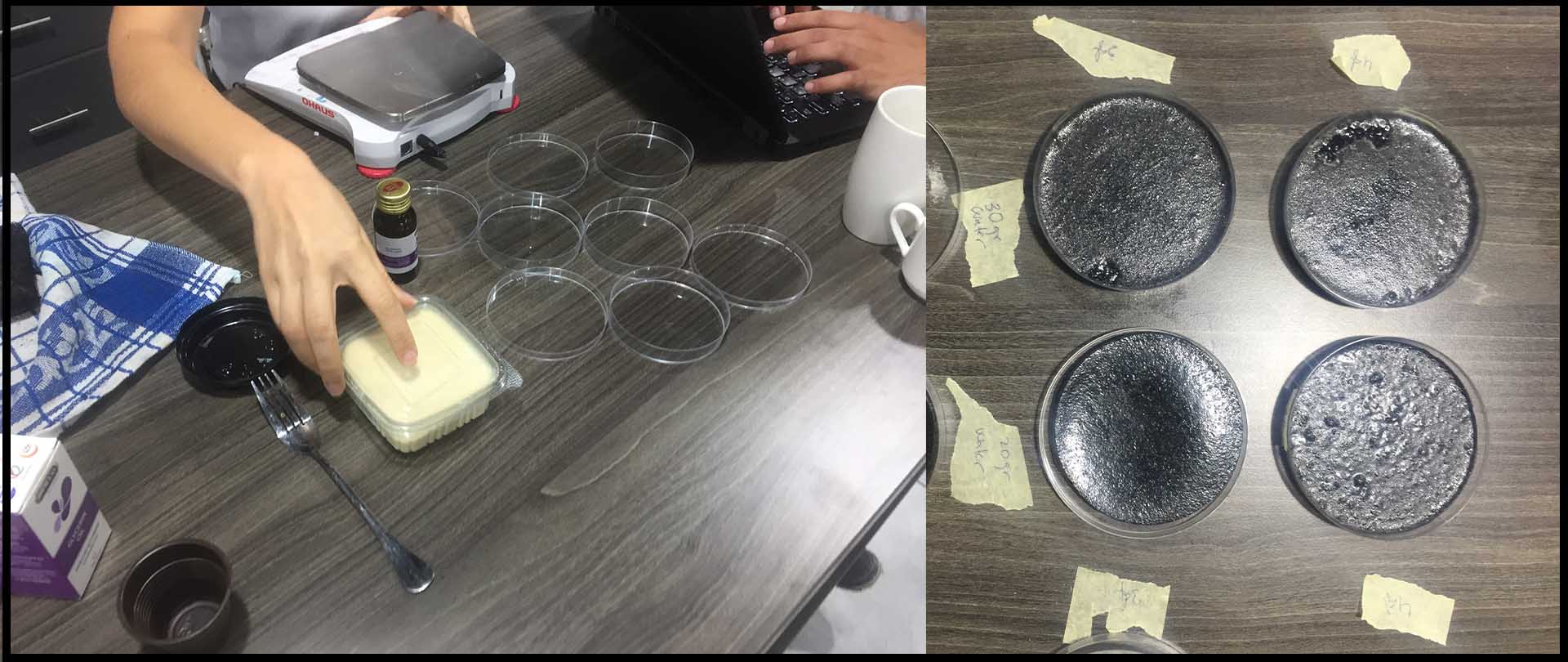

| Samples | Water | Gelatin | Activated Charcoal | Glycerol |

|---|---|---|---|---|

| #1 | 35 ml | 7.5 g | 4.5 g | 7.5 ml |

| #2 | 25 ml | 7.5 g | 4.5 g | 7.5 ml |

| #3 | 30 ml | 7.5 g | 4.5 g | 4.5 g |

| #4 | 30.3 ml | 4.48 g | 4.48 g | 3.30 ml |

| #5 | 30.3 ml | 4.48 g | 4.48 g | 4.3 ml |

First step :

In a cooking pot, off heat, mix the gelatin powder and the water. Stir and wait until the mixture thickens like a glue.

Step two : Start to heat the mixture on high heat. Stir time to time but not excessively to avoid additional foam. When the preparation become liquid again, add the glycerin.

Step three : Lower the heat as soon as you start to see a white deposit appearing on the surface of the mixture. Remove gently the foam with a spoon. Add the activated charcoal and stir.

Step four : Pour the preparation on a flat surface (in glass, silicone, plastic or varnished wood) with edges delimiting the desired shape. IMPORTANT : prepare your mold before starting to cook to avoid a final panic !

Step five : Wait 4/5 days of drying before removing the bioplastic material from its molding surface.

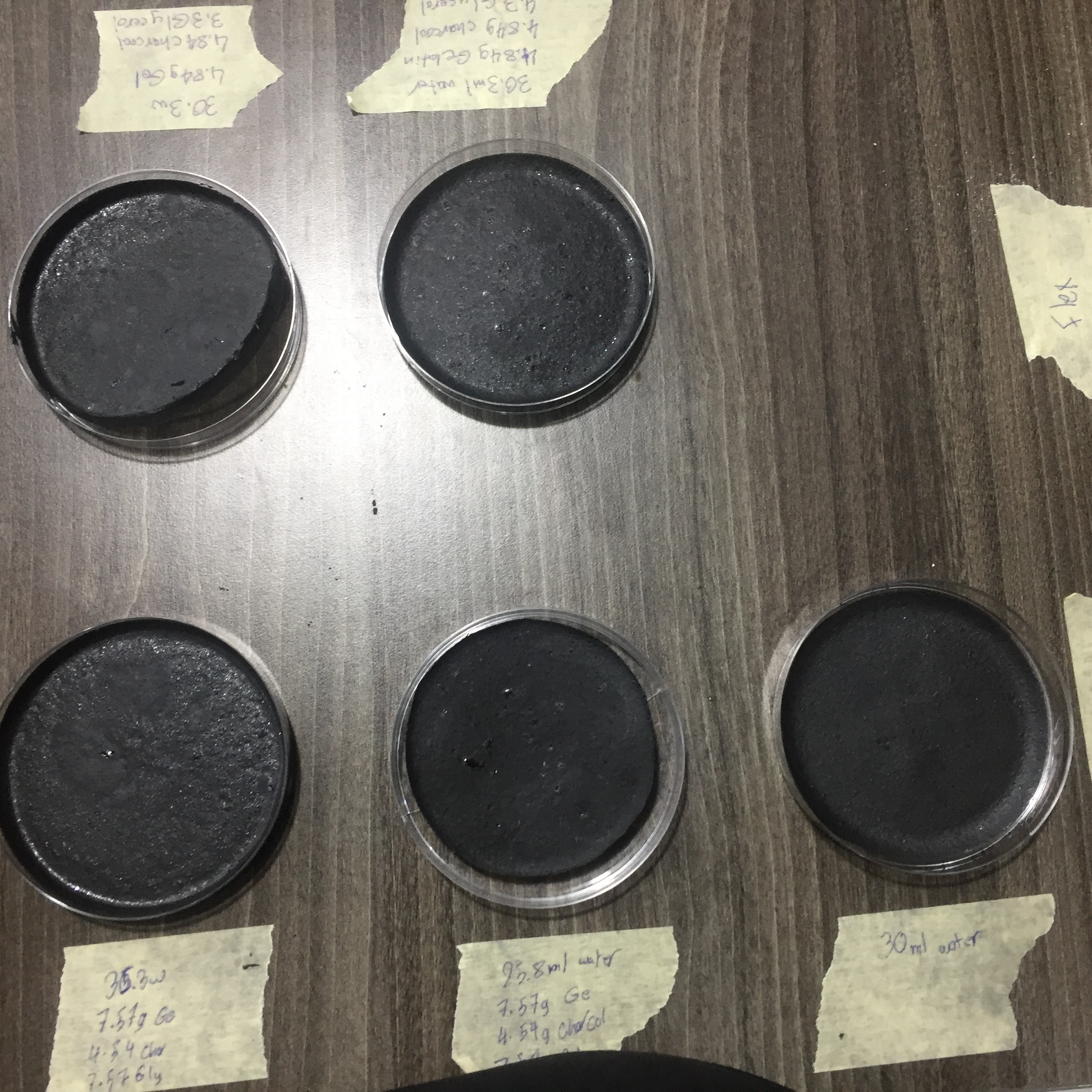

So after 4 days the samples were ready and i found that the sample # 5 was the best as shown below.

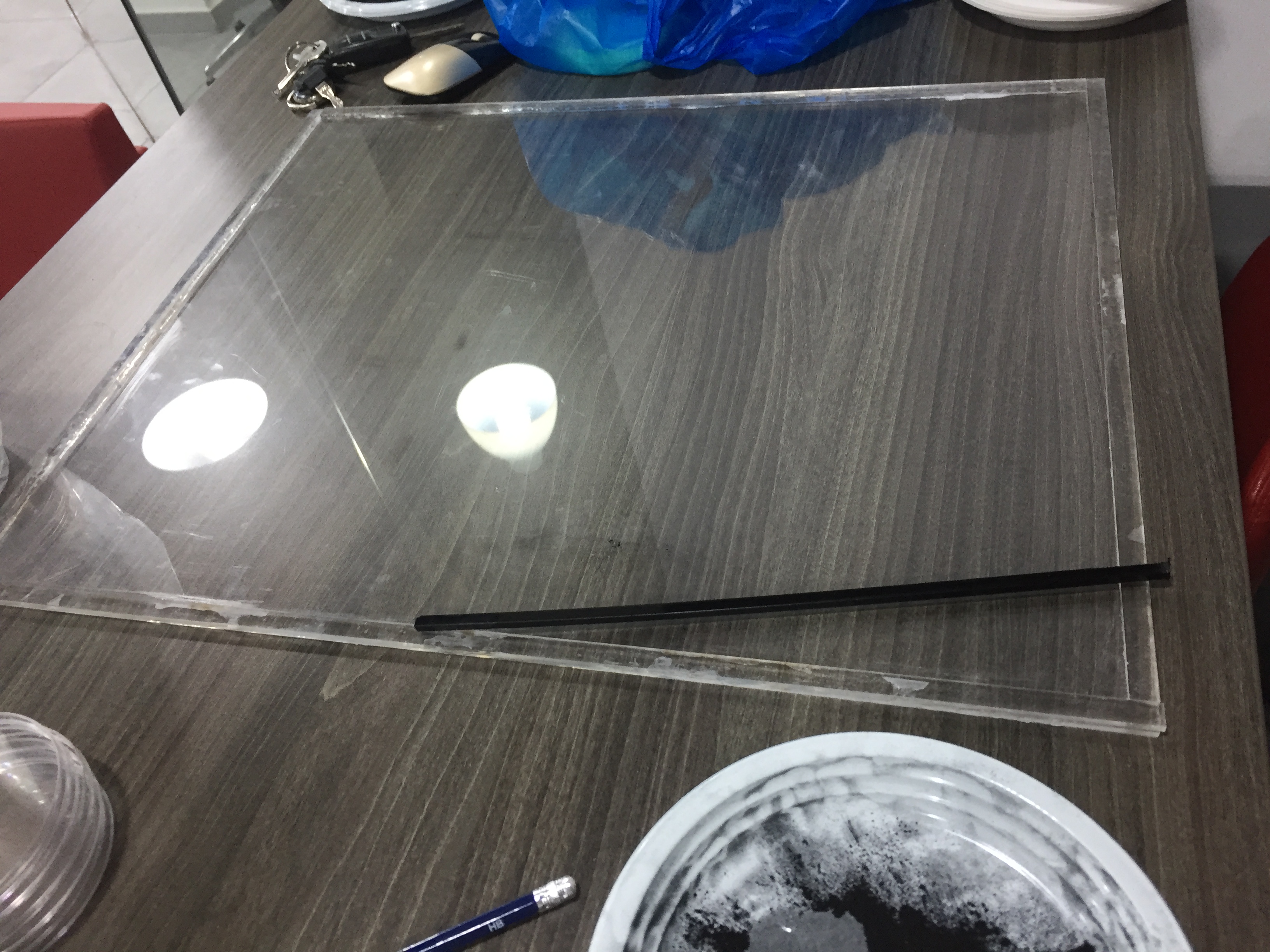

After this i wanted to make a bigger size of it in a big mold 20cm * 60cm * 3.0mm

After this i tried to pour the mixture in the mold but something bad happen because the acrylic curved because of the heat of the mixture and the used surface was less than i expected:

After this i wait for 4 days to get the plastic dry but guess what ! the big mold was not the same Variables of the small sample flexible and smooth as shown below :

So i had to do another recipe or to add more glycerin to make it more flexible.

1 - i crushed the dry plastic in a pot as shown below :

2- I added 137 ml of water to the crushed plastic.

3- I added 51 ml of glycerin to the crushed plastic after boiling it.

4- i poured it again in the same mold without exposing the mixture to the Air to not get it dry during pouring it in the mold.

5- Wait for 4 days.

Hero shot¶

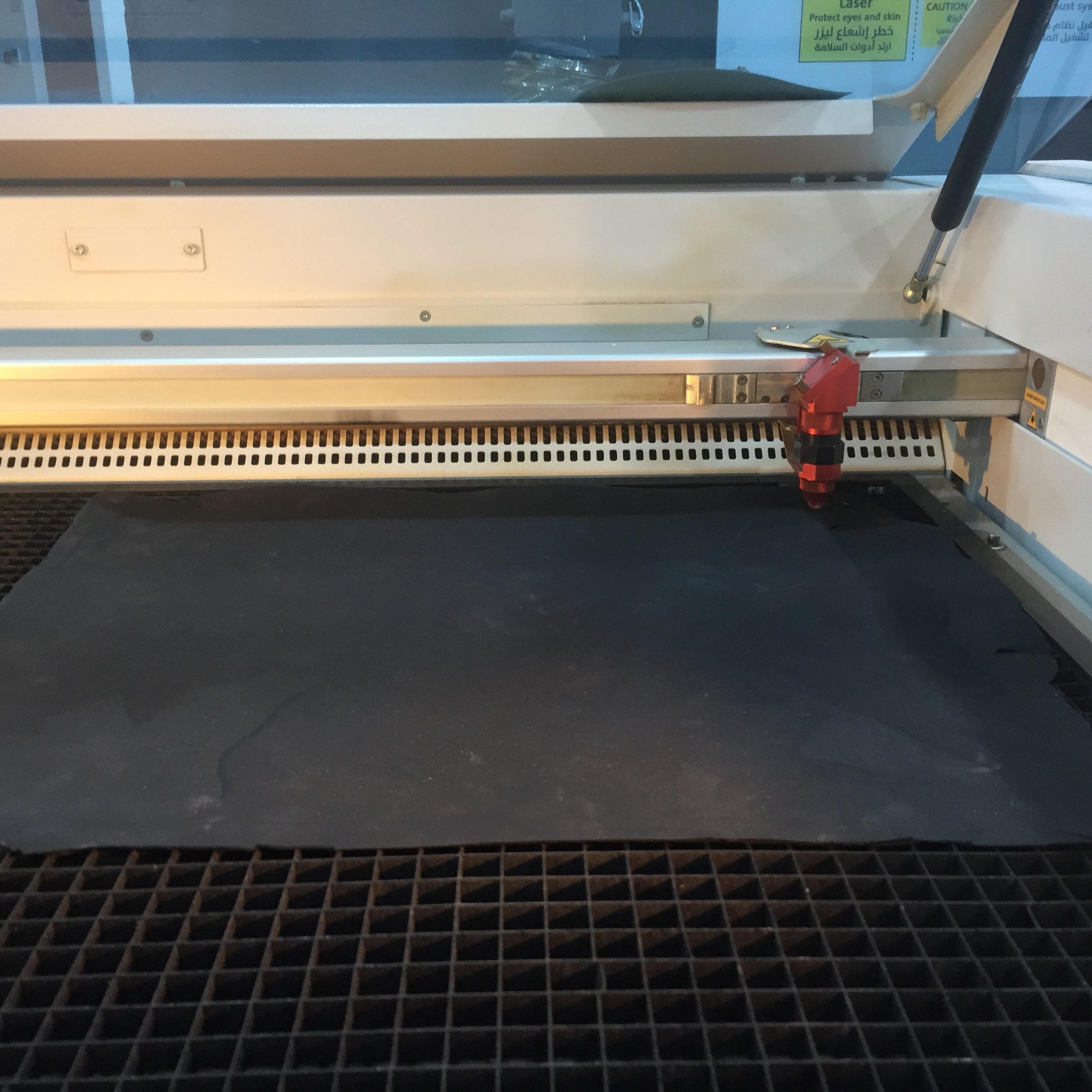

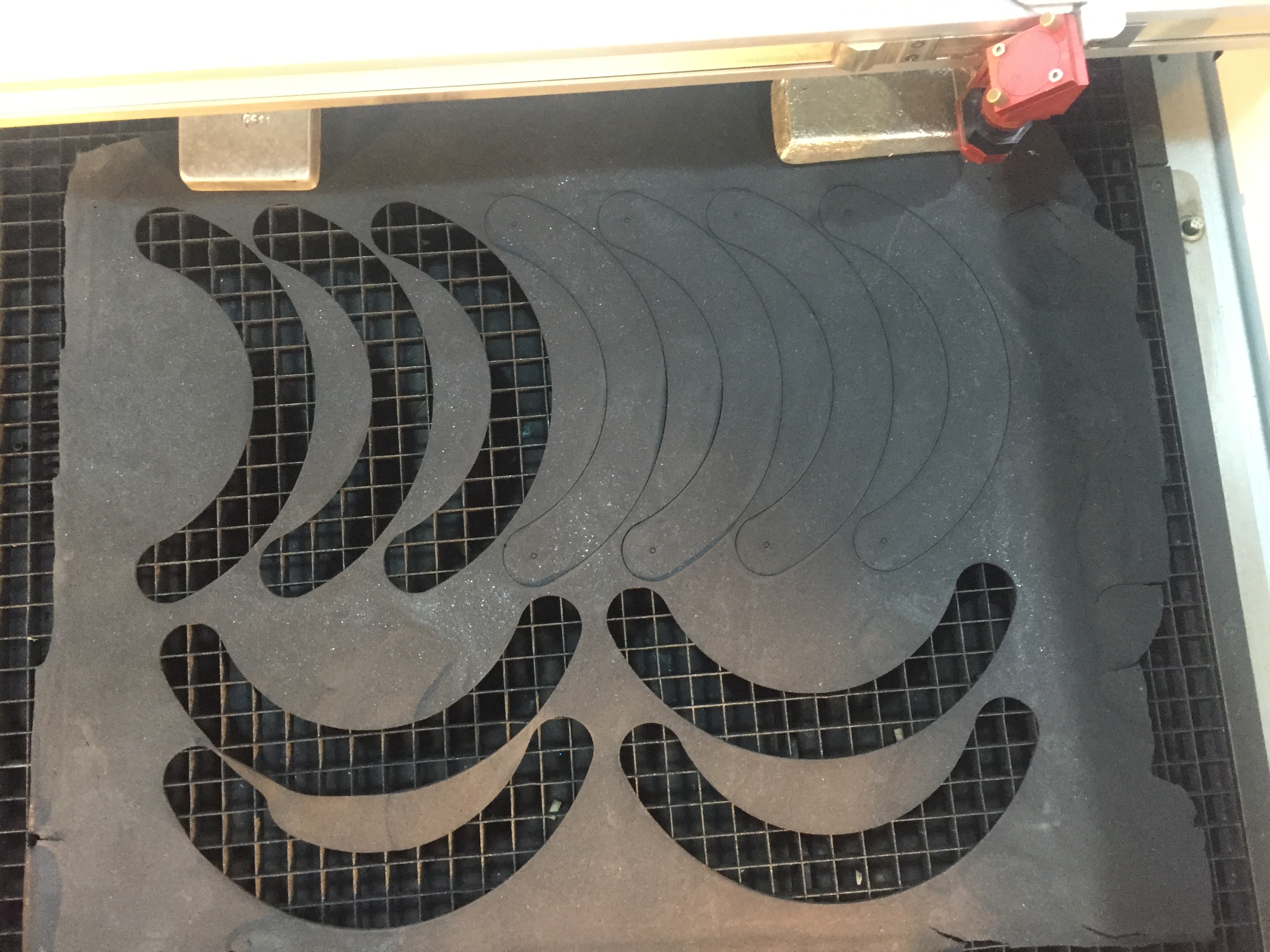

Laser Cut¶

Settings¶

Cut:

Power: 60%, Speed: 01%, and frequency: 5000-+

I have chosen the setting above to cut the bio-plastic into blades.