Robot- Manufacturing¶

let’s begin

Robot Manufacturing: ¶

The processes I used in manufacturing my project was :

3D printing

Laser cutting

Vinyl cutting

3D printing:¶

For the 3D pronting, it was the long process I went through , It tooks me many hours to succeed pronting all my design parts I will try show some of my 3D printed parts :

Here are the settings I used for the printing process :

I used 3 differents 3D printers the Raise3D printing machine and it’s software ideamaker , Prusa and creality, I exported each printable parts of my robot int STL files and I started the process.

The process setting:

.

* Material: PLA

.

* Material: PLA

-

Layer height: 0.2 mm

-

Printing speed: 60mm / s

-

Contour: 3

-

Top layers: 3

-

Bottom layers: 3

-

Infill: 30%

-

And without any support

Wheels

Gears

Outside shape

Bottom

cover holders

For the chaine I printed 96 pieces:

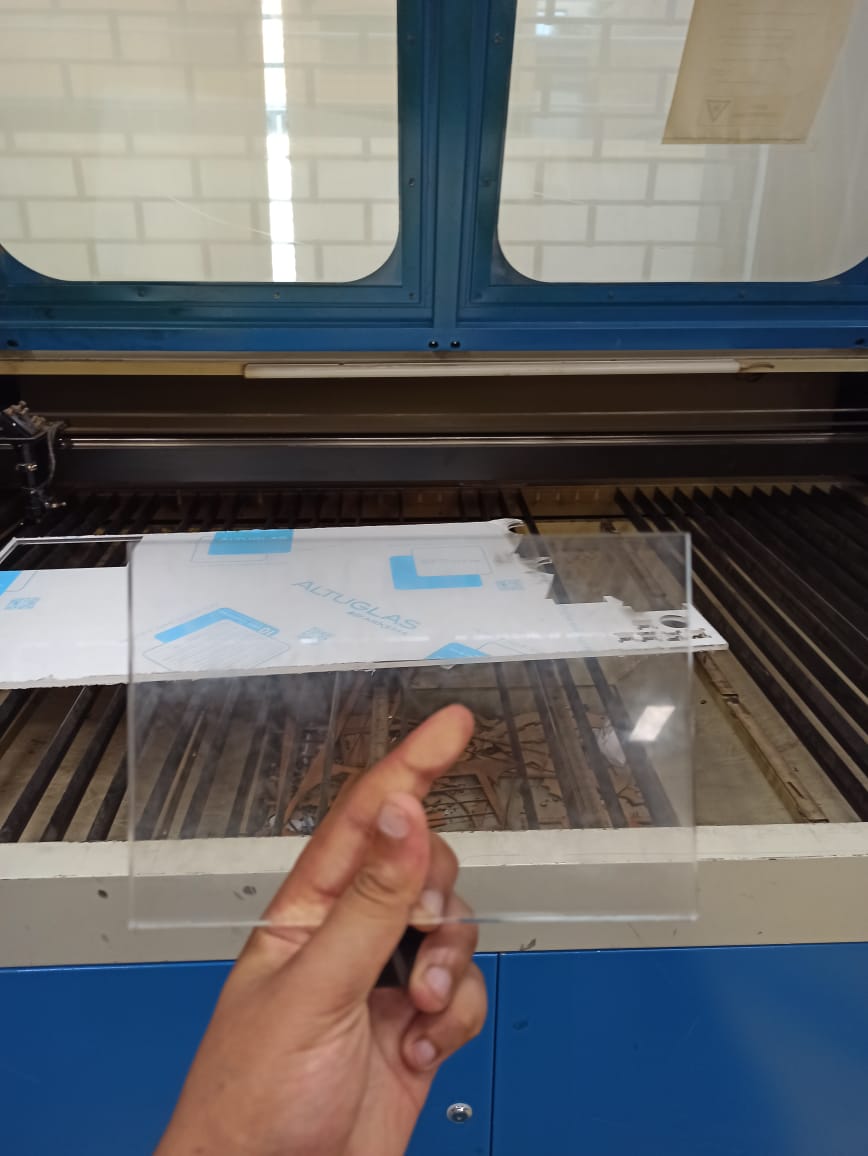

Laser cutting:¶

For the laser cutting process , I designed the up cover, and the Ultrasonic sensor , buzzer , FPV camera Holders as well as the both side protection parts :

I used the 8 mm plexiglass for both , unfortunatly , our cnc machine was broken for that cutted it with laser machine , the process was litlle bit difficult , but , after some protyping , I succeed ^^

I thought about how im going to band the plexiglass to be addapted to my robot , for that I used the heater from the soldring machine , and I calculated the exact angle the banded the 8mm plexiglass here is the process I used :

For the outside Protection I also used the 8mm plexiglass

vinyl cutting:¶