16. Molding and casting¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

This weeks Assignment: ¶

-

Group assignment:

-

Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them.

-

Individual assignment:

-

Design a mold around the stock and tooling that you’ll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts.

For this weeks group assignment you can check our page by clicking here¶

First part:(individual assignment): ¶

-

What is molding ?

- Molding is the process of of manufacturing by shaping liquid or pliable raw materials using a mold or matrix, which have been made using a pattern or model of final object.

-

what is casting ?

- Casting is a manufacturing process in which a molten metal is injected or poured into a mold to form an object of the desired shape.

-

Difference between molding and casting:

- Molding is the preferred process for manufacturing plastic parts. Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. It is ideal for producing high volumes of plastic parts due to the fact that several parts can be produced in each cycle by using multi-cavity injection molds. Some advantages of injection molding are high tolerance precision, repeatability, large material selection, low labor cost, minimal scrap losses, and little need to finish parts after molding. Some disadvantages of this process are expensive upfront tooling investment and process limitations. Csting involves pouring liquid metal into a mold, which contains a hollow cavity of the desired shape, and then allowing it to cool and solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods.

Types of Molding¶

Molding * is primarily used during the manufacturing process of plastic. Plastic is a synthetic materials, and to form it into the desired shape different molding processes are used. Each process requires the manipulation of molten plastic, and then leaving it to set. Thermoplastics can then be melted down and reformed if necessary, however thermoset plastics cannot be reheated.**

Casting * Is a basic molding process as it requires the least amount of complex technology. Plastic is simply heated so it turns into a fluid, and then transferred into a mold. It is left to cool and the mold is removed. This process can be used for intricate shapes and performed under a low pressure. However, it is a common process used for making plastic sheeting, starting from 0.5 inches thick and greater.

Injection Molding * is used for creating high-quality three-dimensional objects, that can be commercially reproduced. The molding process begins by melting plastic in a hopper. Then the plastic is injected into a tightly closed, chilled mold. The plastic quickly takes the shape of the surrounding mold. Once it has completely set, the mold is opened and the plastic object is released. Yogurt pots, butter tubs, toys and bottle caps are made using this process.

Blow Molding * Is a process used for making piping and milk bottles. Plastic is heated until molten. Then it is injected into a cold mold. The mold has a tube set within it, which has a particular shape when inflated. So, while the plastic is molten, air is blown into the tube and the plastic is formed around the tubing. It is then left to cool and removed from the mold.

Compression Molding * The most labor-intensive type of molding process is compression molding. Therefore, it is only used for large-scale production purposes, and not for mass production. For example, boat hulls and car tires are made using this method. Molten plastic is poured into a mold. Then a second mold is pressed into it. This squeezes the plastic into the desired shape before being left to cool and removed from the mold.

Rotational Molding * Toys, shipping drums, storage tanks and items of consumer furniture are made using rotational molding. Each object is made by coating a mold from the inside. A mold is held in place between two mechanical arms. Then, the arms rotate the mold constantly at the same level, while molten plastic is placed inside. As it turns, the plastic coats the inside of the mold to create a new hollow, plastic object

For this week I decided to design A Gear, for that I used Fusion 360 .

Below are the steps I used:

1- I designed a rectangle :

2- Inside the rectangle, I create two circes one inside the other as it is shown below :

3- After that I created these outside shape on the outside circle :

4- At the menu bar - press create - circular pattern then I selected the last shape to clone it allover the outside circle as it is shown below :

5- I extruded the rectangle down at a specific value , then the outside cercle up :

6- On the rectangle I created a new sketch the I designed a small new rectangle allover the big one an I extruded it until the height of the material I had as it is shown below:

7- After done withe the previous steps , I selected te interior circle and I applied a function colled fillet on it as it is shown down here :

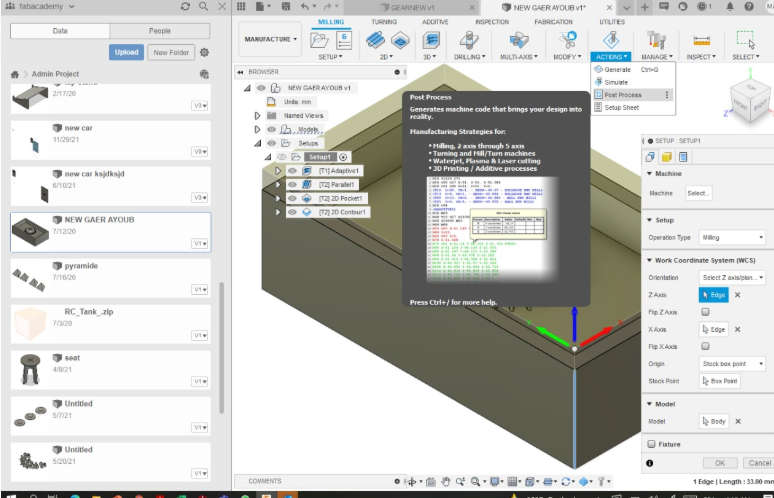

8- I finished with the design, the turn next was for generating the CNC process (manifacturing) , the need tools , the right opperation (Adaptive, Parallel, 2D Pocket and 2D Contour).before all of tha you need to select the right (Z,X,Y)

9- I checked my work using the fusion fuction simulate to verify if there was an errors or not the I generated the (G-6CODE).

After I finished my design Its time no to upload the code to the CNC machine to start the milling process :

For that at first : I linked the material I used with a double sided tape to ignore any move

Here is the process :

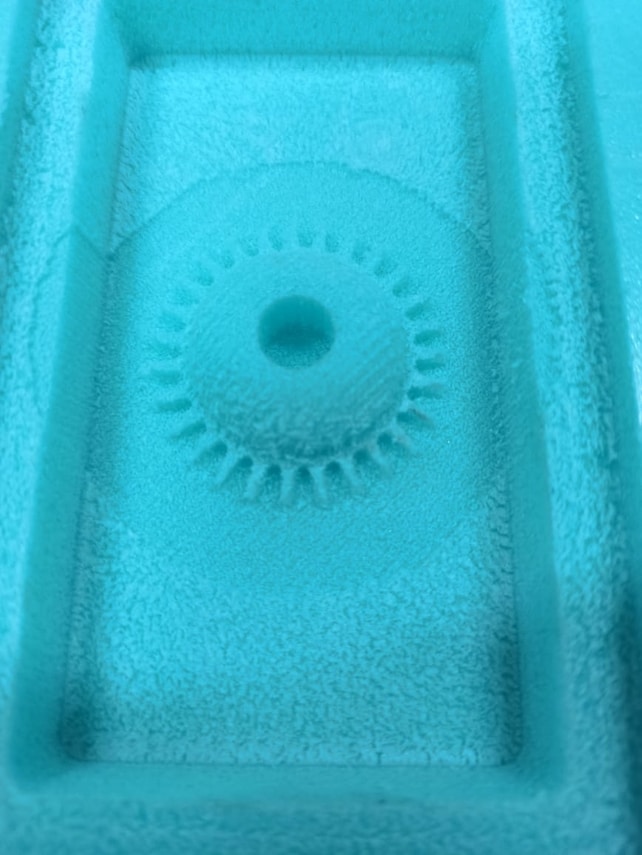

After I finished, it was time for mixing the selicone two parts to start the casting process:

I read the datafile of the two prodact carfully

When I mixed the two parts I tried to eleminate all the air bubblez

And here is the final result

And here is the final result

I thought to use the wax with it , so I bought some light candles and I burned it , after that i puted the hot was in its place and I wated for it to freez and here is the result I got :