|

Week7: Molding and Casting

Neil

says this is the last week where we can be creative...ok, this time im

going to make a small proyect to get the rules of the molding and

casting, and then maybe take some risks.

Now, when i see the function of the fab modules in Neils computer,

i realize that fab modules dosent care if the file to send to the

milling machine is STL o PNG. It will always get a final png to process

the mold. So the first thing i thought was... was i able to think a 3D

mold from a 2D image? ok, lets take a look.

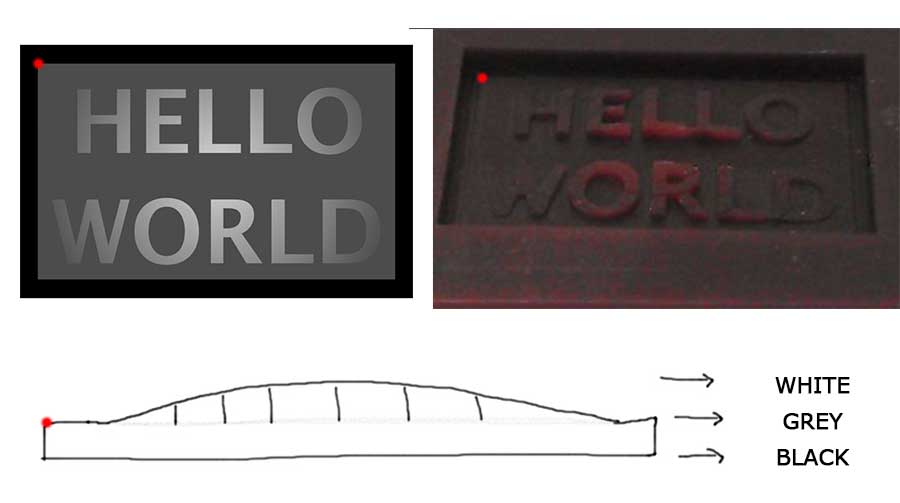

Looking at the

HELLO WORLD model that is in the schedule, the file PNG is very

similar to the final piece. The final piece has a lower part

surrounding the letters, and the letters are domed, so the center of it

is higher than the rest. If you can see in the file, the lower part is

painted in GREY, and the letters goes from GREY TO WHITE. So if i put

this colours in a 3D perpective:

Use the red dot to get a reference. You must notice that the PNG is the positive Here are the request to start molding from PNG:

- Image must be in greyscales. The modela could not understand well colours.

- Image must have 500 ppp of resolution.- The final image must be save as .PNG

After

this previous considerations, lets see the process for my assignement.

I want to make the Fab Lab Logo, because its formed by three identical

parts with diferent colours. So if i made a mold of one part, and cast

three parts with diferent colour plastics, i can have the final logo.

So i pick the logo from the Fab Academy page. I would prefered a .svg

file, so i decide to convert a jpg file to svg with Inkscape.

- Open the file with Inkscape.- Go to menu Path - Trace Bitmap- Press the Accept button. This give us a black and white logo, but with the vectors instead a raster image.

This process could change depending the photo you use, but with the fab lab logo its ok without touchin anything.

Now

we have the vector file. Eliminate the third par of it , paint it all

in dark grey with a degradate from dark grey to dark white. I want to

give the mold a 3D appareance, so the degradation from dark grey

(bottom) to dark white (upper) will make that Modela make the mold with

this shape.

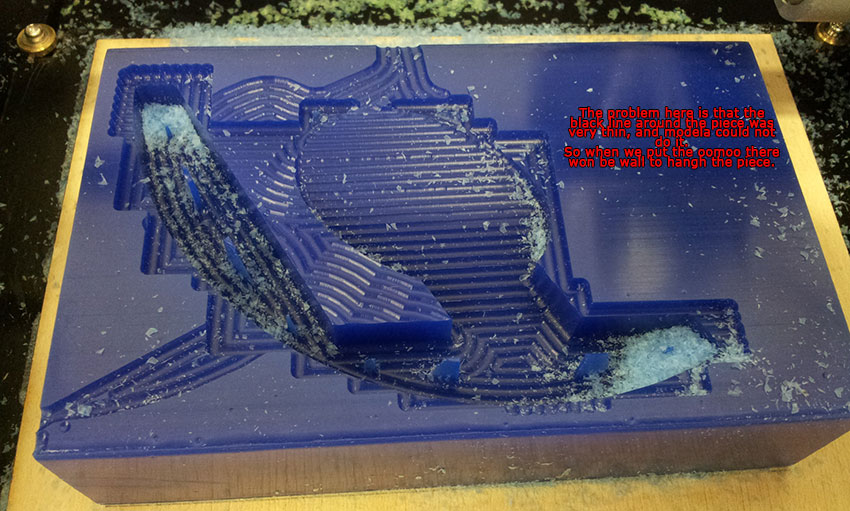

- Add a full black edge around all the piece. This add a wall around the piece to fill with the oomoo.

- I add a light white edge, to help take out the mold off the wax.

Remember,

image must be flattern, without layers, in greyscale and 500ppp. I

check this in Photoshop before sen it to the modela.

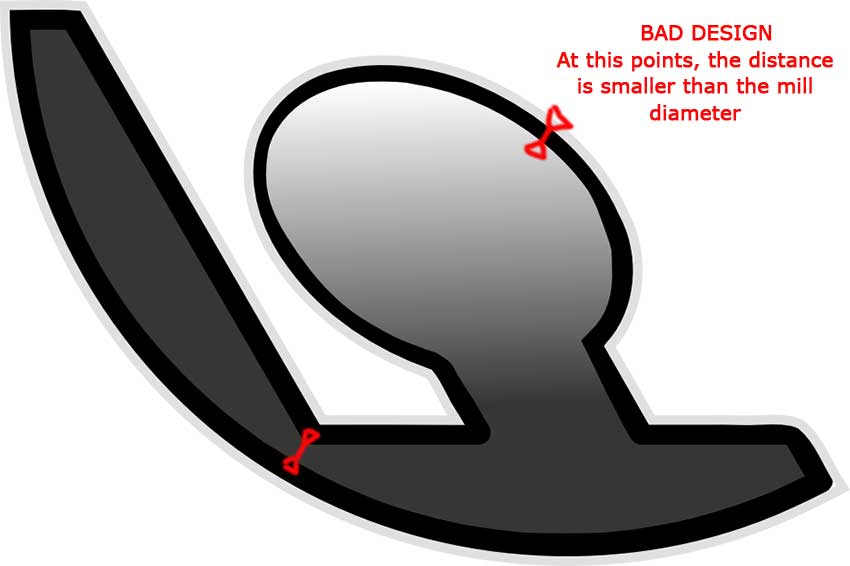

IMPORTANT.

I

use a 3mm mill in the modela, BE SURE the mill can go all way and all

gaps in the wax. At my first attemp, i realize that one gap in the

design are less wide than 3mm, so the mill dont mill this place.

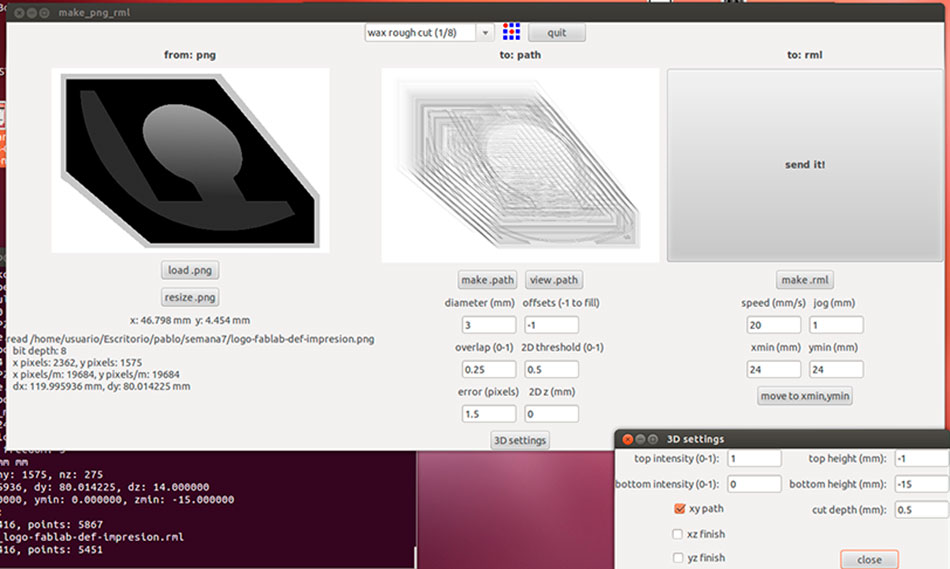

Milling the Wax

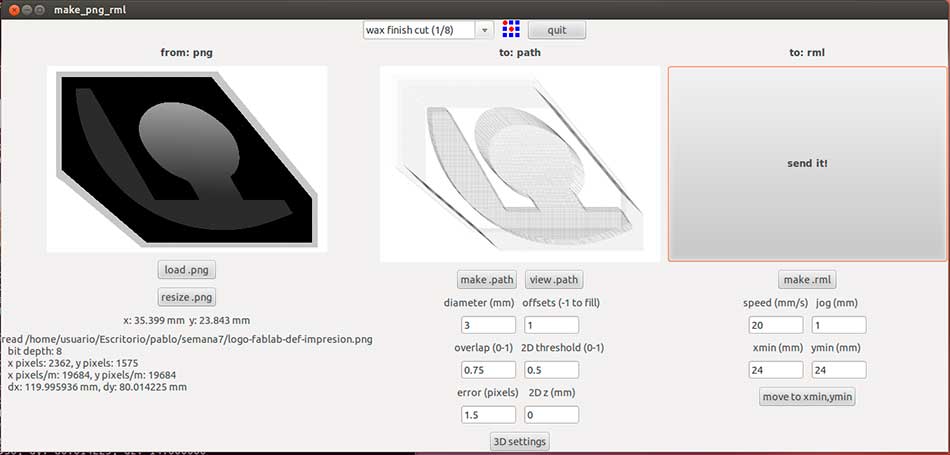

Once the file has been prepared, lets send it to the fab modules.

- Images (.png) to Roland Modela- Load .png- Select the 1/8 wax rough for the first pass- We have a 3/8 mill, so we need to change the diameter from 3,125mm to 3mm-

I did the piece in tha half of the height, so i determine the bottom

height of the piece in 1.5cm. This from a PNG file, so this parameters

arent filled by the fab modules (in an STL, the bottom heigh is the

height of the model)

IMPORTANT!!!!Whatch your design orientation. Remember the (0,0) point is at the bottom left, so if your design is in horizontal, the wax MUST be at the same orientation. (yeah, it happens to me at the first time).

To

cancel a job with Roland Modela, press view button and, when the light

is on, press UP and DOWN at the same time. The led will blink until the

memory are dump (for me took about 20 minutes).

After the rough cut pass, we selected the finish with the same

parameters, except the overlap where we use 0.75 to have a softer

finish in the piece.

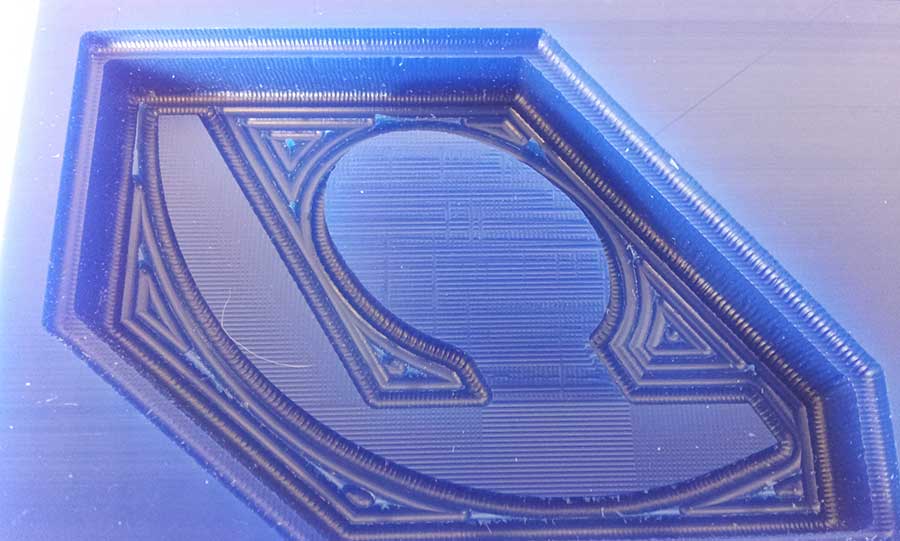

After milling all the pass, this is the result of the wax.

After

finish i reallize that the bottom of the piece wasnt finished with the

finish cut. I dont really know why this happened. I also reallize that

the Modela left some part unmilled....also dont know why this happen.Well,

now i have the piece lets fill it with the mold. I will use OOMOO 25 to

make the mold, because its faster in demold time than other solution.

OOMOO comes in two parts (A and B), and must be mixed with a ratio of

weight 100 from part A and 130 from part B. So now i want to know how

many amount of each part must i mix to fill the wax exactly.CALCULATE THE MIX

-

Fill the mold with water to the edge. Then weight this water. In my

case 69gr of water, assuming the density of water in 1, its 69 cc in

volume.

- The density of the oomoo 25 is 1.34g/cc. So like desity=mass/volume , mass= 69 * 1.34= 92.46 gr of OOMOO i need.- Ratio: Part A is 100, Part B is 130, so Total is 230. So the Part A is the 43.47% of the total, and Part B is the 56.53%- The total of oomoo i need is 92.46gr, so PART A=40.2gr and PART B=52.26gr

Now

lets make the mixture of the two components. The part B (blue) is

enough liquid to work easy with it, but the part A (yellow) its very

sticky, and its hard to work with it. I put some tape around the wax to

avoid spill the oomoo.

After

a bit time (75 minutes aprox), the mold was ready, and i decide to

unmold it. It was fresh and sticky, but i can manage it.

I

had a big bubble in the middle of the piece. Also a lot of bubbles

around the mold. This oomoo 25 its a sticky mold, and its very dificult

to have a perfect result (at laeast at the first time). After

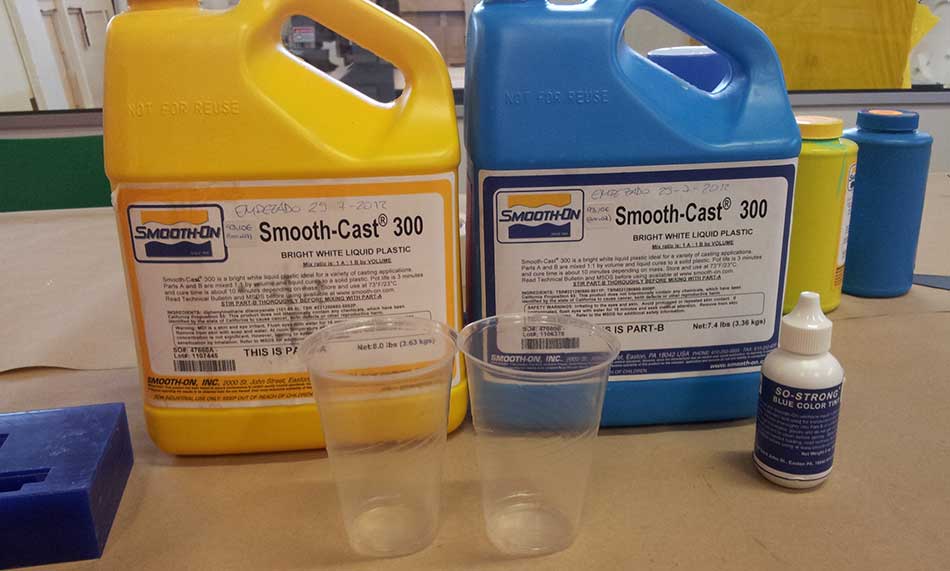

this, i did the piece in plastic, with Smooth-Cast 300. The mix ratio

is 1:1, so you just have to mix equal quantity of part A and B. Also i

use colorant to add to the plastic. This colorant must be added to Part

B before mixing with part A.

And

the first final piece is ready in a few minutes. The i repeat the

process with other two colours, and finally i had the Fab Lab

logo.

|