|

Week4: Electronics Production

This

week we learn the the different ways and materials to make a

PCB

with components inside. At the end of the week we must build the FabISP.

The

first thing we must do is to cut in a rigid PCB, with the Modela, the

diagram of the FabISP circuit. I choose the Hello.ISP.44.cad board,

because seems to be easier for my first PCB.I downloaded the traces file and the interior file from the Fab Academy web page.This

was my first time working with the Modela, and it seems to be a machine

with a lot of precision. Here in the Fab Lab Leon we had a great

workflow to work with the modela. The 1/64 endmill seems a really small

thing. First thing I need to do is practice with placing the Z axis in

the correct position. ¿Why this machine doesnt have a Z-cero caliber,

as the CNC? The way i must put the enmill touching the PCB is highly

stressful ! :)

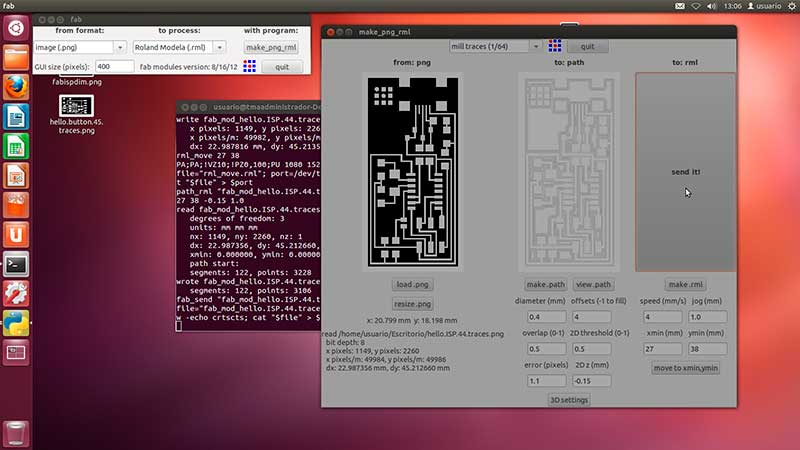

After some testing finally

started to mill the PCB with the circuit. This was the parameters in

fab modules.

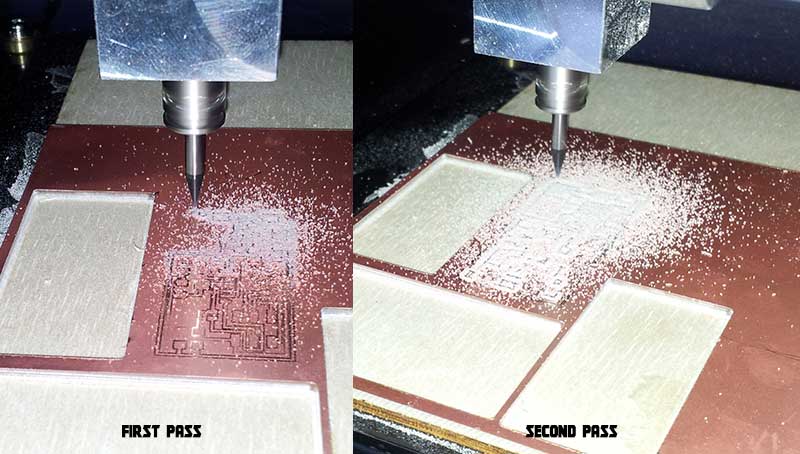

The

PCB seems not well attached to the base, so in half of the PCB the mill

do his job, but at the other half dont mill enough. To correct this i

made other pass , adjusting the Z a little bit down, as you can see in

the parameters. The first pass was with 2Dz at -0,1mm and the second

pass was with 2Dz at -0,15mm.

This seems to be enough to make a

nice cut with the 1/64 endmill.

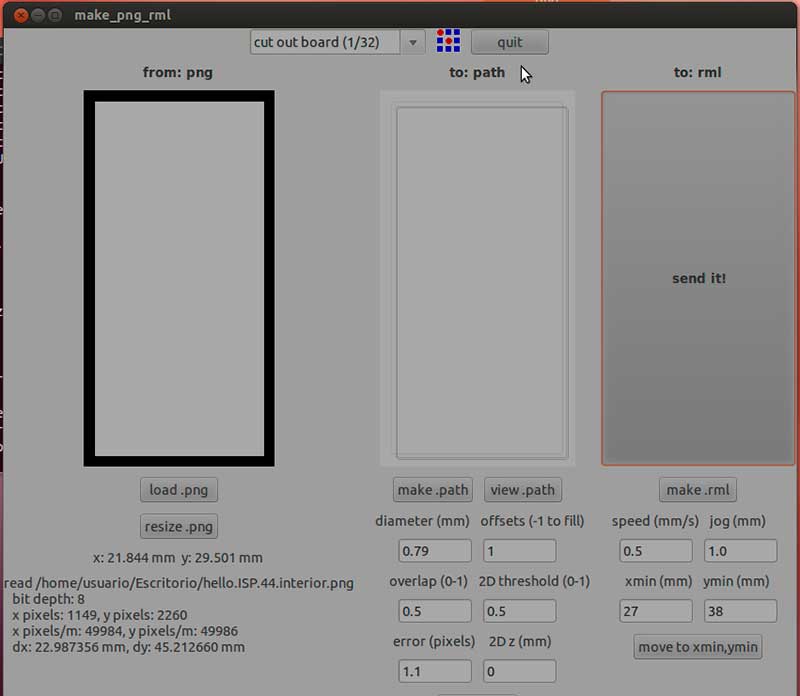

Finally I cut the margin with the

1/32 endmill with the following parameters:

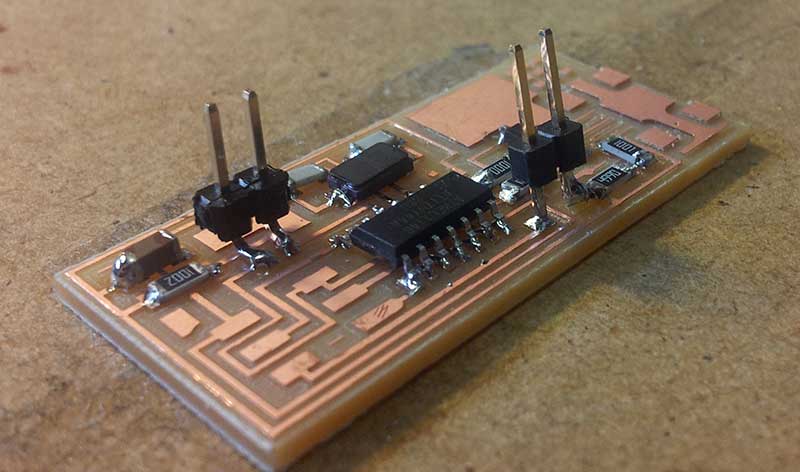

Assembly components

Now we must fill the PCB with the

components required. This is the list and the diagram:

RESISTANCES: R1 1K // R2 499 // R3 100 // R4 100 // R5

10k

CAPACITORS: C1 1uF // C2 10pF // C3 10pF

DIODERS: D1 3,3v // D2 3,3v

An ATTINY 44 microcontroller

A 20Mhz Cristal

Mini USB conector

J1 ISP connector

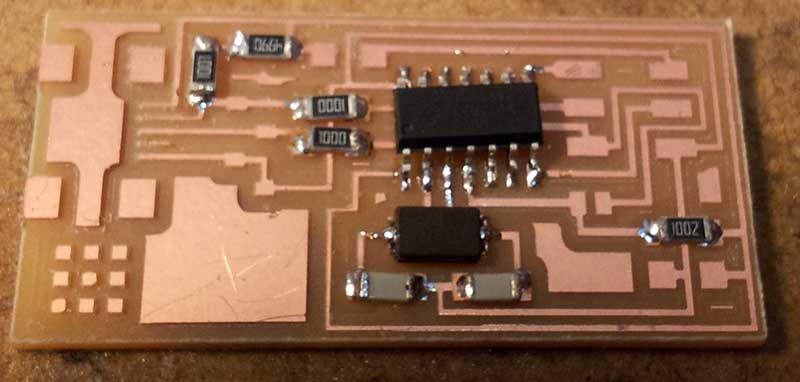

Then

i solder the components on the PCB as seen on the diagram. Thanks to

Ruben Ferrero that teach me the basis of soldering with tin, my first

time soldering wasnt a nightmare. First i must heat the pad, then put a

little cuantity of tin, and then heat the pin of the component and the

pad at the same time. Finally we add a bit mor tin to cover the pin.

After

some practice, i get all the resistances, capacitors, dioders and the

ATTINY44 micro solder to the PCB. Then i must put the 0 resistances in

their position. A teammate in the fab lab, Alejandro, suggest me to put

a pair of jumpers in the 0 resistances position. So if in the

future if i need to reprogram the PCB, i just need to put the jumper.

If the software is ok ,i must remove the jumpers to avoid it to delete

the firmware.

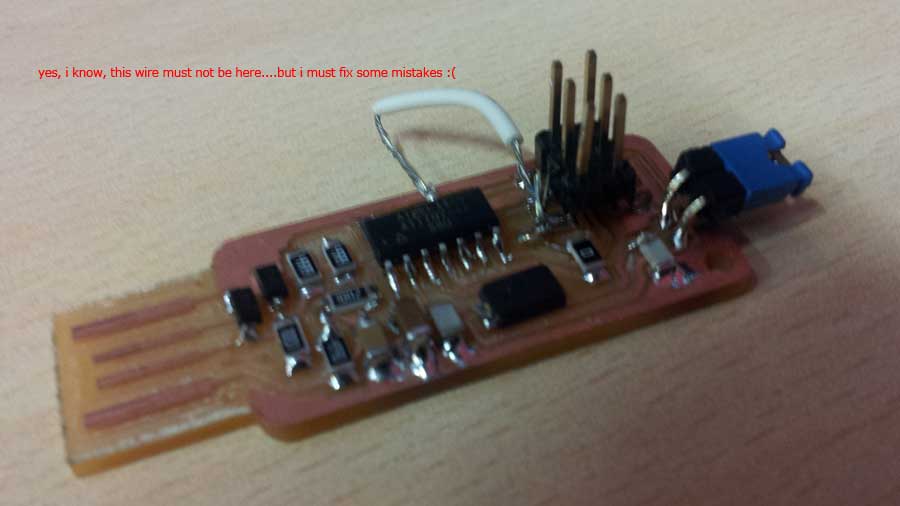

So here are my tho jumpers in the PCB:

Yes, i know, i must improve my skills in soldering :)

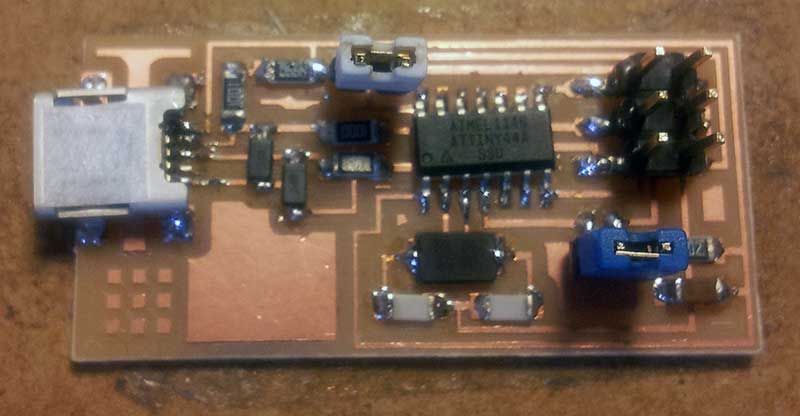

Finally we add the J2 and J1 connectors and the Mini

USB.

After

this, the multimeter says that some pins of the Mini USB arent well

solder. So i spend a hole morning trying to solve it. After check that

all the paths goes individually, i can finally program de FabISP.

Programming the FabISP

To

program it we use another valid FabISP in Fab Lab Leon. Connect the two

USB of the two PCB to a MAC computer, and then make a 6 pin cable to

attach at the J1 connector. Be sure the red cable are at the same

position in both PCB.

After this, make all the process:

nano Makefile (here we change the option to use MiniUSB

make clean

make hex

(sudo) make fuse (check programmer in Makefile, may need to repeat)

(sudo) make program

Everything

goes fine, and all the process completed with an OK. Then un plug the

PCB and try that a Windows computer recognice it as a FabISP....without

luck.

After spending couple of hours inspection it and

re-do all the process, my instructor Nuria Robles realized that the V

pin of the MiniUSB got out of the housing, and that was the problem.

So i must start all the process again, to get a shiny

new FabISP Programmer.

! electronic are really hard job !

UPDATE:

finally i review all the pcb and find some traces that arent well

connected, and at the end i could program the FabISP and it can program

other boards....!great!Starting with the Andy FABIsp

After

realize that the mini USB connector is a nightmare to a new-born in

soldering like me, i try the Andy FabISP, which has a built in USB

connector in his copper layer. So no more small pads to solder the

miniUSB... yahooo!!!

I

download the routes and the interior, milled in the Roland modela and

solder the components on it. The schema isnt really self-explaining,

because the ground are all around the programmer, so its hard to see

clear which pads are for which component.

After guess the components i solder all the stuff in the pcb, and got a FabISP.

Unfortunately

this fabISP isnt working no more. My skill in solder wasnt good enogh

for this programmer, and i finish burning the traces.Later in time i try to fix this board, and finally got a FabISP with USB incorporated...nice and small.

If you cant build a FabISP and has an AVR programmer, you can use it to program the nex boards in the Fab Academy.

Installing the programmer AVR in Windows 7 64 bits:

|