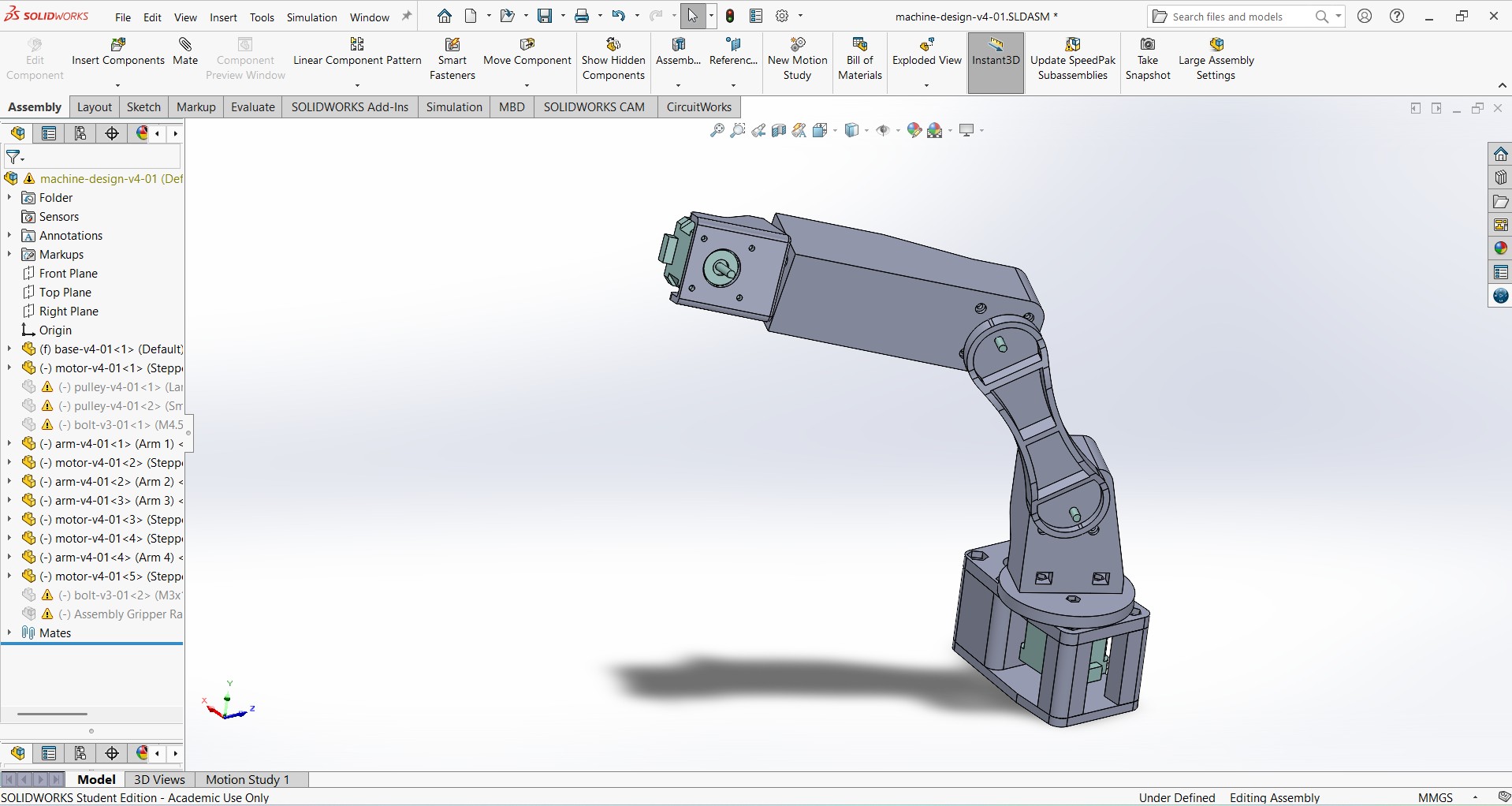

4-Axis Robotic Arm

Project Overview

For Week 12, our group designed and built a 4-axis robotic arm for performing tasks such as milling and isolation routing, pick-and-place tasks, controlled by Nema 17 stepper motors and firmware. I was part of Group 1, focusing on the design, 3D printing, and assembly of the mechanical structure. Our team was divided into three groups:

- Group 1: Design and Assembly - CAD design, 3D printing, and mechanical assembly (my role).

- Group 2: PCB Design and Manufacturing - Custom electronics for motor control.

- Group 3: Firmware and Interfacing - Firmware and web interface.

The arm was designed to demonstrate coordinated motion and automation, with applications in manufacturing and education.

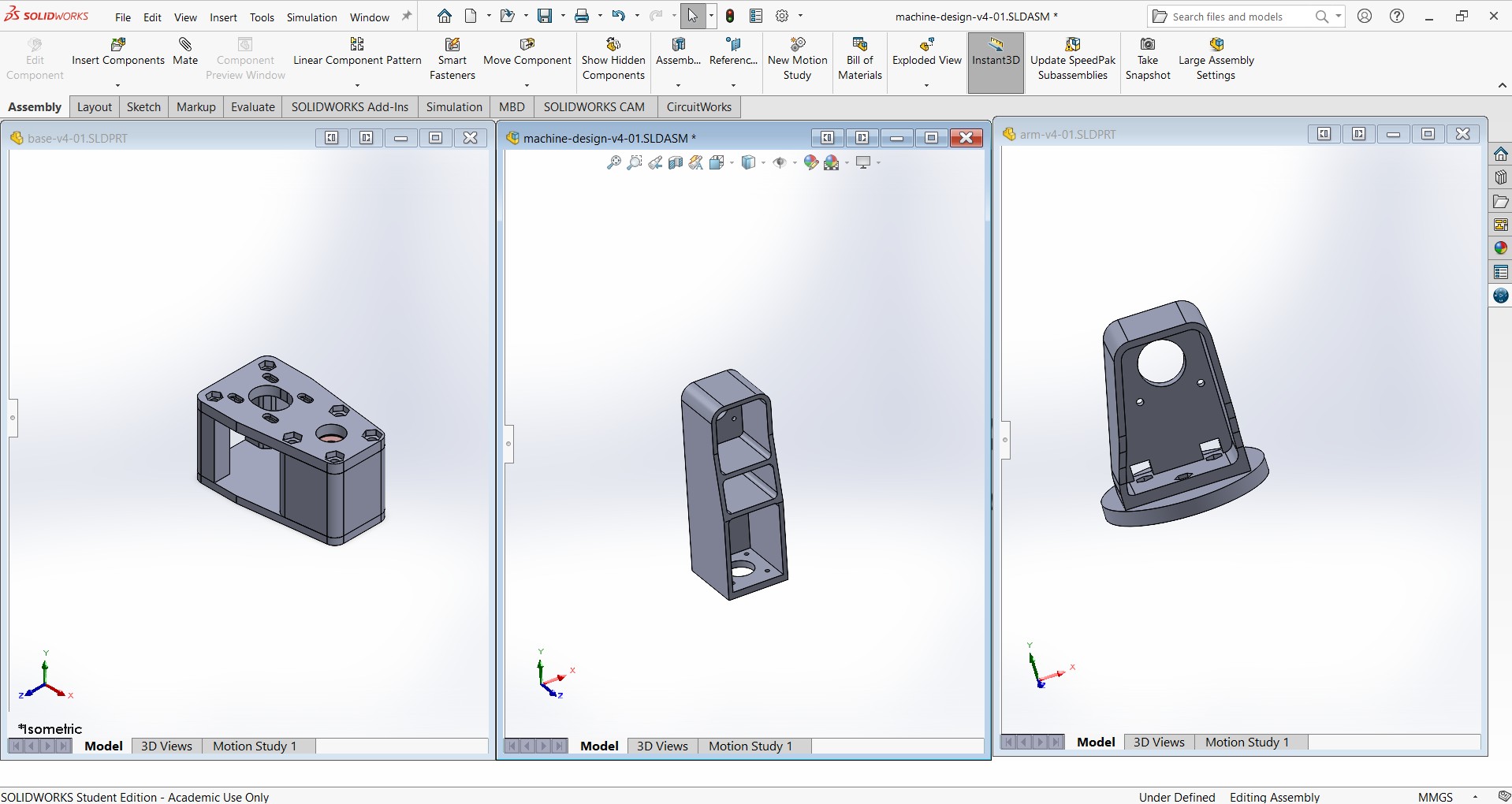

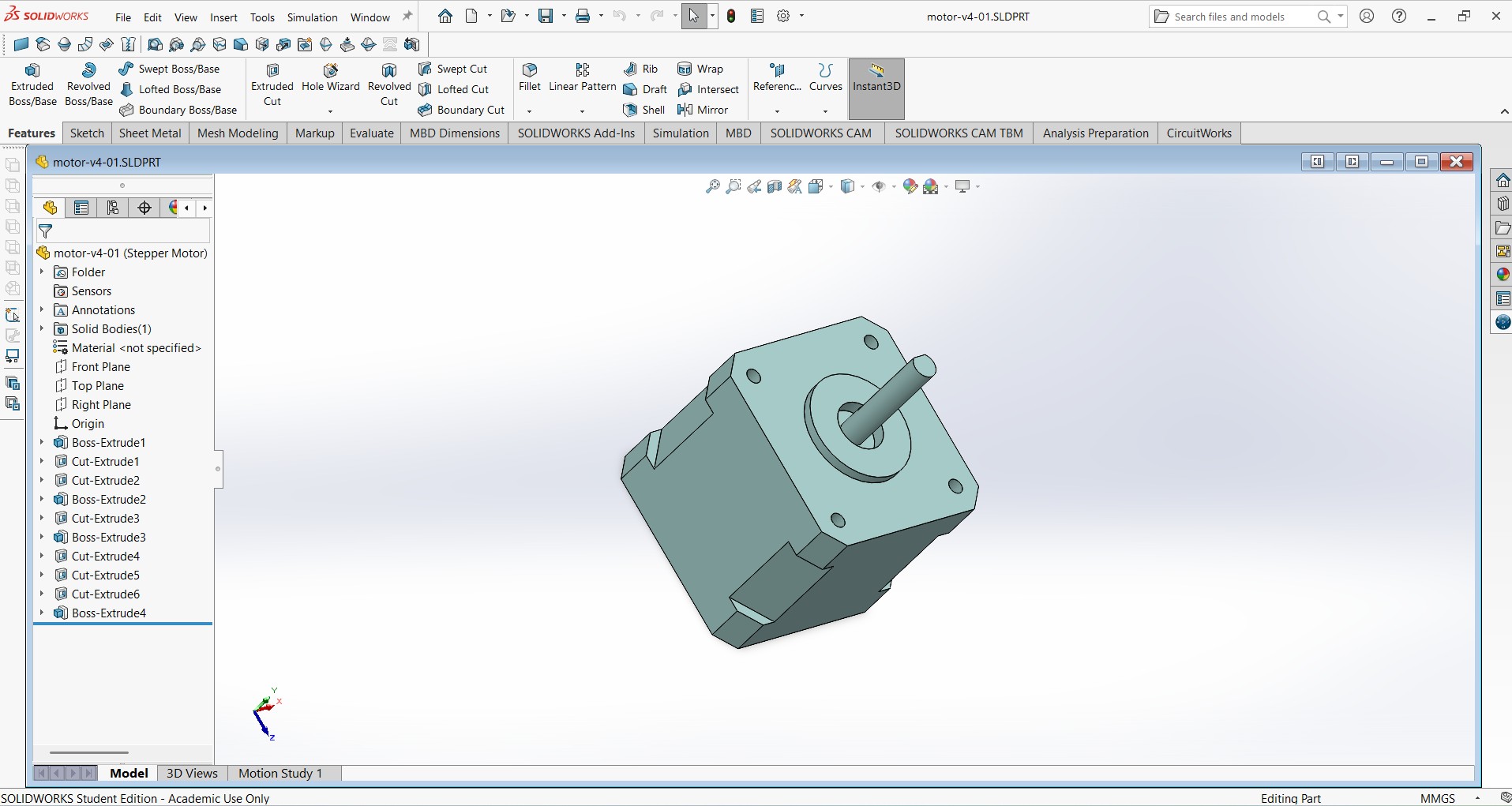

CAD Design

I used SolidWorks to design the 4-axis robotic arm, creating a modular structure compatible with NEMA 17 stepper motors and a manual gripper. WE reserched the internet for ideas of the already existed projects as we didnt have much time to starct from scratch. We visited the following pages

Nema 17 stepper motor

Nema 17 stepper motor

3D Printing

I 3D printed the arm’s components using PLA on several 3D Printers as the parts were many. Below is a zip file for the Solidworks and STL files

Week 12 STL For Download

- Components Printed: Base mounts, four arm segments, motor brackets.

- Print Settings: 0.2mm layer height, 25% infill, 50mm/s speed, brim for adhesion.

- Material: PLA, chosen for availability and ease of printing.

- Total Print Time: Approximately 24hours across multiple prints.

I minimized support material by orienting parts carefully and iterated designs to prevent print failures.

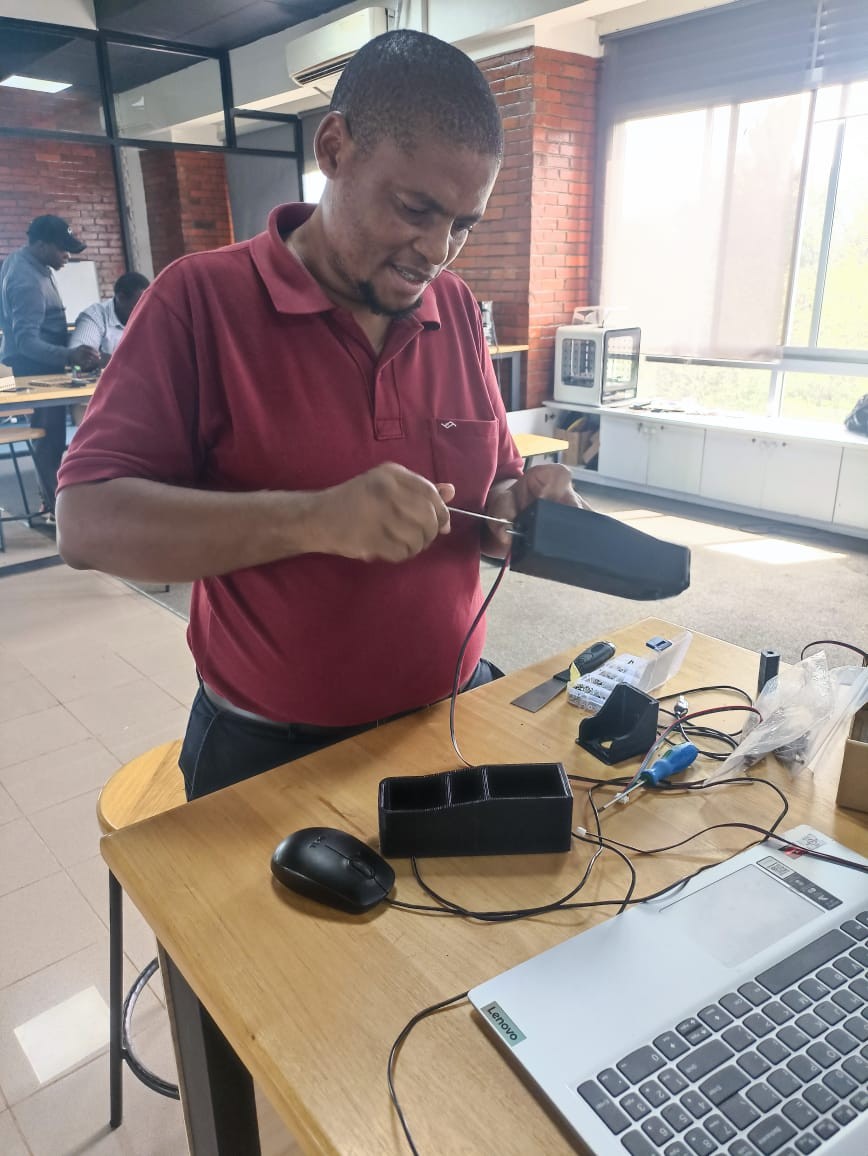

Assembly

I led the mechanical assembly, ensuring all components were aligned and functional.

- Mounted the Axis 1 stepper motor with a 3D-printed base segment and bearings.

- Attached Axis 2 (shoulder) and Axis 3 (elbow) segments, securing motors with M5 bolts.

- Added the gripper

- Manually tested each axis for smooth motion and reduced toque on the bolts.

Challenges

I encountered several challenges during the process:

- Print Failures: Warping occurred; resolved with brims and bed temperature adjustments.

- Heavy stepper motors The motors were too heavy for the joints

Team Dynamics

Our team’s structure leveraged individual strengths:

- Group 1: Designed and built the arm’s structure (our role)

- Group 2: Developed PCBs for motor control.

- Group 3: Created firmware and a web interface.

We coordinated through weekly meetings and WhatsApp. My mechanical work integrated seamlessly with the electronics and software, resulting in a cohesive final presentation.