- Conceptualize and design a meter-scale object

- The concept is to build an ironing board cum chair, the item is to have the ironing board that can be used as a chair and also a store some items. The idea was inspired by a facebook DIY video depicting an ironing board that can be made both as an ironing board and aslo as a chair. This saves space to put ironing board and chairs Open this link to view the Unique chair Ironing Board

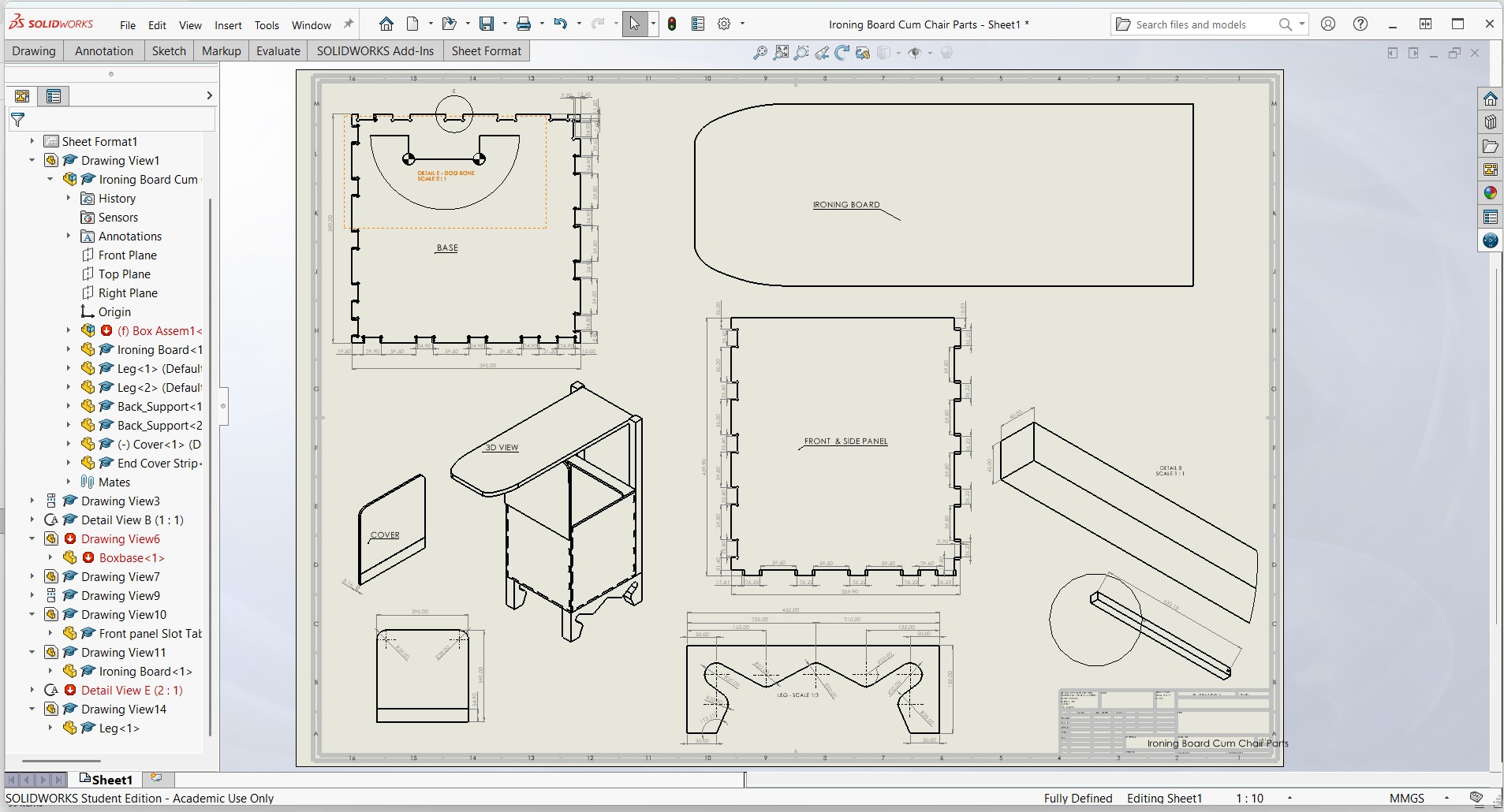

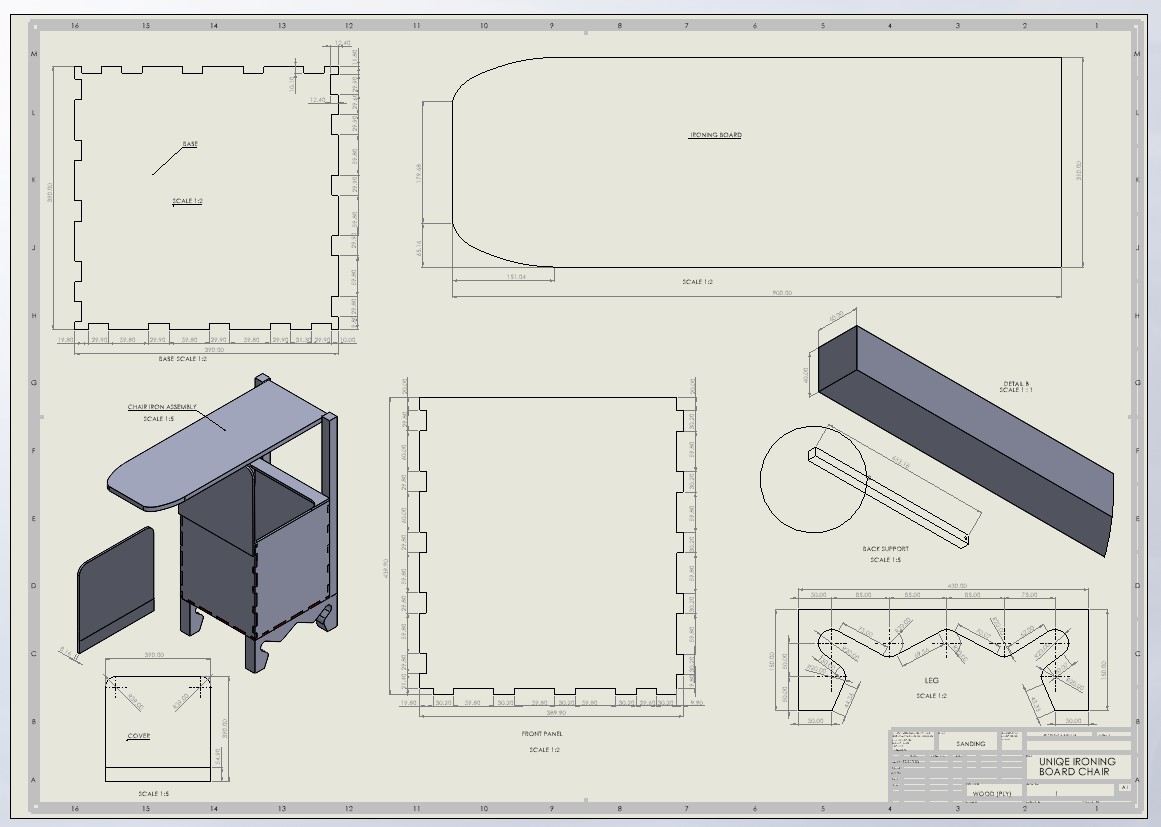

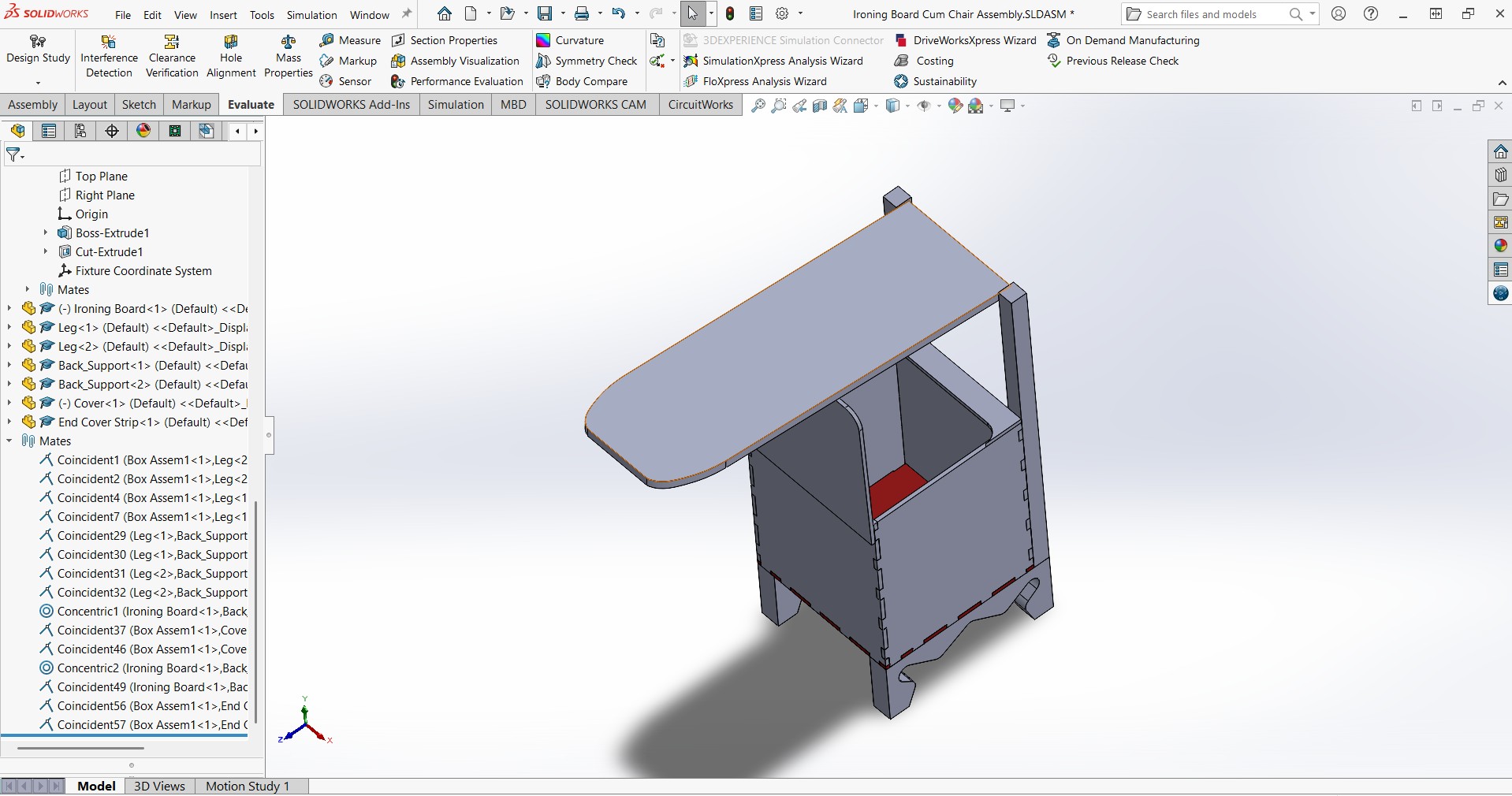

- Design: Parts, Sub assemblies and complete assembly of the chair cum ironing board.

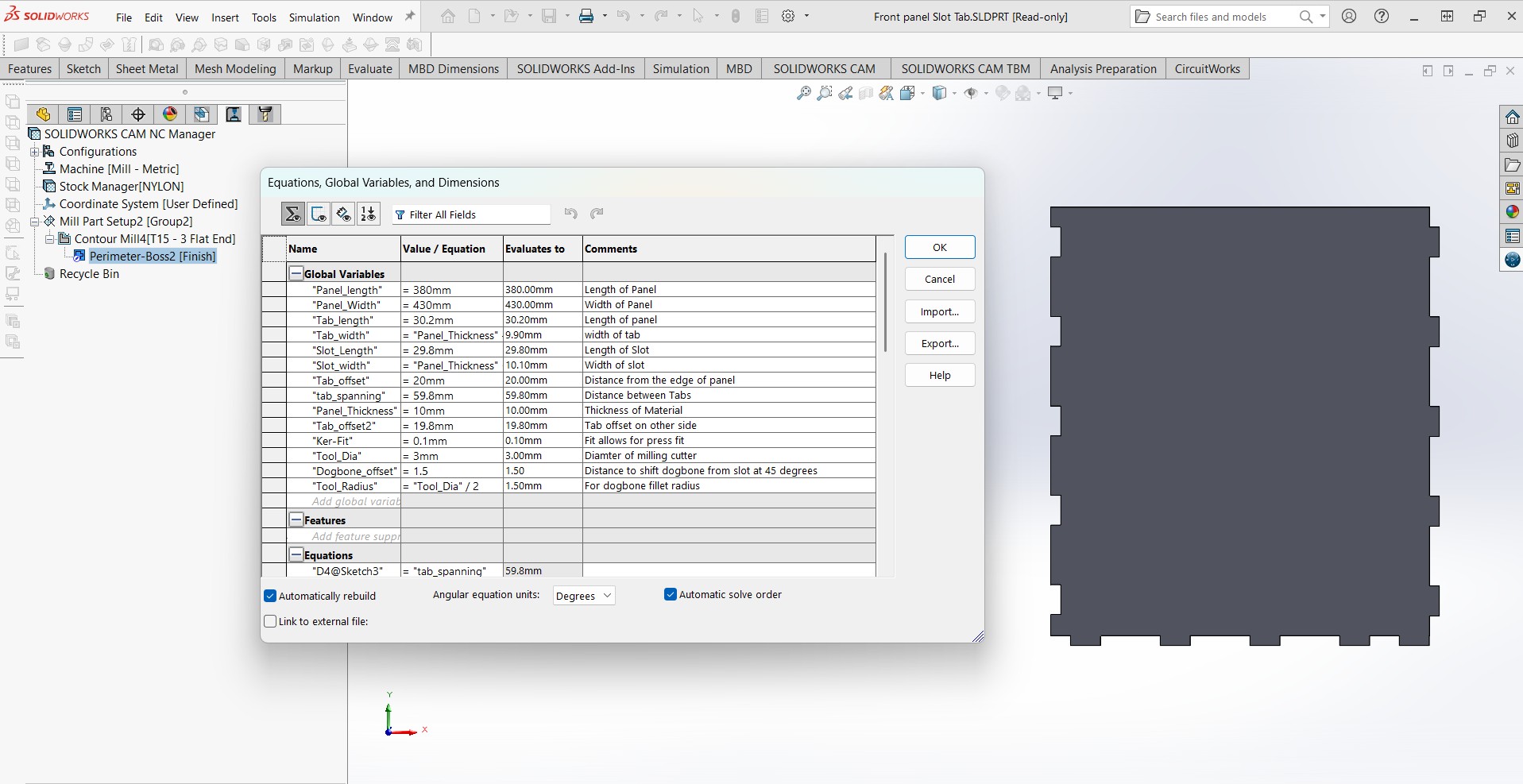

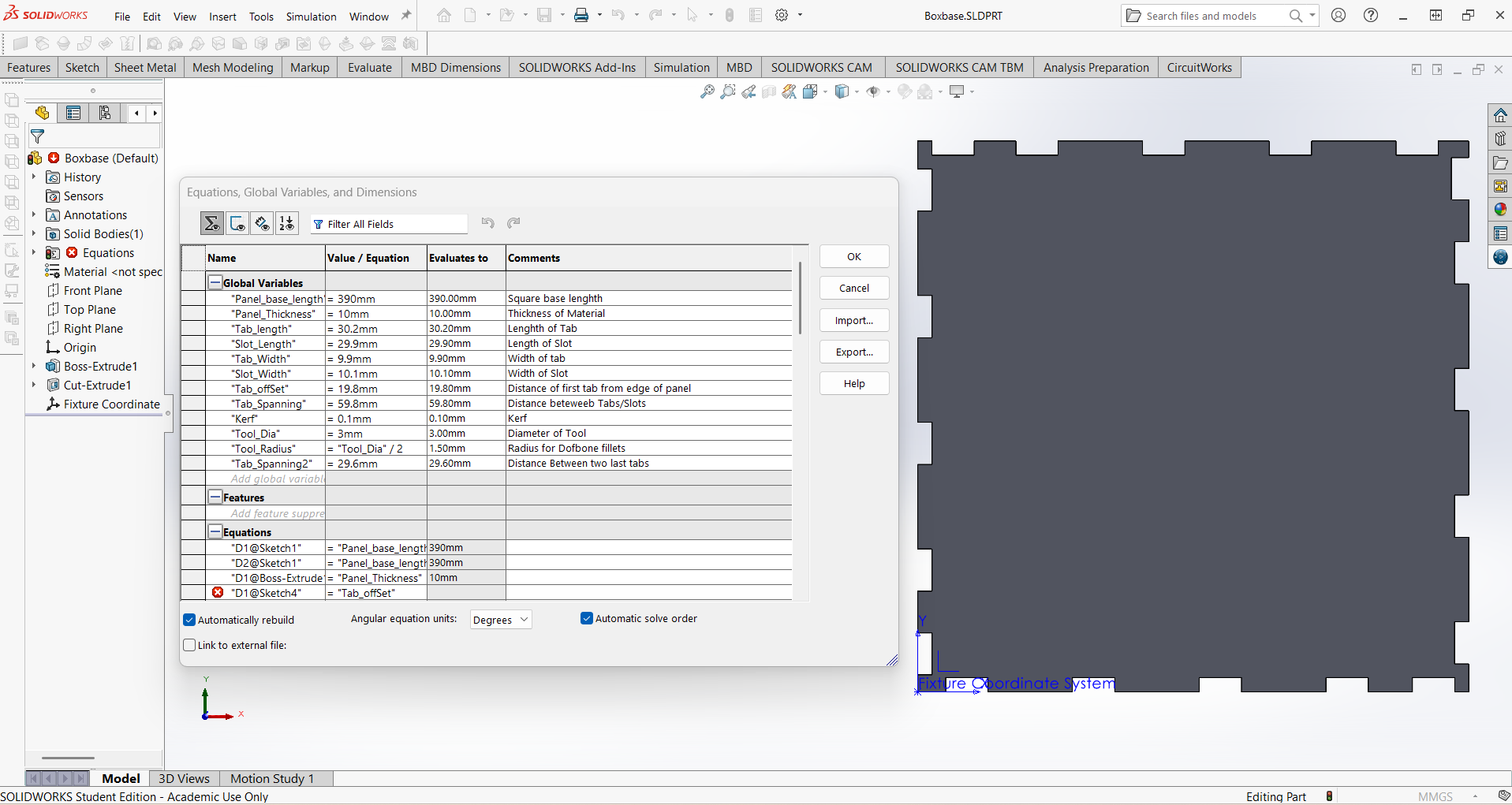

- Use of Tabs and Slot and parametric equations

- Parts

- Complete assembly and Animation

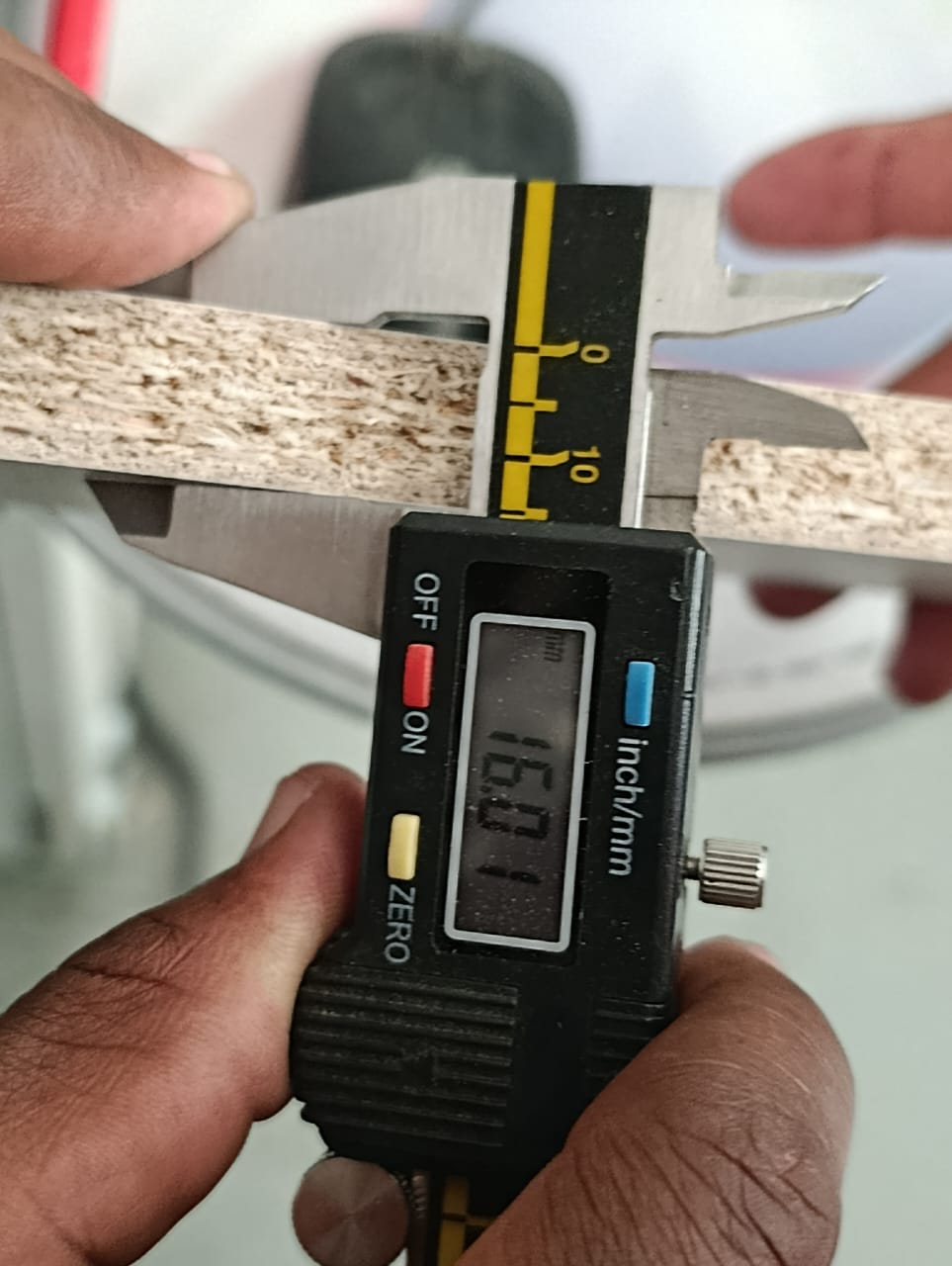

- The CNC in our Labs at BIUST and UB did not work, so I went out to a Machine shop and requested then to assist me to do the assignemnt. I programed the design for use with the CNC Router at Woodland in Gaborne. With the help of the gentleman there I selected appropriate tools, speeds, feeds, and materials.

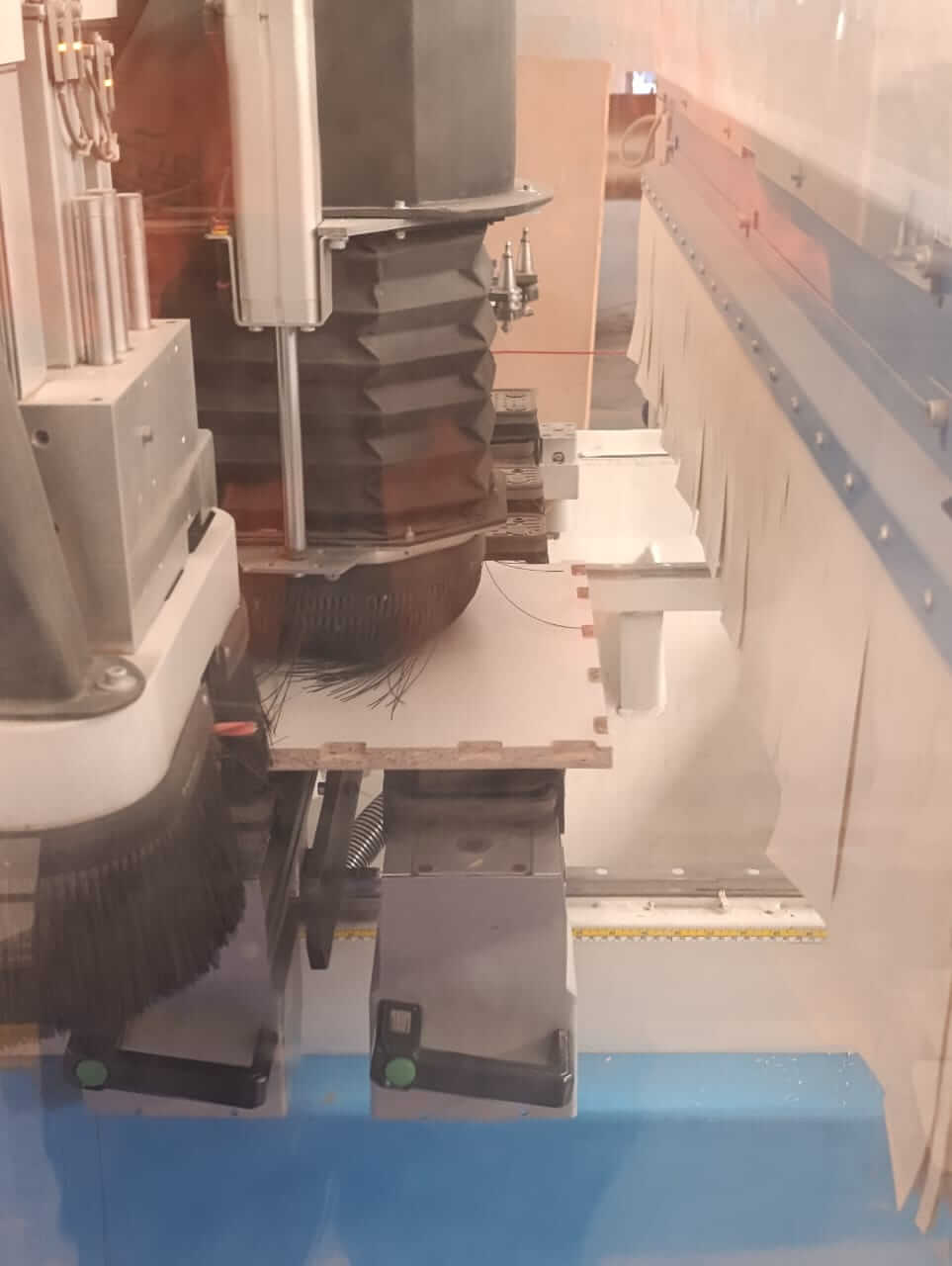

- CNC Mill Router

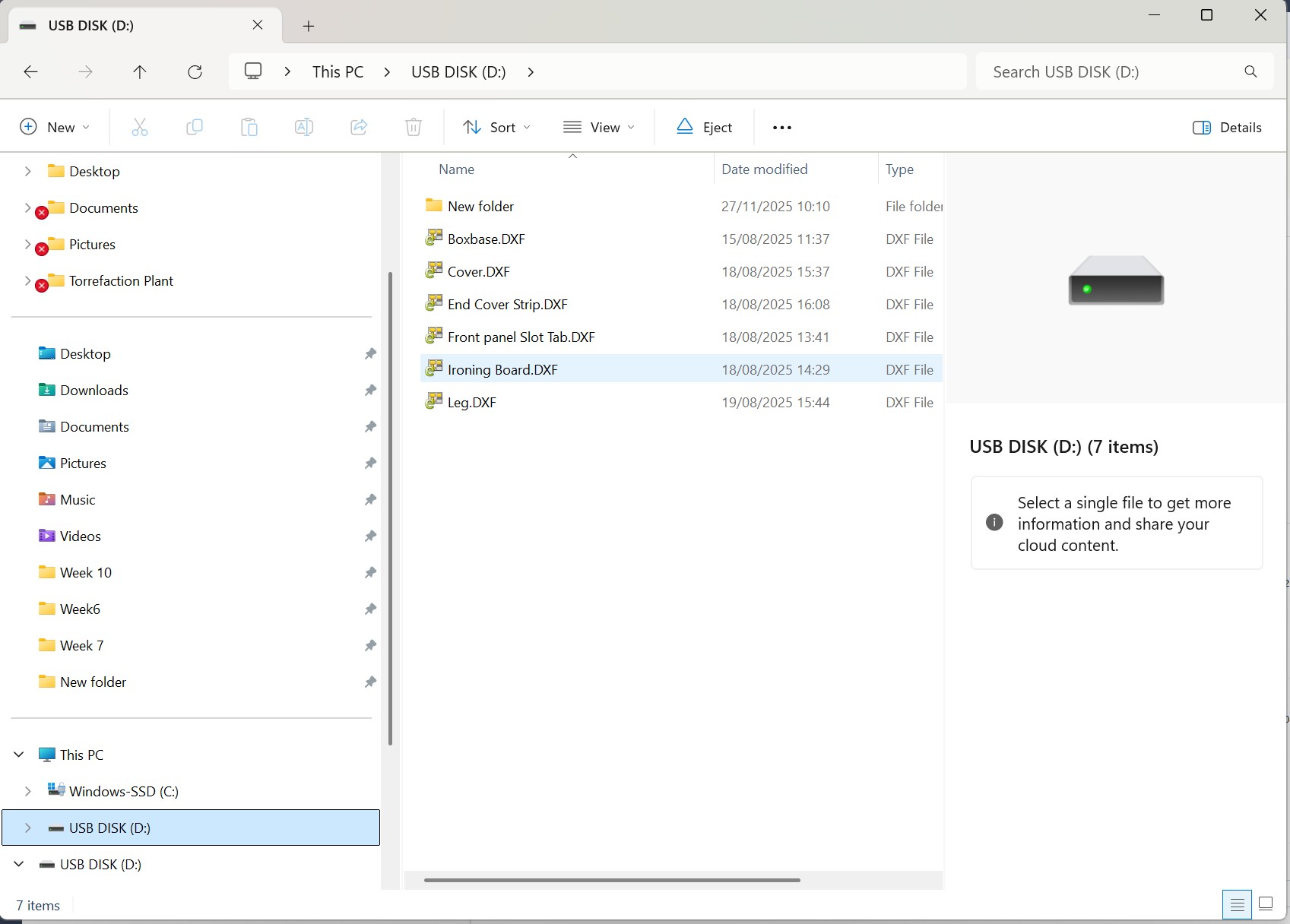

- I opened the machine computer and inseterd the usb, then opuned the dxf files

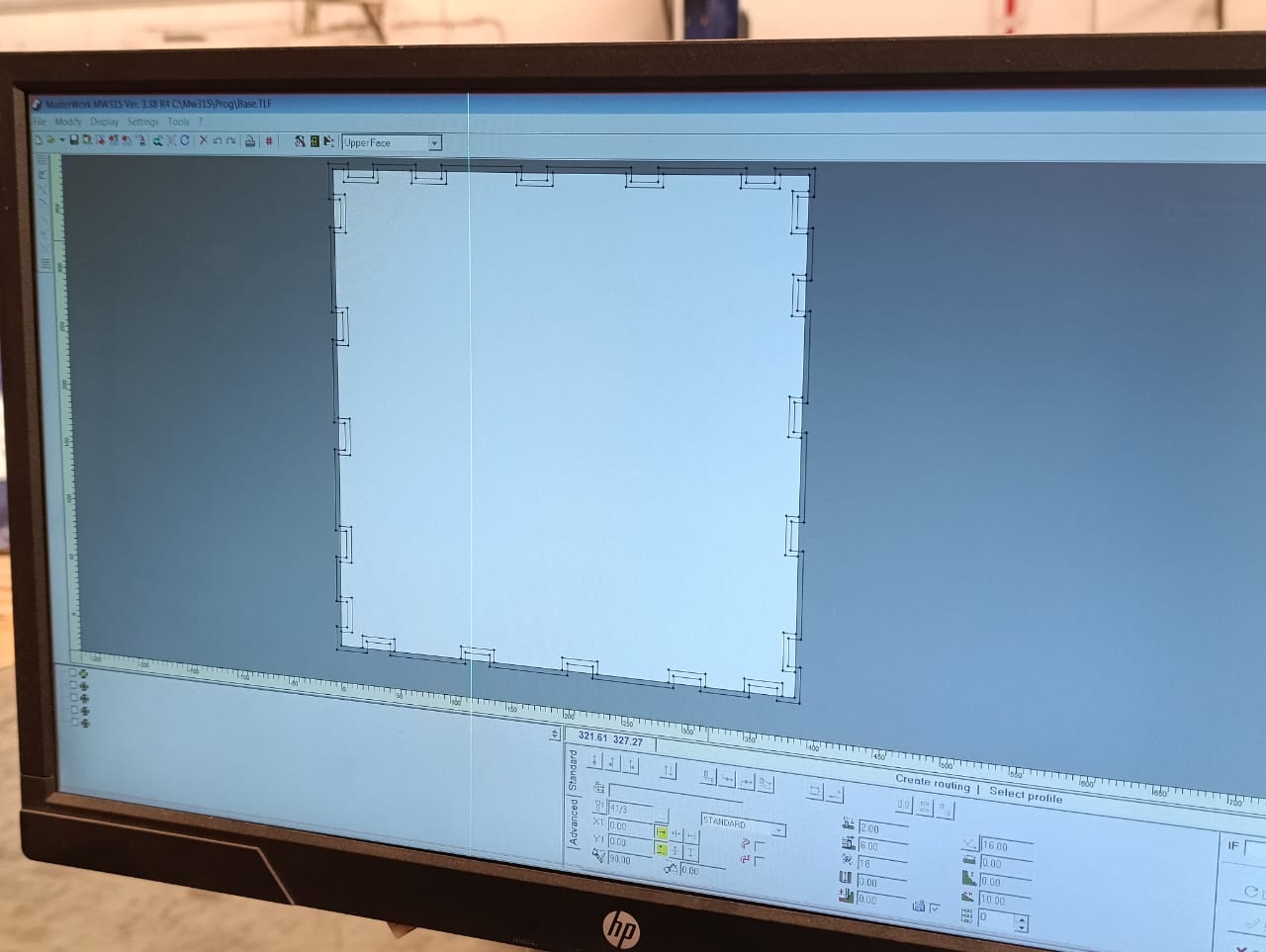

- I then opened Masterwork MW315 Ver 3.38 then opened the dxf file then generated the tool path.

- I then generated the G-code

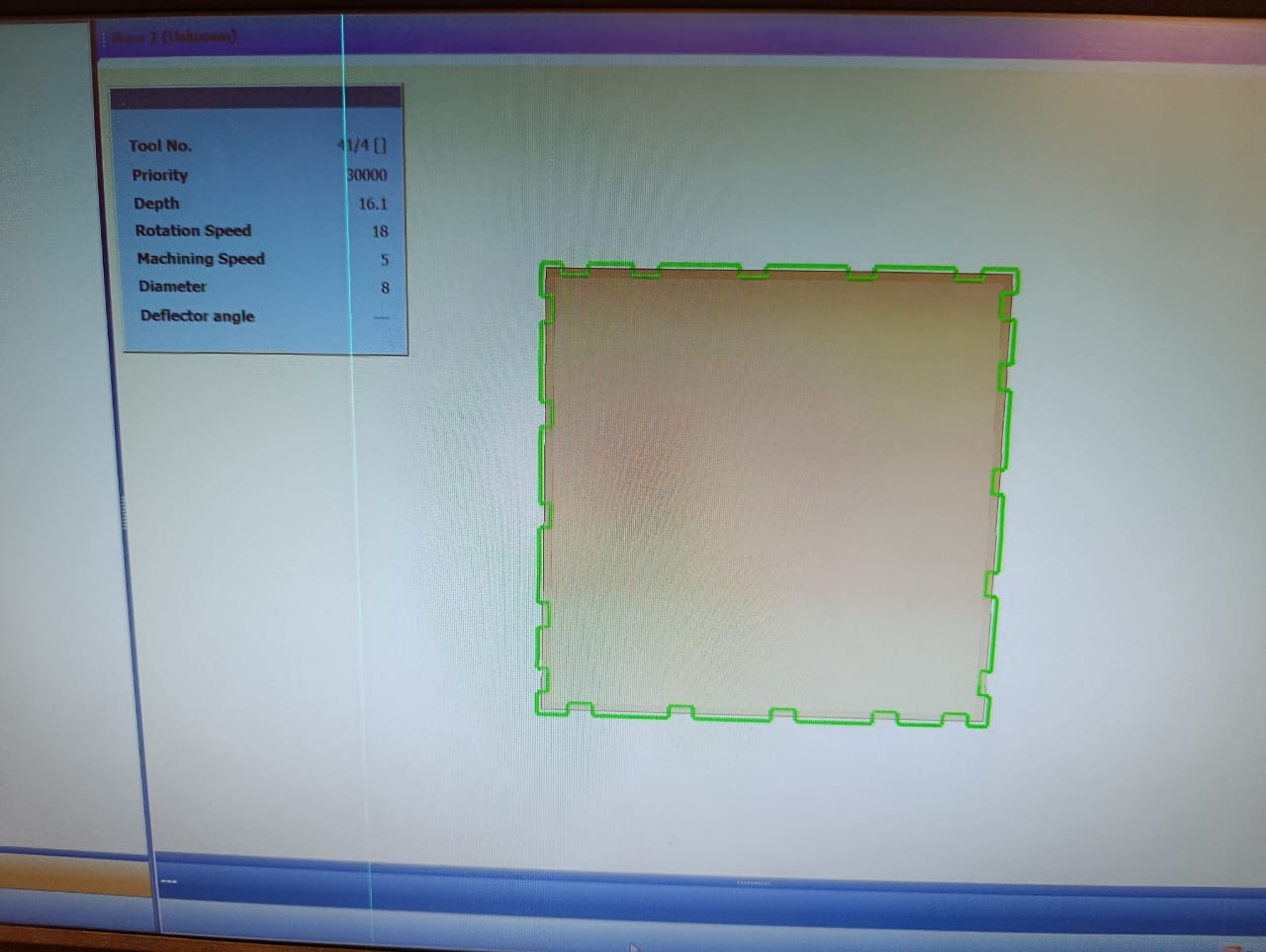

- I then chose the tools, 8mm for cutting tabs and slot and 12mm for drilling holes for dowels

- I then set put in setting for speeds, feeds and offsets

- Did a program check, this is equivalent to dry run at the lab but at the commercial workshop they dont do dry runs as it wastes time, the simply do a check and it was ok

- Program ready to cut

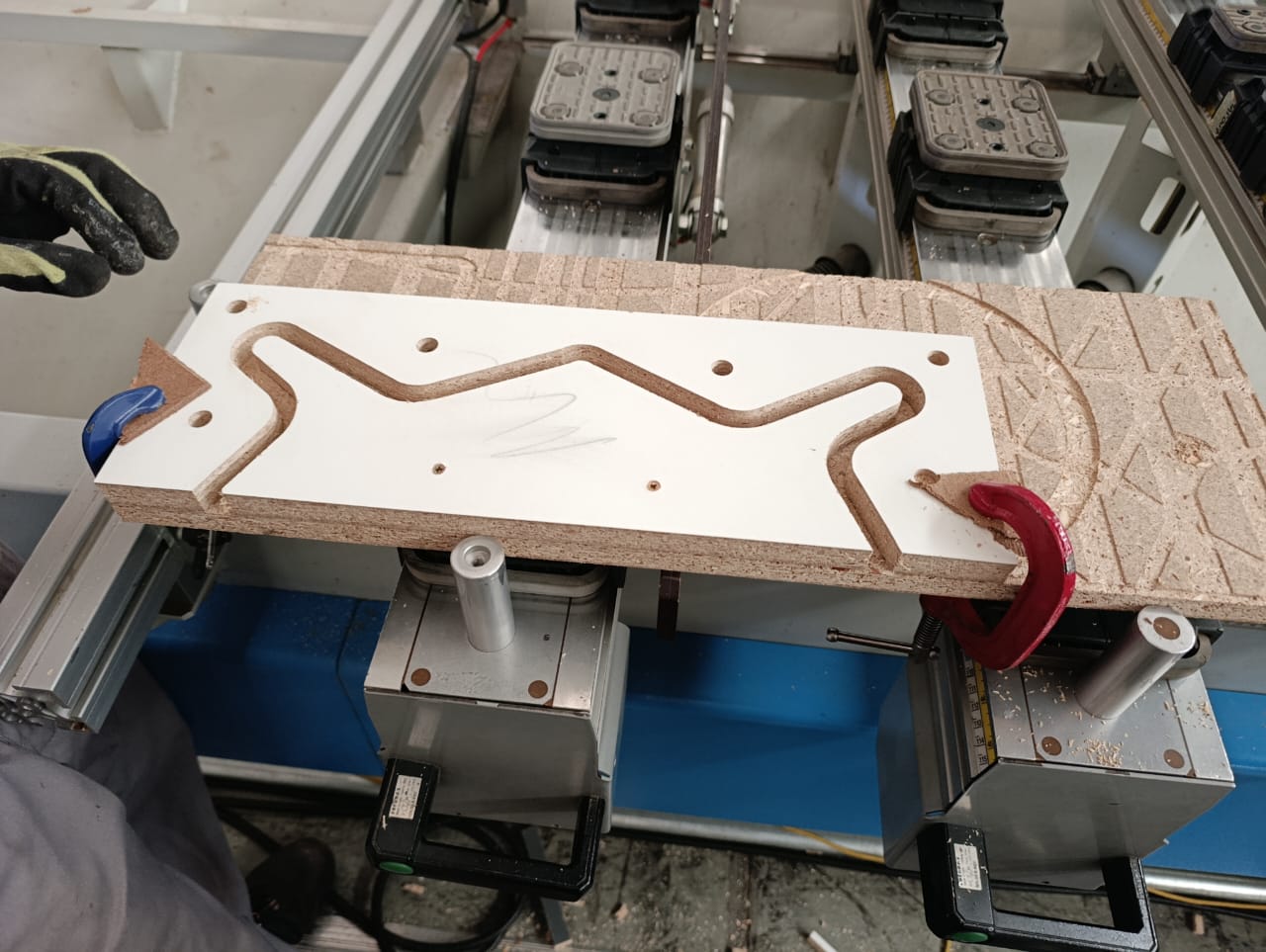

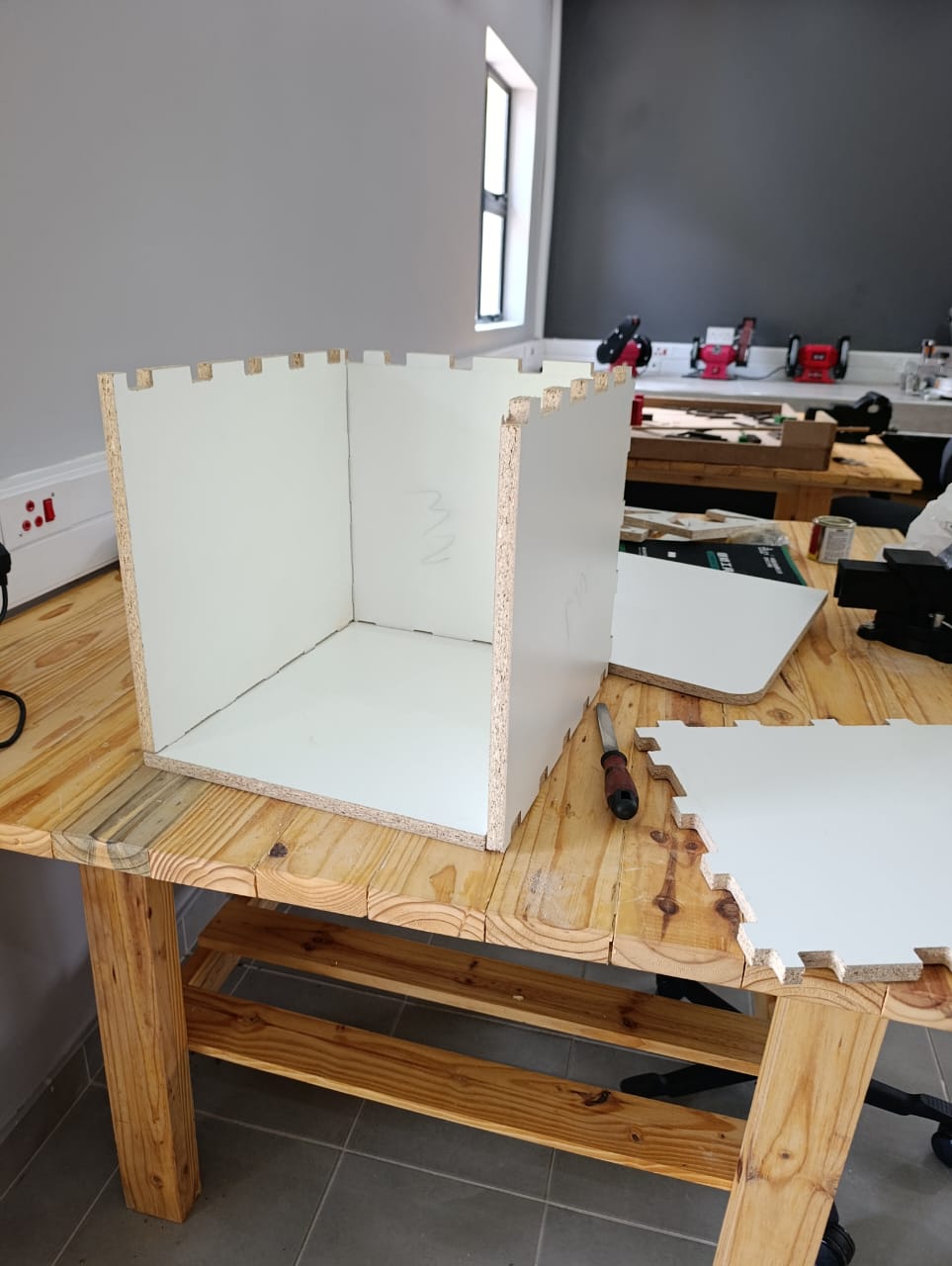

Milling and Milled Componnets

- Setting blanks on the machine bed

- Starting the vaccum pump

- Machine picking the tool from the carousel

- Cutting process

- Cutting Box Base

- Cutting Legs

- All Cuts done