1. Introduction

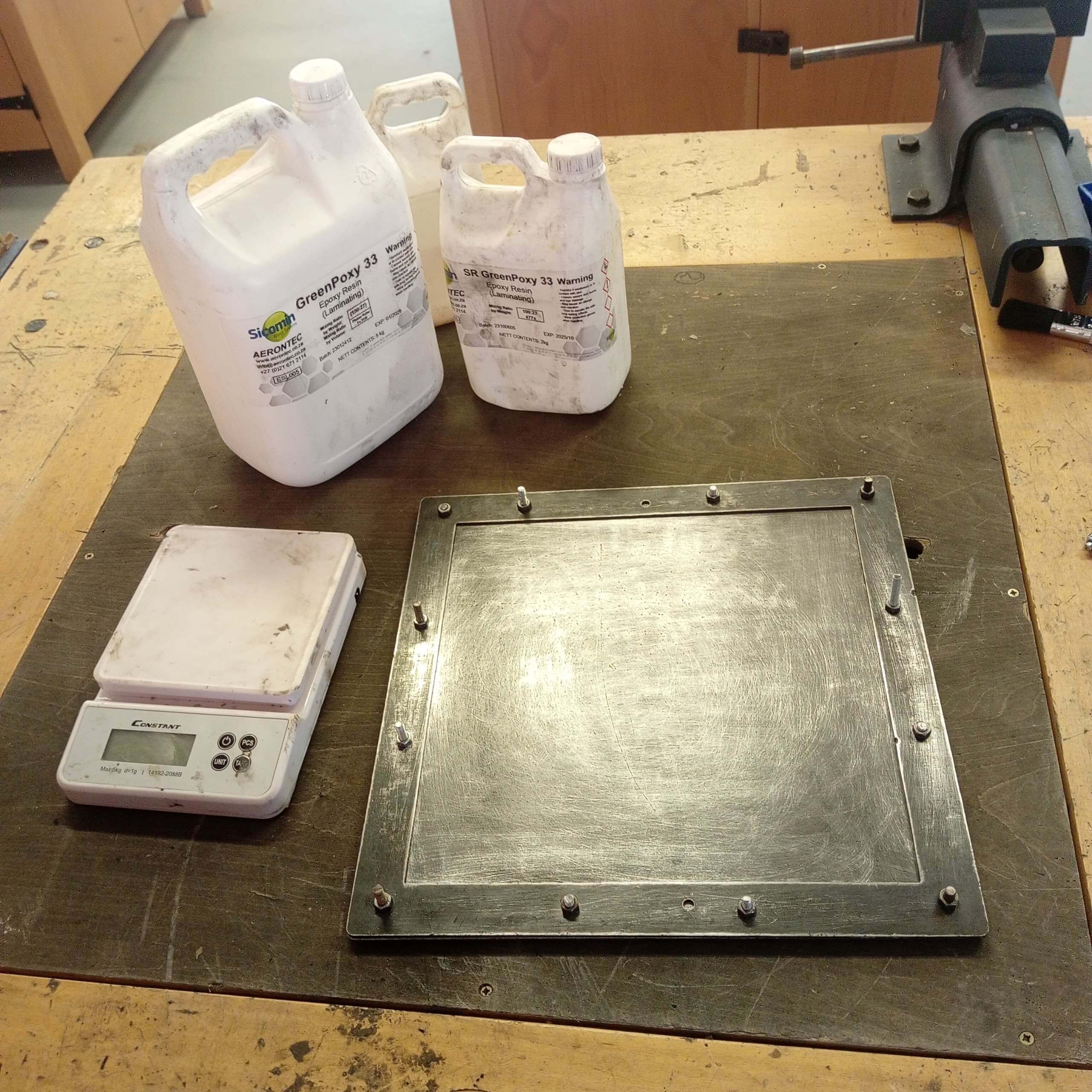

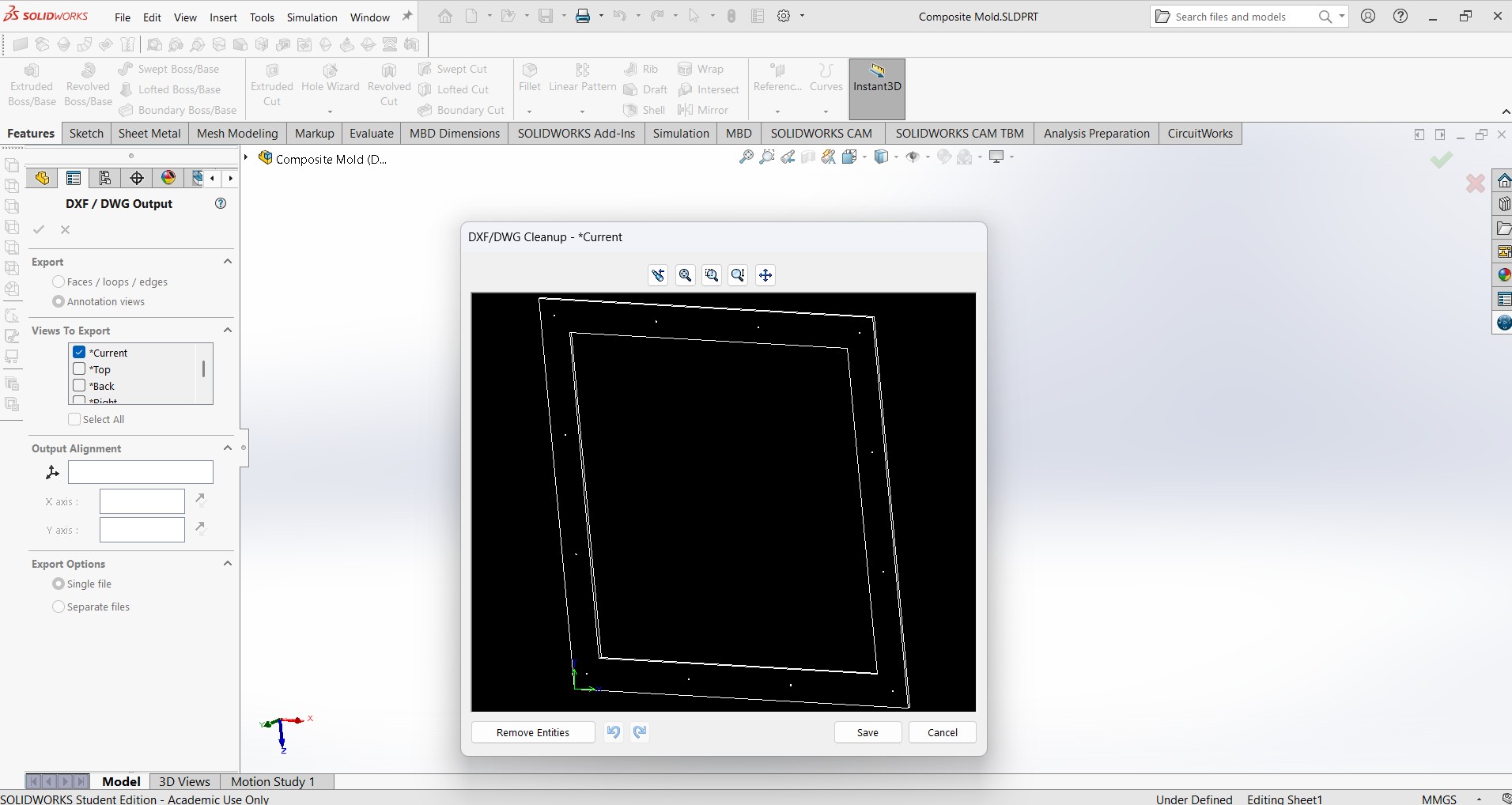

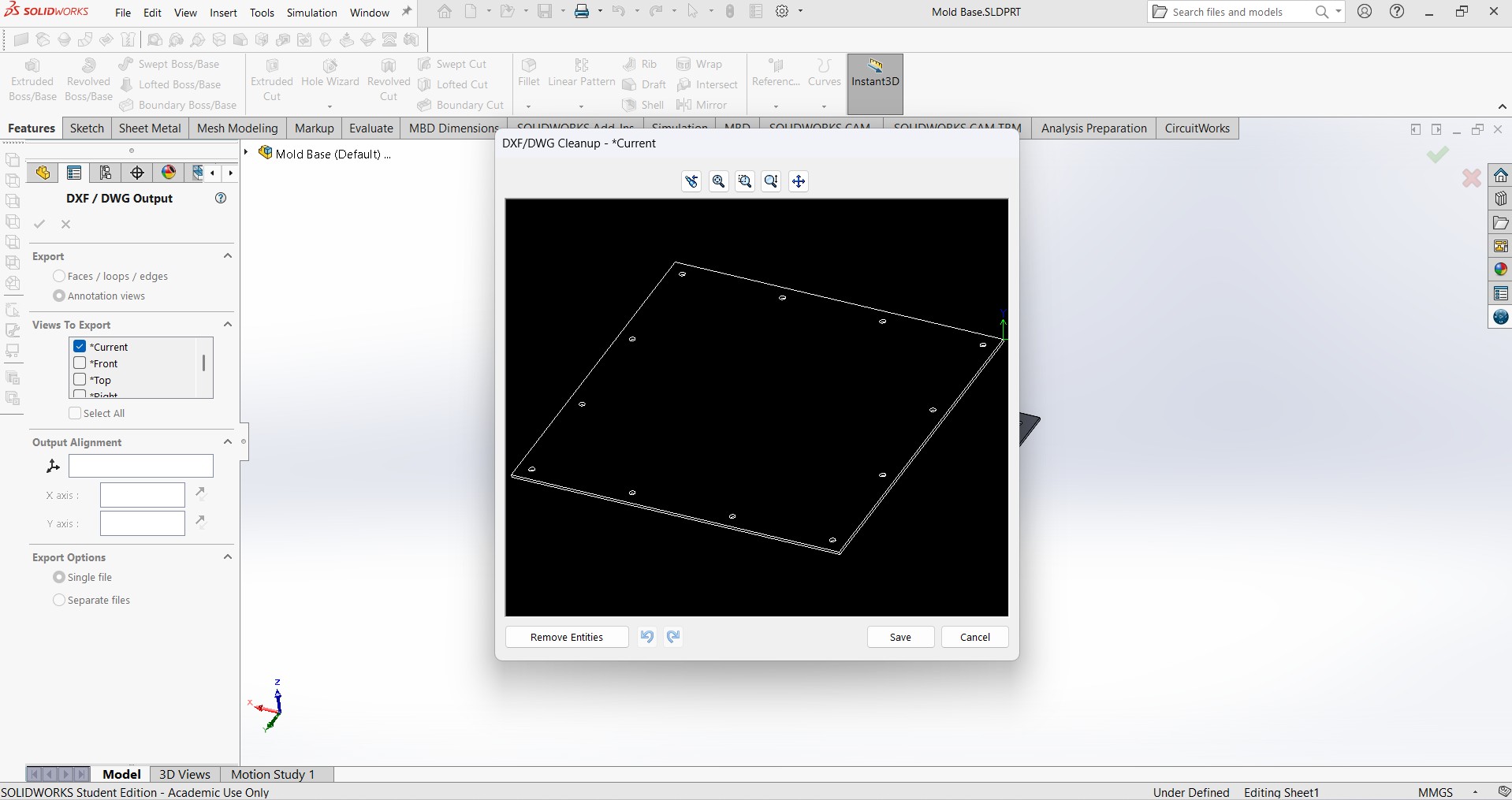

This document details my design and production of a water jet mold for fabricating a plywood sawdust reinforced composite material made from SR epoxy 33 and SD4775 Hardner. The process integrates computer-aided design (CAD) in SolidWorks and computer-aided Controlled Cuting via CNC water Jet Cutter and composite fabrication, meeting the assignment’s requirement for a digital process not covered in other assignments.

1.1 Purpose

I purpose to design a reusable mold, produce a composite panel using resin and hardner fused with plywood dust from the wood workshop, and provide comprehensive documentation, including safety considerations and reproduction instructions.

1.2 Scope

My project includes:

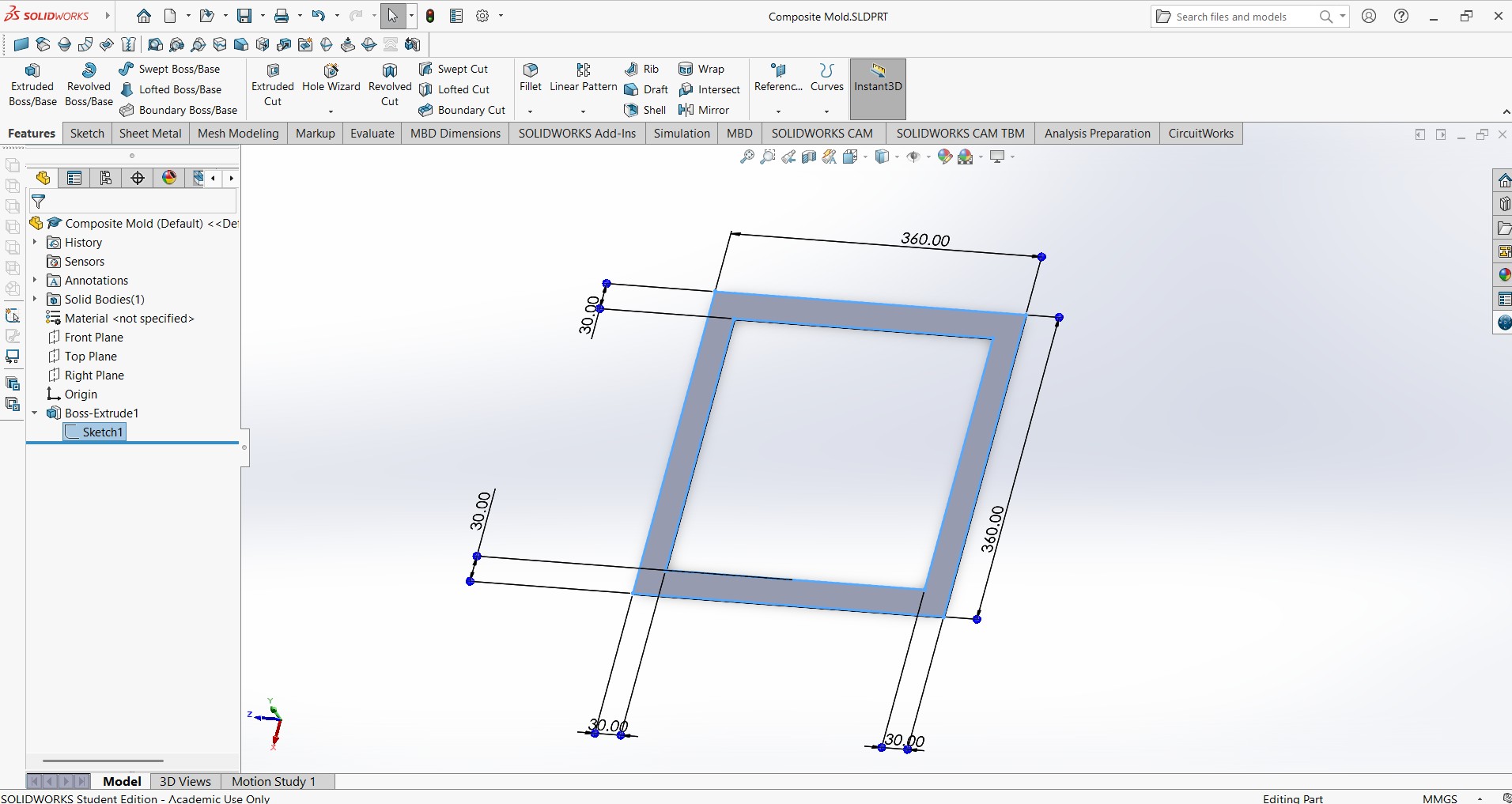

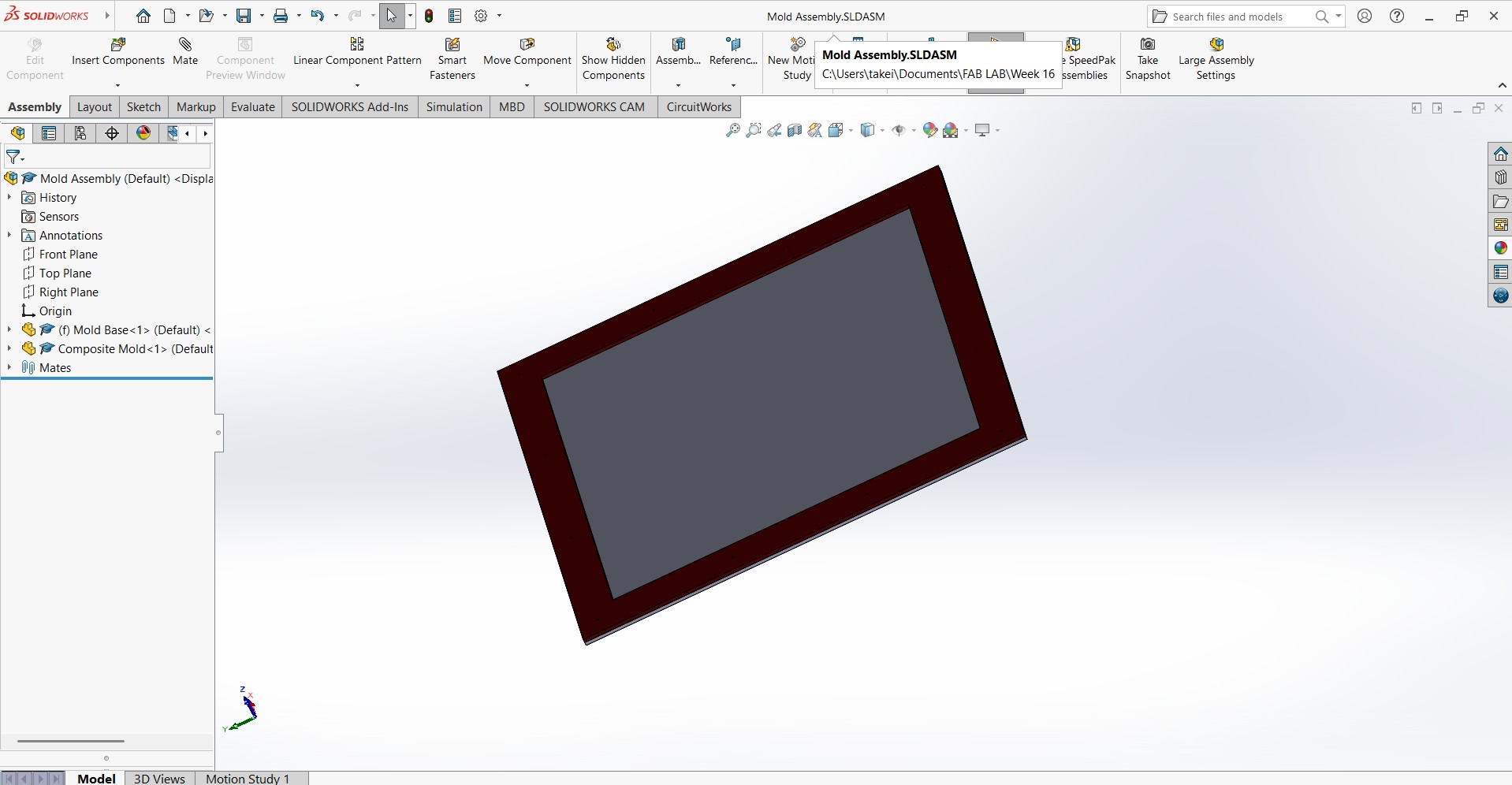

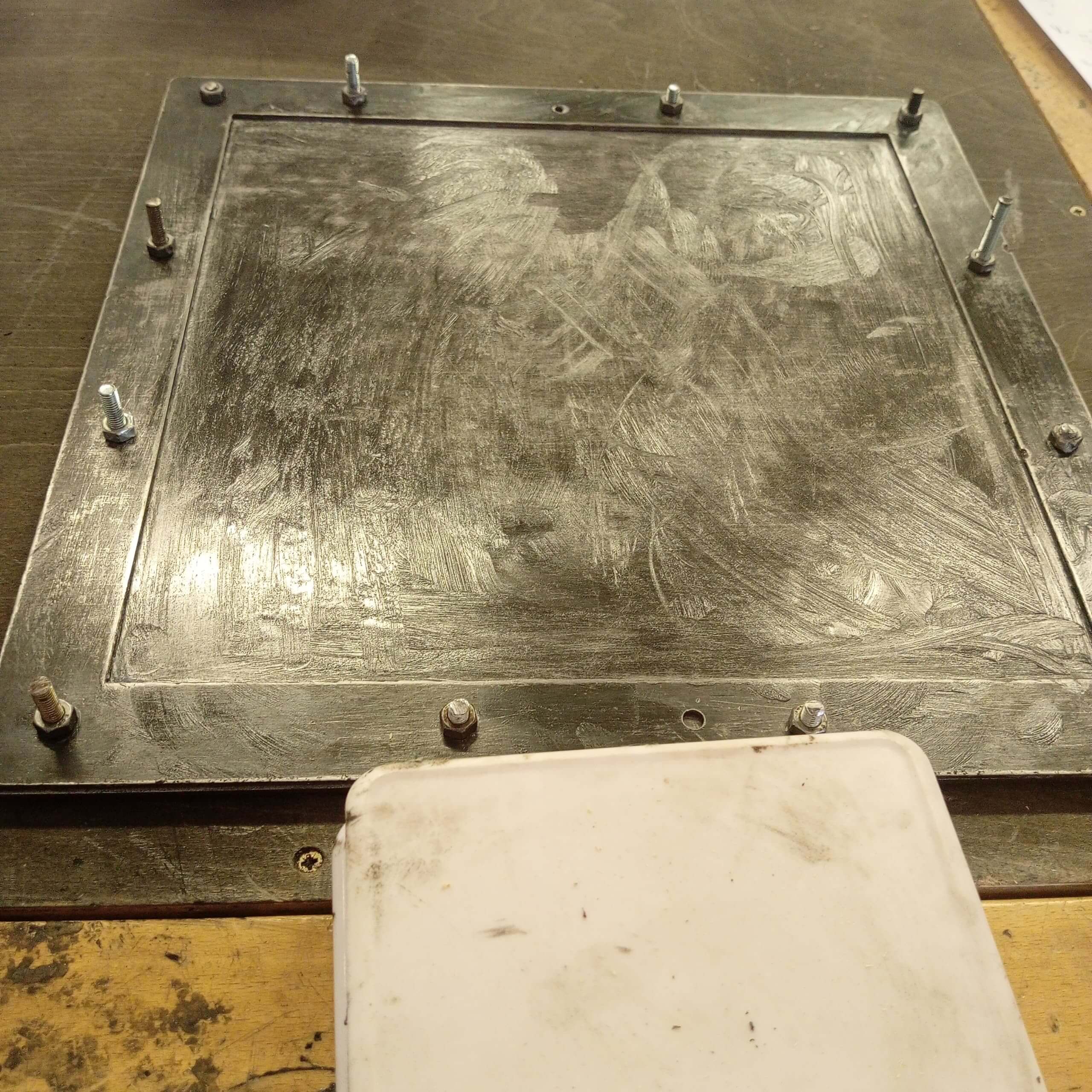

- Designing a 3mm mild steel flat mold (300mm x 300mm x 3mm) using SolidWorks.

- Cutting the mold on a water jet cutter

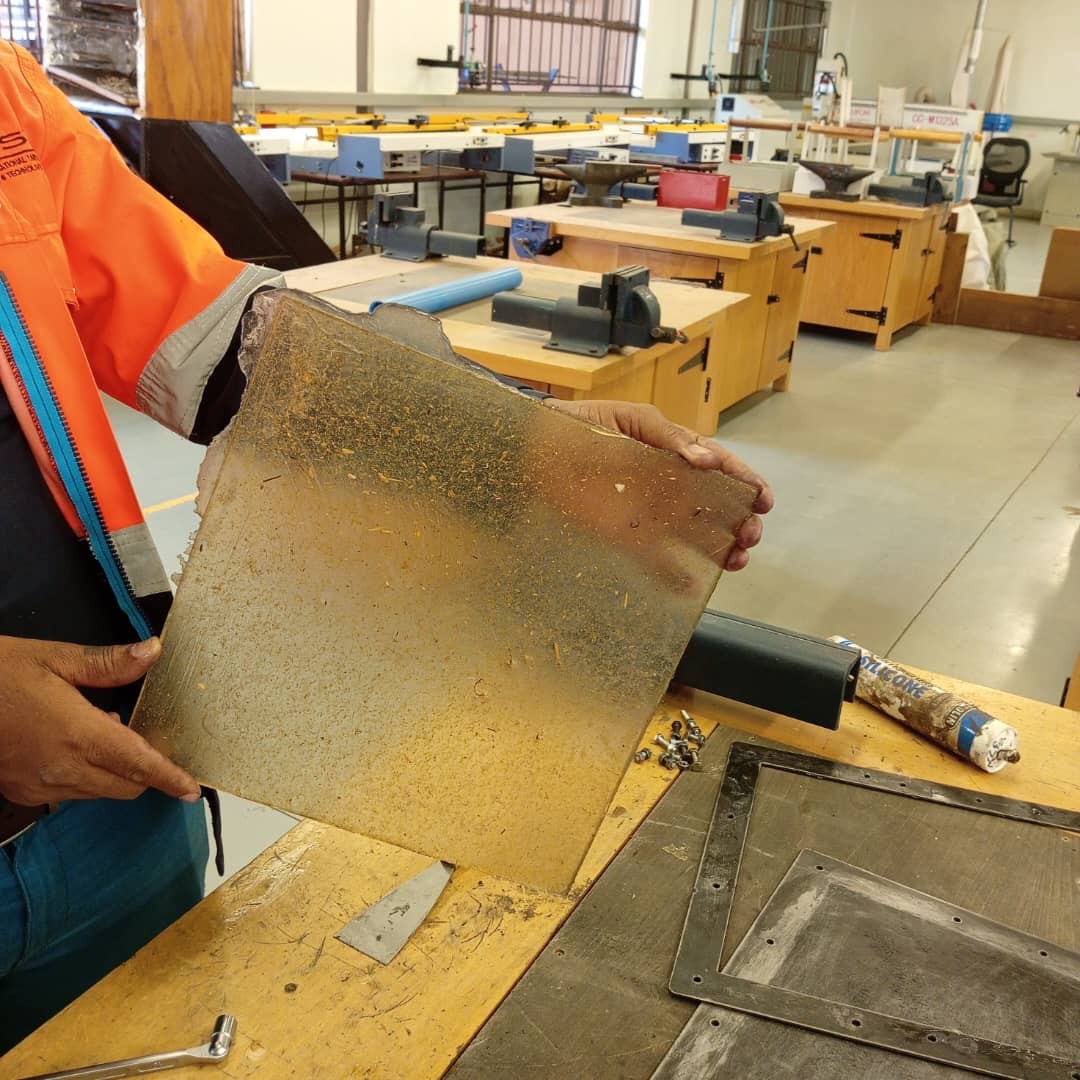

- Fabricating a composite panel 270 000mm3 using SR epoxy 33 and SD4775 Hardner fused with plywood sawdust from the wood workshop

- I Assembled the Mold

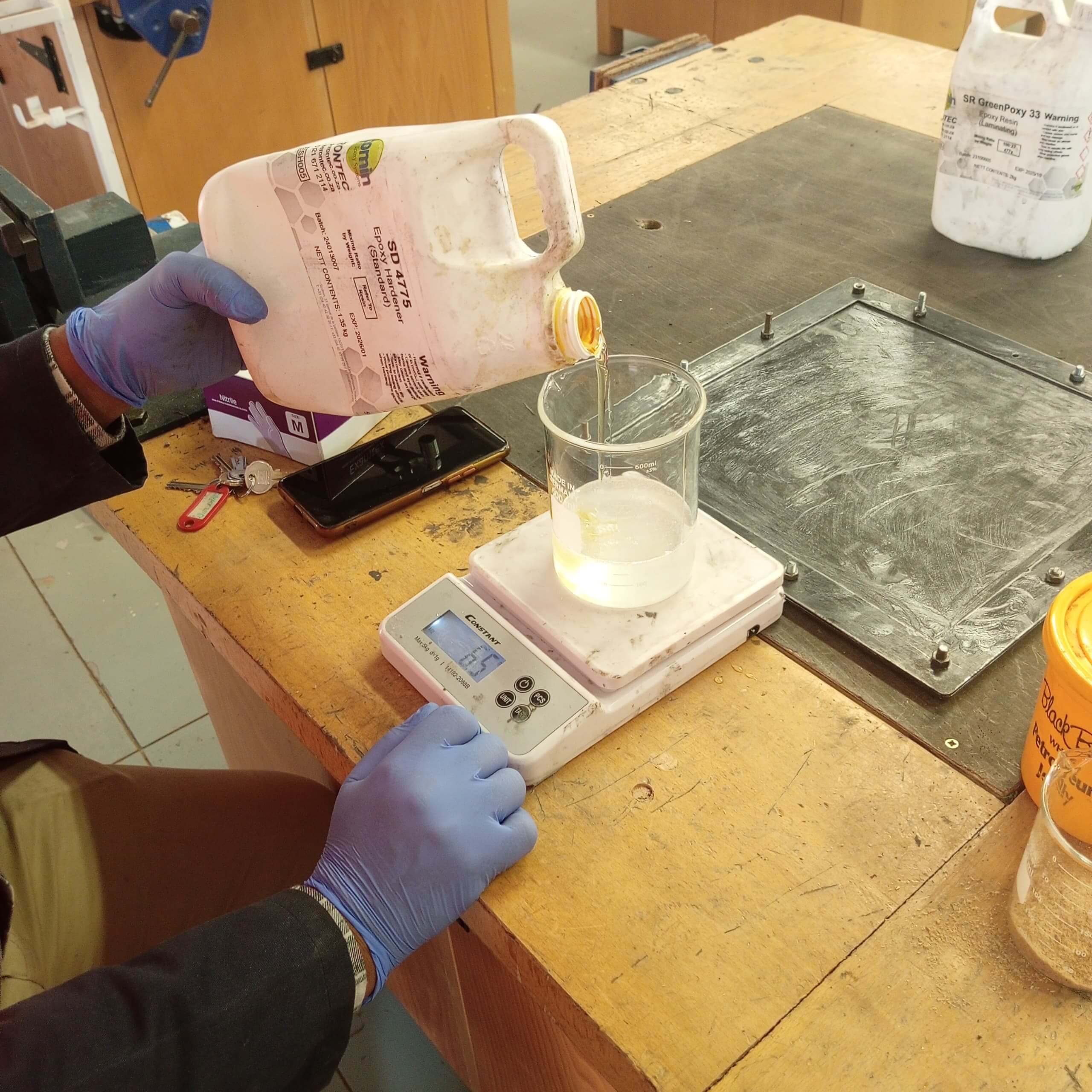

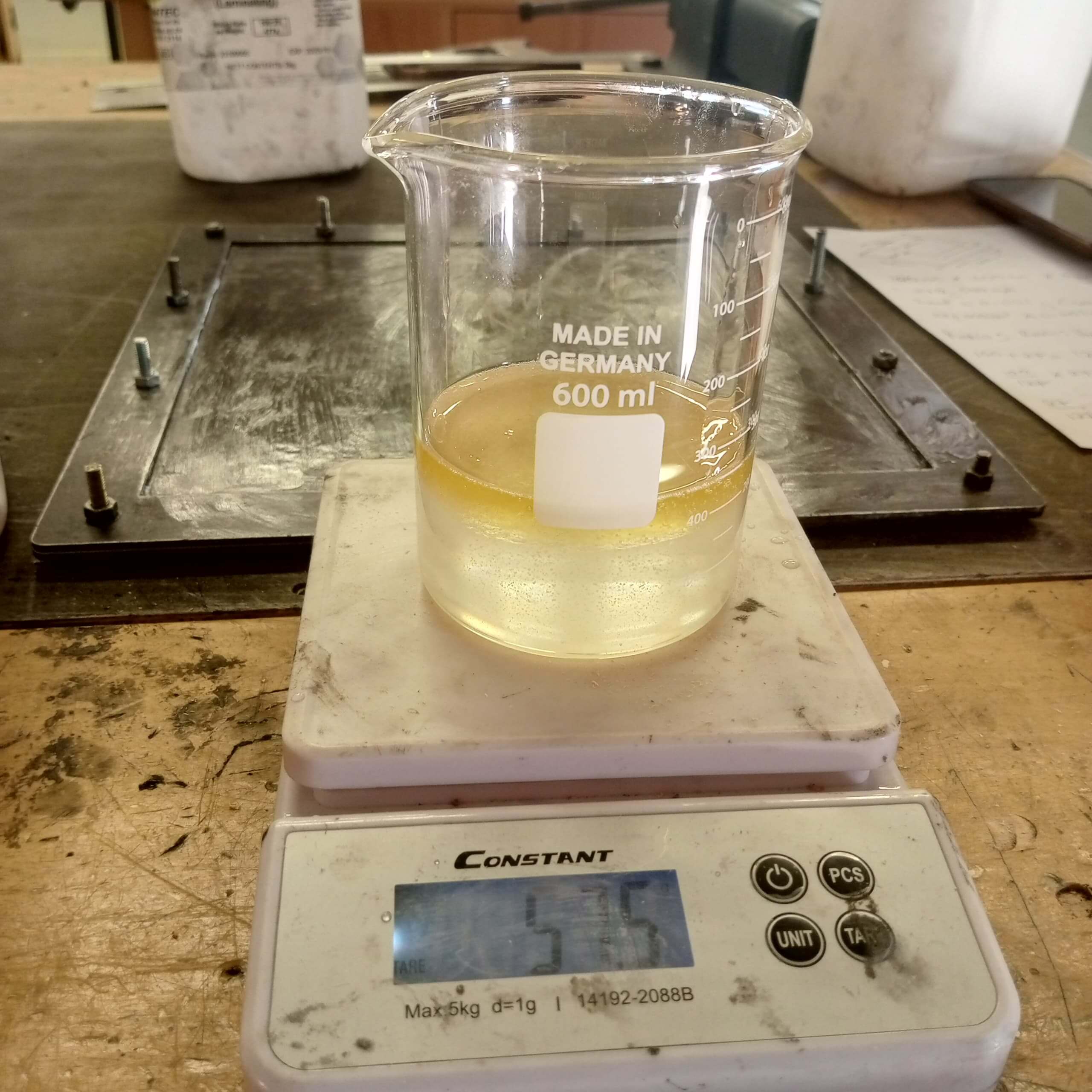

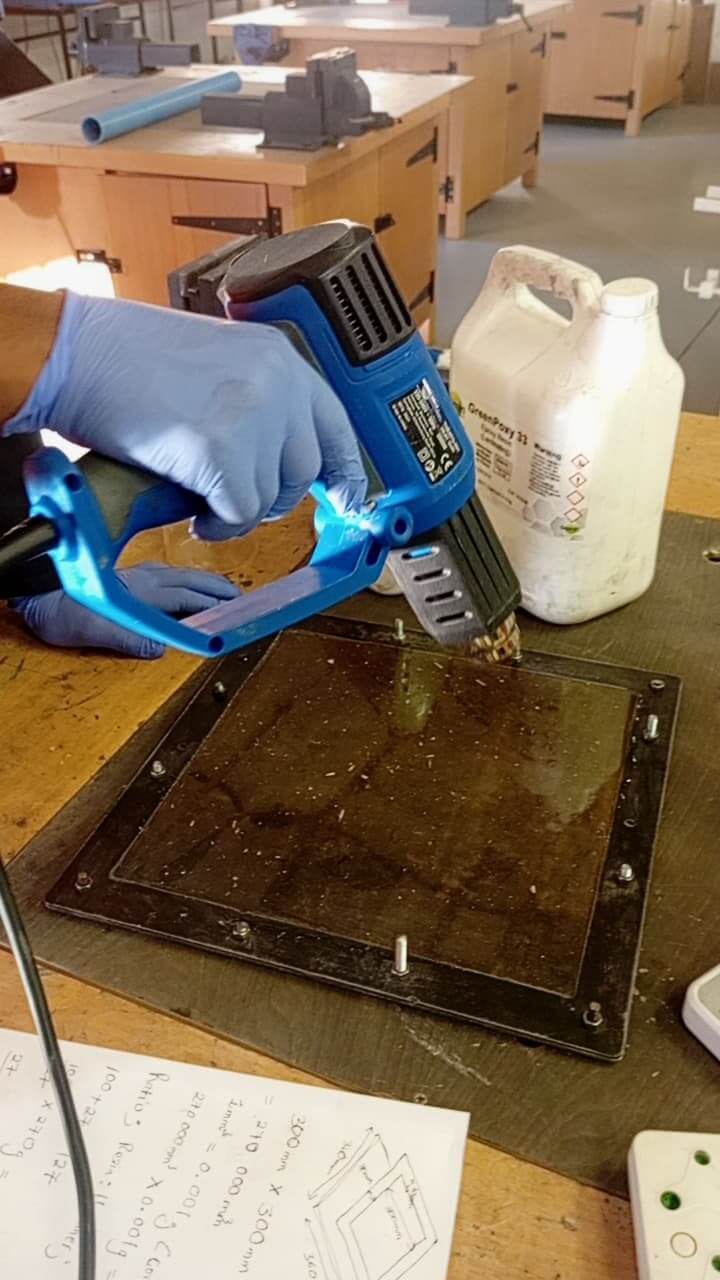

- I added Adding the resin

- I added added the Hardner

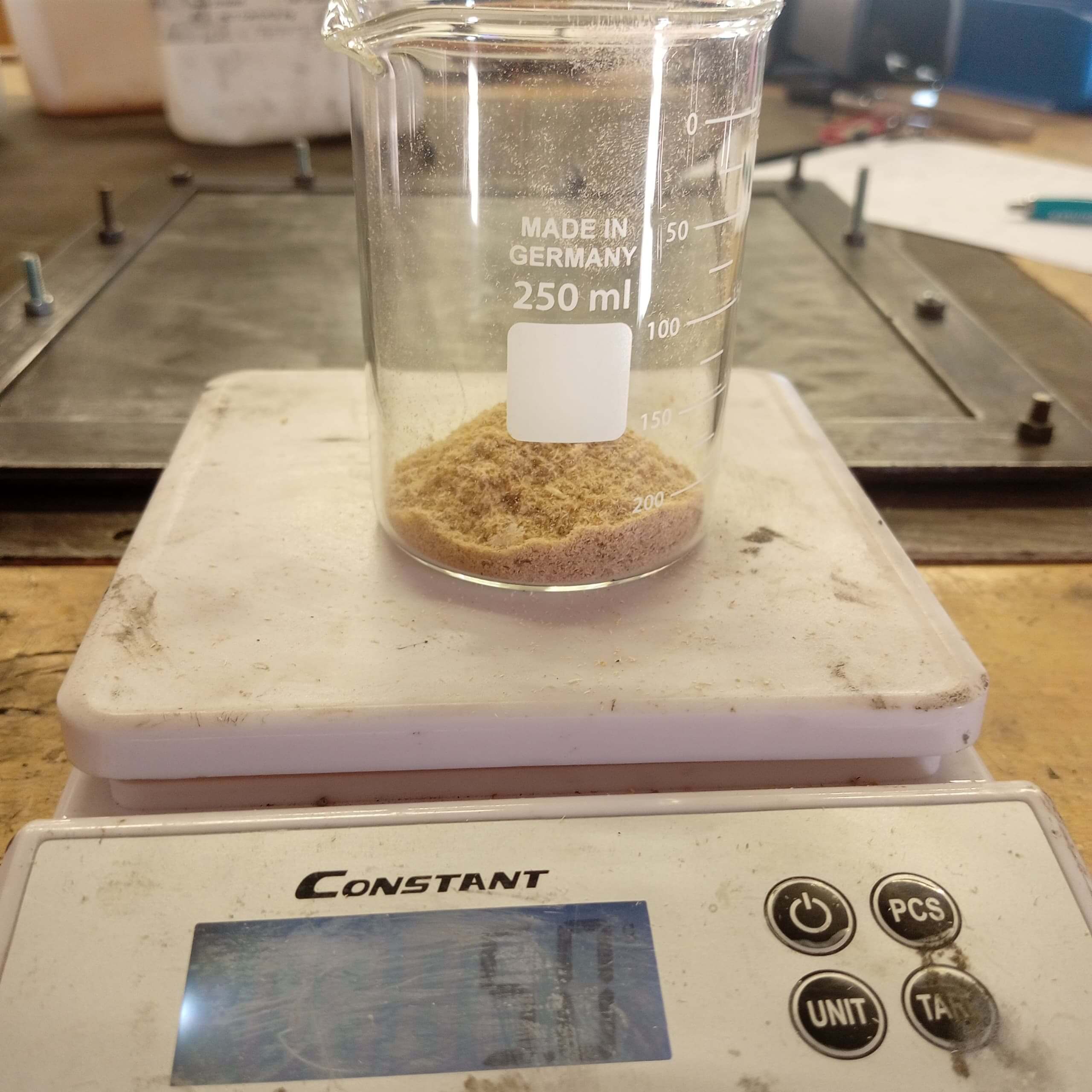

- I added Saw Dust

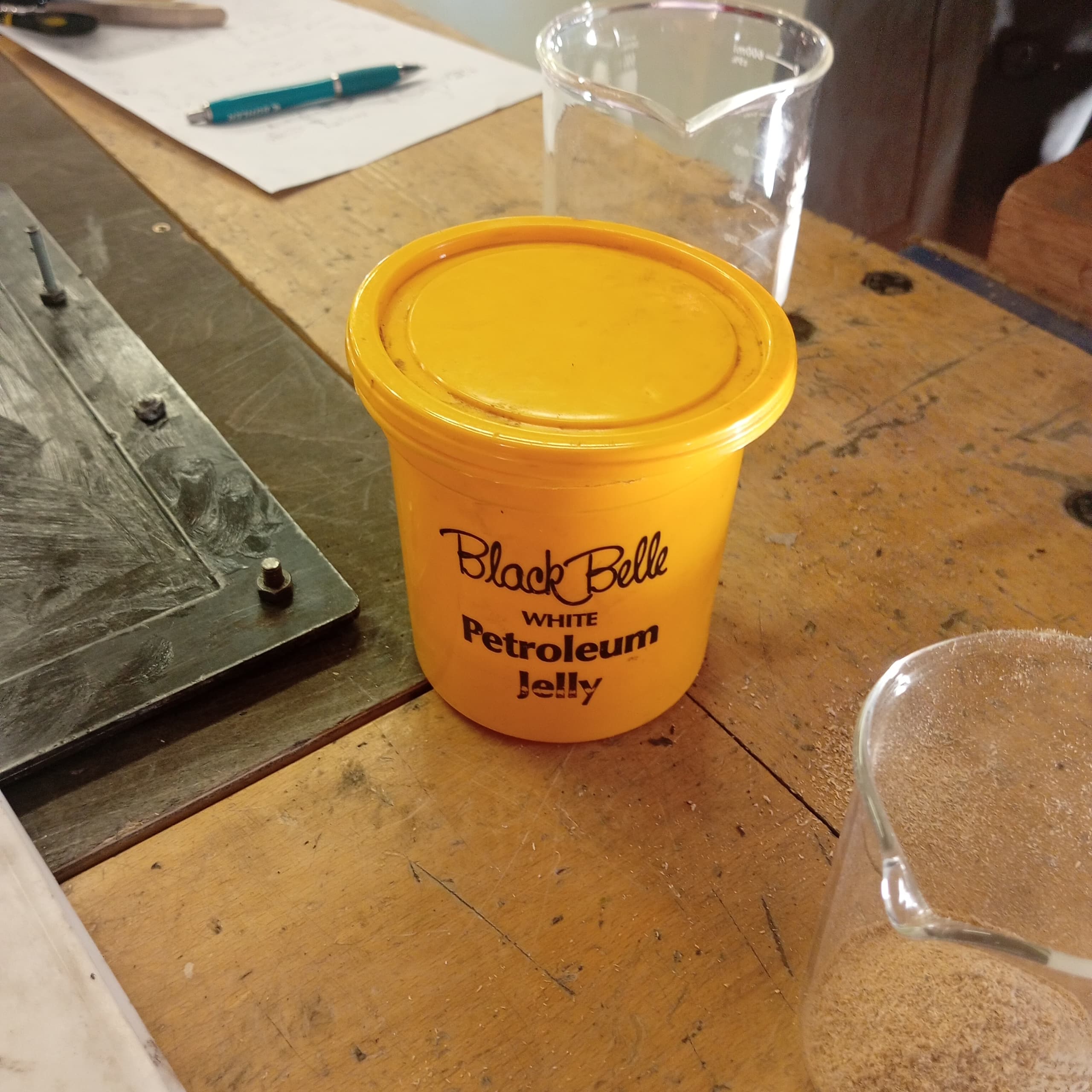

- I applied applied Blue seal (petrolim jelly) as a releasing agent

- I Mixed the contents together with a wood dowel

- I poured the mixture into the mild steel mold

- I Reviewed the Safety Data Sheet (SDS) and Technical Data Sheet (TDS) for a generic epoxy resin.

- I documented all steps for reproduction.

- Calculating Volume300mm x 300mm x 3mm = 270000mm3

- 1mm3 = 0.001g (according to conversion rate)

- 270000mm3 x 0.001g = 270g

- Ratio:Resin:Hardner; 100:27, Refer to the dadat sheet

- Resin:100/127 x 270g = 212g

- Hardner:27/127 x 270 = 57.4

- Wood saw dustwe put on 5% of wood dust by mass