2. Group Assignment

Group Assignment PageGroup Assignment Molding and Casting Visit our Week 13 group link

3. Individual Assignment

3.1 Design a Cake Mold

Objective: Design a cake mold for casting casting with candle and with chocolate

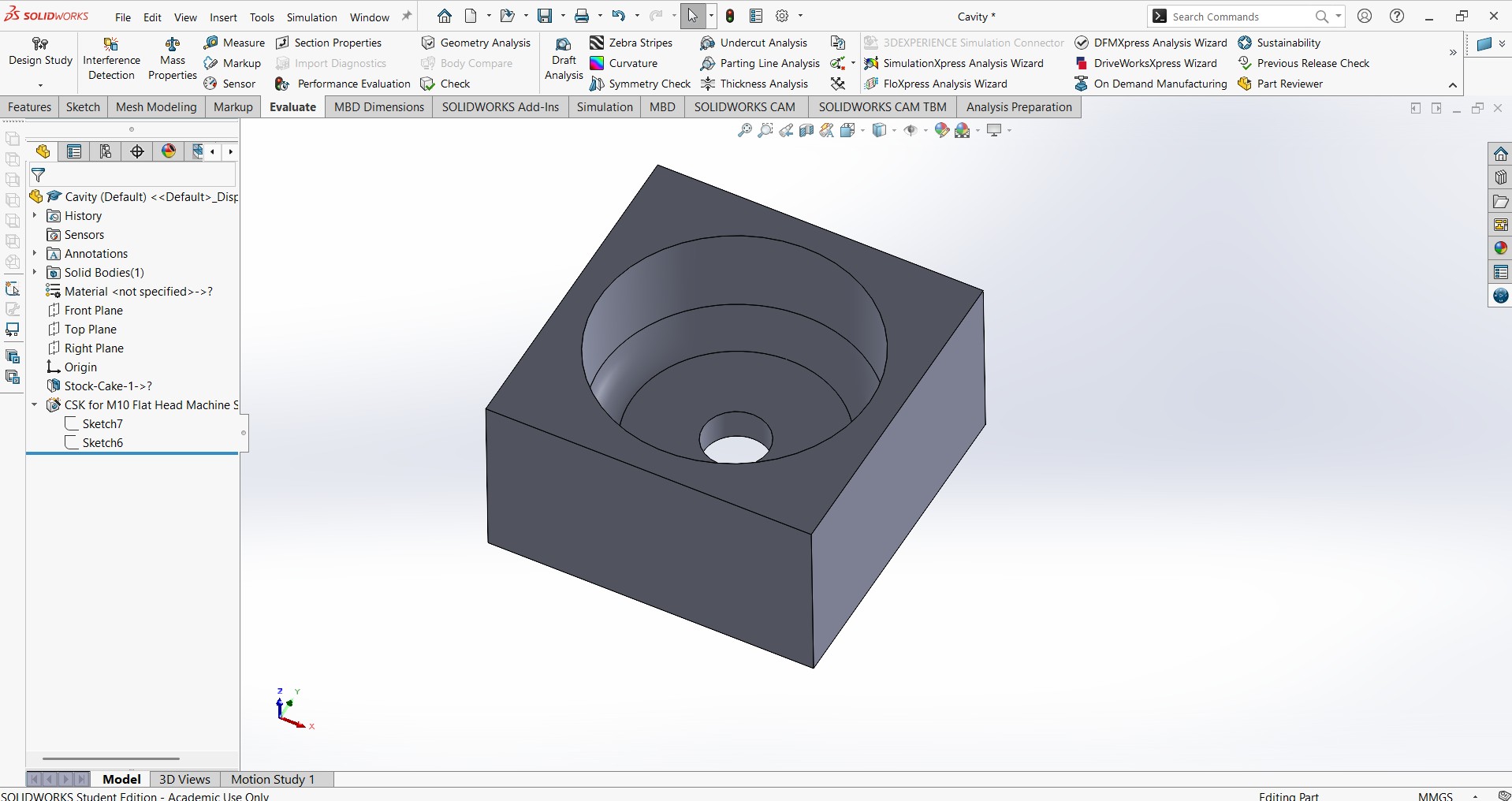

- Create Master in SolidWorks:

- Design a 55 mm x 55 mm x 30 mm cube with a 45 mm diameter and depth of 18mm hollow center.

- Add a 10 mm diameter hole on one side with a couter sunk of 20mm for pouring.

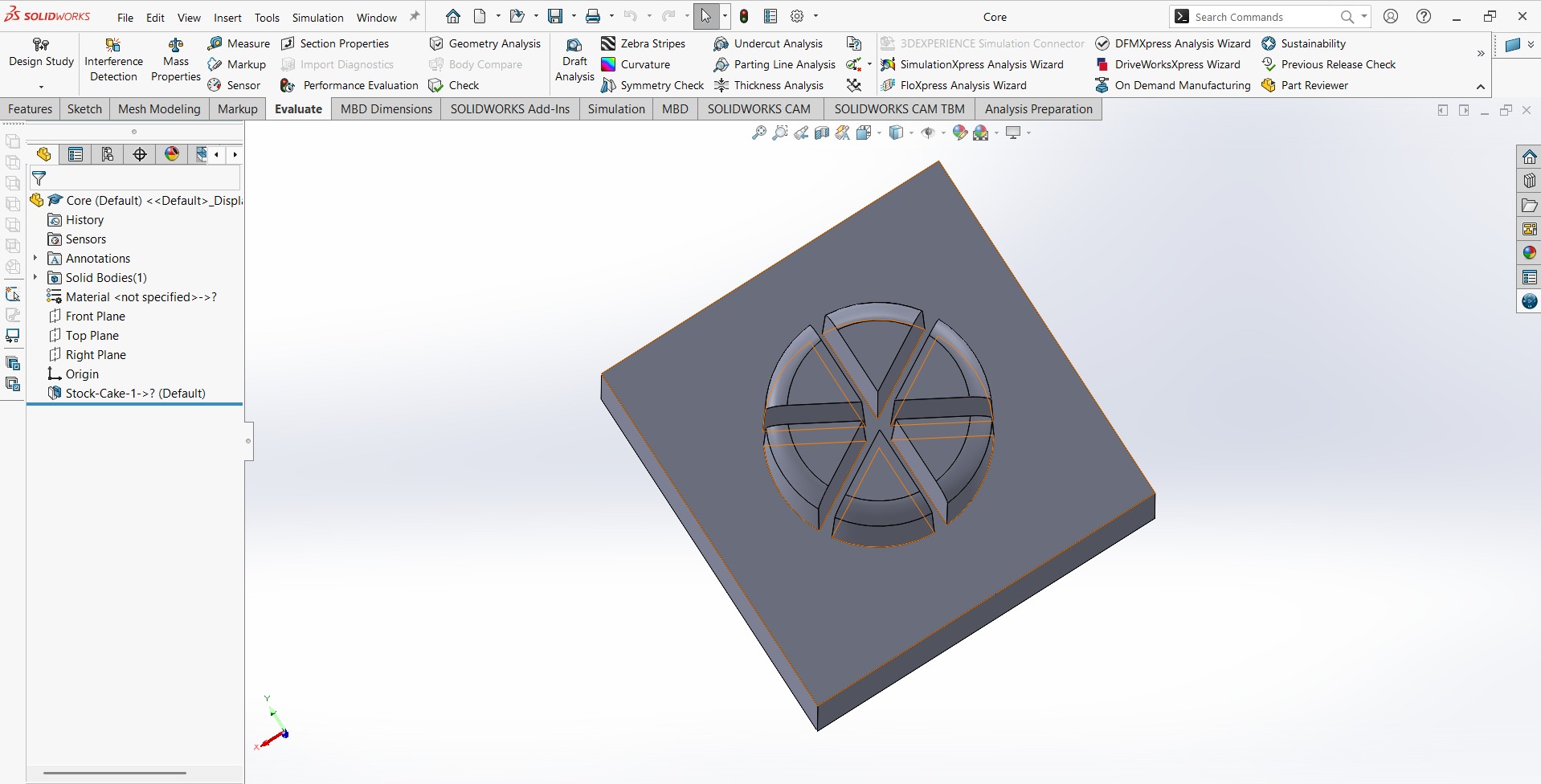

- Create a base of 55 mm x 55 mm x 20 mm cube with a 45 mm diameter core and height of 18mm.

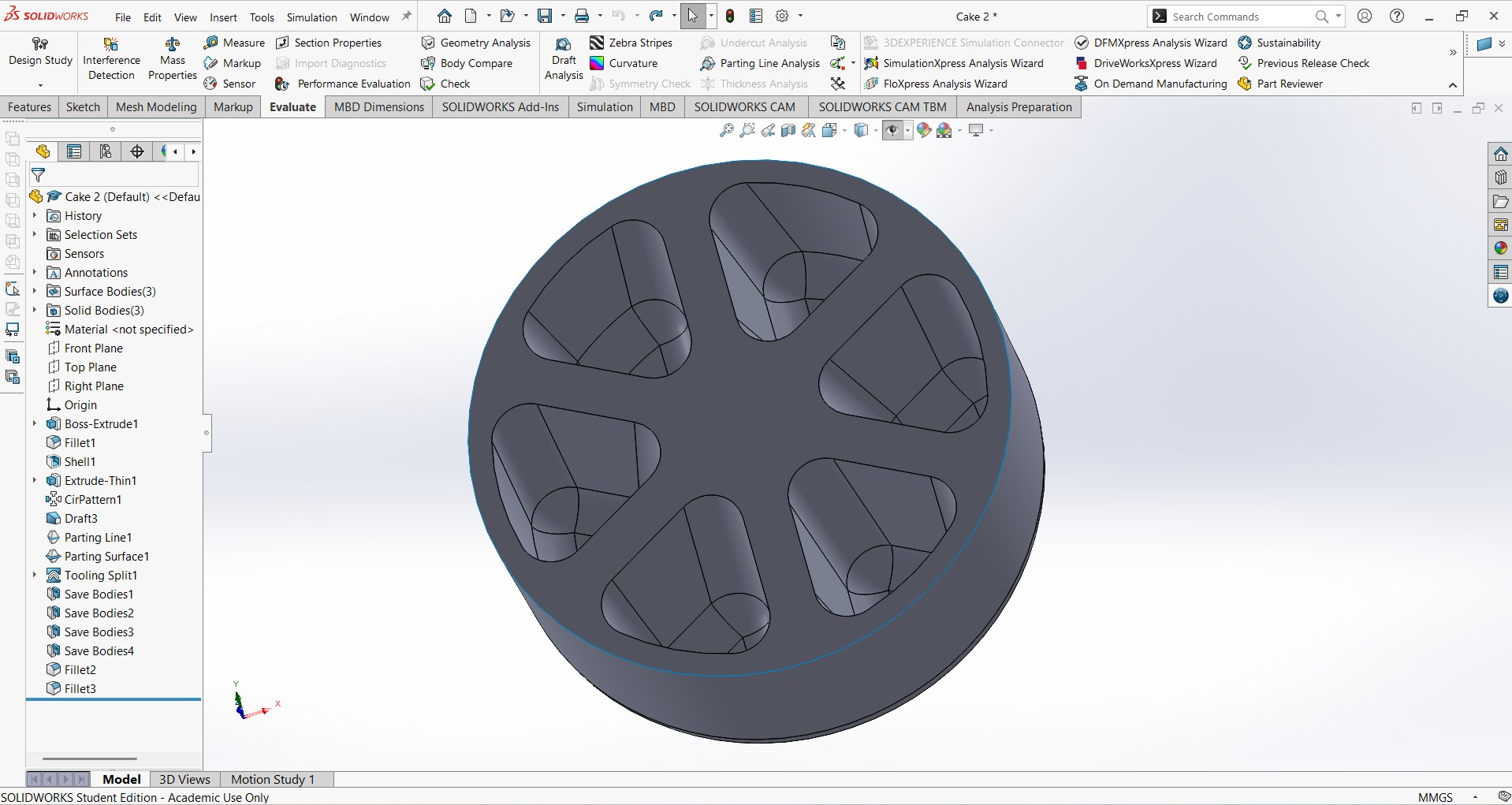

- Create a cake of diameter 45mm and a height of 18mm. It should have hollow shells slip five times at a thicknes of 4mm

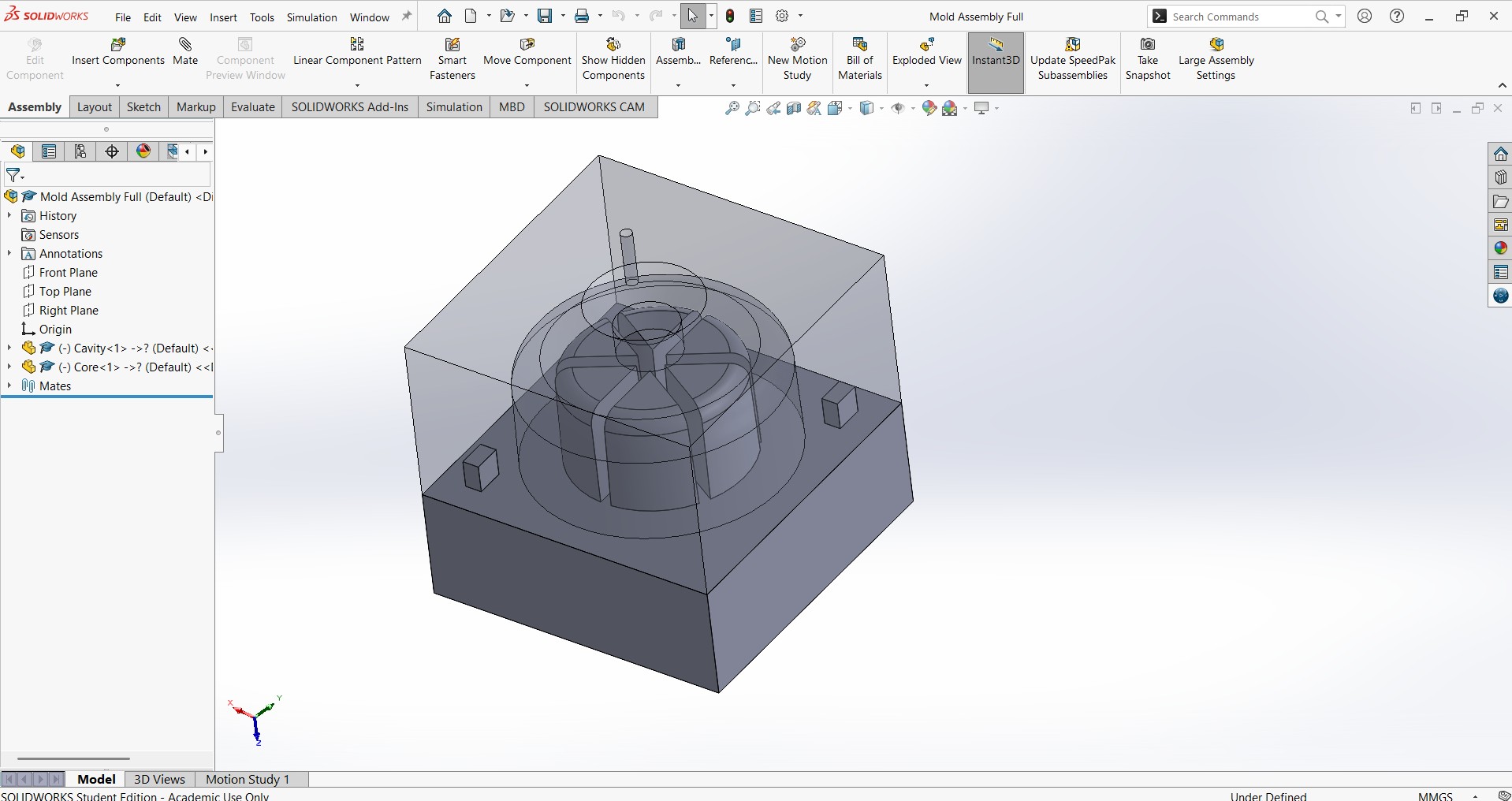

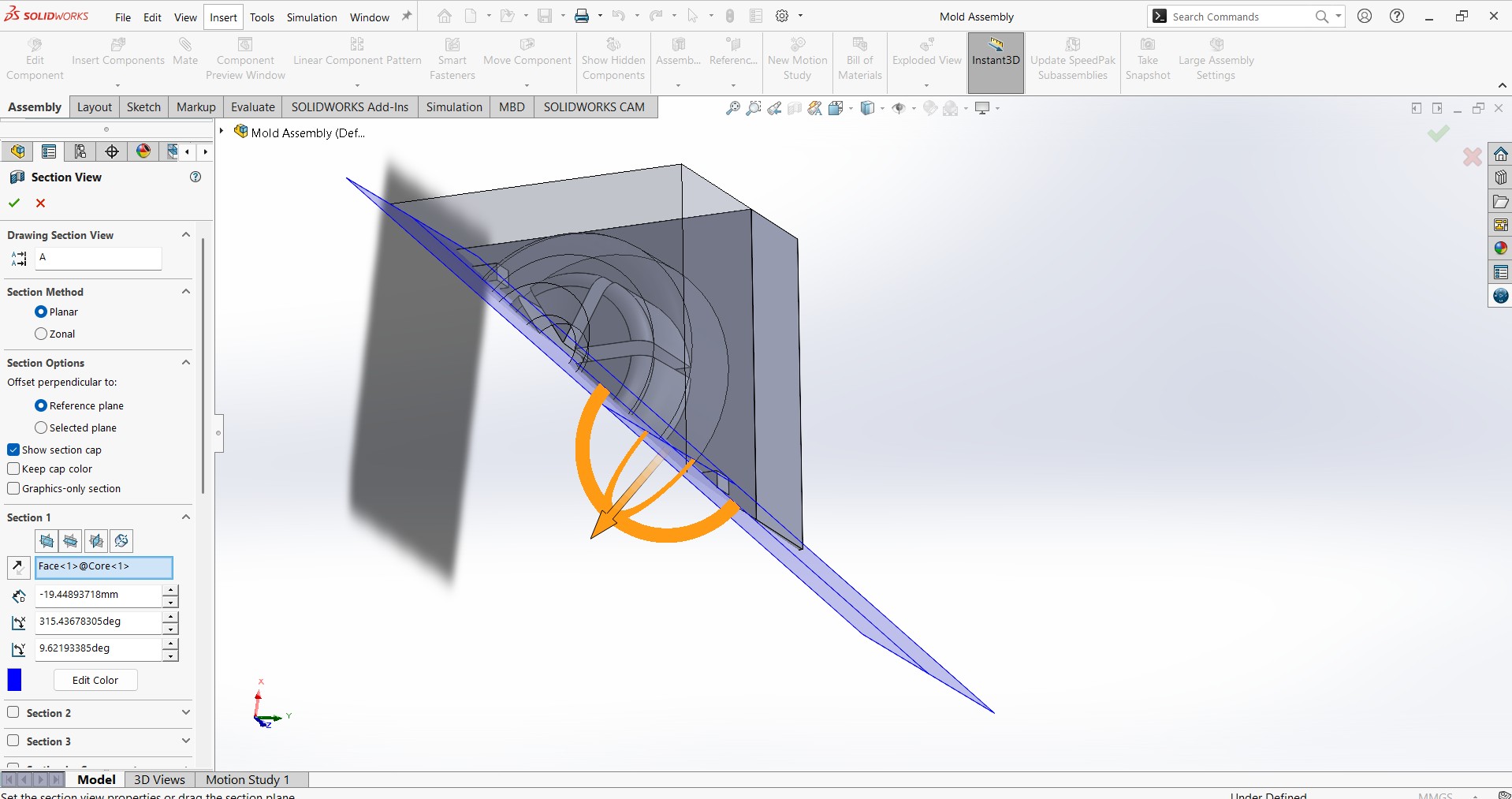

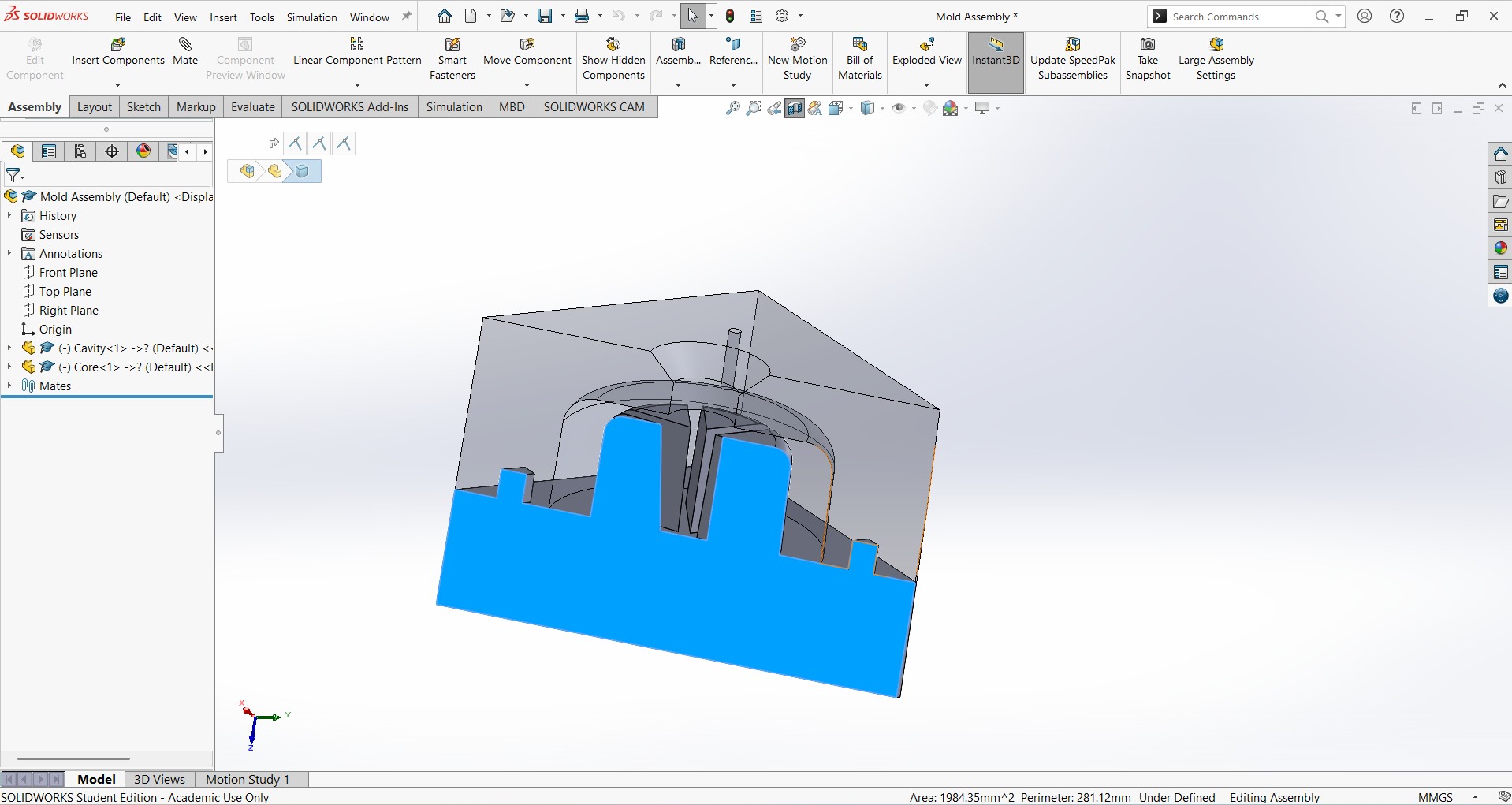

- Create Assembly of core and Cavity:

- Align parts using pins/holes for precise assembly.

- Sectioned parts ofethe Assembly to view internal

- Add Sprue and Vent:

- Include a 10 mm x 20mm contersink diameter sprue channel for resin pouring.

- Add a 2 mm diameter vent for air escape.

- Verify:

- Ensure smooth surfaces and tight tolerances for alignment.

- Export as STL files: Cake 2.STL, Cavity.STL, Core.STL.

Design Files for Download

Moulding Zip

3.2 Mold Production

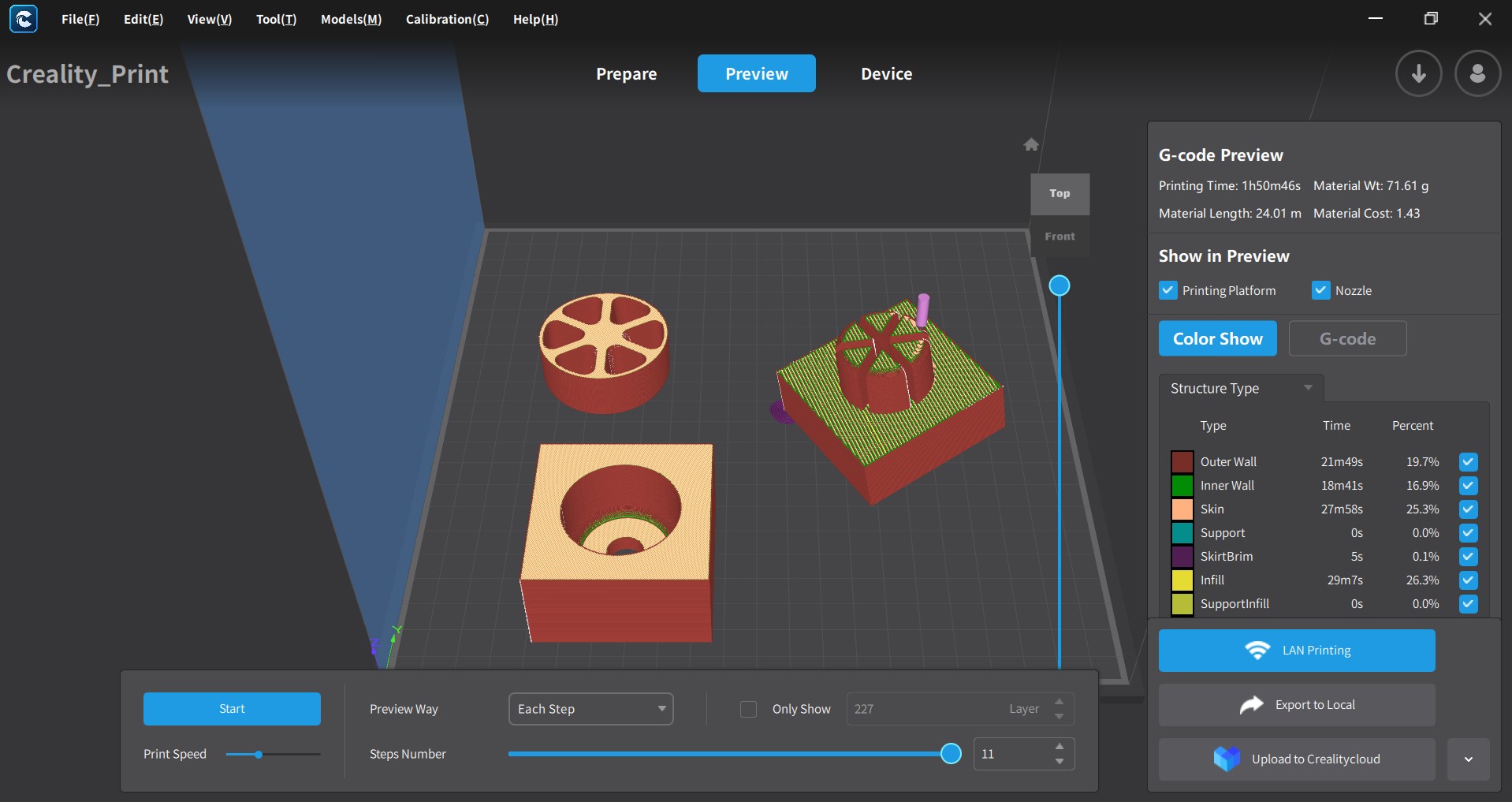

- 3D Printing:

- Import STL files into Cura.

- Settings:

- Printer: FDM CR.

- Material: PLA (1.75 mm).

- Layer height: 0.1 mm (for smoother surfaces).

- Infill: 20%.

- Supports: Not Needed.

- Build plate adhesion: Brim (5 mm).

- Slice and export G-code: mold_base.gcode, mold_top.gcode, mold_insert.gcode.

- Print time: ~1 hrs 50min 46 sec for all the parts

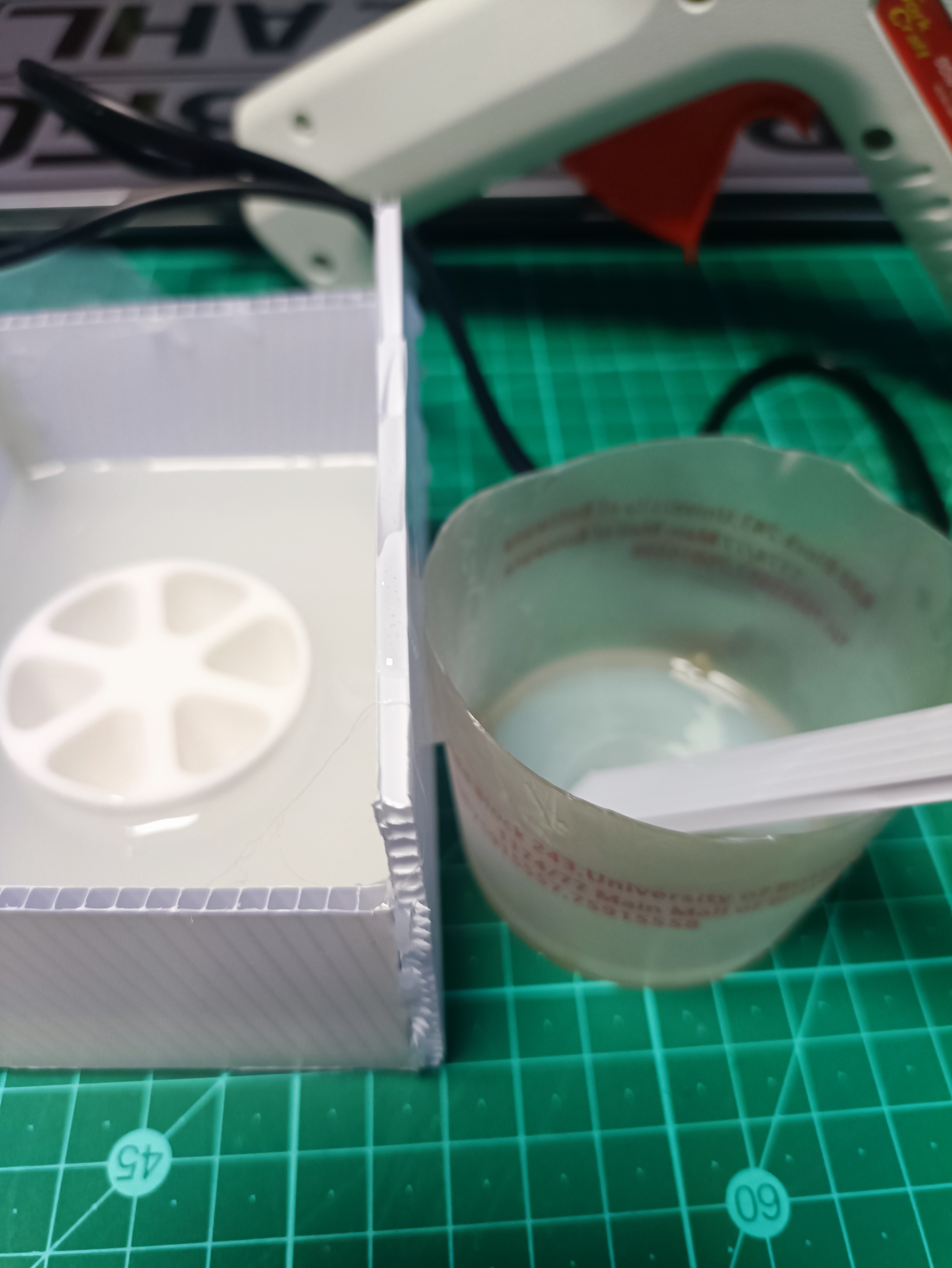

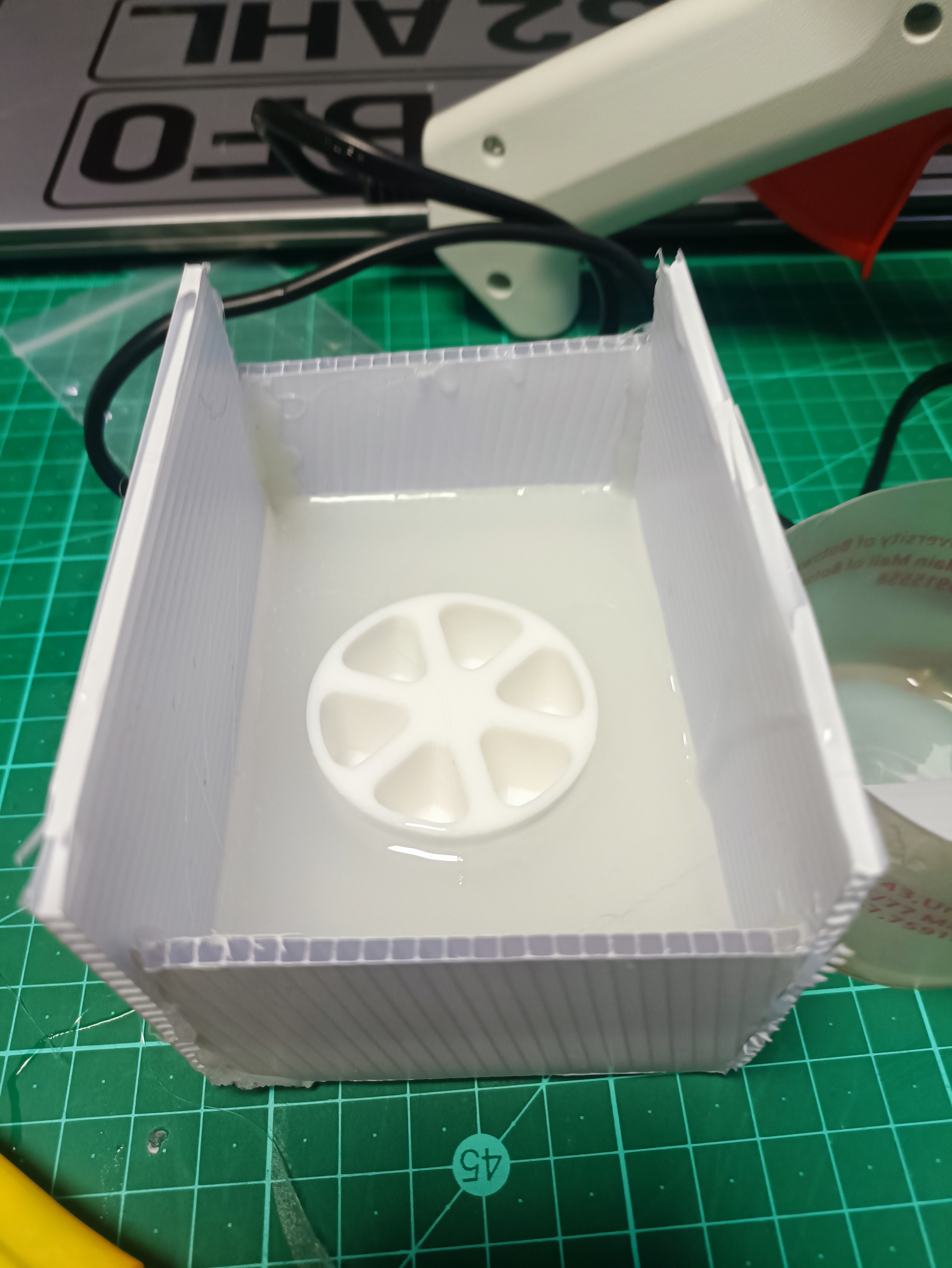

- Prepare Mold:

- Assemble two mold parts, ensuring alignment via pins.

- Secure with tape.

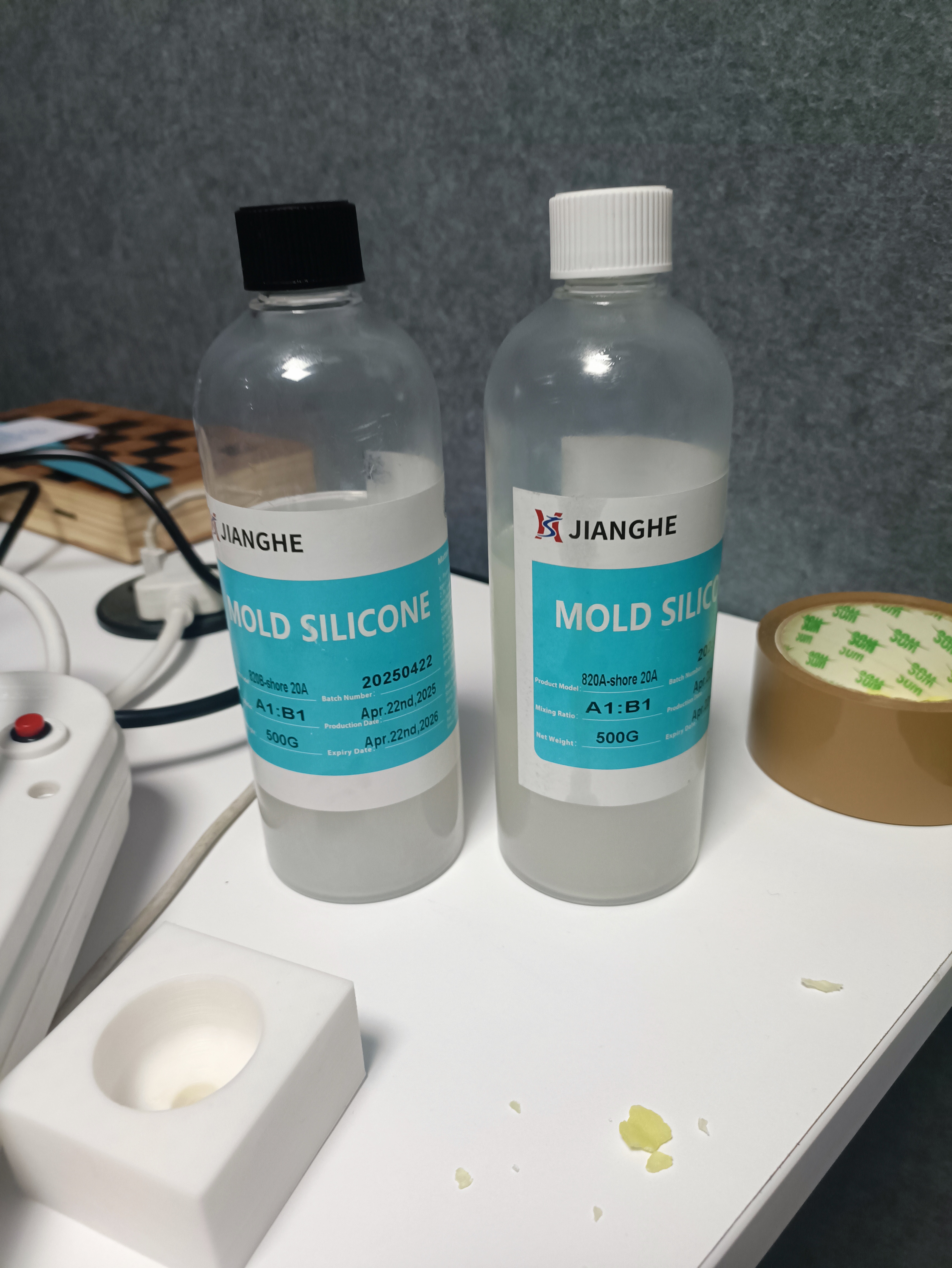

- Mix Resin:

- Mix epoxy resin and hardener (1:1 ratio, per TDS).

- Work in a well-ventilated area, wearing gloves, safety glasses, and N95 mask (per SDS).

- Cast Part:

- Pour resin into sprue until mold is filled.

- Cure for 24 hours at 25°C.

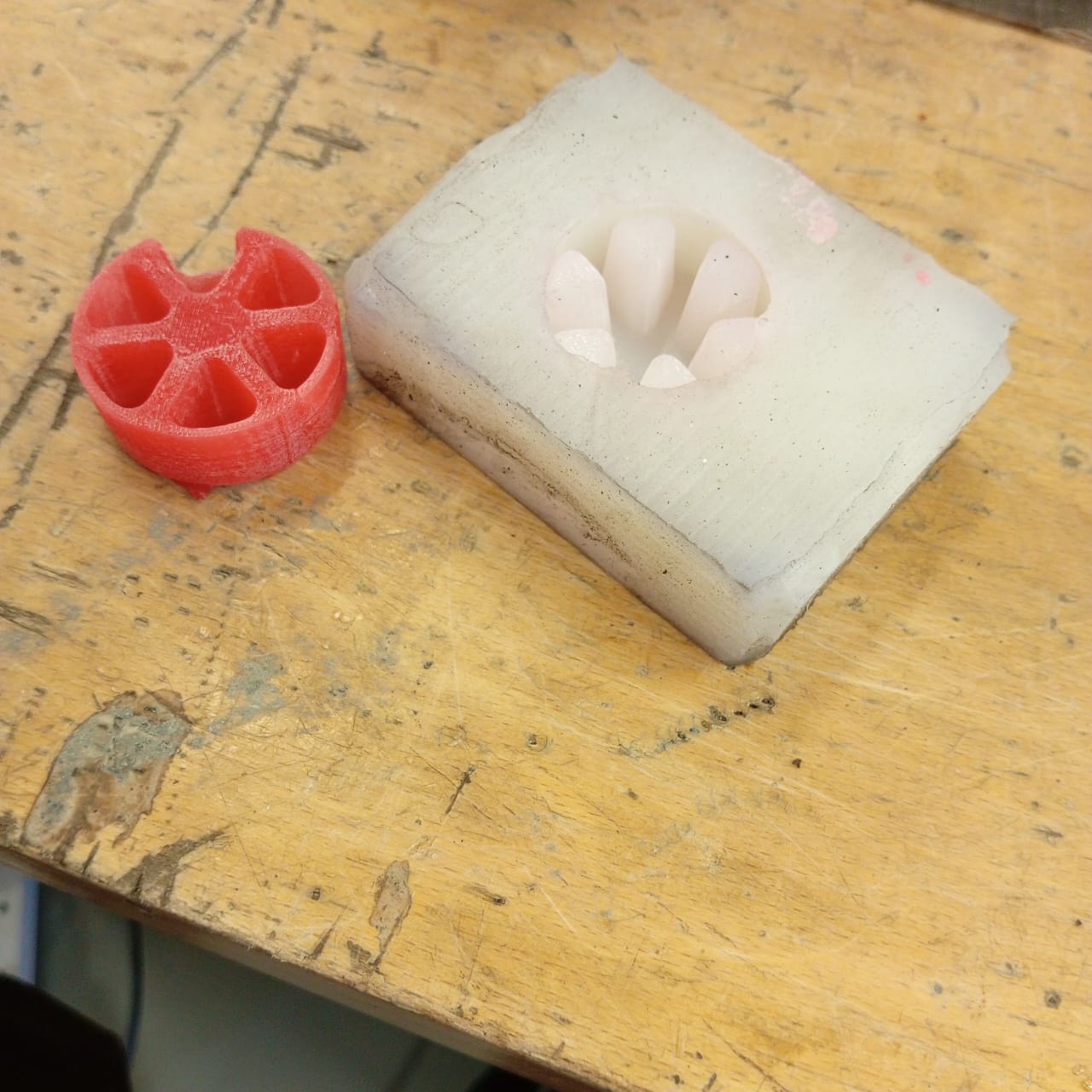

- Demolding:

- Disassemble mold parts carefully.

- 3D Printed PartsCake, Core and cavity

- Files for Download:

Zip Files for Downloads

STL files

3.3 Casting Process

3.4 Design Output

4. Reproduction Instructions

- Cast Parts:

- Source epoxy resin, mold release, and safety equipment.

- Casting Candle

- Final Product

- Candle cake from Silicon mold

5. Conclusion

The group assignment provides a comprehensive comparison of molding and casting materials and processes, highlighting trade-offs in flexibility, durability, and ease of use. The individual assignment demonstrates mastery of mold design and production, achieving a smooth three-part mold for casting.