Week 12 - Group / Molding and Casting¶

This is group assignment page of Molding and Casting (Kitakagaya students):

- Shin Masuoka

- Hiroe Takeda

Group assignment¶

- review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them - extra credit: try other molding and casting processes

Materials¶

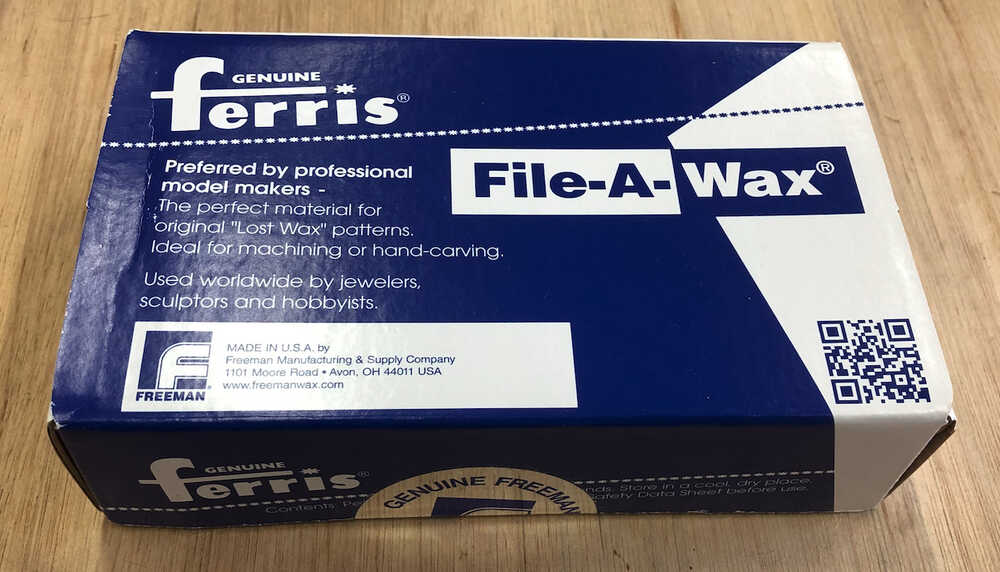

Modeling Wax¶

According to safety data sheets (SDS), important to be careful below.

- Molten product can cause serious burns. Avoid contact with molten material.

-

Wear appropriate personal protective equipment. Avoid contact with skin and eyes.

- Eye/Face: Wear safety goggles.

- Hands: Wear thermally resistant gloves and long sleeves if handling molten product.

- Skin/Body: Prevent skin contact, wear long sleeves and/or coveralls.

-

Do not walk through spilled material. Do not breath dust or fumes.

- Avoid release to the environment.

- Avoid dust formation. Use clean non-sparking tools to collect material into suitable container for disposal.

- Wash thoroughly with soap and water after handling.

- Use only in a well-ventilated area and avoid breathing fumes and dust (dust is unlikely).

Resing Cast¶

More hazadous and toxic compared with other materials. Take care to avoid eye contact or contact with skin. Avoid using in a place with poor ventilation or possibiity of inhaling vapors.

- Safety precautions

- Keep away from sources of ignition such as heat/sparks/open flames/hot objects.

- Ground/earth the container.

- Use explosion-proof electrical equipment.

- Avoid inhalation of dust, fumes, gases, mists, vapors, and sprays

- Use only outdoors or in a well-ventilated area

- Wear protective gloves/protective clothing/eye protection/face protection, etc.

- Avoid release to the environment

Test Cast by Wave Resin Cast EX¶

After ensuring adequate ventilation, put on goggles and a protective mask and begin the test.

Equal amounts of Wave Resin Cast EX Liquid A and Liquid B were measured on a scale and poured into a paper cup. We mixed them thoroughly and poured them into the test vessel.

Cure start about 300 seconds, then it cured well.

The product said that it starts curing in 180 seconds, but today’s low temperature (about 13 degrees Celsius) seems to have lengthened the curing start time.

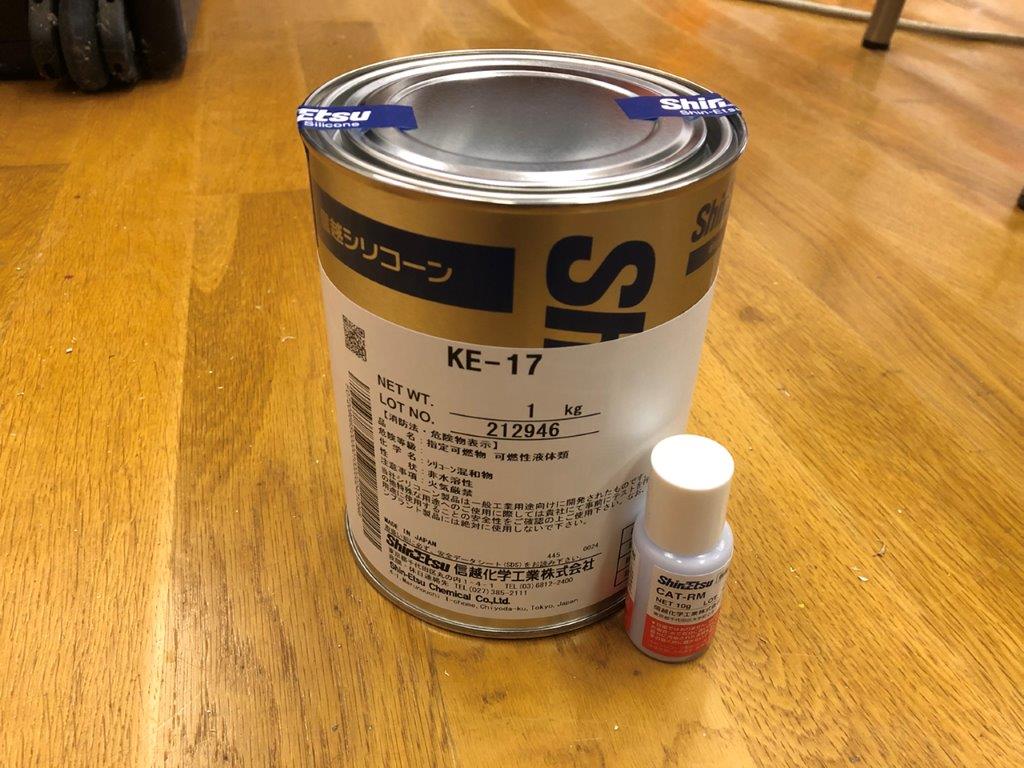

Silicon (KE-17 by Shinetsu)¶

- We used a product by “Shinetsu Silicone” a Japanese chemical company.

-

KE-17 is over 30 years long selling item.

-

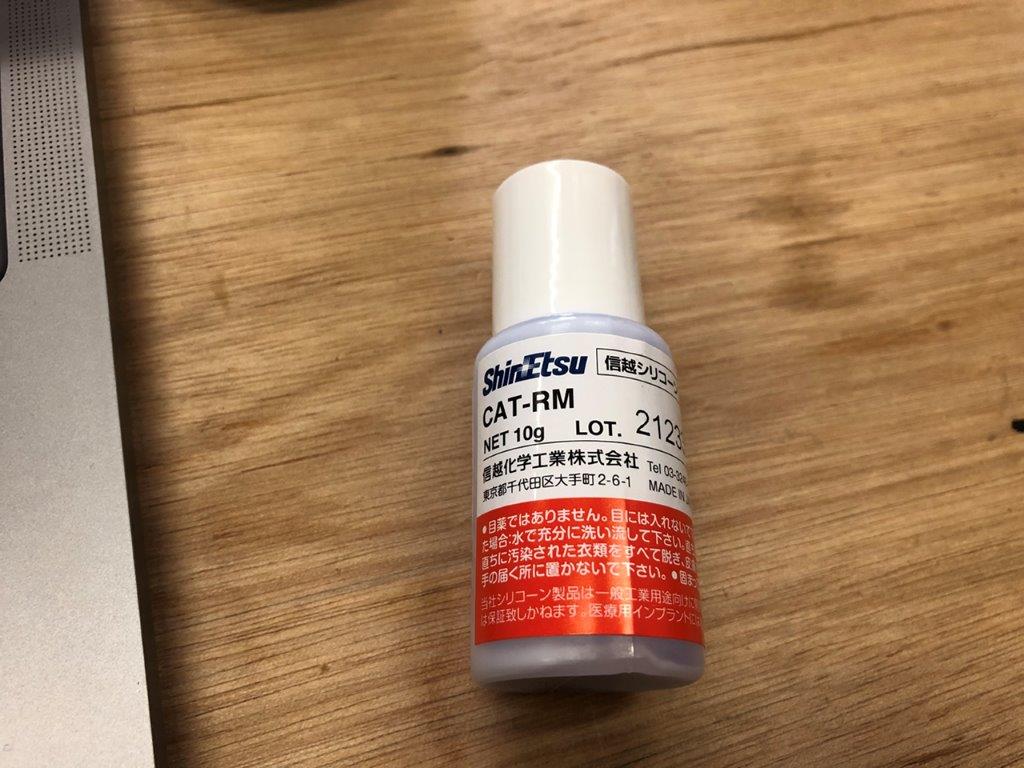

KE-17 is packed with its curative agent “CAT-RM”.

- Especially CAT-RM is more hazardous, so we need to prepare safety measure for CAT-RM and it meets KE-17 as well.

- We must avoid touch, breath-in. Wear gloves, masks, clothing for this work. Even if the clothe touched this liquid, it must be well washed.

- We put on gloves and masks while working on this. And also the room should be well ventilated.

- Data sheet was available only in Japanese.

- KE-17 written in Japanese

- CAT-RM written in Japanese

Release agent (Mr. Silicone Barrier)¶

- This prevents silicone from sticking to each other and improves resin casts.

- Below caution is written on the box.

- Keep out of reach of children, avoid swallowing or eating accidentally. Contains organic solvents, ensuring ventilation while painting or drying. Be careful not to see people or objects when spraying paint. Wear a mask or gloves to avoid touching the skin as much as possible during handling. When it gets on the skin, wash it with soapy water. When it gets in your eyes, rinse with water. When you feel sick, keep calm in the clean air place. Consult a doctor immediately when there is pain or appearance change.

- We put on gloves and masks while using this.