Week 3. Group / Computer Controlled cutting¶

This is group assignment page of Computer Controlled cutting (Kitakagaya students) :

- Sosuke Kanegae

- Shin Masuoka

- Hiroe Takeda

group assignment:¶

- characterize your lasercutter’s focus, power, speed, rate, kerf, joint clearance and types

1 machine¶

1-1) FABOOL Laser CO2¶

The photo is quote from smart DIY

1-2) specuration:¶

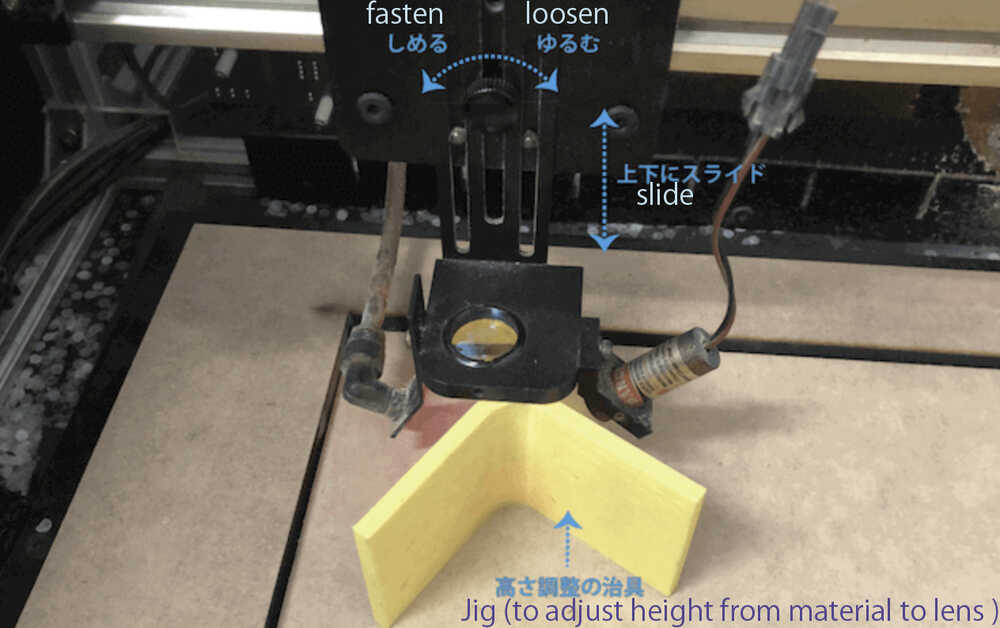

- focus :

Use jig (fablab West-harima is made) and adjust focus.

- power : 0 – 100 % (as maker setting)

- speed : 50 – 8000 mm/min (as maker setting)

- rate(Hz) - not adjustable

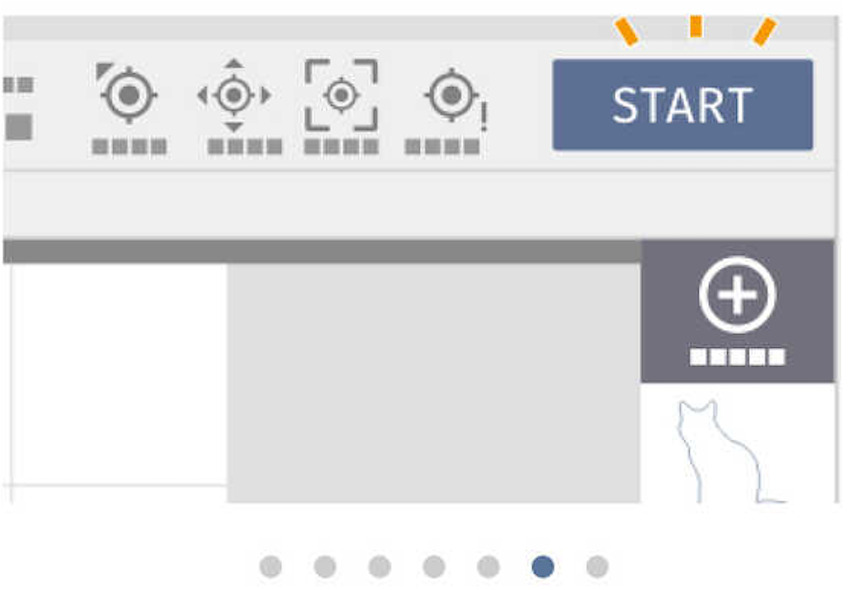

2 : Software¶

SmartDIYs Creator from smartdiys.com

3. How to use¶

1.Open SmartDIY Creators, and Connect to FABOOL Laser CO2.

Import the file.

Set position and size.

Set parameters. (Power/Speed/Times)

Comfirm the work size, and start.

NOTE:The above photo is taken from the installation of SmartDIY Creators.

3-1) NOTE:¶

- Never touch the lenses with your hands, and be very careful when handling them.

- The lenses contain toxic ZnSe, so if you do touch them, take measures such as washing your hands with detergent.

- Power 100 seems to cause a lot of laser pain, so I refrain from using it.

- Enable” in the upper left corner of the “Parameter Setting Dialog” allows you to set whether or not the target item will be processed. If “Enable” is unchecked, the target item will not be processed.

- Always stay close to the FABOOL Laser CO2 during processing. Be careful of fire.

- Wear protective goggles.

- If processing is started with the door open, the laser head will move, but the laser will not be emitted.

- If the PC screen saver starts to move, the FABOOL Laser CO2 will stop processing.

3-2) Materials (DO NOT USE!!!)¶

We were warned about materials that FabLab users tend to purchase at home centers and that cannot be laser processed.

-

If the material is chloride, DON’T use it.

[Example]: Vinyl chloride board, Vinyl chloride pipe, Vinyl chloride sheet, etc.

[Reason]: Toxic gases are produced. It also causes rust on the metal parts, which shortens the life of the laser machining machine. -

DON’T use mirrors or mirrored surfaces.

[Reason]: The laser will reflect and cause a malfunction. Examples of holes in the machine, blindness, and possible injury. -

DON’T use highly flammable materials.

[Example]: Explosives and highly pyrophoric materials, for example, spray cans, batteries, paint, etc. -

DON’T use materials that contain fluorine.

[Example]: Be careful not to include it in the ingredients of tapes and rubber sheets.

[Reason]: Toxic gases are produced.

4. Calibration¶

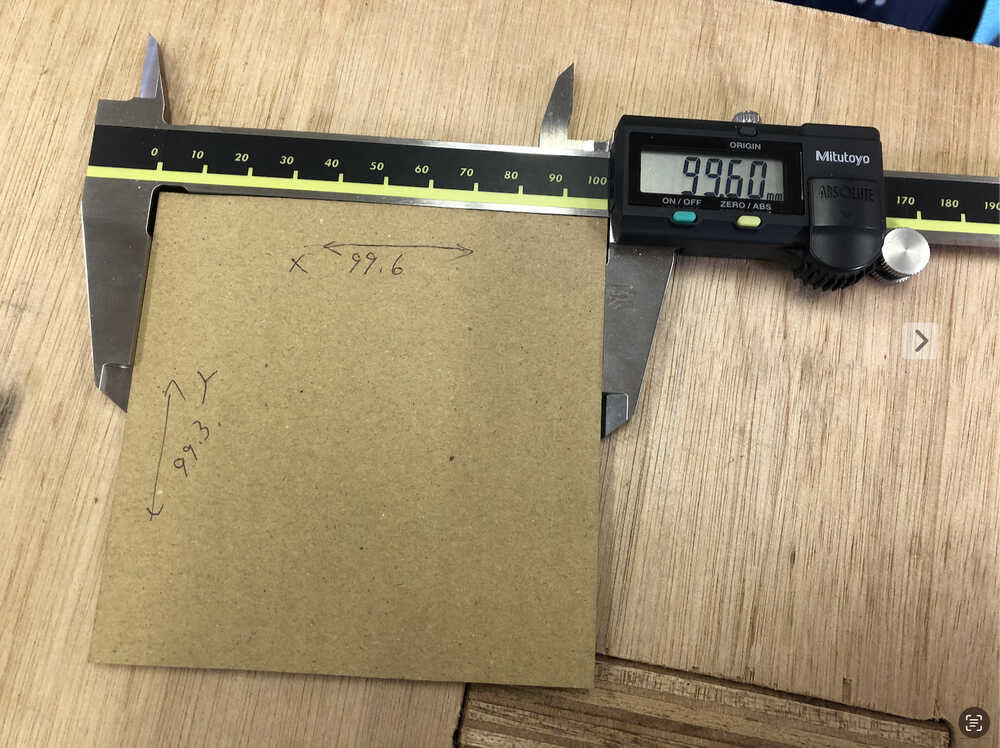

- 4-1) Cut the square (100x100mm)

- 4-2) Measure the cut part

- 4-3) Calculate “the correction value”

- “the correction value” = 100 / the measure size x 100

- (In case of photo “X” : 100/99.6x100 = 100.401606)

- 4-4) In SmartDIY Creators > Setting > correction input “the correction value” to X and Y.

- 4-4) Test cut

- 4-5) Mesure the cut part

if the size become near 100x100mm, the calibration is finish. If not, repeat calibration.

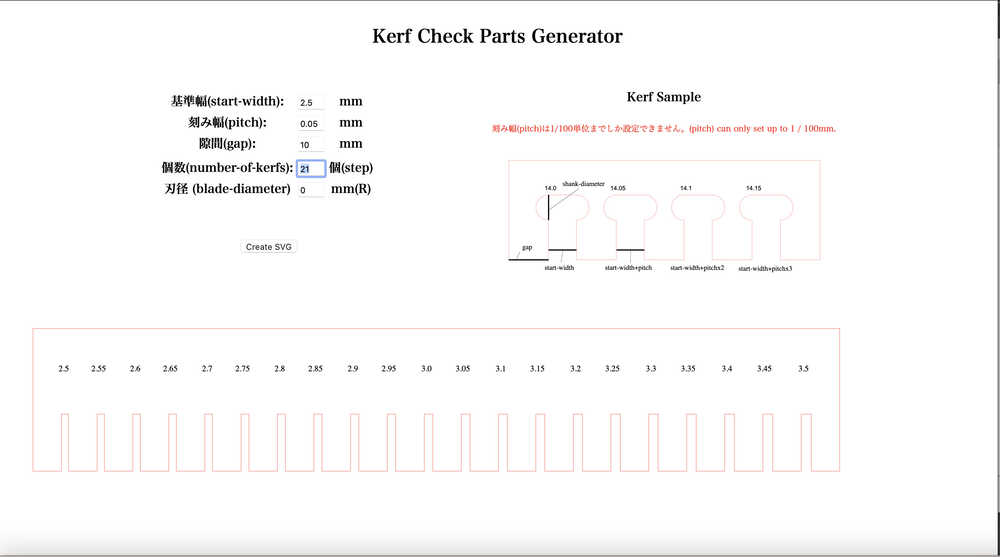

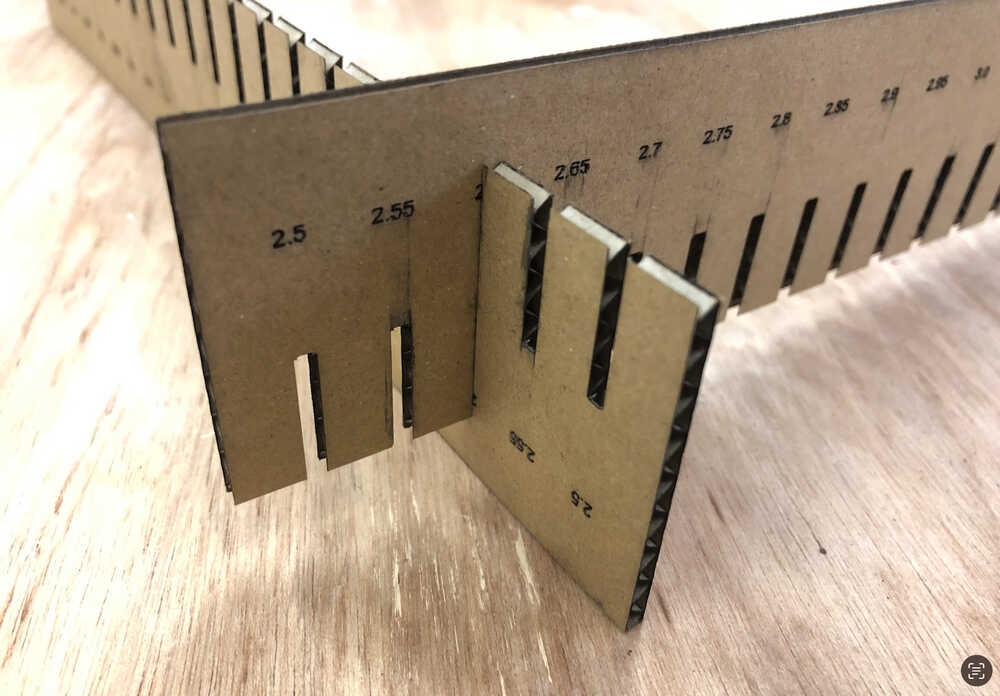

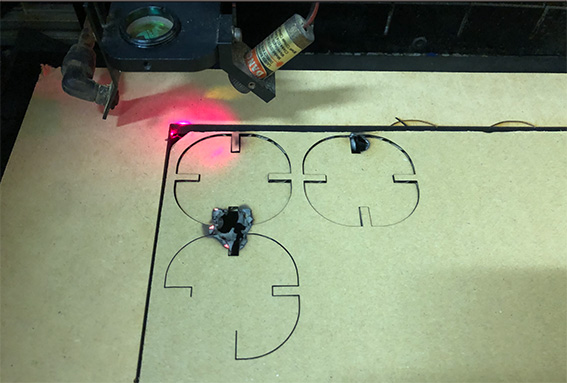

5 kerf test¶

We consider how should we test. The 2022 Fablab Kamakura Group documents helps a lot.

- Measured the t3.0mm cardboard.

Actual t2.6mm-2.8mm -

Using Kerf Check Parts Generator, and download the SVG file.

-

Cut the SVG file with FABOOL Laser CO2.

The result:

- 2.6mm is Best fit for 3mm cardboard.

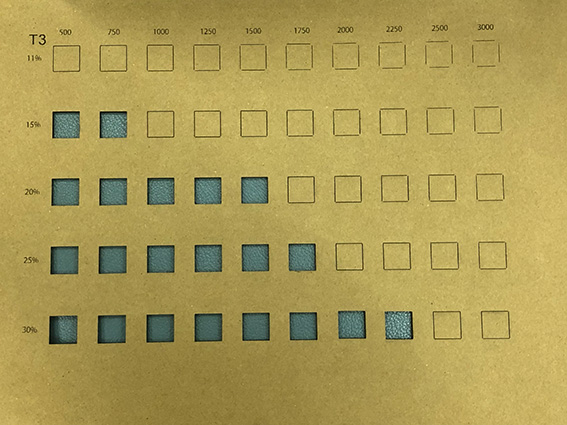

6. Parameter mix¶

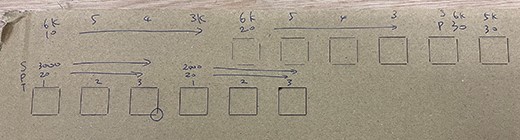

- This test is for finding appropriate mix of parameters; power, speed and cutting repetition.

- At first, we checked cutting parameters roughly.

- It turned out the laser is not working with power 10% or less.

- Cardboard is made of paper so recommended power is 20% or less. The higher the power, the easier getting fire.

- But with lower power, difficult to cut it at one time.

-

With this test we assumed power 20%, speed 2,000mm/min, 3-4times cut would be enough for cutting the 3mm-thick cardboard.

-

With above result we did below test; power varies 11%-30%, speed varies 750-3000mm/min,

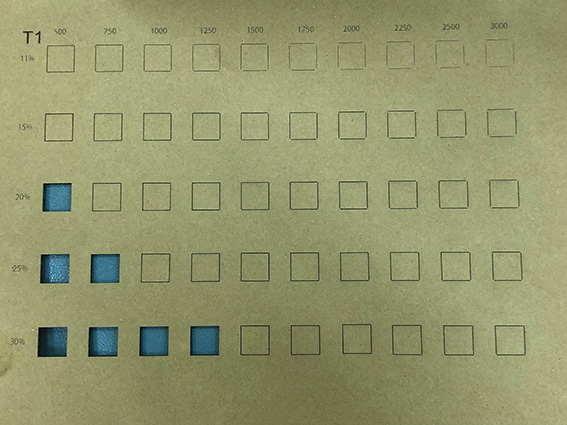

6-1). Cut one time¶

- We can cut this cardboard with over 20% power. But this is not recommendable power.

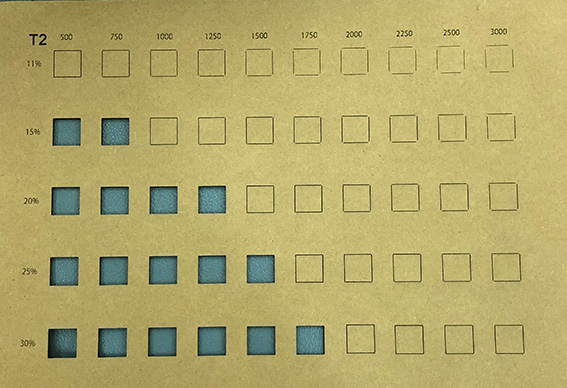

6-2). Cut 2 times¶

- This result shows that power15%, speed 750mm/min 2times cut is enough.

- To find weather power 11% is possible to cut, we tried 3times cut as below;

6-3). Cut 3 times¶

- Could not cut with power11%

- While individual work, the material got fire with power 25%, speed 500mm/min. But the test data above did not get fire. The reason seems the shape of material. If we cut narrow or small shape, it is easy to get fire. Because the narrow or small parts the heat is not transported so easy to reach ignition point.

- If the cutting data includes narrow or small part, we should adjust the parameters safer side.

- Test cutting with the minimal part is necessary to avoid getting fire.

- Otherwise power 15%, speed less than 750 mm/min and 2-3 times cut is reccpmentdable for this material (3mm thick cardboard)

(end of document)