20. Project development¶

individual assignment¶

In the following work I have to answer the following questions:

What tasks have been completed?¶

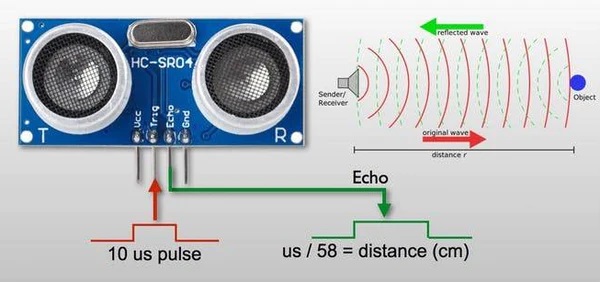

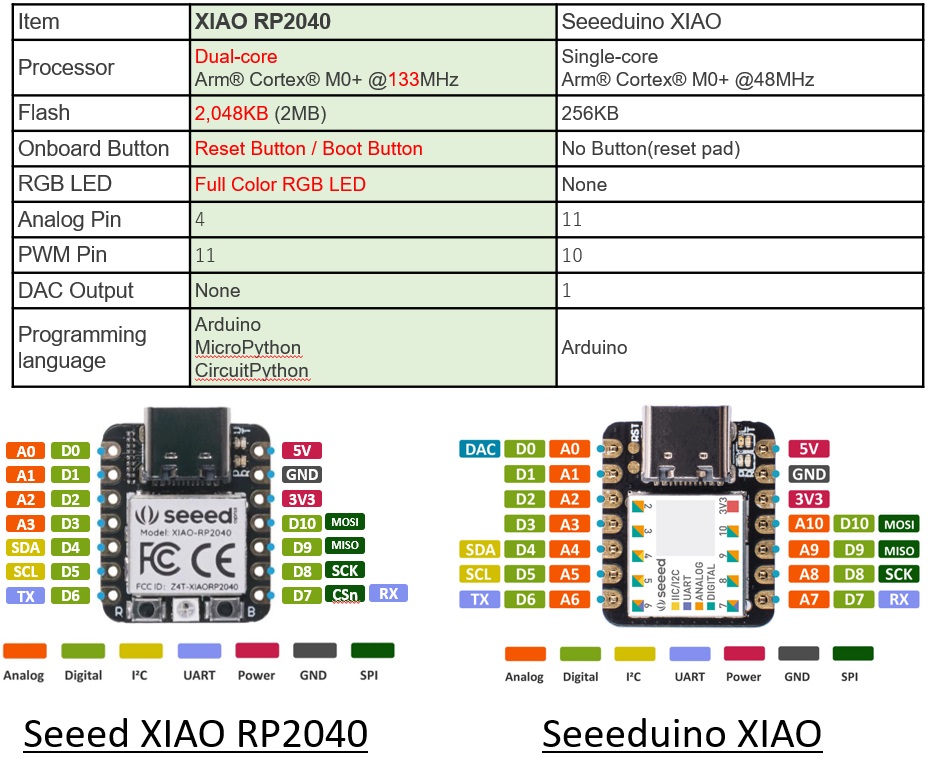

To develop my project I used different materials such as MDF, which is made up of medium-density bonded fibers. It is this characteristic, in addition to the use of servomotor, distance sensor, and printing of the electronic circuit and connections, and also the different resistors and leds that will be placed, the most important thing is the electronic part with FAB XIAO RP2040 card,

Design stage:¶

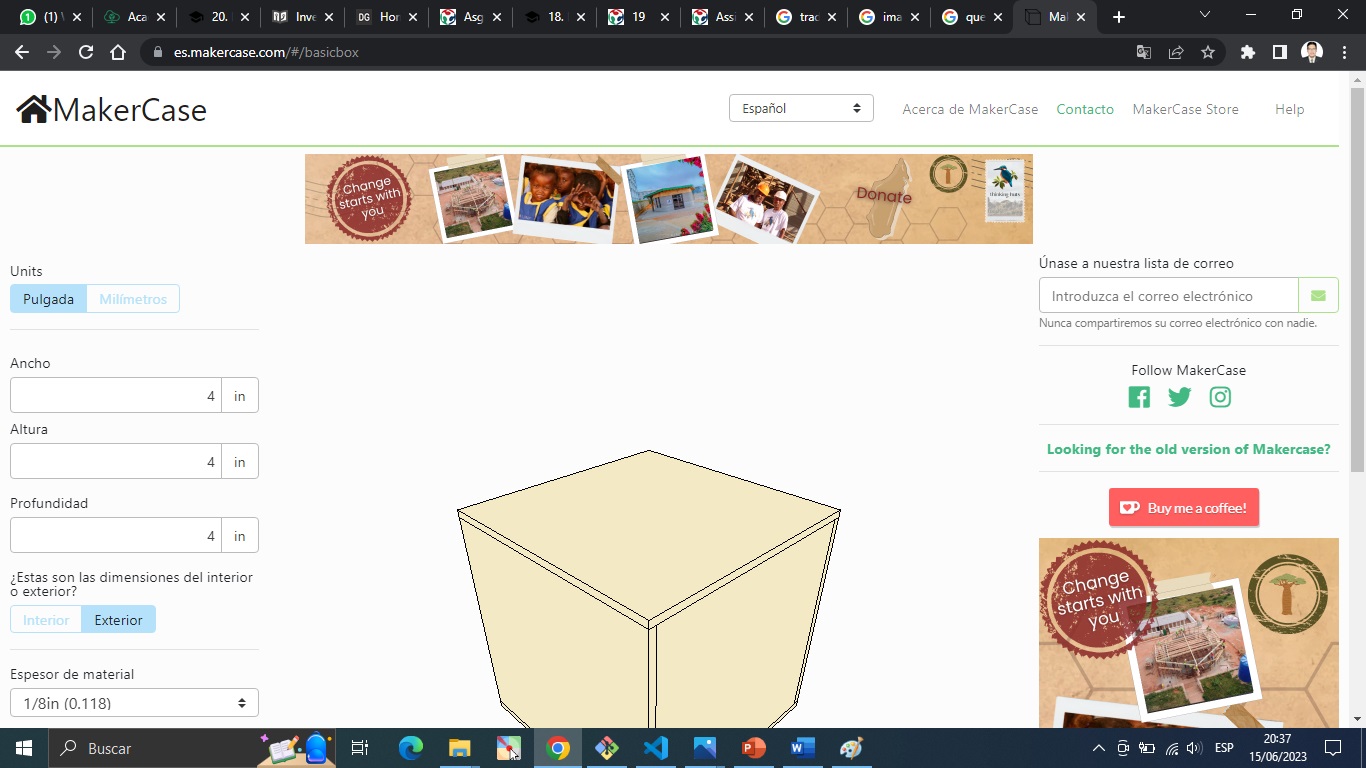

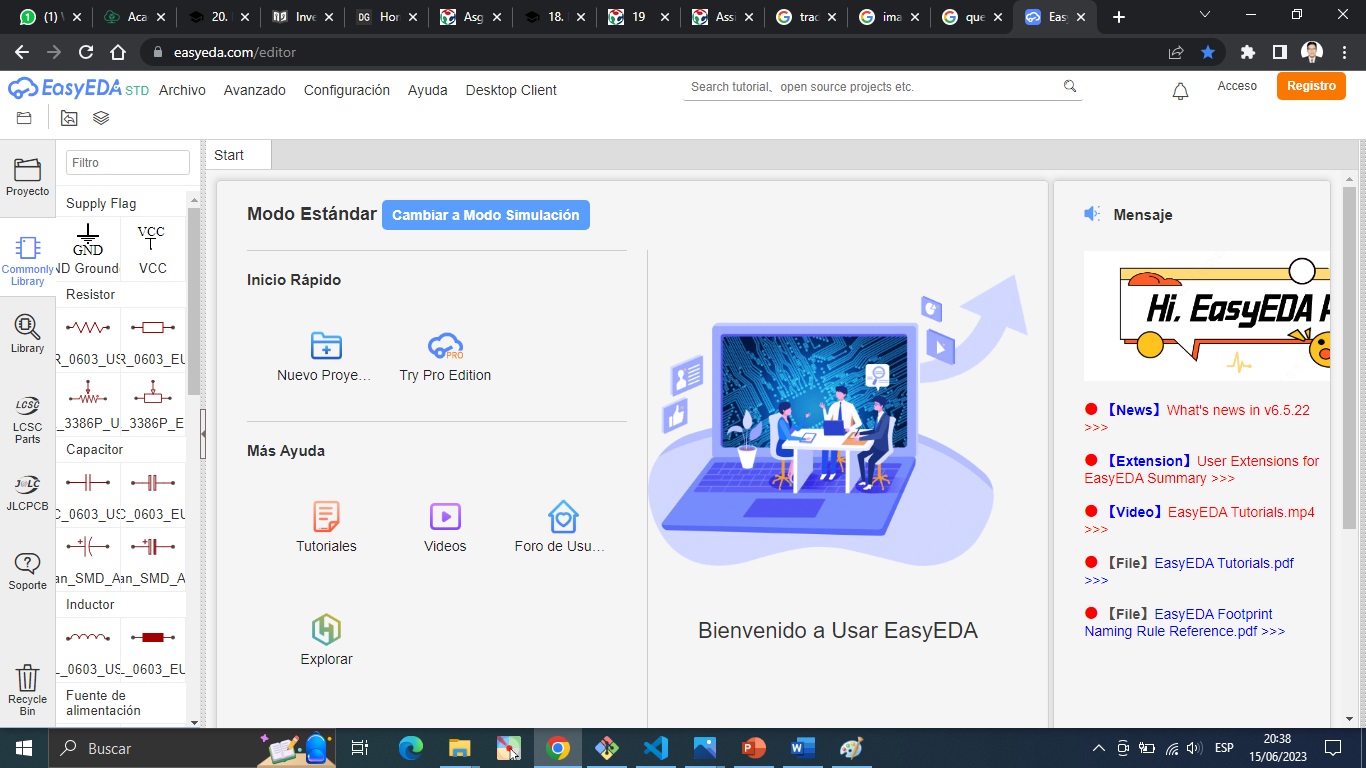

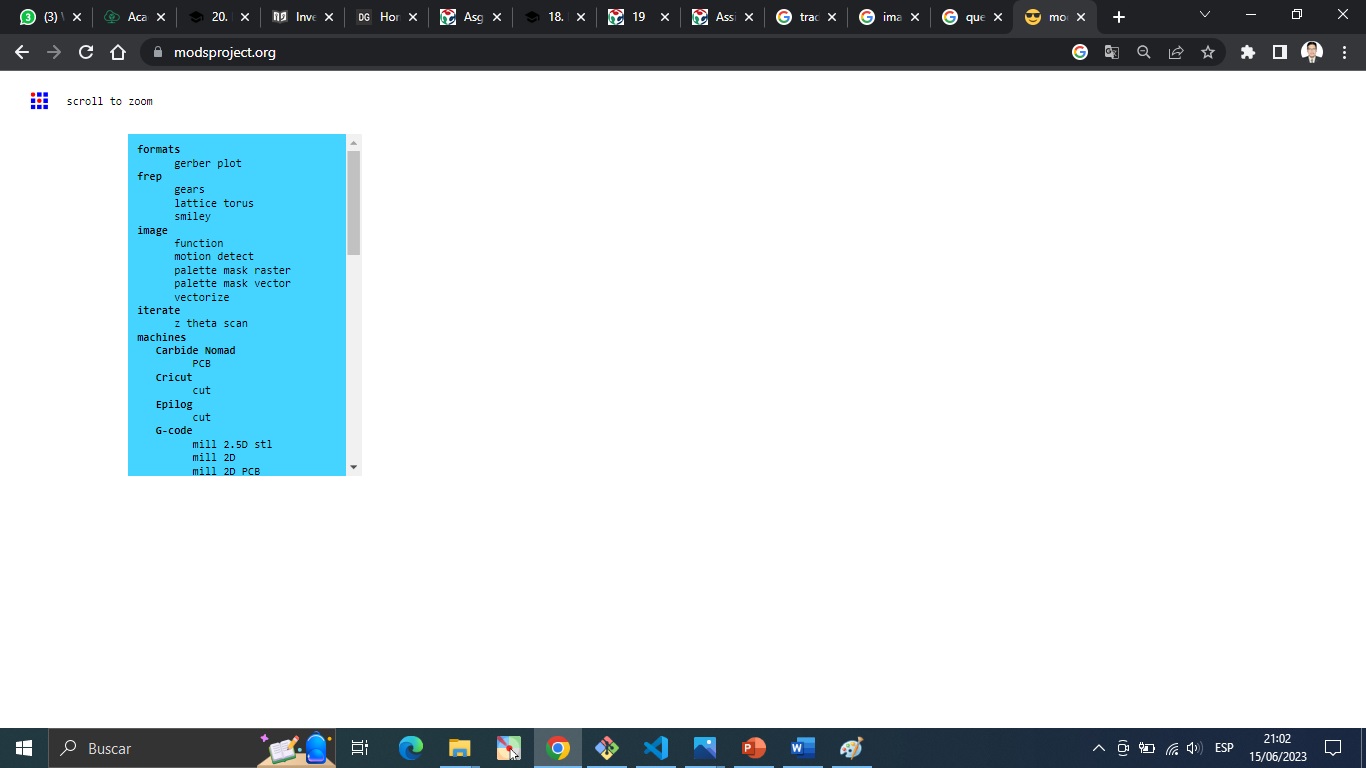

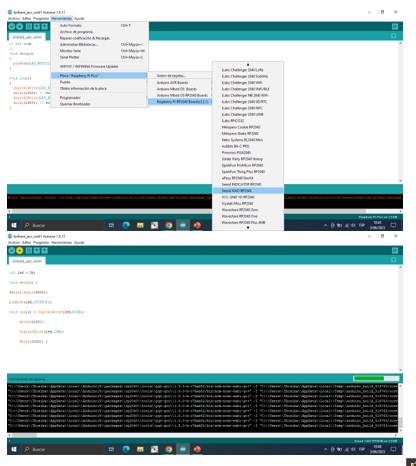

Software for 2D and 3D design (FREECAD, SOLIDWORKS, Auto CAD, MakerCase), software for electronic design and production (EASYEDA), software for Arduino IDE programming were used.

Manufacturing:¶

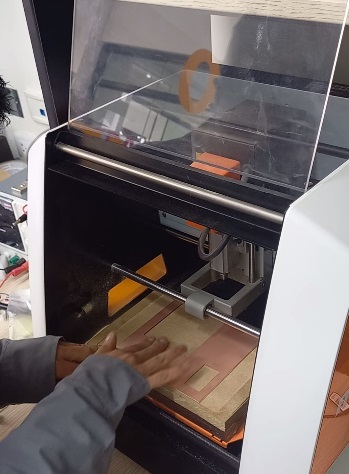

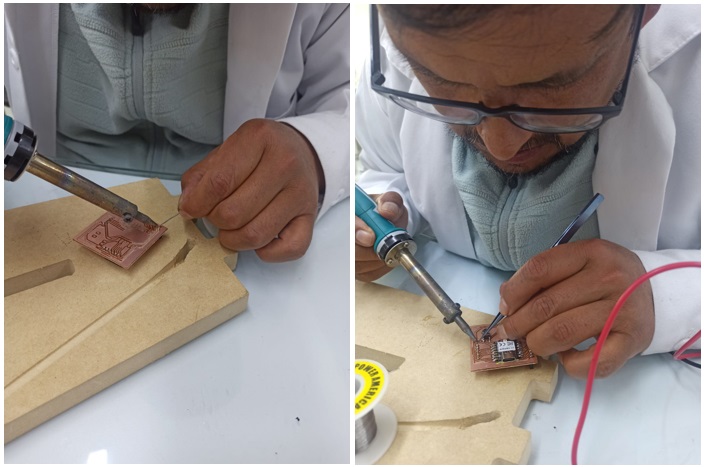

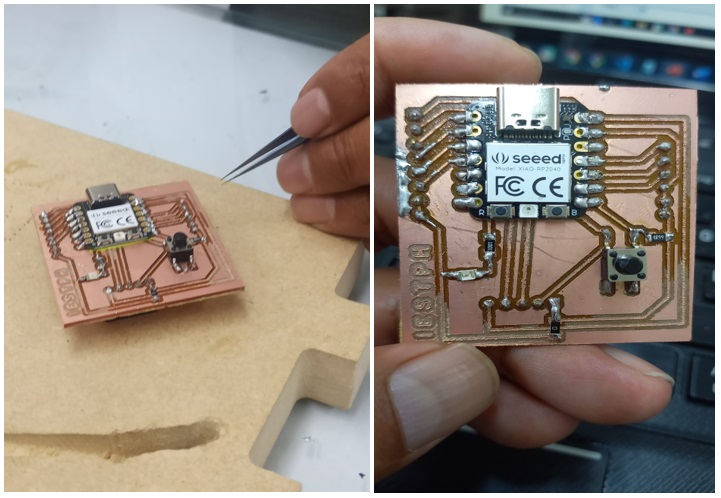

Smart Tacho: made of 5mm mdf, laser cutting was used for the shape of the box and the figure to be projected. FAB XIAO RP2040 card: made with a mini milling machine, welding process and functional tests.

The tasks in their entirety were completed.

¿What tasks are left?¶

All tasks have been completed in the process.

¿What has worked? ¿no?¶

During project testing, everything worked as expected with FAB XIAO RP2040 board, HC-SR04 distance sensor, MG946 15KG/CM 180° METAL SERVO MOTOR.

PRESENTATION OF THE ELABORATION OF THE PROJECT¶

SMART TACHO:¶

-

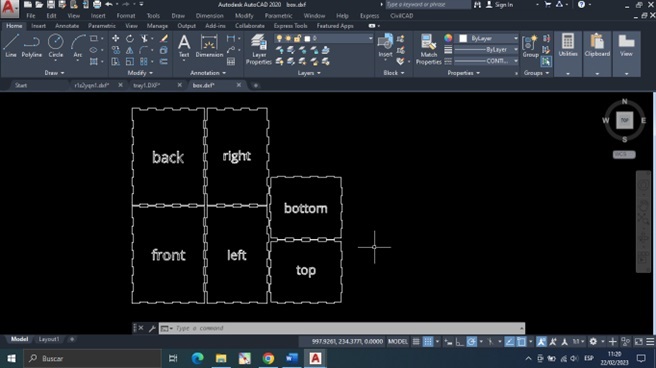

The design was made in the Auto CAD software and it was converted into DXF format to be cut in the laser cutter.

-

The 5mm thick MDF material is cut and later the assembly of the bin is slipped.

-

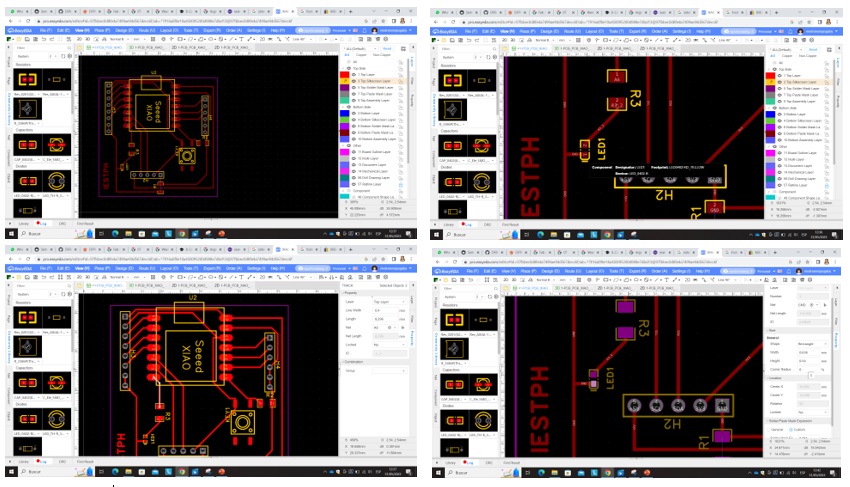

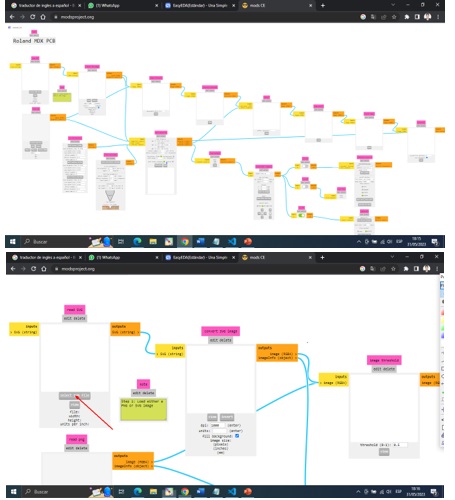

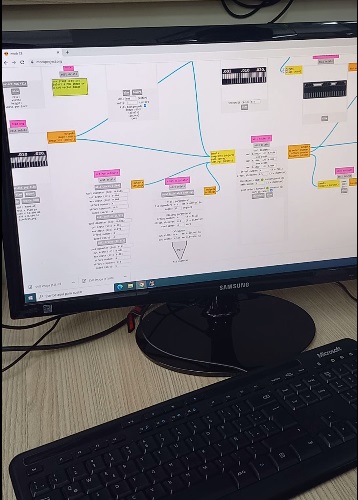

In this process, the electronic circuit is made with the EasyEDA program, after programming and engraving of the circuit with the mini-mill, then proceed to assemble the electronic components such as the XIAO RP 2040, led, push button , resistors based on soldering iron.

-

Programming is done with the help of the ARDUINO IDE program, programming tests are performed.

-

The circuits are assembled in the bin and tests are carried out and the final result is working well.

I THANK FAB ACADEMY FOR THE OPPORTUNITY OF GIVING US TO DEVELOP MY PROJECT AND LEARN MORE ABOUT DIGITAL MANUFACTURING. THE TRUTH I HAVE LEARNED A LOT USING THE MACHINES: LASER CUTTING, 3D PRINTING, MINI-MILLING MACHINE AND DESIGN SOFTWARE.