17. Machine design¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

Maslow CNC Machine¶

Maslow is a large (4’x8’) CNC cutting machine designed to let you cut big, useful things out of wood and other flat materials. Cut out a tiny house, a kayak, a tree house, some furniture, or anything else you can imagine. Maslow is designed to be affordable to buy, cheap to ship, easy to use, and powerful. Because designs can be shared digitally, you can build on the work of others or create your own from scratch.

Maslow CNC Setup and Calibration¶

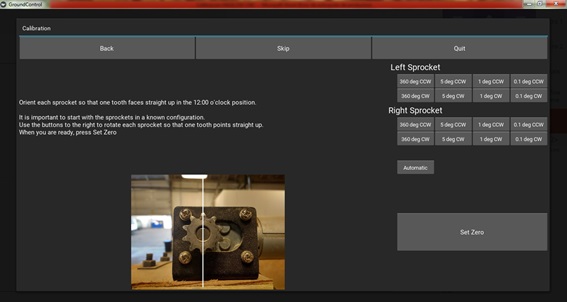

I. Calibration

- First, download and install Ground Control Software v1.26 from this official website. (Extract files to any folder)

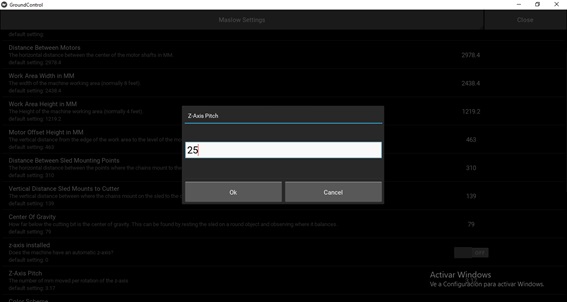

- Launch application , go to Settings, on Maslow Settings change Z-Axis Pitch parameter to 25, because of Metal Maslow mechanism. Then Ok button to save configuration.

-

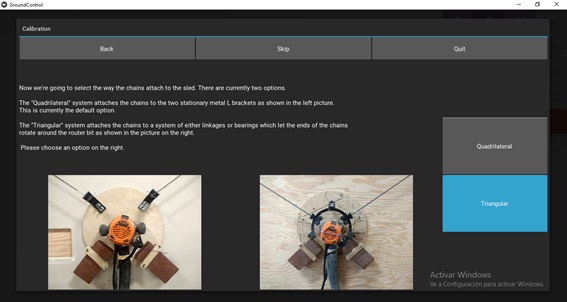

Now, we select Triangular system, because system attaches the chains to a system of either linkages or bearings which let the ends of the chains rotate around the router bit as shown in the picture on the right.

-

Next, we need to enter a rough measurement for how far the motors are above the top of the work area. Measure from the center of the motor shaft to the top of the sheet of plywood. Millimeters units used.

-

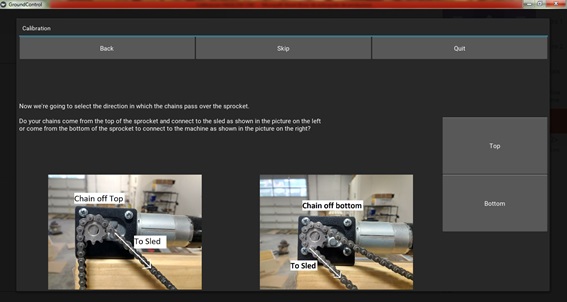

Now, we’re going to select the direction in which the chains pass over the sprocket. In this case Bottom selected.

-

Next, we need to enter a rough estimate for the rotation radius, this is the distance from the tip of the chain to the center of the router bit. Fort he ring the distance is 150mm.

- To get more precision, re-cut test pattern. Type the new measurements on the boxes. Repeat process until get best results. I mean Cuts 1 and 2 measurements so similar or equal to Cuts 3 and 4