6. 3D Scanning and printing¶

3D PRINT¶

3D printing CAD software allows you to conceptualize, design and optimize models to adapt them to production technologies 3D printing is a rapid prototyping and mass-customizable manufacturing process, as well as a technology that enables the creation of complex geometries not previously possible through other manufacturing processes. It’s also a digital manufacturing technology that requires no tooling changes for revised parts, so there’s no downtime between product revisions or manufacturing completely new products. With 3D printing we go a step further and it is possible to go directly from a digital design to a final piece, without intermediate steps in the process. Thus, 3D printing eliminates the use of tools and the consequent associated capital investment

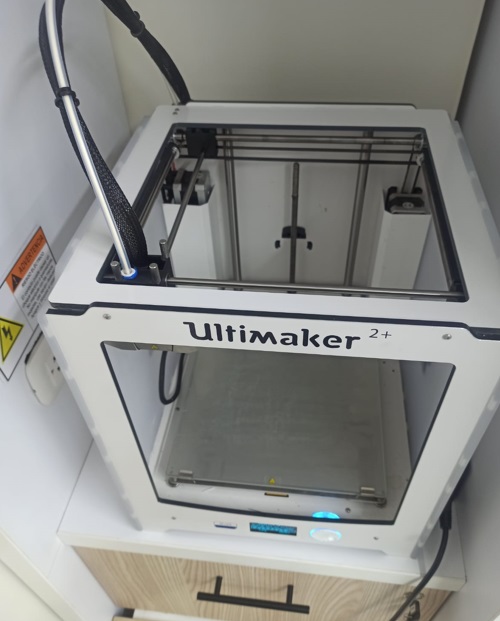

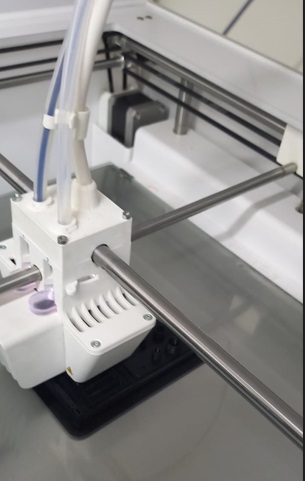

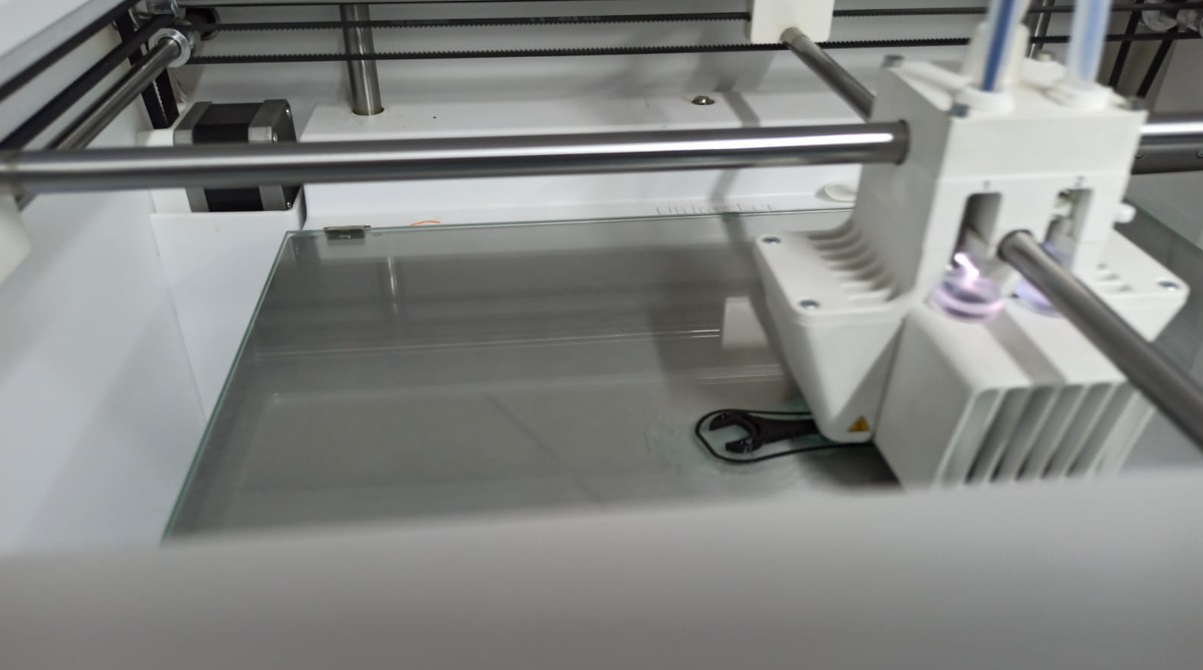

ULTIMAKER 2+ 3D PRINTER¶

With network functionality and a new touch screen, the Ultimaker 2+ is your first confident step into the world of easy, remote 3D printing.

SPECIALIZED TECHNICAL SUPPORT¶

Our 3D printers and software are backed by expert technical support and customer service.

HOT PRINTING PLATE¶

It allows to increase the adhesion of the first layer with a wider range of 3D printing materials. FILAMENT FLOW SENSOR If you run out of filament during a print, the printer will stop and ask you to add more material in order to finish the print job.

CHARACTERISTICS OF THE PRINTER¶

PRINT VOLUME¶

Physical space inside Ultimaker 2+ that can be used for single extrusion 3D printing 223 x 220 x 205 mm (8.7 x 8.6 x 8 inches)

ASSEMBLED DIMENSIONS¶

The XYZ dimensions of the 3D printer including spool holder and Bowden tubes 342 x 460 x 580 mm (13.5 x 18.1 x 22.8 inches)

PRINTING TECHNOLOGY¶

It is the process of depositing layers of filament, one on top of the other, to create shapes and patterns. It is a form of additive manufacturing technology and the process used by all Ultimaker 3D printers (Fused Filament Manufacturing).

COMPATIBLE FILAMENT DIAMETER¶

The filament diameter that delivers optimal results on Ultimaker 3D printers. (2.85mm). WEIGHT. The net weight of the 3D printer 10.3 Kg (22.7 pounds).

POWER INPUT¶

100 – 240 V AC power input is required. 50-60hz.

MAXIMUM POWER OUTPUT¶

The maximum power that the printer can achieve, typically when the platen and hot ends get hot. 221 W.

PRINTER PROPERTIES¶

LAYER RESOLUTION¶

The measurement used to define the thickness of a 3D printed layer is the micron. 20 microns equals 0.02mm thickness. Thinner layers are used to print with great detail, while thicker layers are ideal for rapid prototyping. 0.25mm nozzle. 150 – 60 microns 0.4mm nozzle. 200 - 20 microns 0.6 mm nozzle. 400 – 20 microns 0.8mm nozzle. 600 – 20 microns

XYZ RESOLUTION¶

The more precise the printer’s stepper motors are, the higher the degree of precision and resolution of each print. 12, 5, 12, 5, 5 microns.

NOZZLE DIAMETER.¶

Smaller nozzle diameters achieve more detailed prints and larger diameters reduce the overall print rate. 0.4mm nozzle included; other nozzles sold separately. 0.25, 0.4, 0.6, 0.8mm.

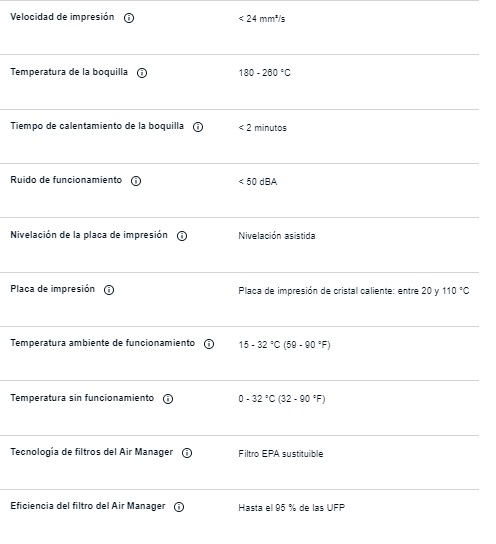

OPERATING PARAMETERS.¶

PRINTING SPEED¶

The one that can extrude the filament through the hot end of the 3D printer. the higher the value, the faster the print speed <24mm3/s.

NOZZLE TEMPERATURE.¶

Having a wide range of nozzle temperatures provides more flexibility to choose the 3D printing material is 180 – 260 °C.

NOZZLE HEATING TIME¶

Nozzle warm-up time is directly related to how fast you can start printing, as well as how fast you can melt the filament (warm-up time is < 2 minutes).

PRINTING PLATE¶

With a printing plate temperature range between 20 and 110 °C. you can be sure that the first coat will adhere reliably with a variety of materials.

OPERATING AMBIENT TEMPERATURE¶

This Ultimaker 2+ 3D printer works best in locations with temperatures within this range 15 – 32°C (59 – 90°F). • Minimum print thickness: 600 µm • Printing speed: 300 mm/sec • Max. volume: 223 × 223 × 205mm (10.19 cm3) • File format: .stl • Software: Cura, Repeater • Connectivity: Wi-Fi • Supported operating system: n.a. • Power: 100-240V / 50 - 60Hz / 221W

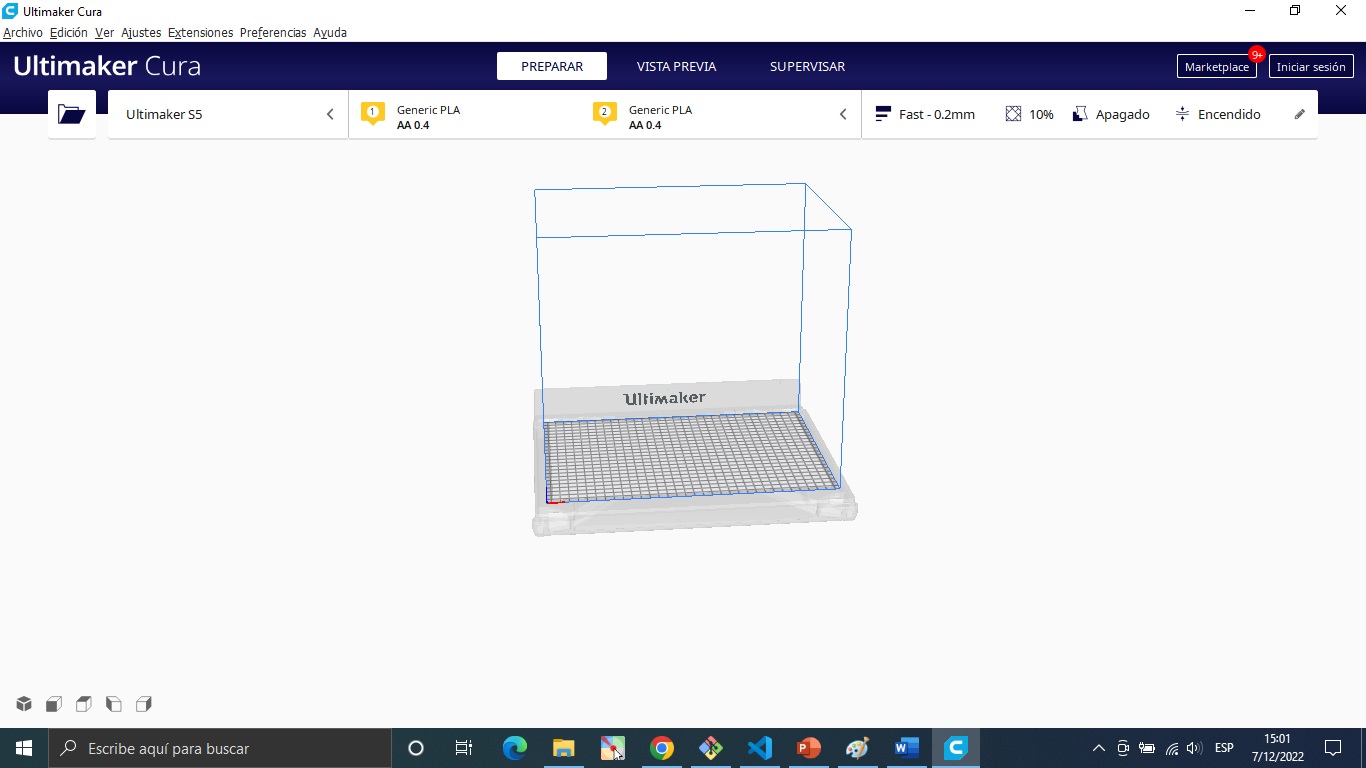

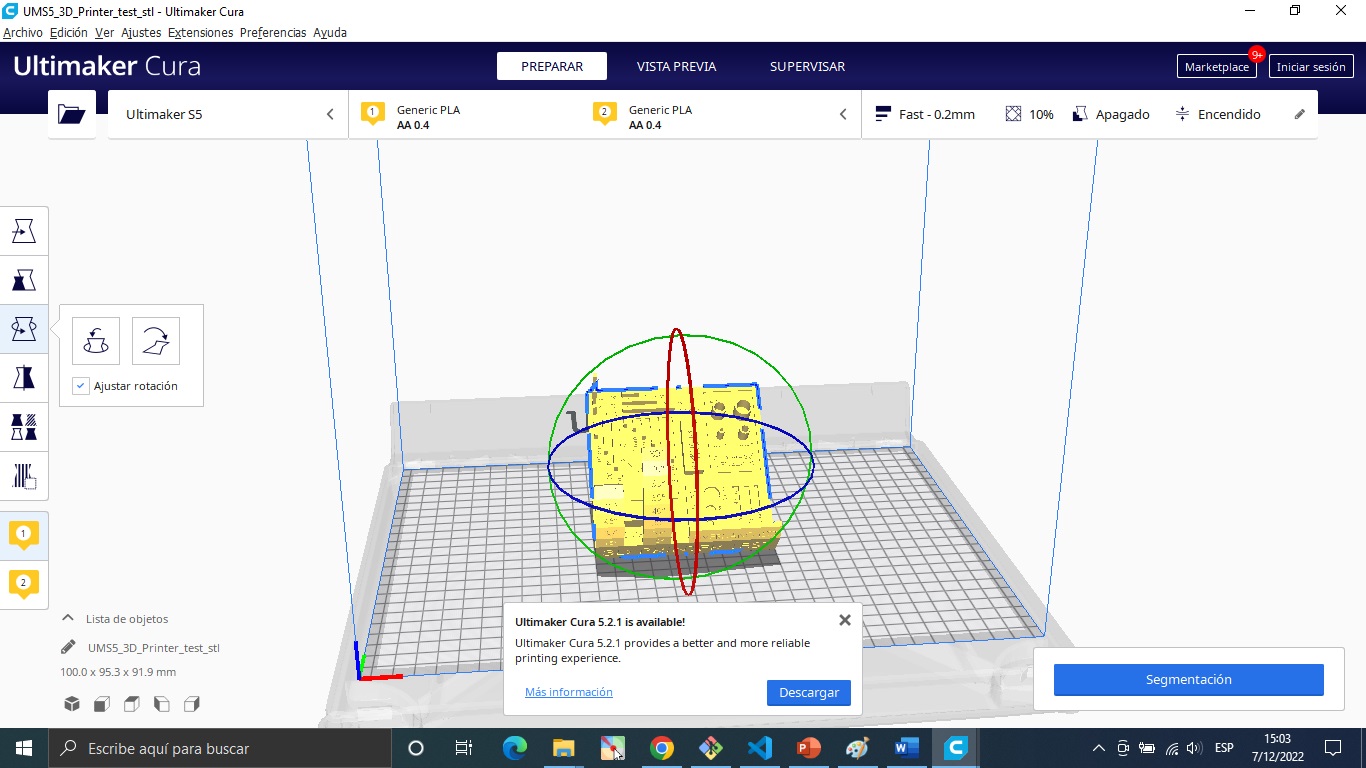

Ultimaker Cure¶

Of the main features of Ultimaker Cura, the following stand out: Cross-platform open source software, available completely free of charge. It has two types of use; Recommended mode or use Custom mode to configure over 300 settings, for maximum control. This is an application designed for 3D printers, in which you can modify the printing parameters and then transform them into G-code. It was created by David Braan, who after a while would work for Ultimaker. In order to make the software maintainable, it is made available under a LGPLv3 license. The development is hosted on GitHub. Ultimaker Cura is characterized by providing a graphical interface to prepare models for 3D printing, which is adjusted according to the model and the program determines the scenario of the 3D printer during the sequential application of each layer. In the simplest case, it is enough to import the model in one of the supported formats (STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG), select the speed and quality settings and send the print job. There are plugins for integration with SolidWorks, Siemens NX, Autodesk Inventor and other CAD systems. The CuraEngine is used to translate the 3D model into the 3D printer’s instruction set. Of the main features of Ultimaker Cura, the following stand out: Cross-platform open source software, available completely free of charge It has two types of use; Recommended mode or use Custom mode to configure over 300 settings, for maximum control It features configured profiles, which make hardware and material setup simple and fast. Out-of-the-box support for STL, OBJ, X3D, and 3MF file formats Ability to extend its core functionality with plugins Power capability to manage one or more network-capable Ultimaker printers from a single interface.

COMMENTS¶

INDIVIDUAL WORK¶

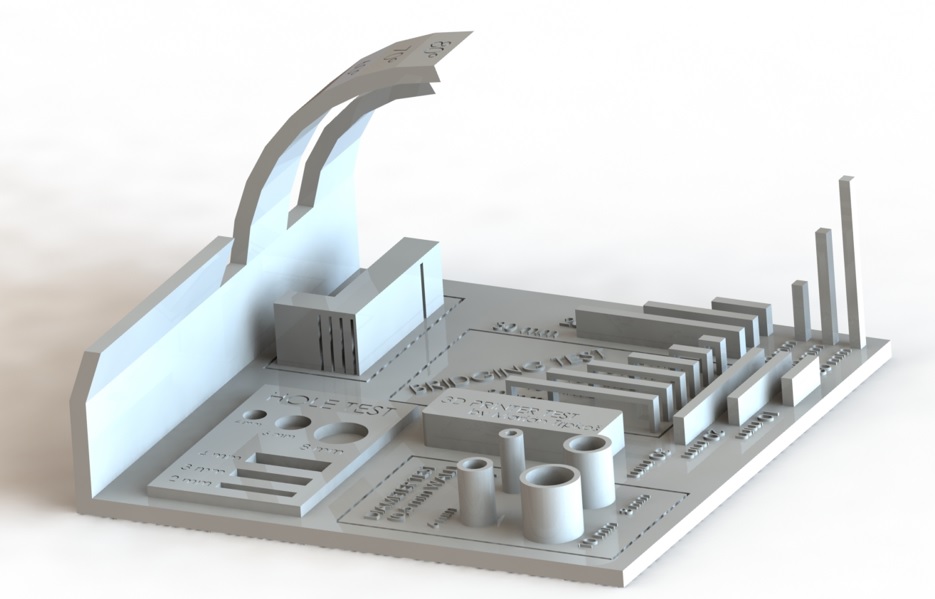

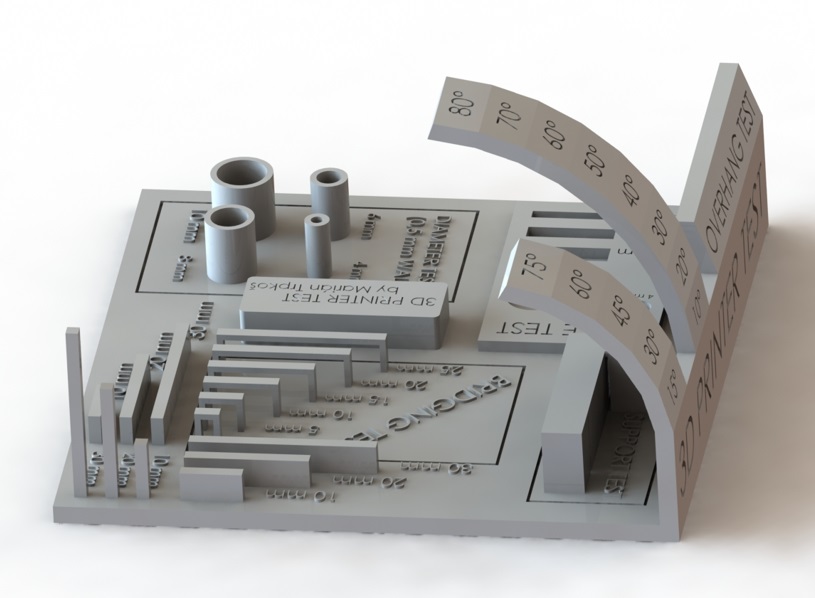

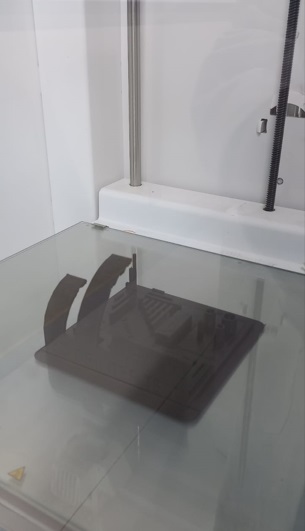

In the work carried out with the Ultimaker 2+ 3D printing machine, it is a piece of equipment that allows us to carry out 3D printing of designed objects and to be able to build models to execute prototypes of small innovation projects. When manipulating the machine, the equipment is first turned on, then it is programmed, the PLA filament of 2.85 in diameter is placed when entering, it melts the filament in the nozzle to then print. The designed object is coded in the Ultimaker Cura software that is compatible with the 3D printer, then the work is done. At the beginning I had a problem that the filament ran out and I observed that the machine stopped working because it has a sensor which does not allow the work to advance, when placing a new PLA filament the machine turns on again to complete the programmed object. The average printing of the design is approximately 2 hours 35 minutes, when the time is up, it is allowed to cool for approximately 15 minutes to extract the object.

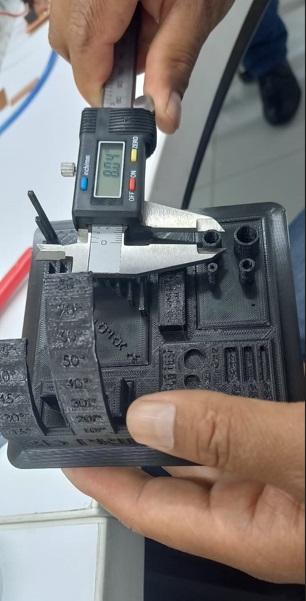

ANALYSIS OF EACH PRINTING PARAMETER¶

According to the work carried out in the 3D printer, the following printing parameters are observed.

• The object at the end of the printing is observed to have a smooth finish in the 3D printer test.

• In the overhang test, it is observed that on a larger scale it is not necessary to place reinforcement to obtain objects with overhangs.

• In the curvature test from 15° to 75°, the parameters are observed from 15° to 50° approximately if you work on a larger scale you do not need to place reinforcement it is resistant to printing, from 50° to 75° and more It is observed that the 2.85 diameter PLA tends to hang in the printing process, for which it follows that to the mentioned degree the object to be printed in 3D needs to be encoded with reinforcement as a support so that the design does not have defects at the time of making the 3d print.

• In the 4, 6, and 8 mm diameter hole test and in the 2,3,4 x 14 mm rectangles, the result is observed to have the correct finish. It is deduced from these measurements that smaller-scale objects can be made.

• In the test of diameters of 4, 6, 8 and 10 mm, the impression is correct both inside and outside, but in the diameter of 4 mm unless the inside diameter is not observed, it could be recommended that from 5mm in diameter to the more you would have the inside diameters for different circular objects.

• In the bridge tests it is observed in the measurements of 2mm, 5mm that reinforcement is not necessary from 10mm, 15mm, 20mm and 25mm, the PLA filaments are observed to begin to hang, so making an analysis it is recommended to carry out in The objects that you have bridges make reinforcements so that the object supports and does not have any defects.

• Of the other parameters, their correct texture is observed and they do not need reinforcements for the object.

In conclusion, carrying out the analysis of the mentioned test to carry out 3D printing, the measurements must be considered and there should be no difficulties when executing the object and having the design.

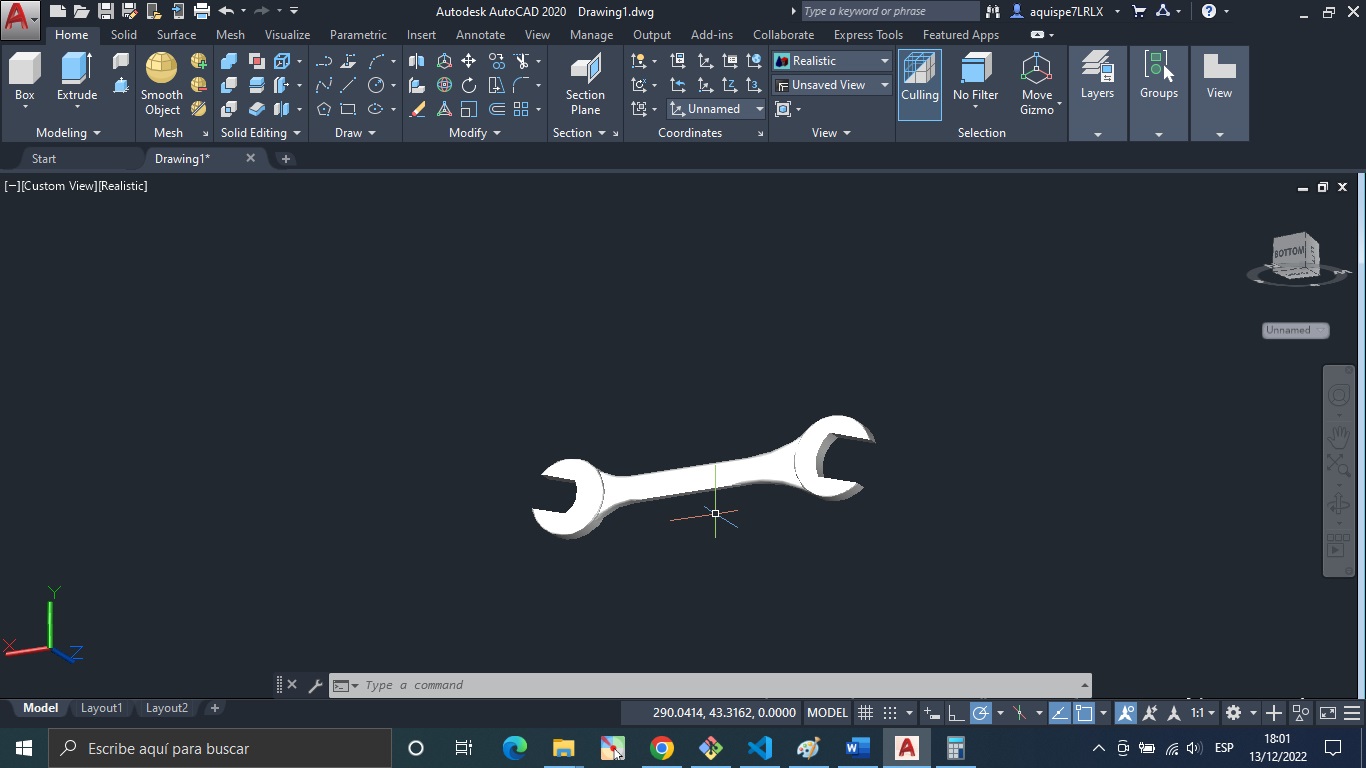

INDIVIDUAL WORK¶

A design was made in the Auto CAD of an open-end wrench with a measure of 70mm, then it is saved in the cura software of the 3D printing machine to be printed and the result is the following:

Useful links¶

3D MODEL SCANNER MATTER AND FORM¶

A 3D scanner is a device that has the ability to analyze an object or scene to gather data about its shape and, occasionally, its color. With the information obtained, one can go on to build three-dimensional digital models used in a wide variety of applications.

In a few words, it can be said that it works by projecting a laser point on an object from which it obtains information.

At first, its applications were relegated exclusively to the industrial field. Today, thanks to its advances and innovations, it is used in activities such as architecture, engineering, archeology, and entertainment, among others.

The 3D scanner has found an irreplaceable application in the dimensional control of the manufacture of components that require a series of very strict requirements. The parts are scanned and the point cloud is compared with the theoretical model, allowing very detailed control over production.

It can also be used to scale designs from models created by hand.

How does a 3D scanner work?¶

As we have explained before, the purpose of 3D scanning is to create a point cloud to extrapolate an object. Knowing how a 3D scanner works is very useful for certain companies that want to make prototypes at an affordable cost. For dental or medical clinics, it is ideal for making a dental mock-up or a medical prosthesis.

Below we offer the steps of how the behavior or process of 3D scanning is:

Using a beam of light, the scanner is capable of calculating the distance from the emitting point to a point on an object located within its trajectory range. Through one or several rotating mirrors, the scanner affects the existing points within an area of space, providing information on the distance between these points. The generated point cloud also contains information about the distance between each other between the different points of the object. Depending on the distance to the object, the desired precision and the object in question, several shots are often needed. To produce a 3D model, you need software applications that allow you to orient all these shots.

Technical specifications¶

Get resolution down to 0.1mm with the precision of these eye-safe red lasers. Compatible with Windows and Mac, with multiple export capabilities for 3D printing.

Scan performance¶

SCAN ACCURACY Within ±0.1mm SIZE AND MAXIMUM WEIGHT OF THE OBJECT Height: 25cm Diameter: 18cm Weight: 3.0kg

Scanner¶

OPTICS HD CMOS sensor 2x class 1 safety lasers CONNECTIVITY USB 2.0 high-speed interface POWER INPUT 100-240V OPERATING TEMPERATURE 15° – 32°C Software

SOFTWARE¶

MFStudio + Quickscan SUPPORTED PLATFORMS Recommended: Windows 7, 8.1, 10 (64-bit) macOS 10.11+

RECOMMENDED COMPUTATIONAL SPECIFICATIONS¶

CPU: i5 RAM: 4GB

EXPORT FILE Point cloud: PLY, XYZ Mesh: STL, OBJ, DAE, PLY, glTF2

Scanner¶

SCANNER SIZE AND WEIGHT Height: 34.5cm Width: 21cm Open length: 34.5 cm Closed Length: 8.5 cm Weight: 1.71kg ESTIMATED SHIPPING DIMENSIONS cm: 21x11x53 Weight: 3.13kg IN THE FRAME Matter and Form 3D Scanner usb-b cable AC power adapter with worldwide interchangeable power plugs calibration card User manual Product Information Brochure small plastic toy

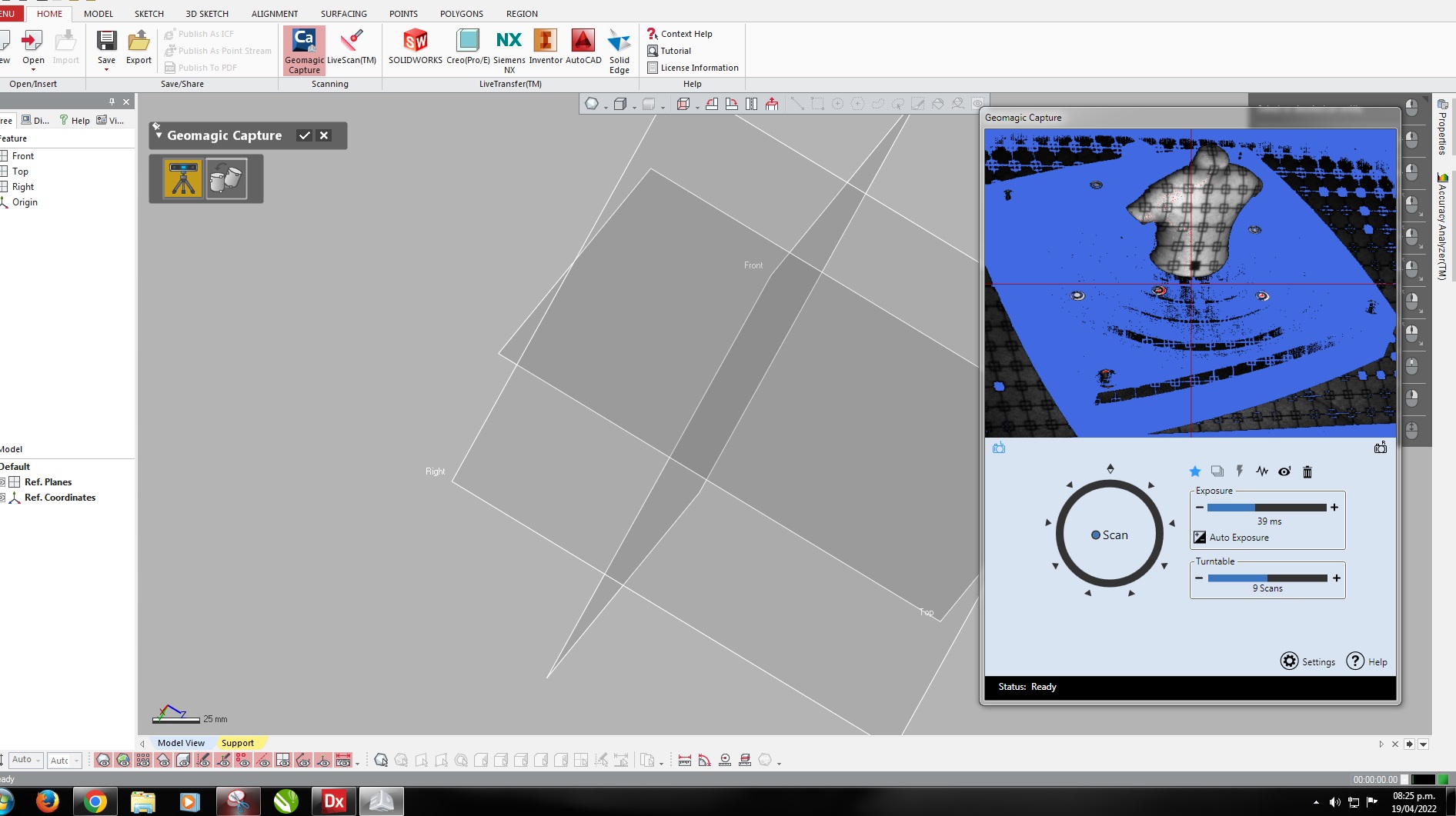

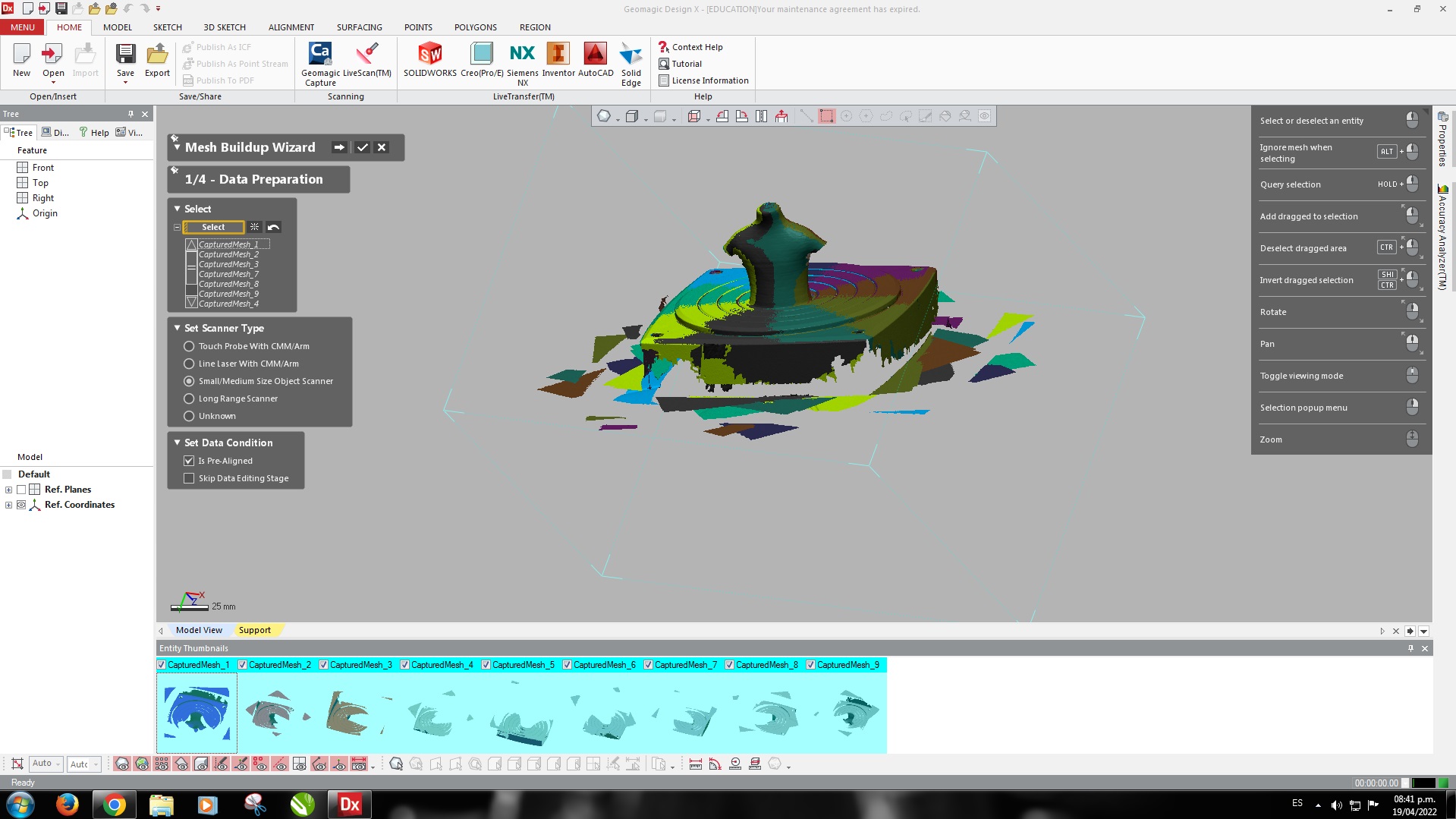

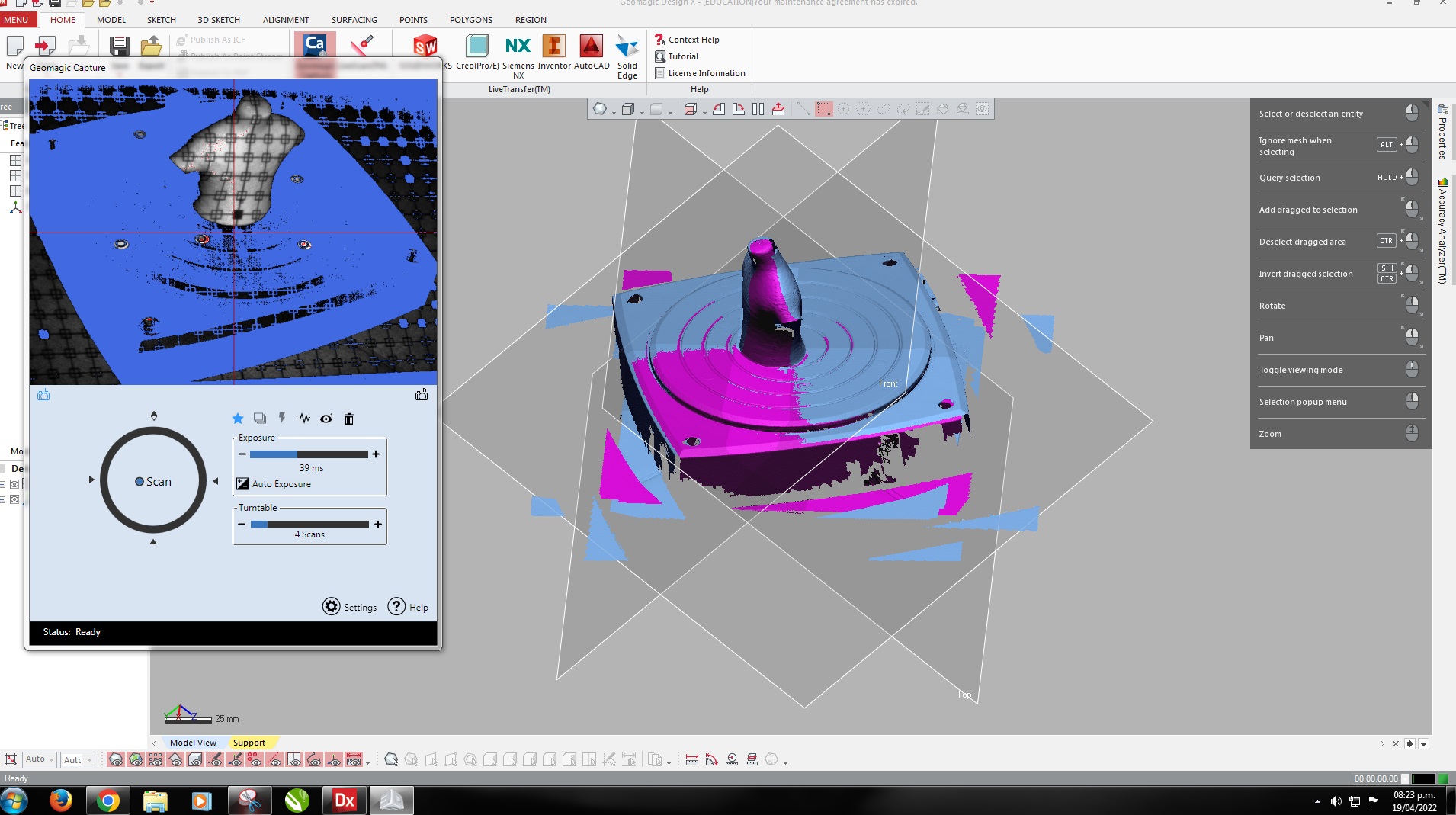

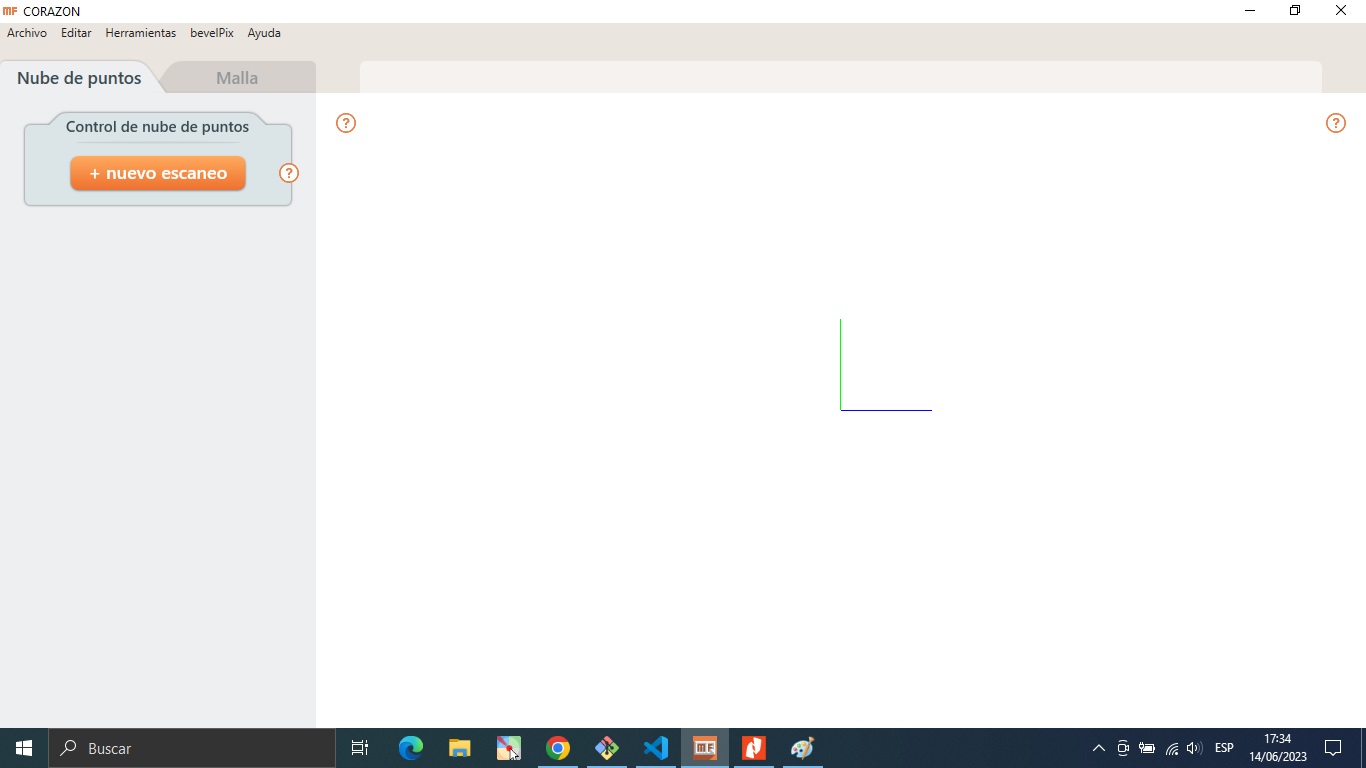

WORKS CARRIED OUT WITH SCANNER¶

During the process, different programming of an object has been carried out to scan and take to 3D to then make a 3D print, a software was used that helps us to carry out the work.