9. Molding and Casting¶

This week I learned about Molding and Casting.

9.0 Assignment of this week¶

9.0.1 Group assignment¶

Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

Extra credit: try other molding and casting processes

9.0.2 Individual assignment¶

Design a mold around the stock and tooling that you’ll be using, mill it (rough cut + three-axis finish cut), and use it to cast parts

Extra credit: use more then two mold parts

9.1 Materials(as group assignment)¶

I checked the MSDS(material safety data sheet)s of the materials which my instructor sent to me and some other casting materials.

9.1.1 Modeling wax¶

MSDS:

Ferris File-A-Wax safety data sheet

Likely a kind of paraffin wax for household products or snow sports. According to the safety data sheet, it seems non-toxic and less hazadous than other materials.

9.1.2 Silicone rubber and cure agent¶

![]()

MSDS:

Shinetsu KE-12 safety data sheet(Japanese)

According to the safety data sheet, the silicone rubber seems relatively low reactive and low irritating. But take care to avoid eye contact or prolonged contact with skin.

But the cure agent is by far toxic and hazadous. Take full care to avoid eye contact or contact with skin.

Ethanol is released during reaction, so keep well ventilated.

9.1.3 Polyurethane resin¶

MSDS:

3M NX-048 safety data sheet(Japanese)

More hazadous and toxic compared with other materials. Take care to avoid eye contact or contact with skin. Avoid using in a place with poor ventilation or possibiity of inhaling vapors.

9.2 Pattern¶

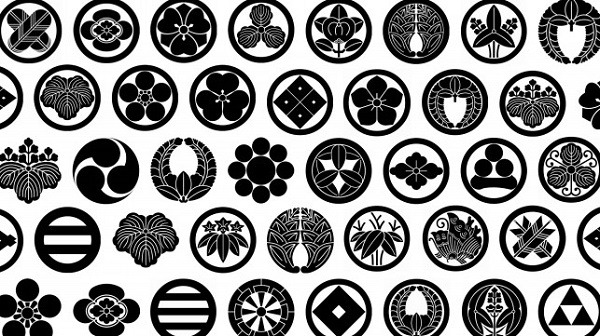

9.2.0 Family crest¶

In ancient Japan, ‘Kamon’(‘family crest’ in English) were widely used(although not so popular nowadays). They indicated identities and roots of families.

My family name ‘Takahashi’(‘high bridge’ in English) is the third popular name in Japan. ‘Kasa’(‘bamboo hat’ in English) was often preferred as the design motif of ‘Kamon’ among ‘Takahashi’ families.

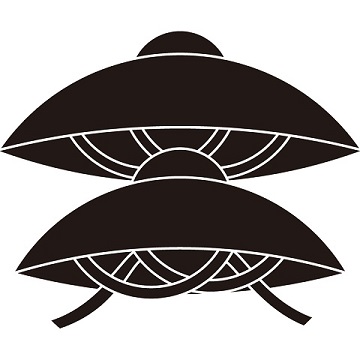

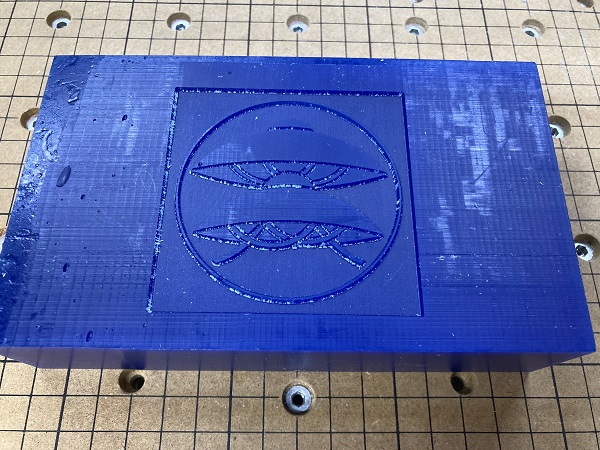

‘Kamon’ of my family is ‘Kasanegasa’(‘stacked bamboo hat’ in English). I chose the design as a milling pattern.

Wide variations of Japanese family crests:

‘Kasanegasa’:

9.2.1 Design of the pattern¶

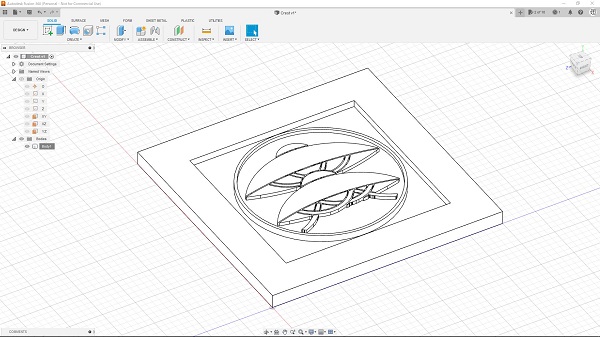

I searched for appropriate images of ‘Kasanegasa’ and downloaded a PNG image. I converted it to a SVG file using ‘trace bitmap’ function of Inkscape, then imported it to Fusion 360 as a 2D schetch.

I extruded the schetch and made a relief like 3D data. It became a milling pattern.

Data files:

nikaigasa-b.svg

Crest.step

Crest.stl

9.3 Milling¶

9.3.1 Facility¶

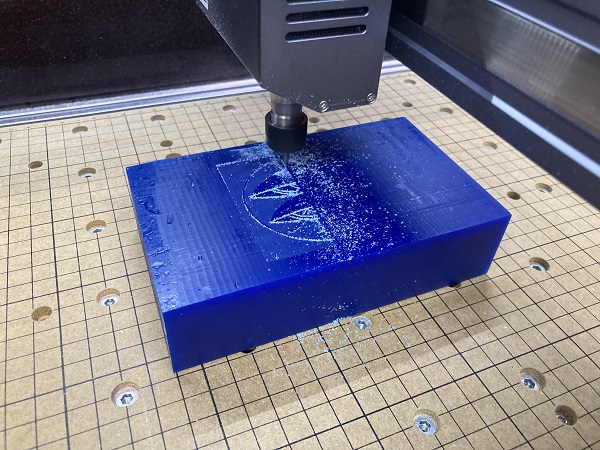

I used ‘Snapmaker 2.0’ for the milling job. The detailed information of the machine are described in Week03 assignment.

9.3.2 Generating G-code¶

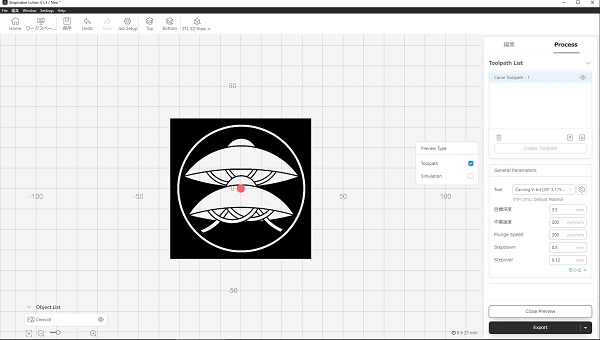

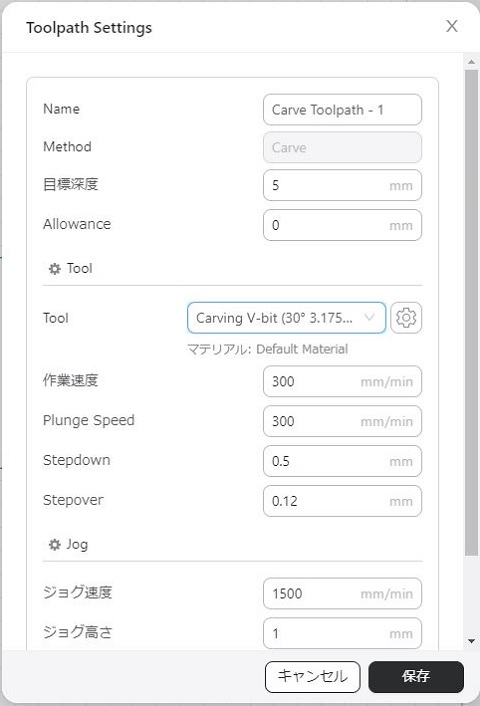

I generated a toolpath for the milling job using Ruban, which was an exclusie software for ‘Snapmaker 2.0’.

G-code file:

Crest.cnc

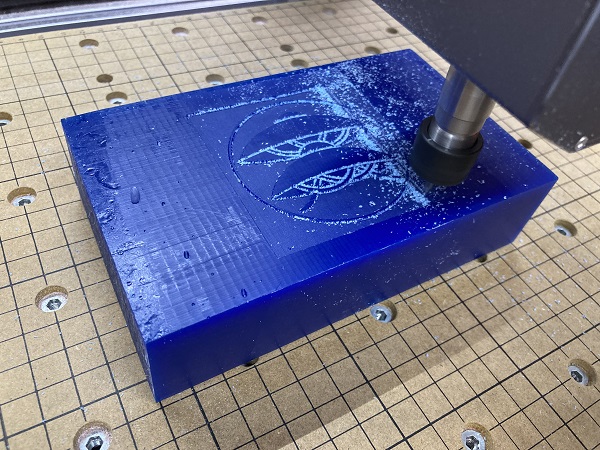

9.3.3 Milling job¶

The milling process took about 6 hours.

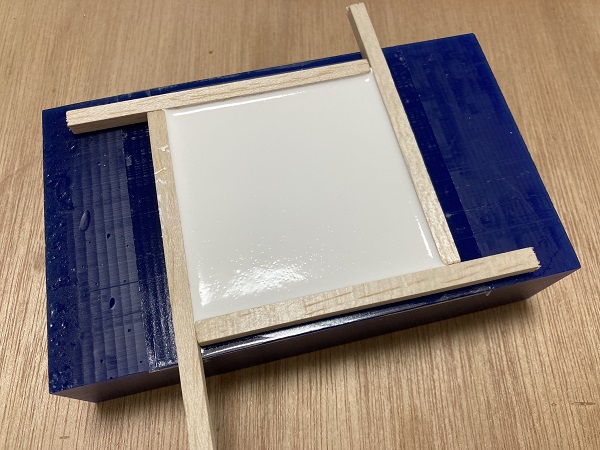

9.4 Molding¶

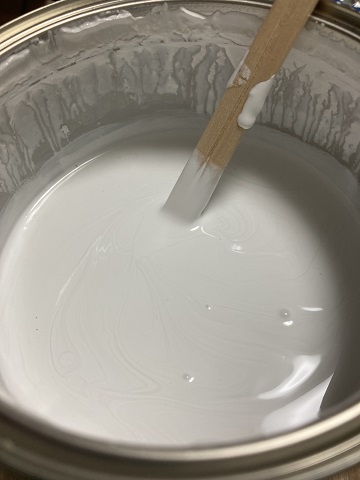

I mixed the silicone dope throughly and then mixed with the curing agent. Mixing ratio of the agent to silione is 0.5 %.

I gently poured the silicone on to the wax mold.

After 24 hours of curing, I released the mold. The silicone was still soft and sticky, so I did it in the water.

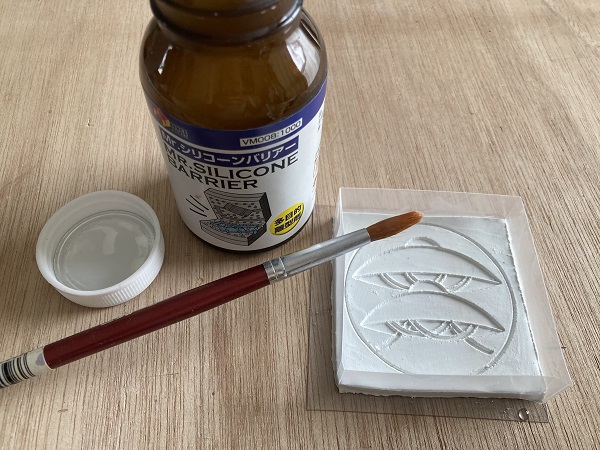

9.5 Casting¶

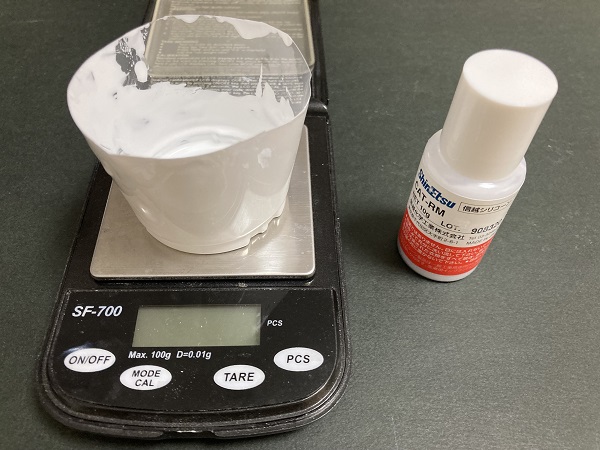

I mixed the liquid A and the liquid B of polyurethane resin. According to the instruction, proper mixture ratio is 1 : 1. So I measured the weight with a digital scale.

Release agent applied on the mold:

Mixed resin poured in the mold:

Resin cured in about half an hour. The parts could be released from the molds easily, because the molds were elastic.

I coated the upper surface of the parts with satin black paint.

Then I removed the coat partly to highlight the mold.

9.6 Conclusion¶

I learned a very basic of Molding and Casting this week.