10. Molding and casting¶

Assignment¶

group assignment:

review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of themindividual assignment:

design a mold around the stock and tooling that you’ll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts

- Linked to the group assignment page and reflected on your individual page what you have learned

- Reviewed the safety data sheets for each of your molding and casting materials, then made and compared test casts with each of them

- Documented how you designed your 3D mould and created your rough and finish toolpaths for machining, including machine settings

- Shown how you made your mould and cast the parts

- Described problems and how you fixed them

- Included your design files and ‘hero shot’ of the mould and the final object

Review¶

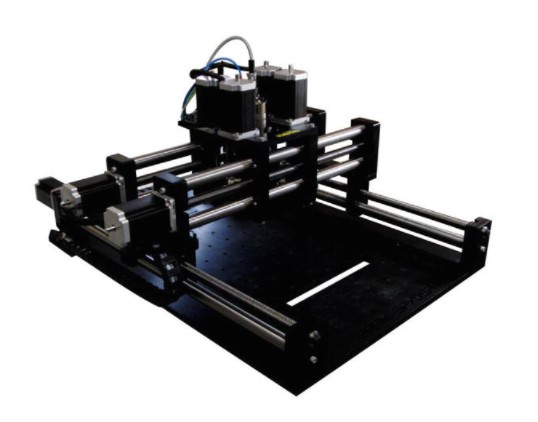

APSX machine

The APSX-PIM: is an automatic plastic injection molding machine that makes injection molding affordable and easy

CNC Swiss Lathe:

NANO CNC Swiss Lathe: It is a precise and rigid CNC Swiss Lathe that can machine metals, and plastics. 6950 dolares. Made in the USA Aluminium machining videoCNC Milling Machine: High precision, rigid and portable CNC machine that can cut metals, plastics and wood.

APSX SPYDER CNC Machine: can machine ALUMINUM, STEEL, BRONZE, BRASS, DELRIN (ACETAL), WOOD and other material with high precision.

It is powered by the SPYDER CNC control software. 6750 dolares. Made in the USA

Materials¶

Machinable wax:

Machinable wax is an extremely hard wax that has been formulated to deliver exceptional machining properties including high resolution detail.

Since it is harder and has a higher melting temperature than most other waxes, machinable wax can be machined, cut, or shaped using standard metalworking or woodworking equipment. High quality surface detail and dimensional accuracy are possible.

* Machinable wax is ideal for verifying CNC machining programs.

* Machinable wax is often used for precision lost wax casting.

* Machinable Wax is available in both blocks and cylinders. We stock the most commonly requested sizes and can usually provide alternate sizes on request.

Typical applications include:

- Prototyping

- Dental CAD/CAM

- Jewelry Manufacturing

- Precision Lost Wax Casting

- Used as a bolus/compensator for electron or proton therapy

- Mold making

- Manufacture of turbines and pump impellers

Machinable wax offers distinct advantages over other prototyping materials for some applications.

The product is environmentally friendly and the shavings produce no harmful dust or hazardous odors.

The material is self-lubricating and easy on tooling.

Machinable Wax Can Be Recycled

The shavings and unused pieces of material can be re-melted and formed back into useable material. This attribute can substantially reduce the cost of using machinable wax over other material.

Resin:

Resin: are hydrocarbon secretions of many plants, particularly coniferous trees.

In polymer chemistry and materials science, resin is a solid or highly viscous substance of plant or synthetic origin that is typically convertible into polymers More information

Synthetic-type resins or plastic resins are a material that has similar properties to natural resins (a viscous liquid capable of permanently hardening) but very different in chemical structure. The chemical structure of plastic resins are polymers (macromolecules), made of monomers or low molecular weight chemical compounds that through a process called polymerization are grouped together forming a new compound: the polymer.

More important Types:

* Polyethylenes

* Polypropylenes

* Polystyrenes

* PET and

* PVC resins

Polyethylene resins are thermoplastic polymers. Polyethylene one of the simplest polymers. It is produced from ethylene derived from oil or gas and depending on the manufacturing process, there are different varieties: High Density Polyethylene (HDPE), Low Density Polyethylene (LDPE) and Polyethylene. Linear Low Density PolyEthylene (LLDPE)

Polypropylene is a hydrocarbon that belongs to the polyolefin family and is produced from the polymerization of Propylene. Its molecular structure consists of a methyl group (CH3) attached to a vinyl group (CH2). Polypropylene can also be copolymerized with ethylene to form random copolymers (for greater transparency and gloss) and impact copolymers (impact and low temperature resistance). It is a very heat resistant material although it is not very flexible.

Polypropylene is one of the plastic resins whose production impacts the environment to a lesser degree as it is 100% recyclable.

Polystyrene is a polymer resulting from the organic synthesis between ethylene and benzene through a polymerization process. This plastic resin is widely used depending on its form of transformation, whether it is extrusion, blown extrusion, or injection molding.

PET resins are the best known thermoplastic polyester. Chemically, PET is a polymer obtained through a polycondensation reaction between terephthalic acid and ethylene glycol. This material has a low crystallization rate and can be found in an amorphous-transparent or crystalline state.

The physical properties of PET and its versatility have been the reasons why its production has increased notably in the manufacture of textile fibers, but it is thanks to its impermeability and the fact that it acts as a barrier to gases such as CO2 and O2. that its use has skyrocketed in the production of a wide variety of containers, especially bottles, trays, strips and sheets. It is also an easily recyclable material.

Polyvinyl chloride, better known as PVC, is one of the best known and most used plastic resins. In its composition are present: carbon and hydrogen in the form of ethylene, derived from oil or gas, and chlorine. The virgin resin is mixed with specific additives to obtain the required properties: flexibility, transparency, texture or color.

PVC is fully recyclable and has low flammability, which gives it significant added value compared to most plastic resins. It is also thermal insulator. There is a Resin Identification Code which is an international system used in the industrial sector to differentiate the composition of resins in plastic products for daily use. It is made up of seven numbers that classify the different types of plastics and mark their level of toxicity and whether they can be easily recycled.

The numbers are integrated into the Möbius triangle (universal recycling symbol). Thus, 1 (PET) and 7 indicate that it should be used with caution in its recycling. The 2 (HDPE), 4 (LDPE) and 5 (polypropylene) indicate that it is a safe material. While 3 (PVC) and 6 (polyester) are designated as harmful material.

What about the rubber, silicone and latex ?¶

Rubber

Rubber is an elastic polymer, arising as a milky emulsion (known as latex) in the sap of various plants, but it can also be produced synthetically. The main commercial source of latex is Euphorbiaceae, of the genus Hevea, such as Hevea brasiliensis.

Silicone:

A silicone or polysiloxane is a polymer made up of siloxane (−R2Si−O−SiR2−, where R = organic group). They are typically colorless oils or rubber-like substances. Silicones are used in sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include silicone oil, silicone grease, silicone rubber, silicone resin, and silicone caulk

Latex:

Natural latex is a colloidal aqueous suspension composed of some fats, waxes and various gummy resins obtained from the cytoplasm of the laticiferous cells present in some angiosperm plants and fungi.1 It is frequently white, although it can also have orange, reddish or yellowish tones. depending on the species, and milky in appearance.2

The latex is different from:

Latex is the most elastic material known. In no case should latex be confused with other substances such as rubber, resin or vegetable gums, since the fact that they have similar chemical compositions, appearance and functions does not mean that they are the same compound.

Rubber or rubber (hydrocarbon with formula C5H8) is a natural substance (although there is a synthetic variety obtained from unsaturated hydrocarbons) characterized by its insolubility in water, its electrical resistance and its elasticity, which is in the form of a colloidal suspension in the latex. Due to its multiple commercial applications (tires, waterproof clothing and certain adhesive products are made of this substance), latex is extracted from the producing plants in order to obtain the rubber particles that are dispersed in it.

Natural resins encompass a group of substances with different chemical compositions, although generally all of them have carbon, hydrogen and oxygen. These flow from the wounds of the producing plants, preventing the entry of pathogenic organisms into the plant and the excessive loss of sap.

Finally, plant gums are a gelatinous substance that is exuded by some plant species, which is composed of acids complex organics and various salts (for example, gum arabic is made up of calcium, potassium and magnesium salts of arabin). Colorless and odorless, the gums have a glue-like texture when wet or moist (they are very soluble in water, unlike latex).

Design a mold¶

I saw some tutorials to create machinable wax and the majority of recommendations towards protection, such as the use of nitrile gloves, goggles and a fire extinguisher and we must be in a well ventilated place

Tutorial for to do machinable wax

The tools used in the tutorial are: a scale, a pot, a heater (the casting temperature should be around 150 degrees Celsius) and silicone containers as a mold.

The necessary elements:

- Paraffin

- Supply material: HDPE (high density polyethylene) LDPE (Low density polyethylene), plastic bags, plastic caps, shampoo bottles

- Proportion: 4/1 (25 grams of caps and 100 grams of paraffin)

Our machinable wix¶

We manufacture our own machinable wax to make the positive mold. We use paraffin 2 parts / low density polyethylene granules 1 part

Preparation of the mechanizable wax with our instructors Silvia and Abdon

Items:

1- Paraffin

2- Polyethylene

3- A pot that will no longer be used

4- A heater

The steps are:

1- Heat the paraffin until it becomes liquid

2- Add the polyethylene and mix until it dissolves in the paraffin

3- Add colored crayons if we want to give some color

4- Place in prefabricated molds (they can be made of wood like the ones we make, securing them with sticky tape)

5- Let cool

For the making of the laser cut wooden mold we use a program makercase suggested by the local instructor Silvia

The result¶

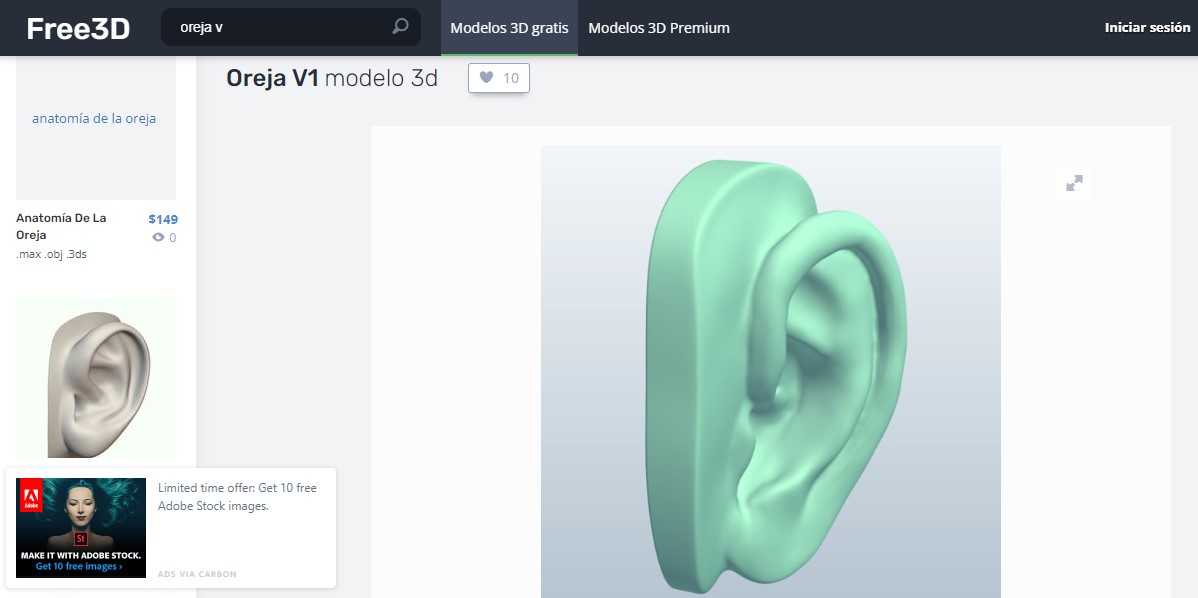

For the positive mold I chose an ear already designed online.

I exported the design in stl format to the program called SRP of the Roland CNC machine

I get it of internet here but is better here you don’t need register

I export it in .obj file extension then changed it to .stl file extension

3D model. STL

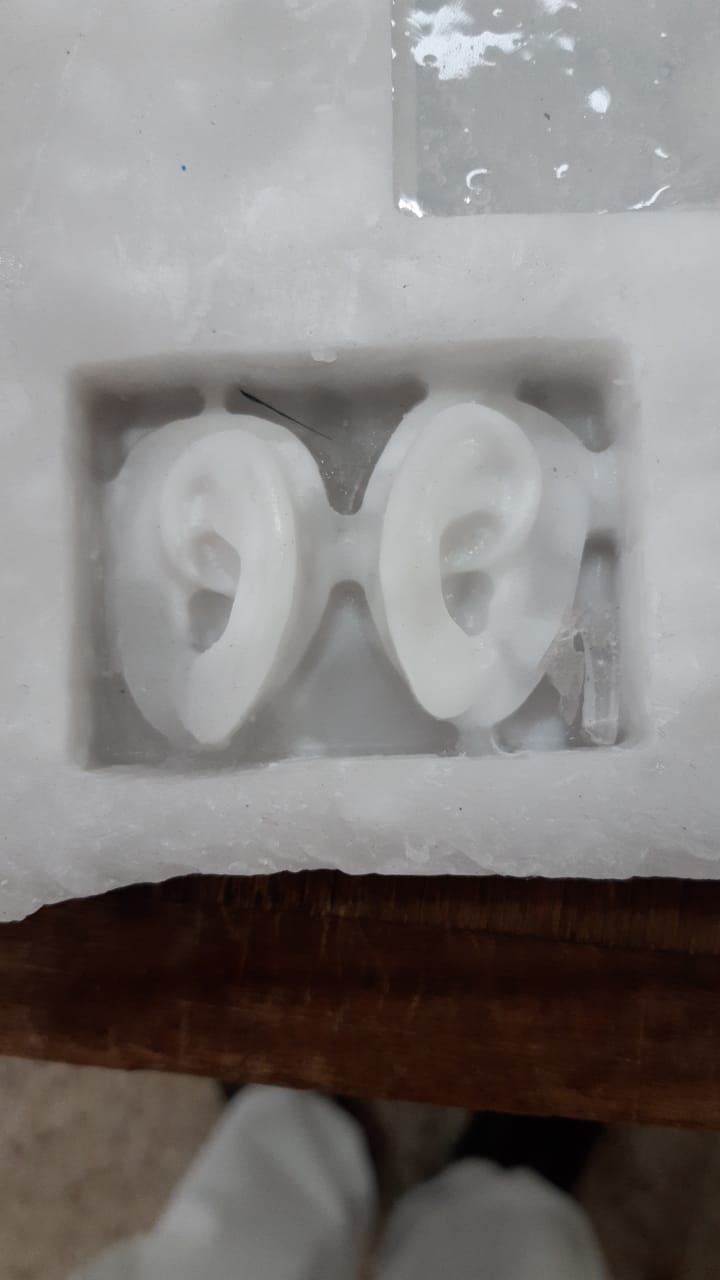

Wix in position

I secured the machinable wax with wood and screws so it stays put during the process

Wix machining

I configured a single Rough toolpath using a 1/8 inch Square mill

The first result was bad, the surface of the wax block was very irregular and the Z calculation was not correct and I ended up drilling the block

Then got good result

I preper the sylicone Material for that:

![]()

You must to mezclar 1/2 and 1/2 and then:

Sylicon in wix mold

![]()

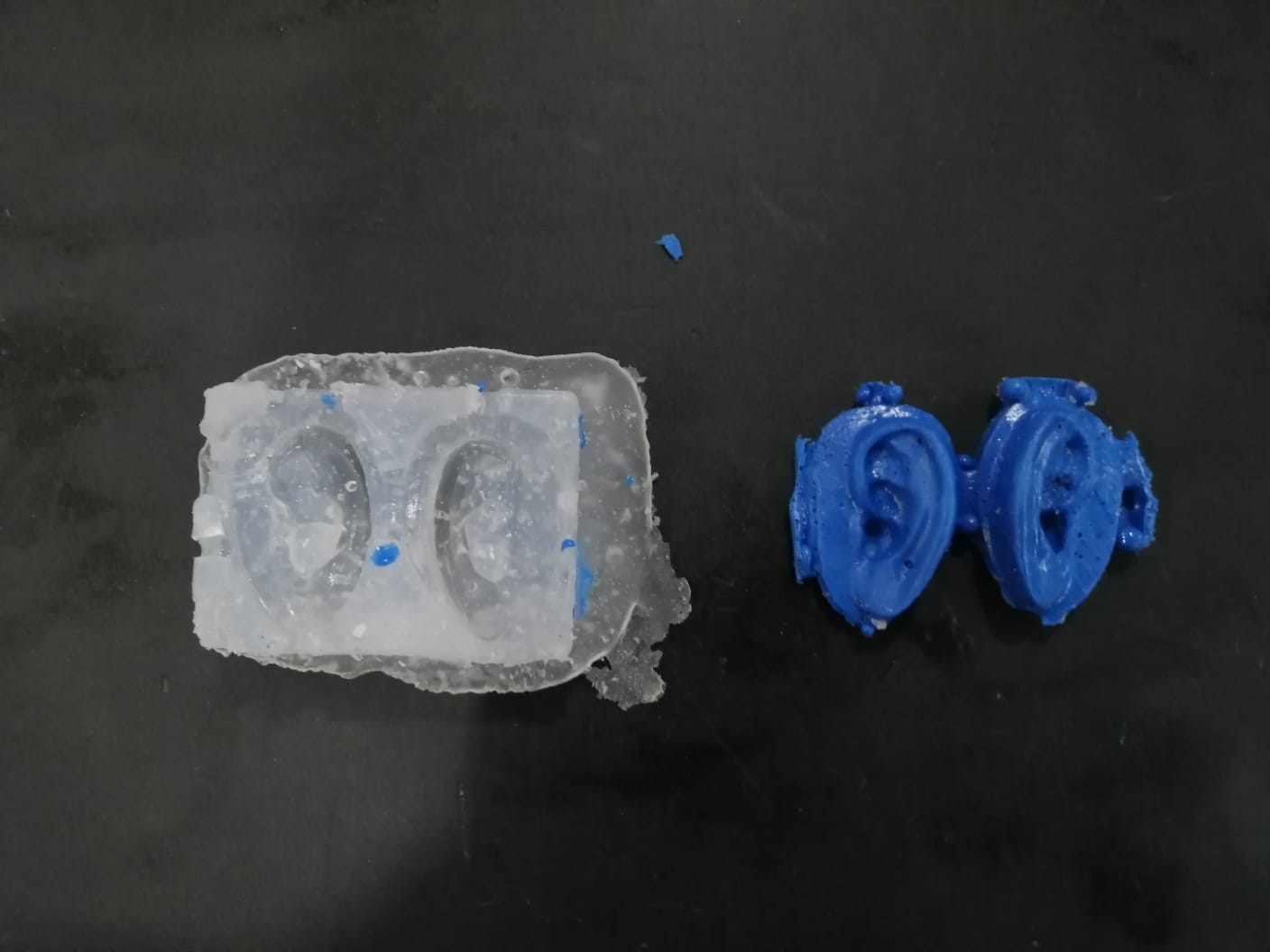

Result of the sylicon mold

Liquid plastic material

Liquid plastic in sylicon mold

Final Result