16. Wildcard Week¶

During the month of may, there are a lot of day-offs, and it is a bit difficult to run machines such as waterjet cutting. In my school, this is the rush for the engineering students for the last study projects. So I try to manage fabacademy but I have to be availabe for them. What a challenge…

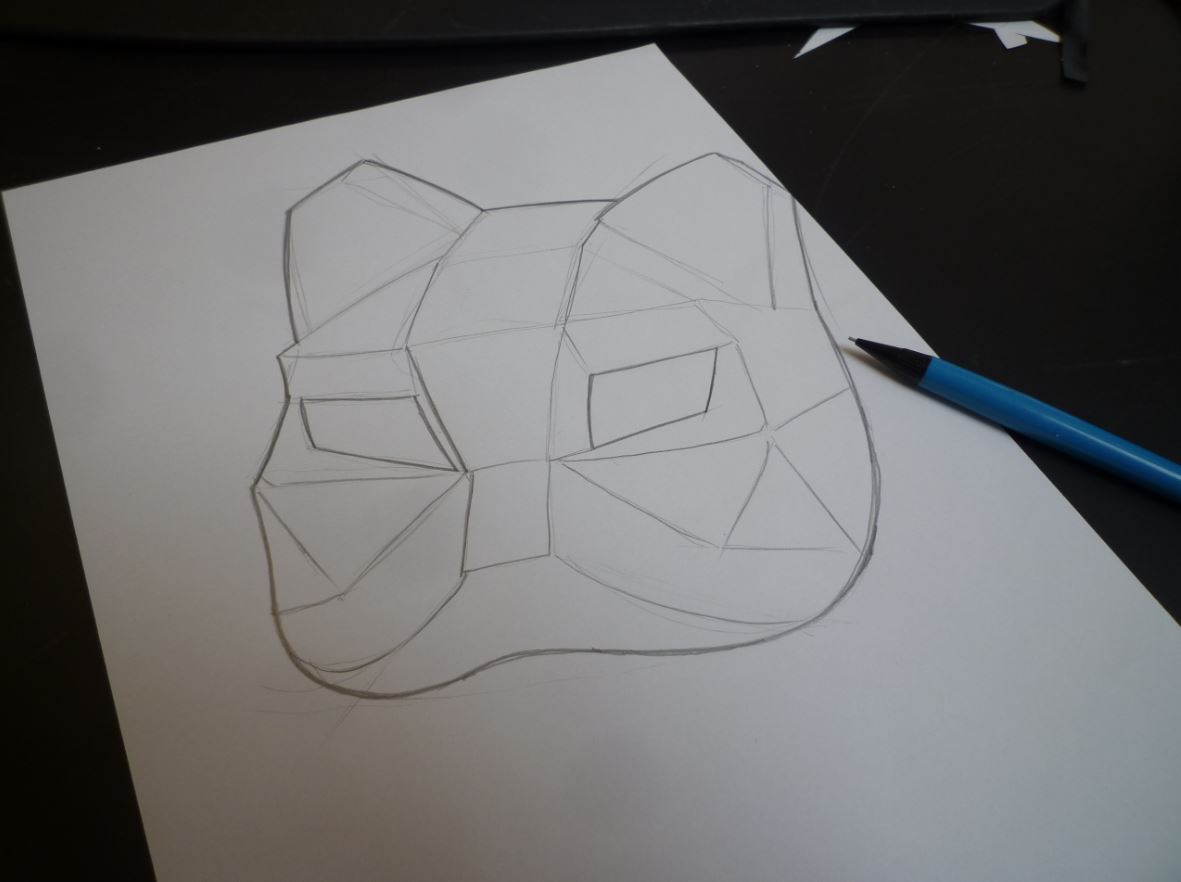

the project: cat mask¶

I wanted to make a cat face to my final project.

That was a workshop I made for kids couple of years ago.

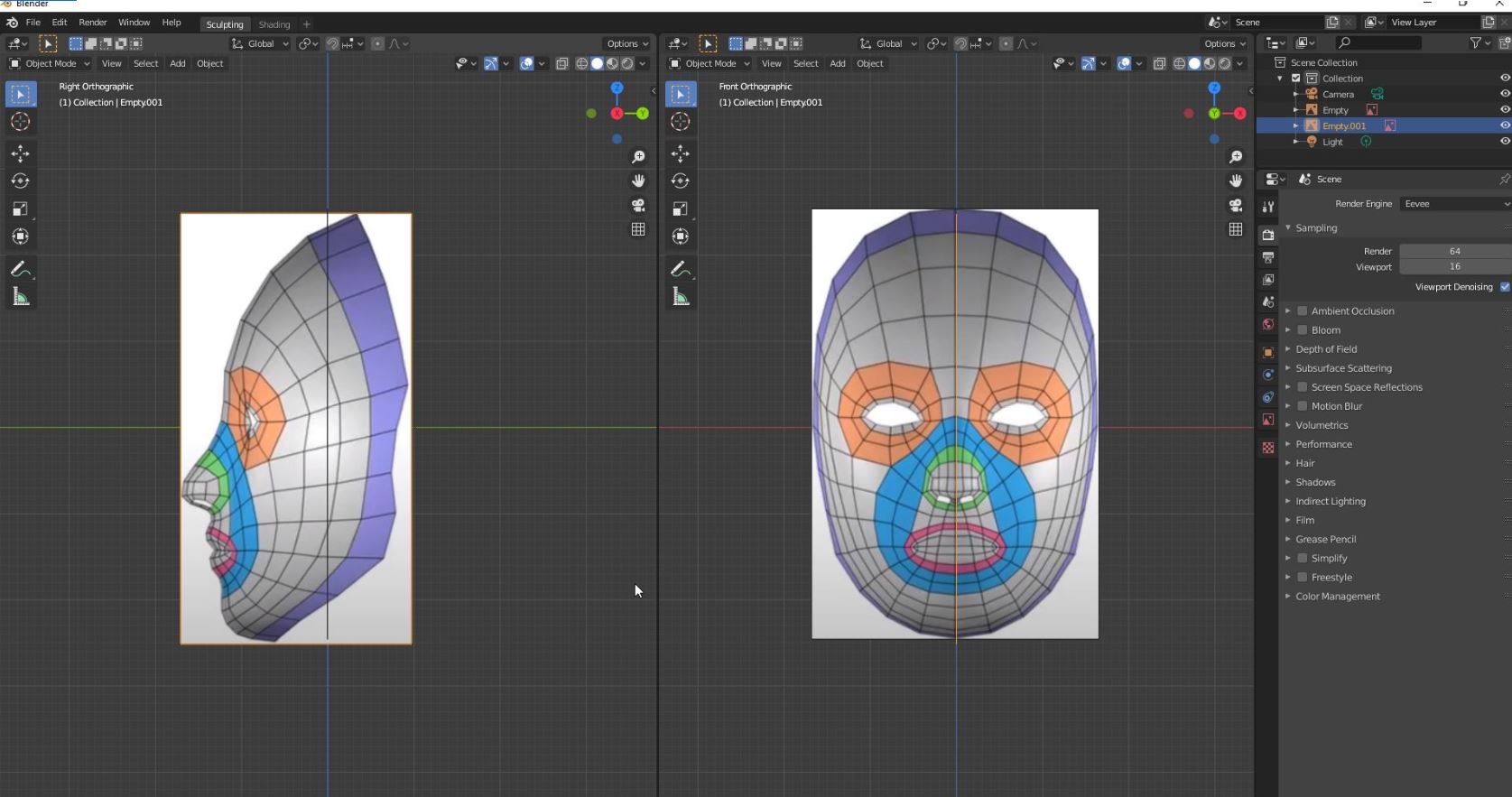

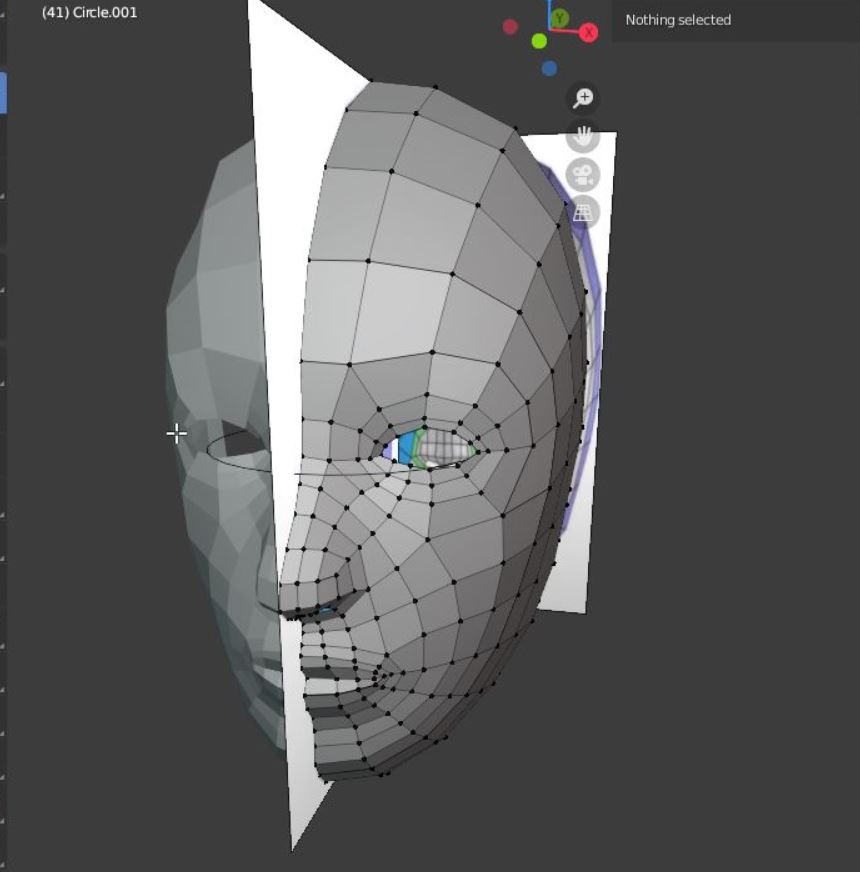

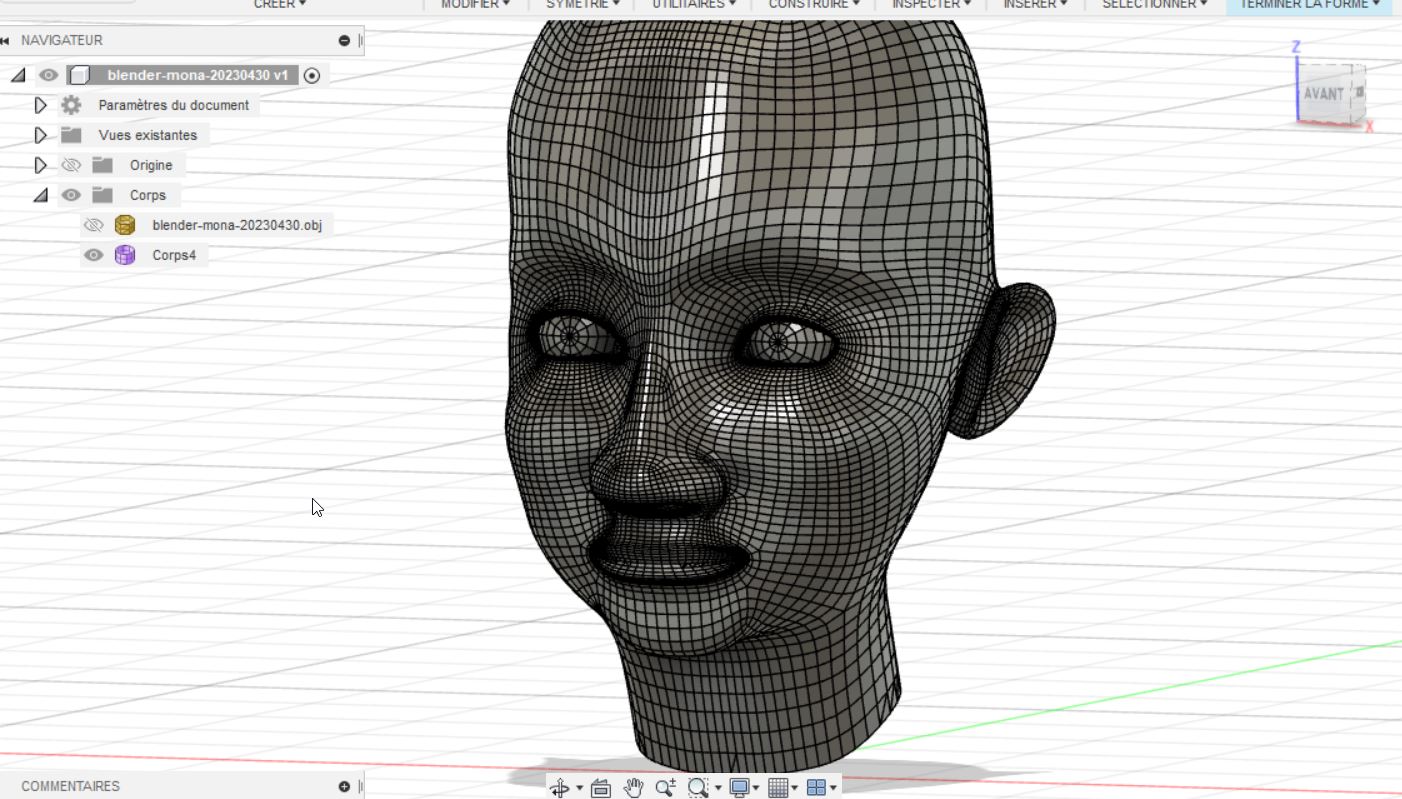

modeling Blender¶

It was my first time on blender, and I follow a tutorial to make a face.

I have followed the tutorial from fabacademy about unwrapping but it missed some details for beginners. I will continue after that by following a tutorial from blenderguru on youtube. That could be an opportunity to perform this fabacademy tutorial.

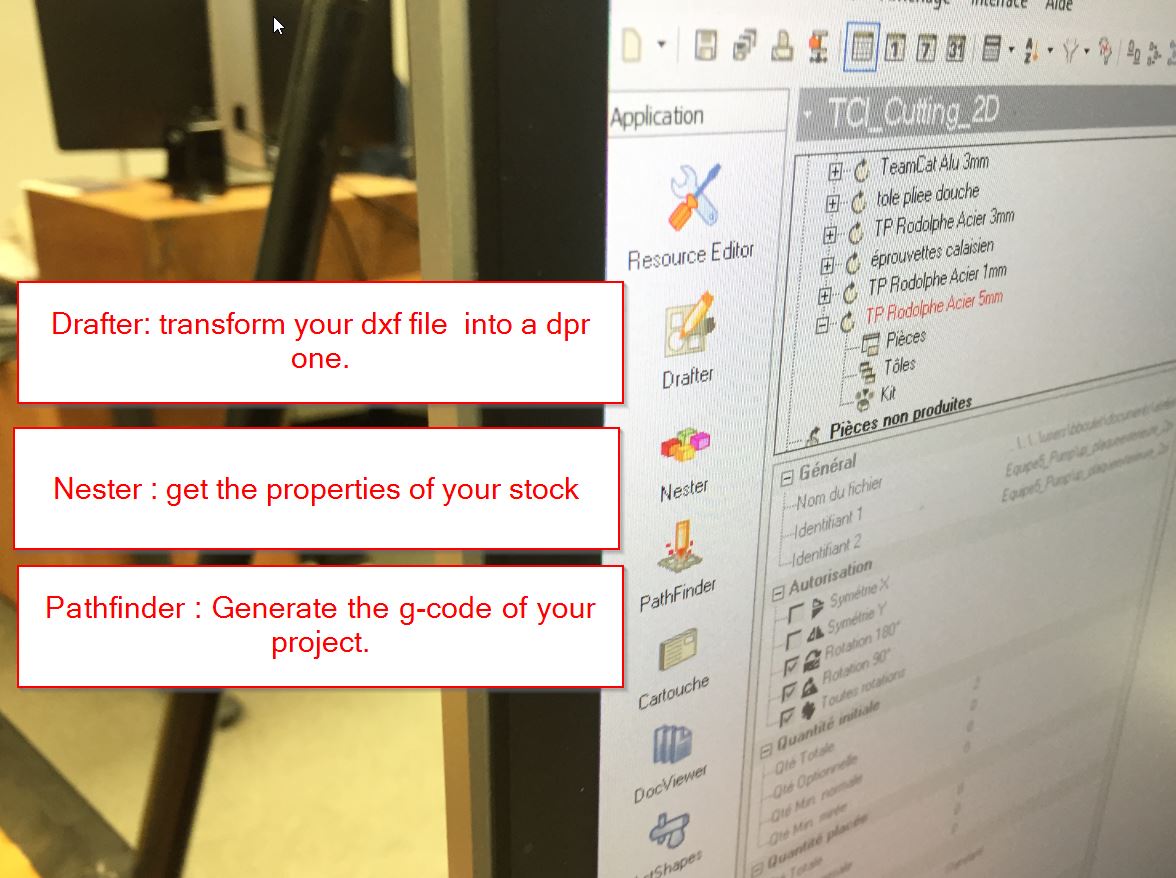

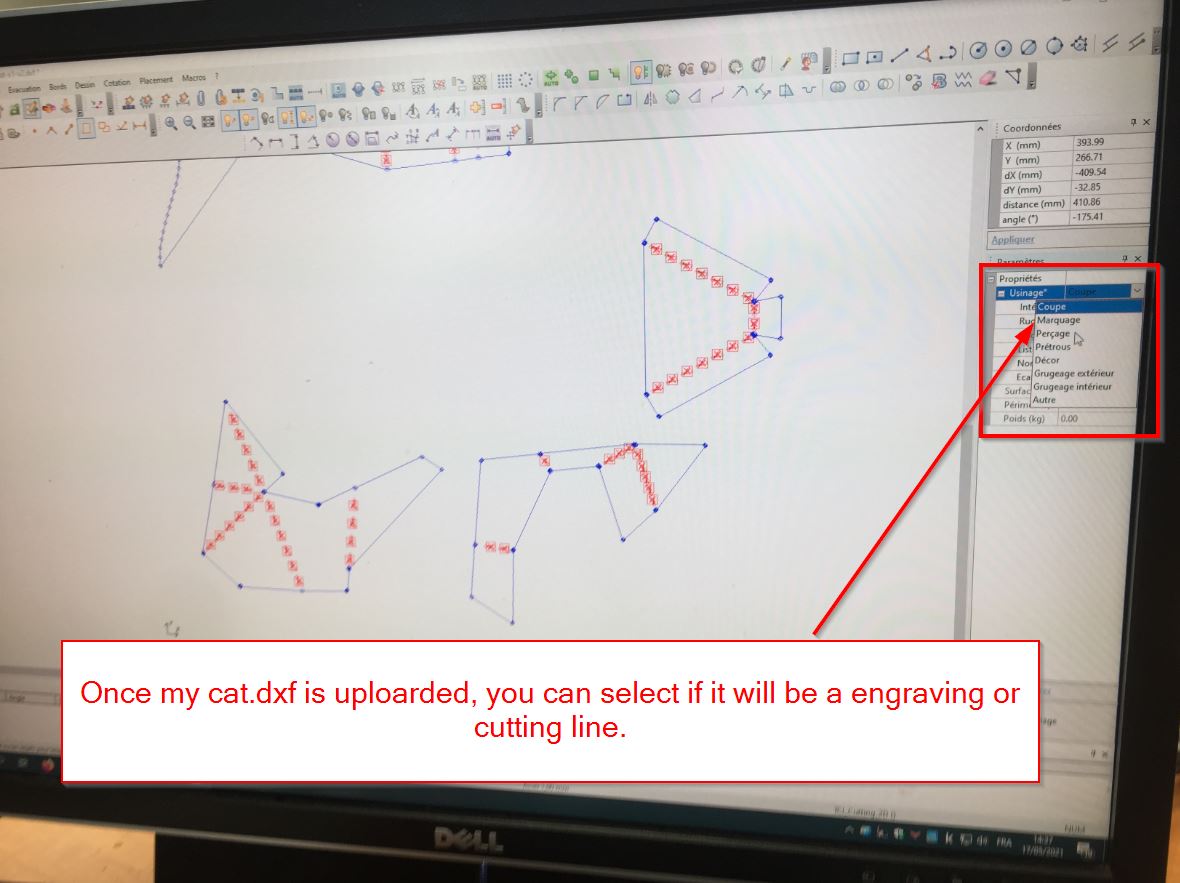

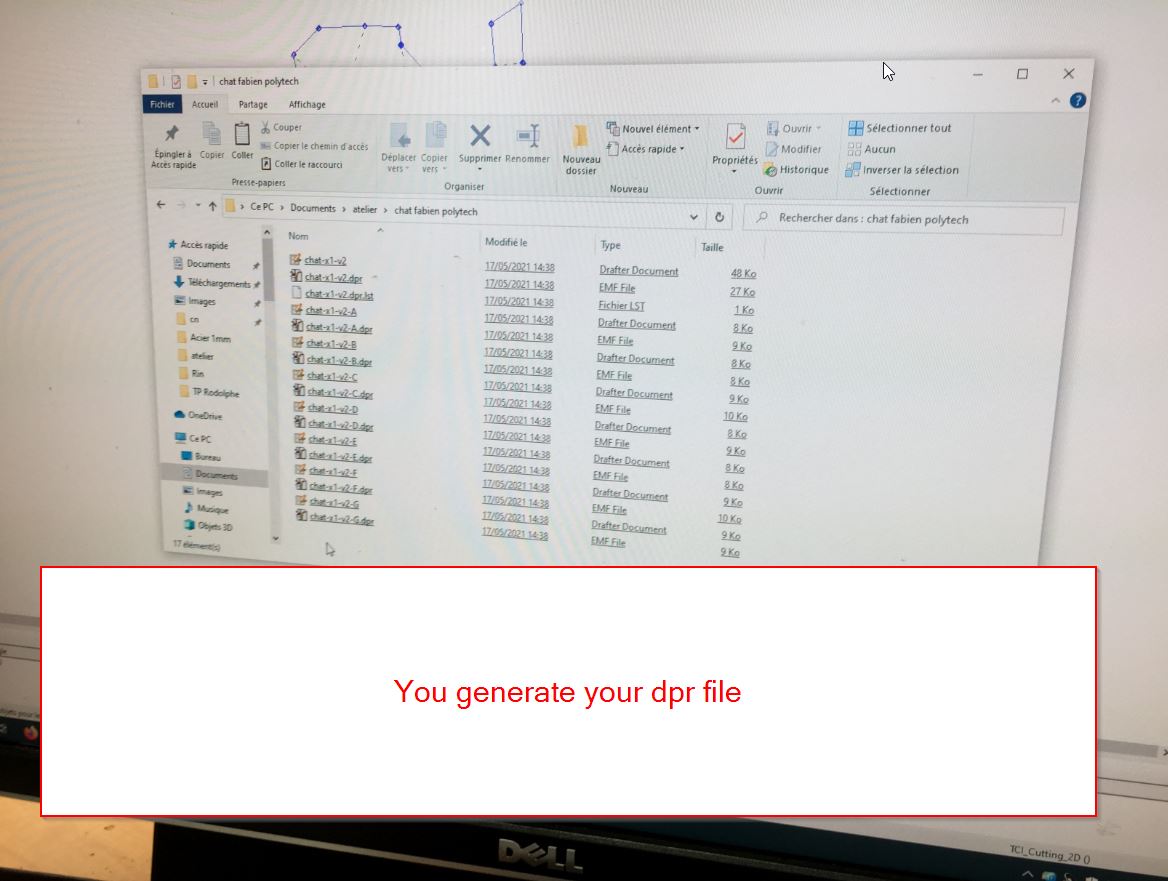

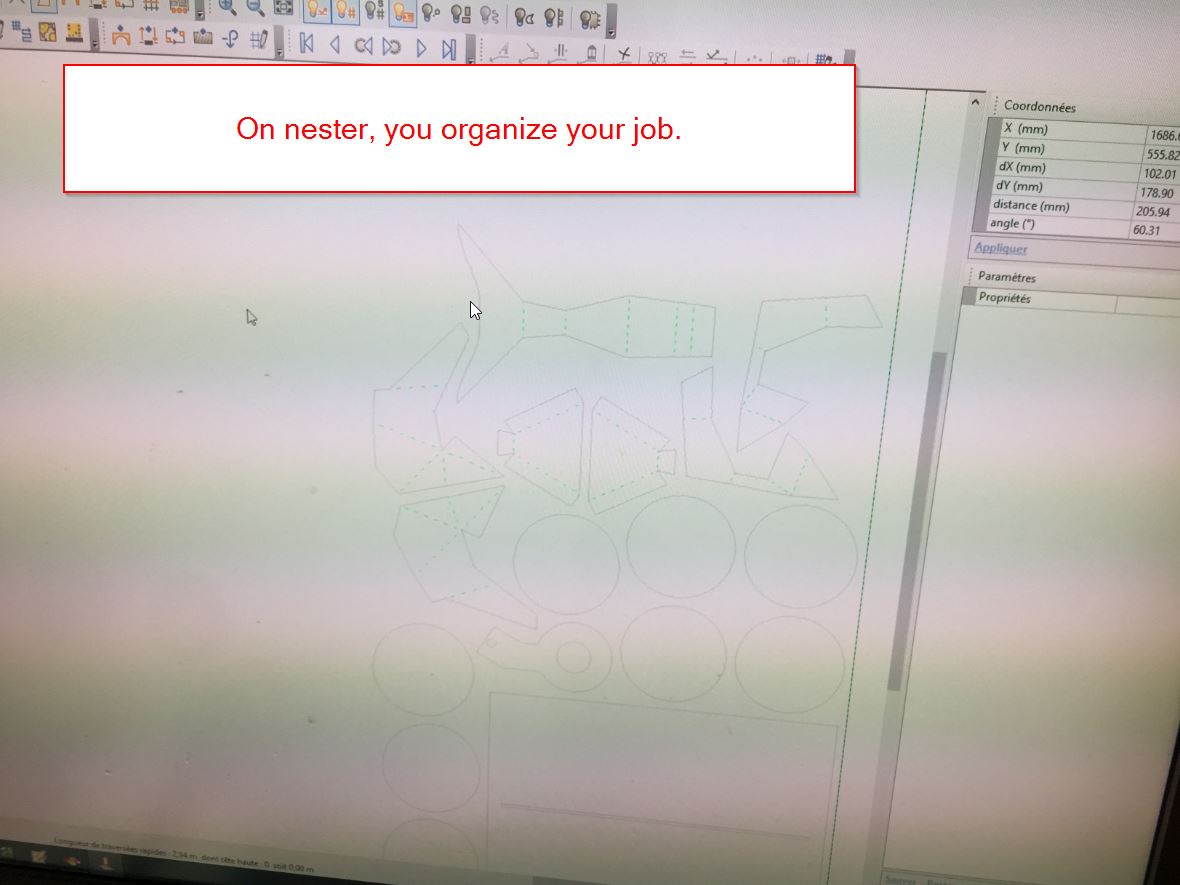

ACTCUT¶

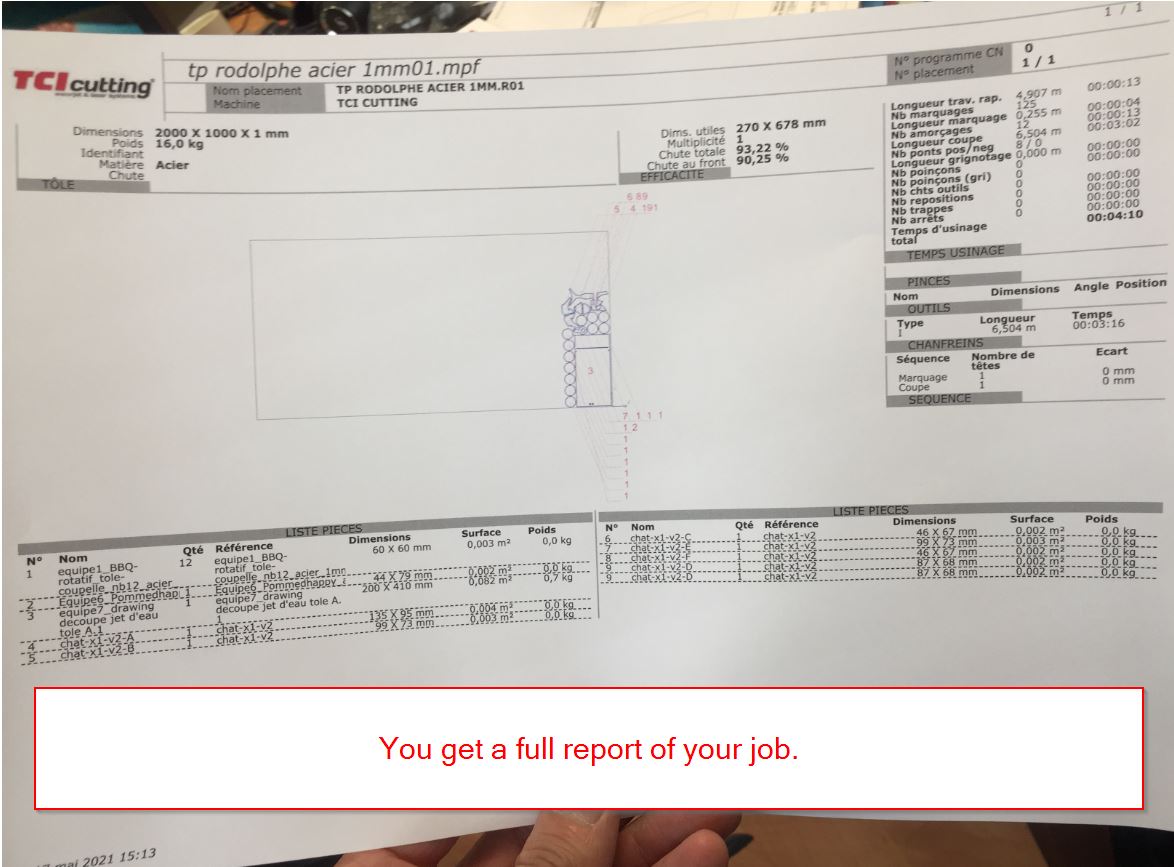

This is the software to prepare your files and send the tool paths to the waterjet machine. It looks like v-carve pro for shopbot or the jobcontrol from trotec.

Here comes the preview of the job.

You get a report from actcut.

TCI cutting - waterjet - BPH-3015¶

|max. thickness of the part |200mm| l|Maximum permitted load | 790kg/m2 |Number of cutting heads| 1 to 4| |Maximum number of bridges| 4| |Simultaneous max positioning speed| 85m/min| |Maxium cutting speed | 20m/min| |Machine tolerance acording to VDI / DGQ 3441| ± 0,05| |Repetition accuracy| ± 0,025mm| |Dimensions | 3000x1500x500 mm |

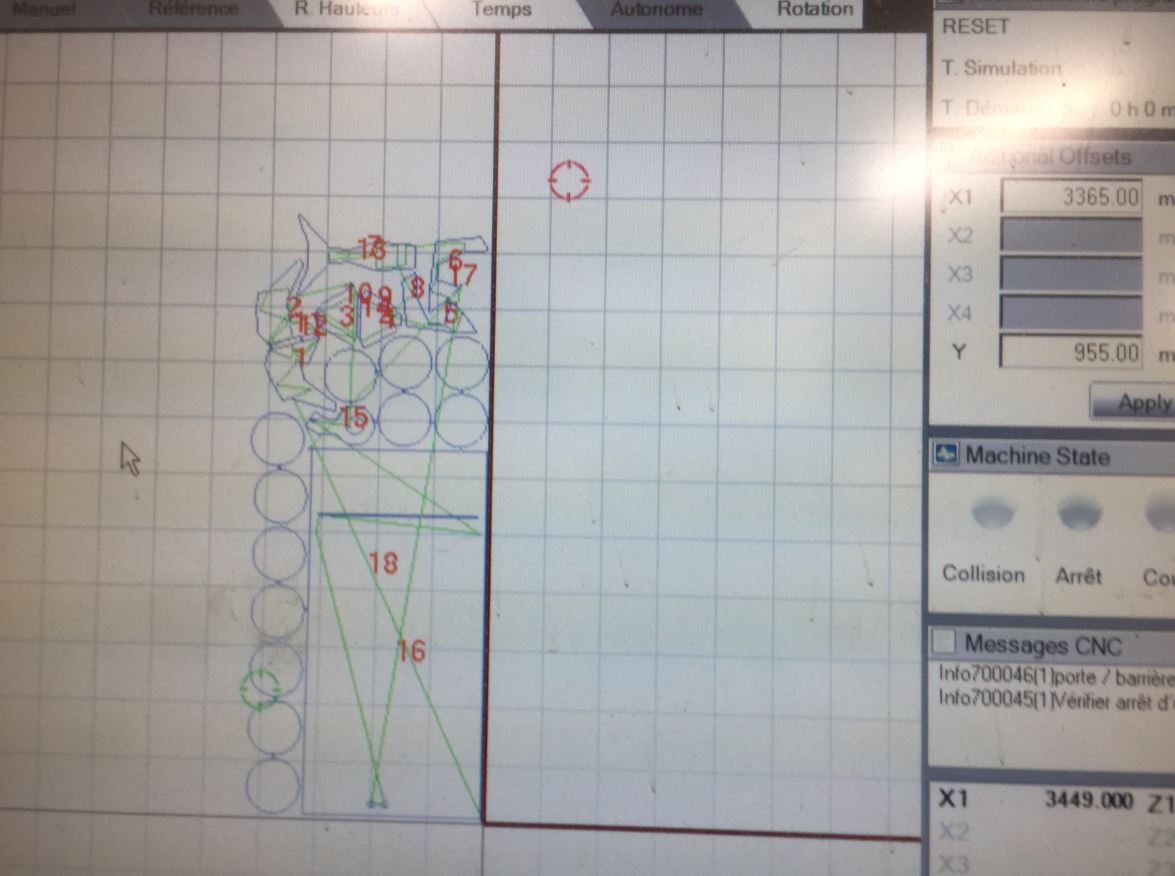

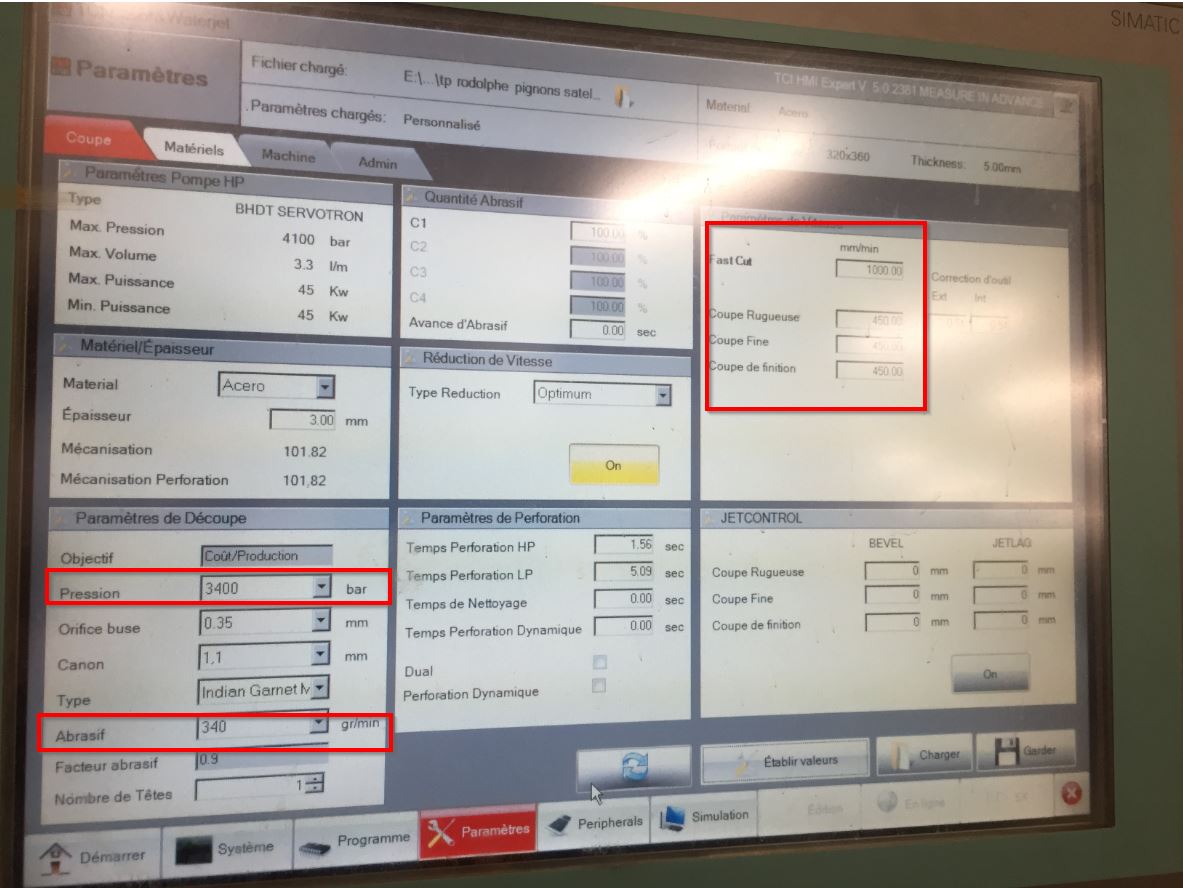

Here comes the pilot monitor.

The machine is surrounded by

In order to get 3400bars pressure, the waterjet has a pressure system:¶

The flux composed by sand and water is filtered:¶

First, the water and sand are going to this big bag.

waterjet-recovering sand system

After that, the water is going to this filter. Waterjet - 00- water filters.

waterjetting.¶

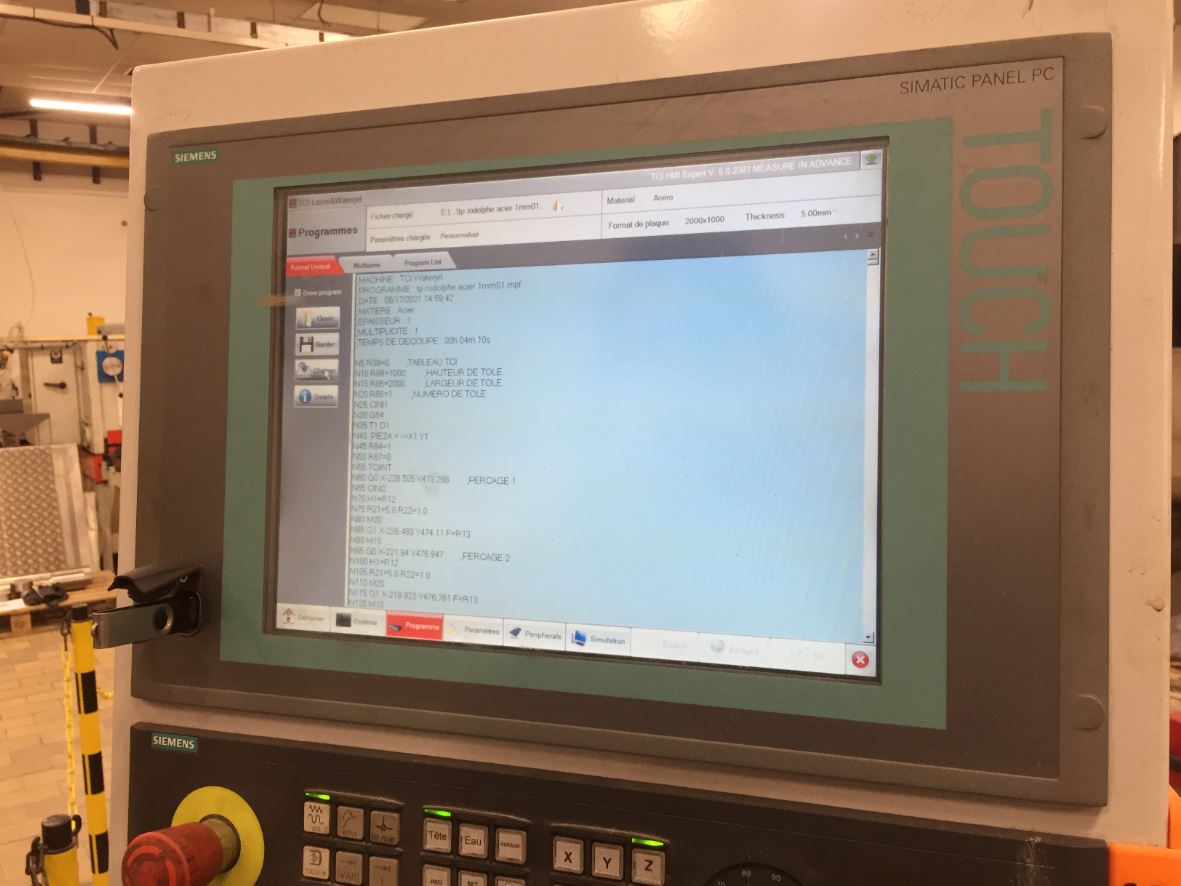

The program is loaded to the machine.

It looks like shopbot environment.

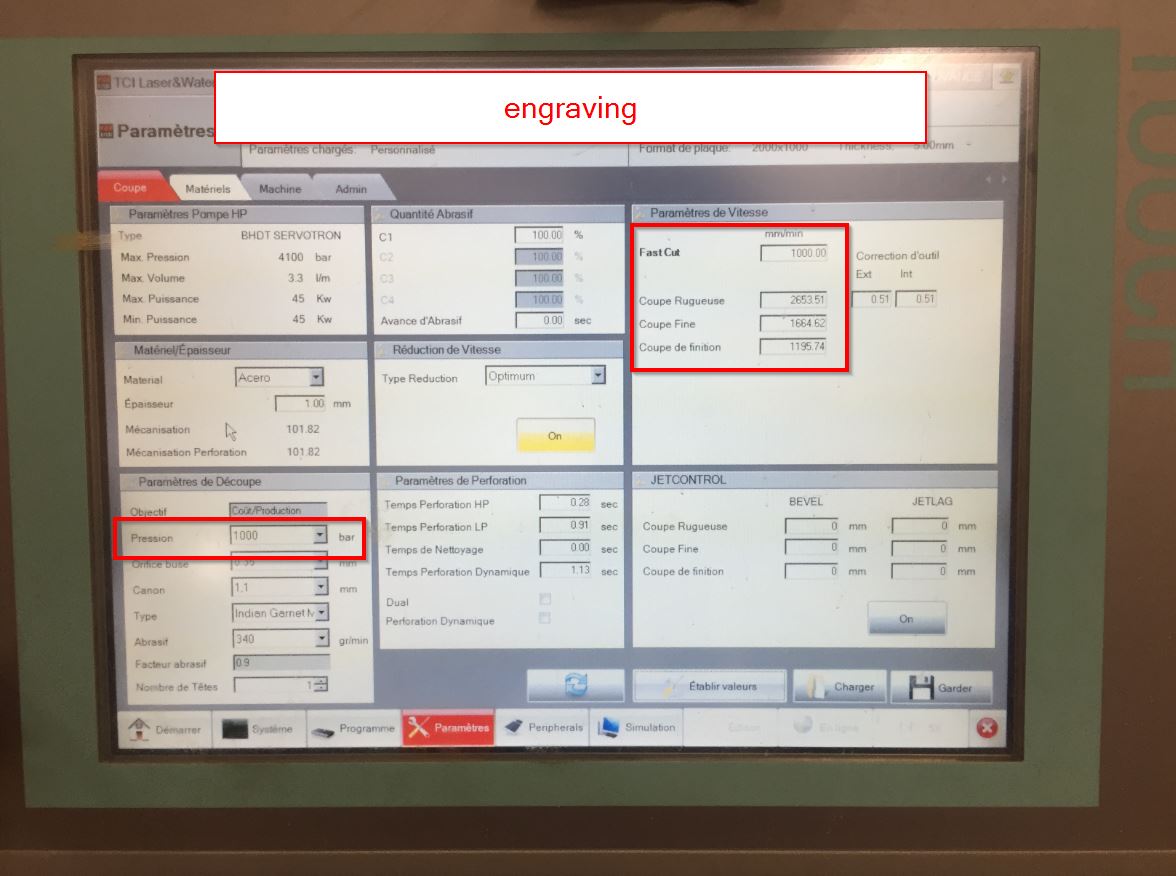

You send your pressure and sanding measurement.

The technician gave a value for engraving, so I tried before lauching the main program.

-waterjet-04- interface during ongoing program

-waterjet-05-on-going

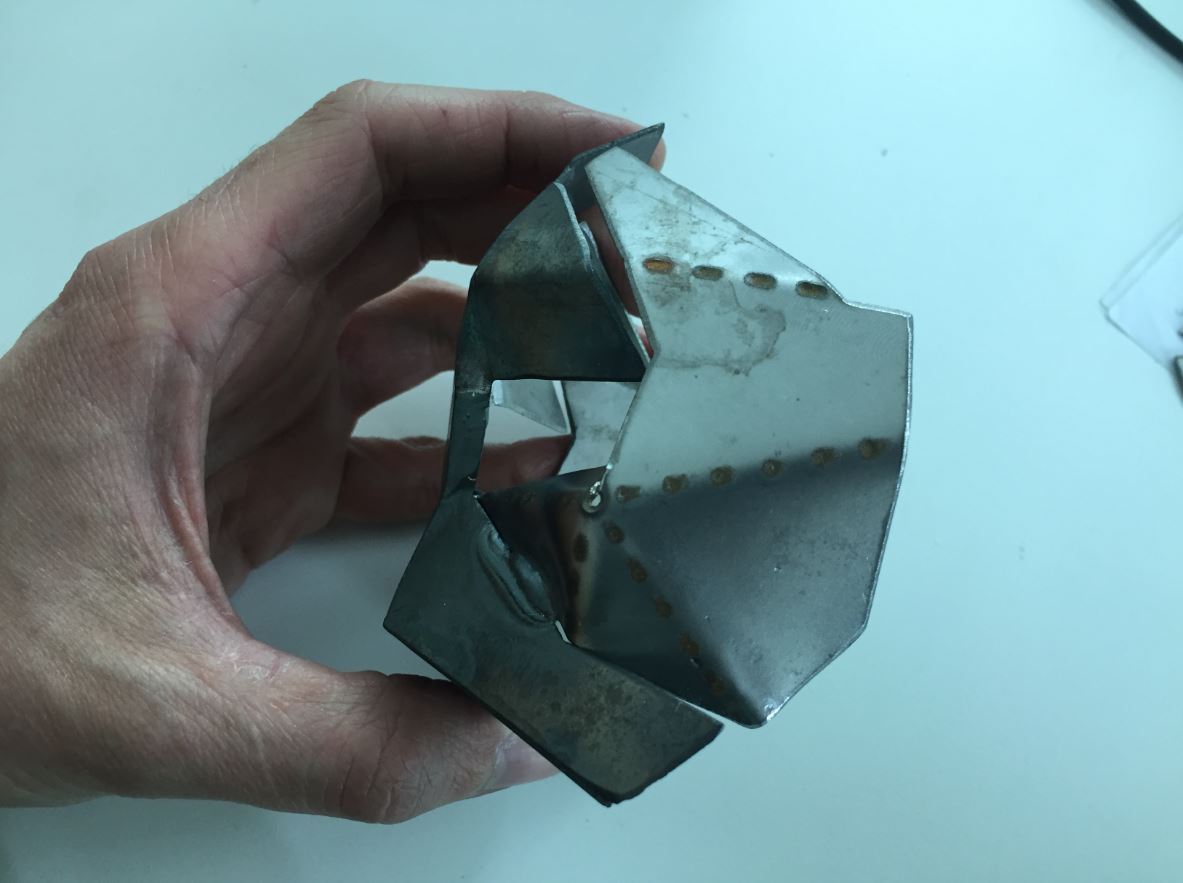

After 15minutes I got my parts:

Cleaning the sheet before next job.

-waterjet-06 cleaning after sanding

Grinding¶

09-Grinding

09-Grinding

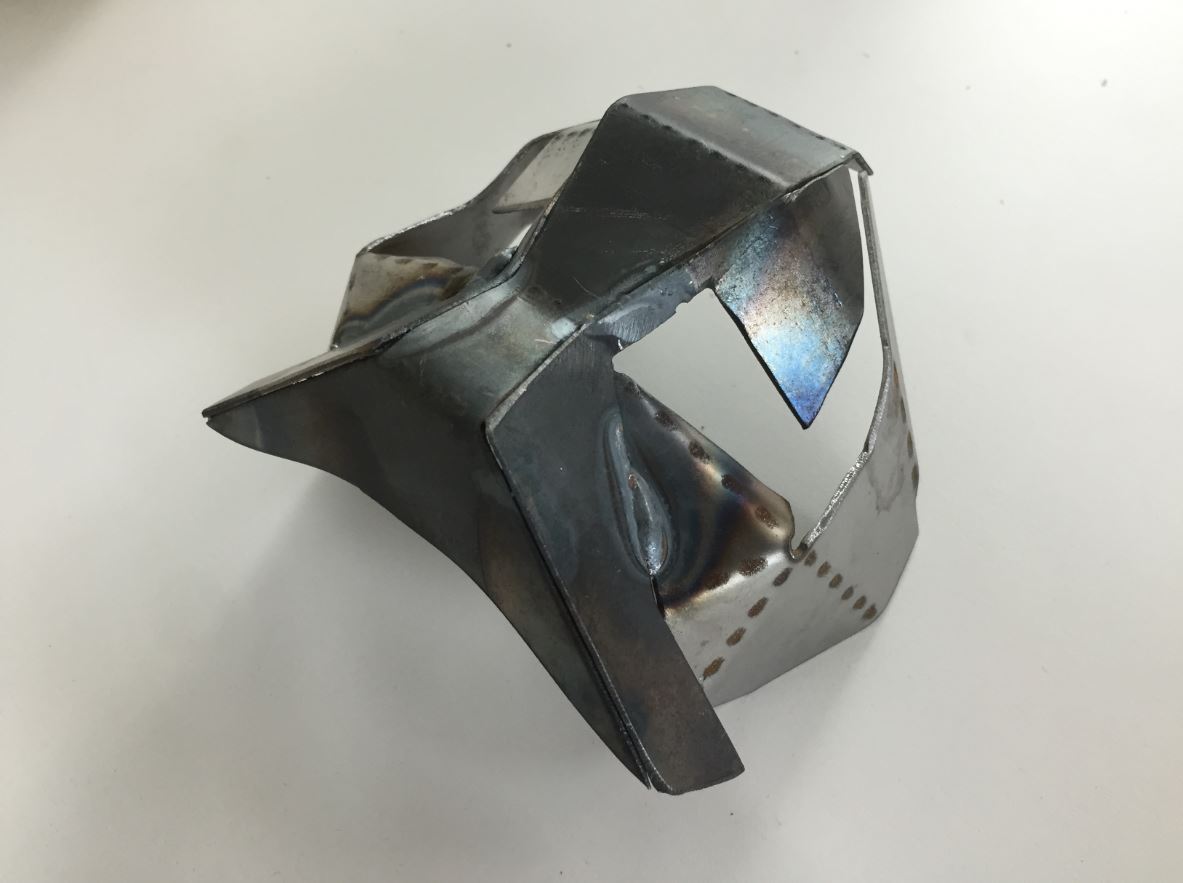

Folding¶

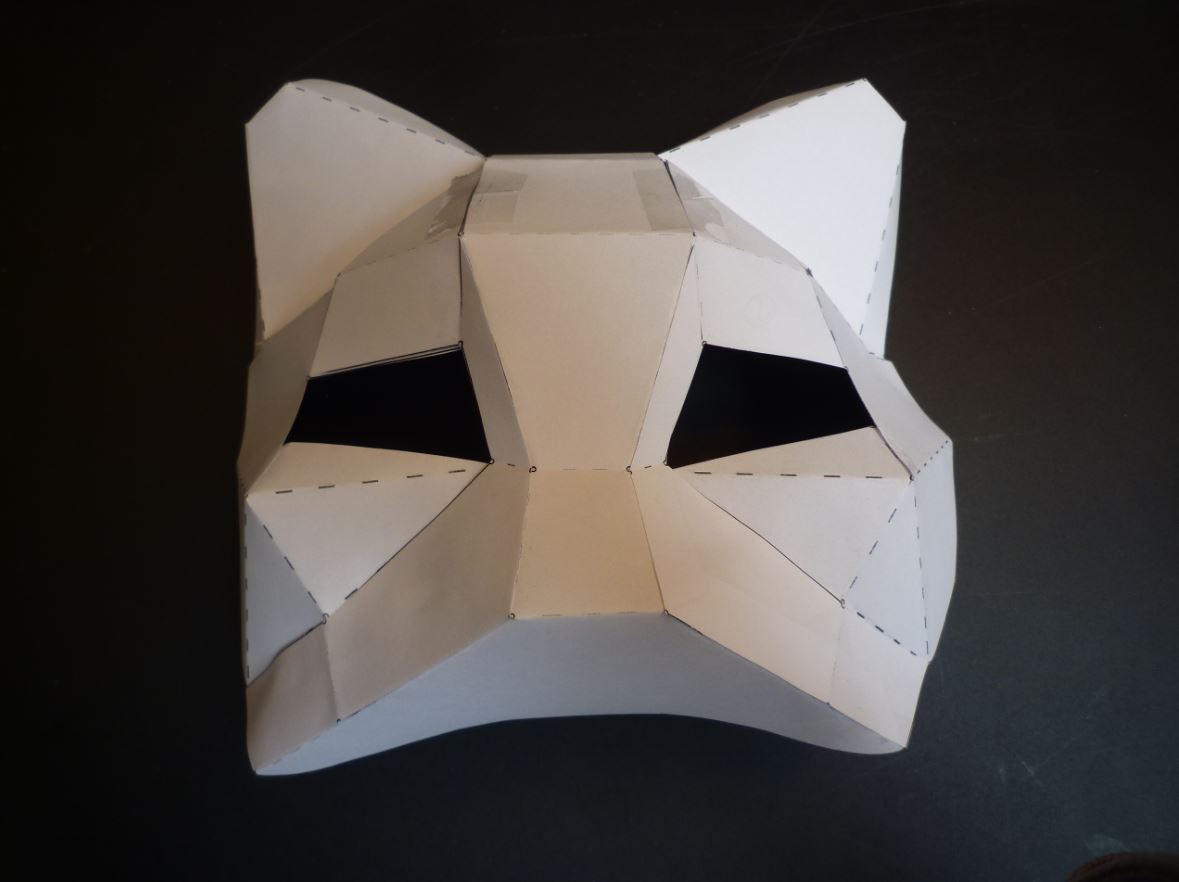

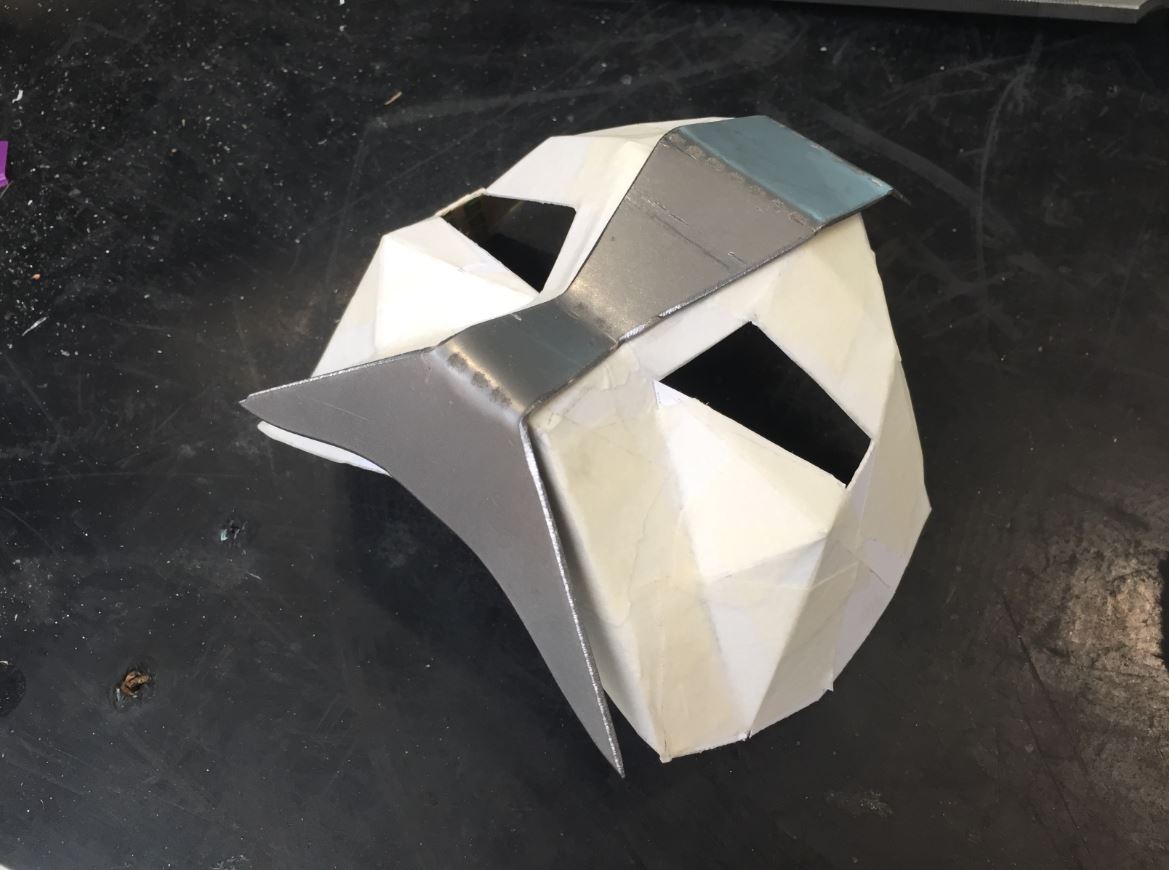

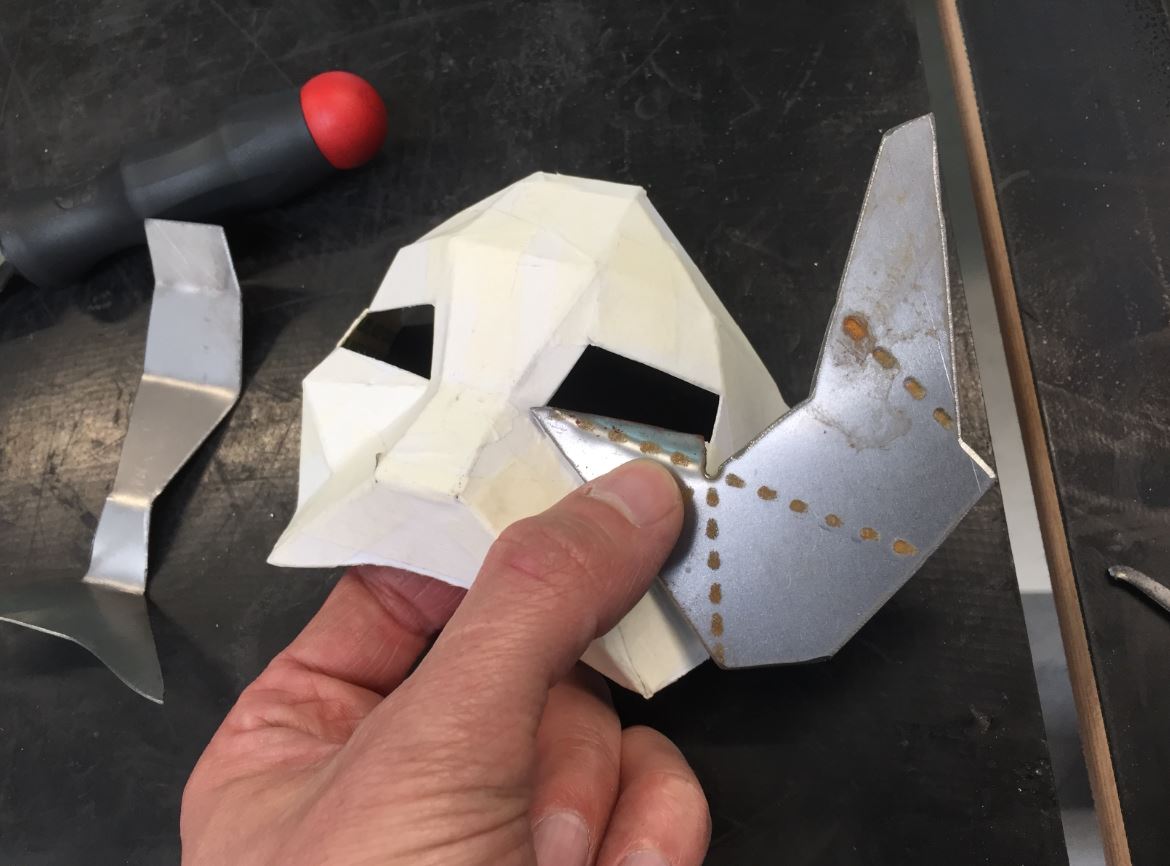

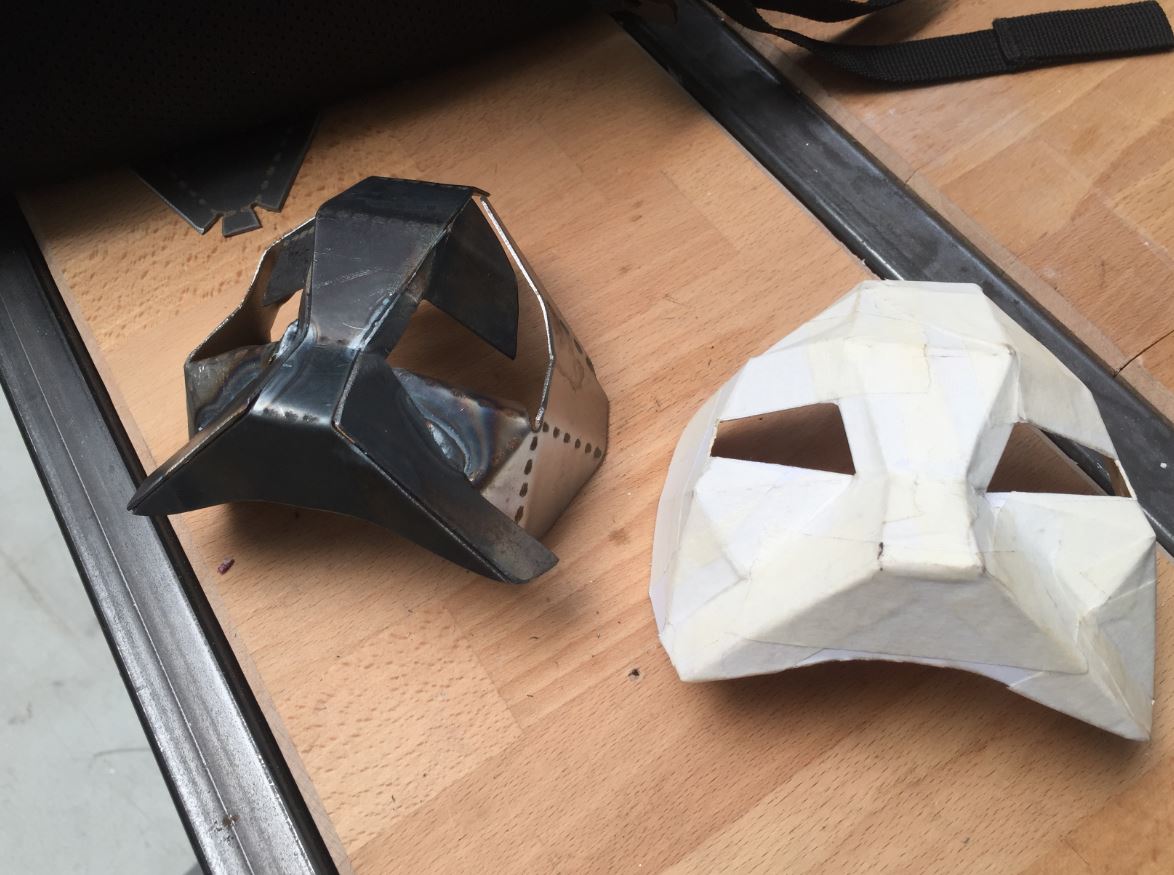

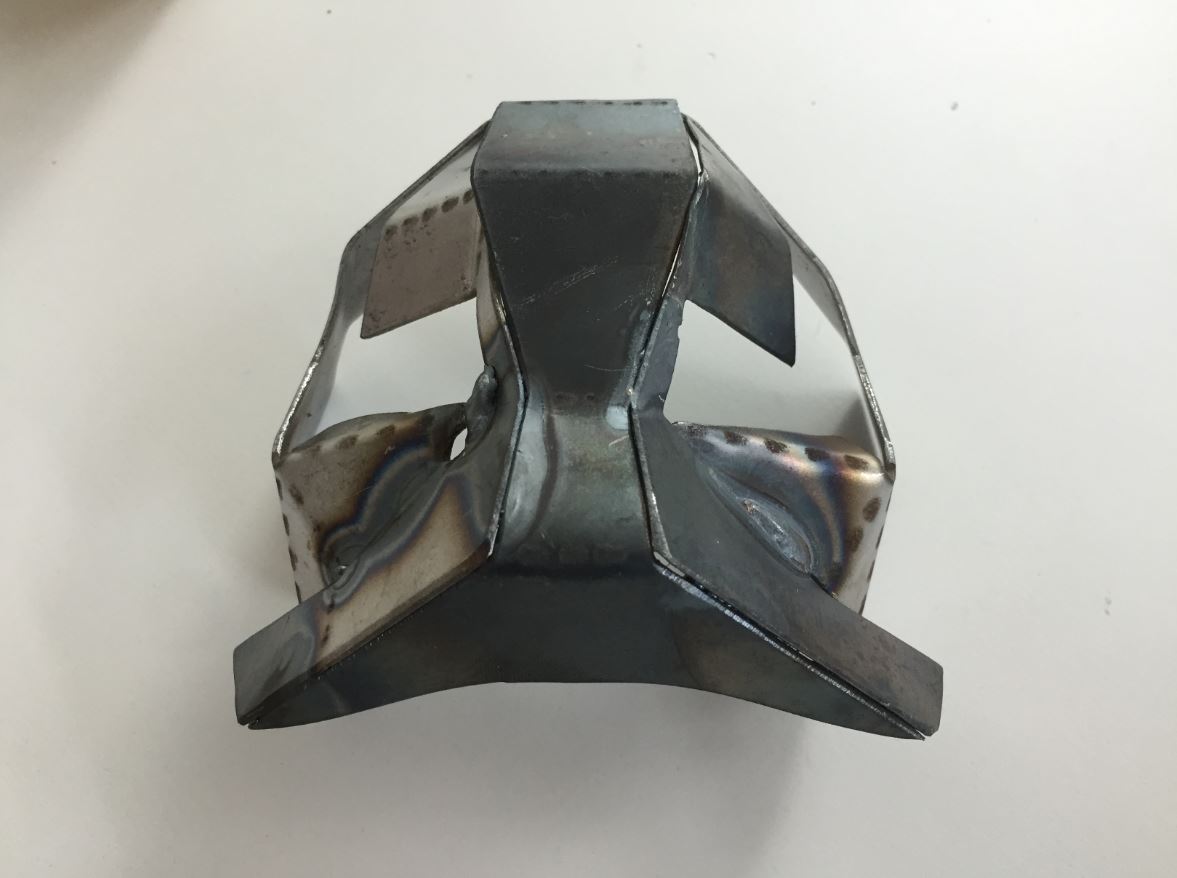

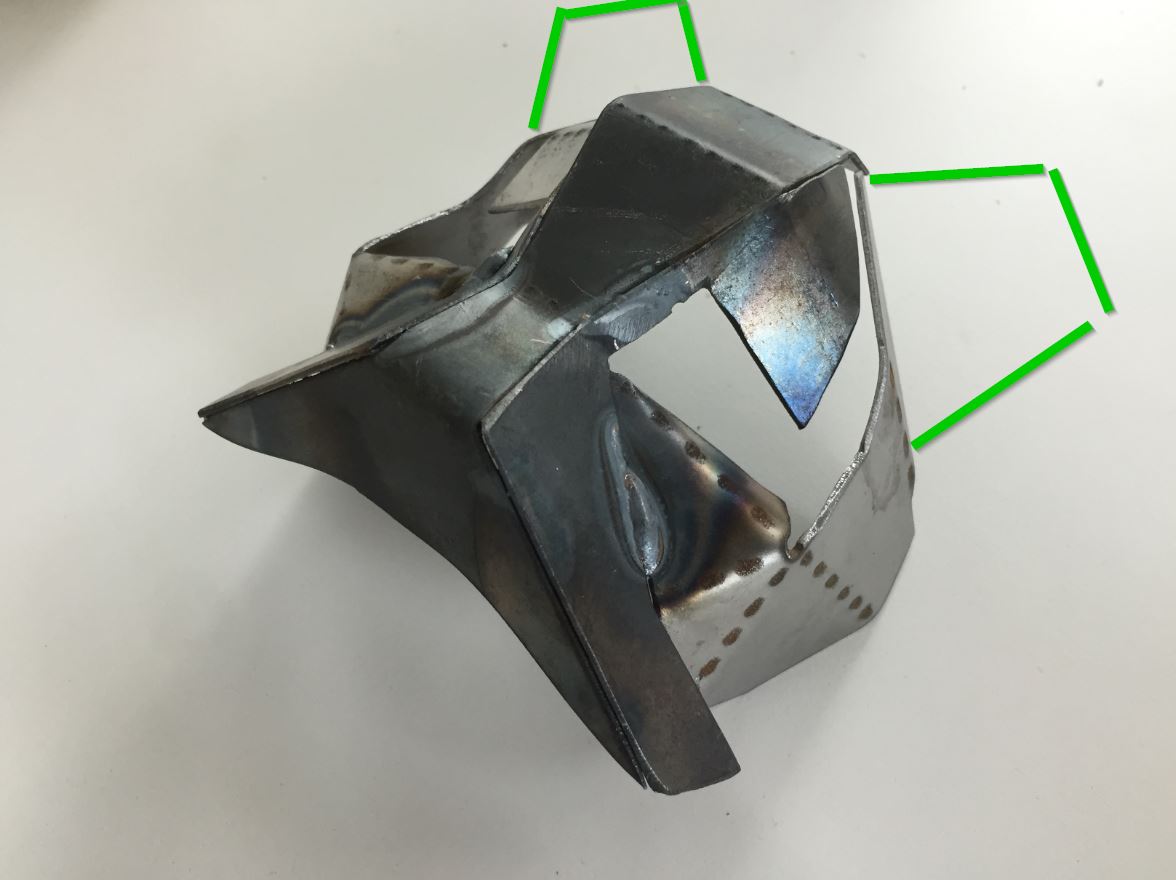

That was not easy at all. Eqquipped with my hammer, I have modelled my cat mask.

-waterjet-08 Folding metal sheet

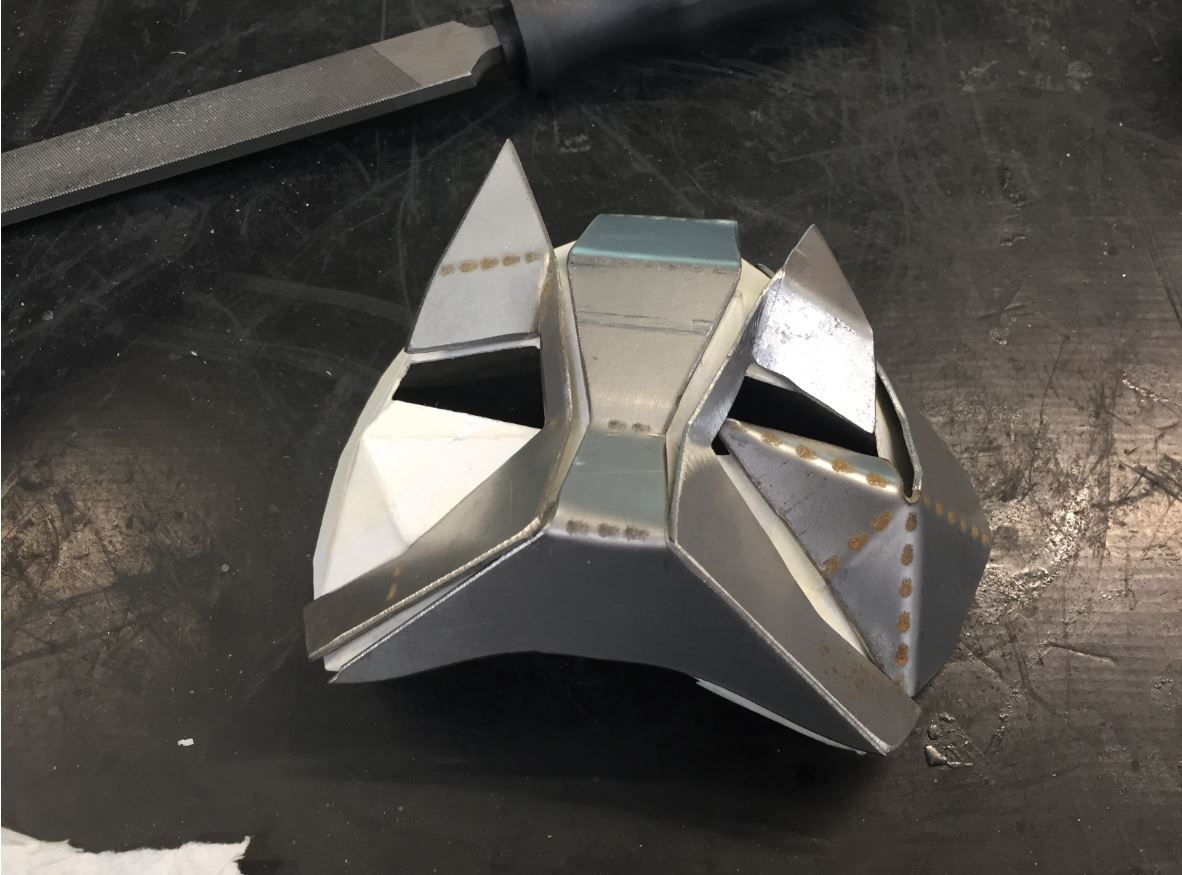

Welding¶

Tin brazure [FAIL]¶

In the workshop, the stock of antioxidant is empty. So it doesn’t work at all.

MAG welding.¶

I am comfortable to weld 2.5mm steel but 1mm was a bit touchy.

To sum up:

Folding metal was not that easy compared to my paper model. I should weld more than folding. TCI cutting machine is too big. Next semester, my school is getting the Wazer, which will match our Fablab.

2023¶

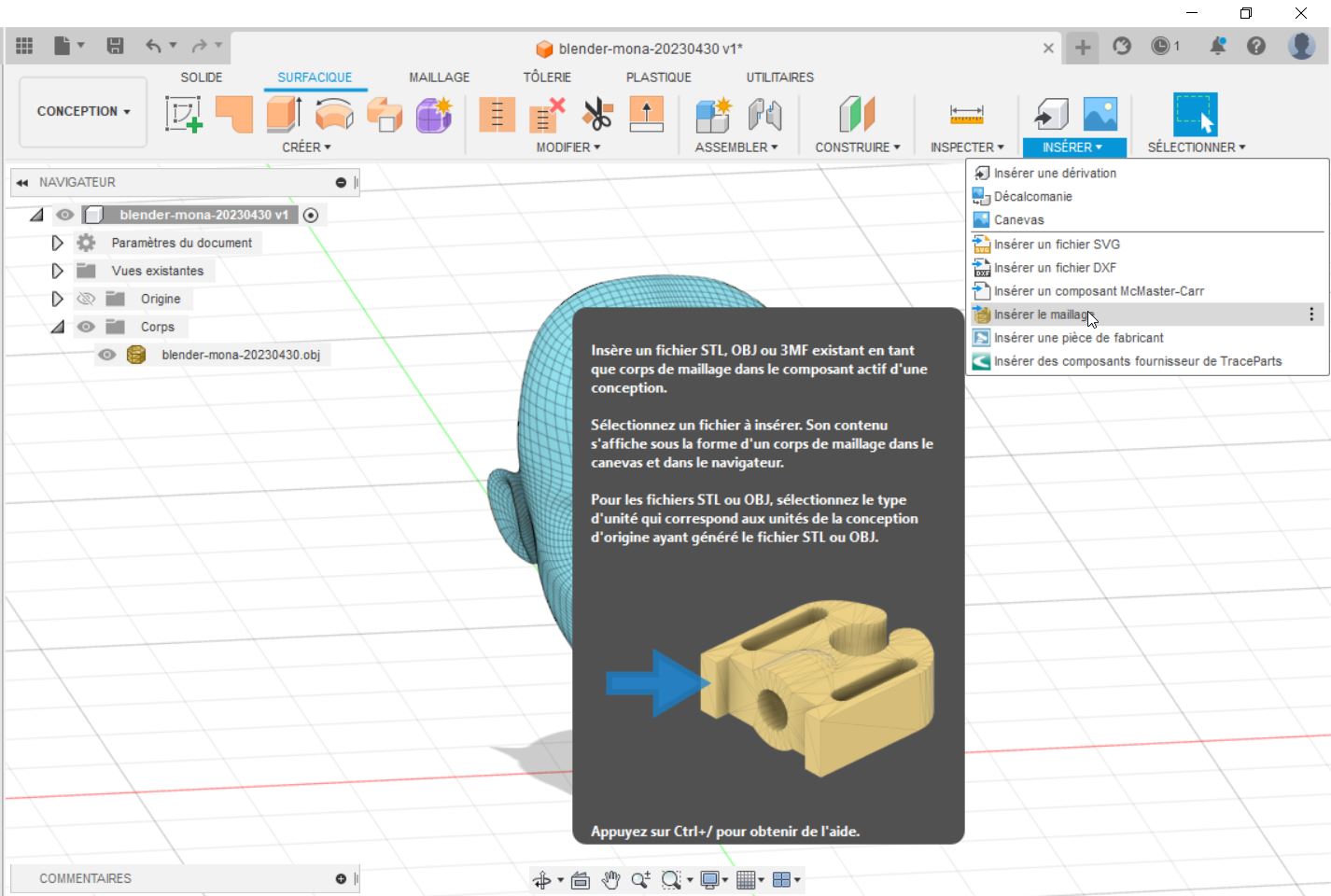

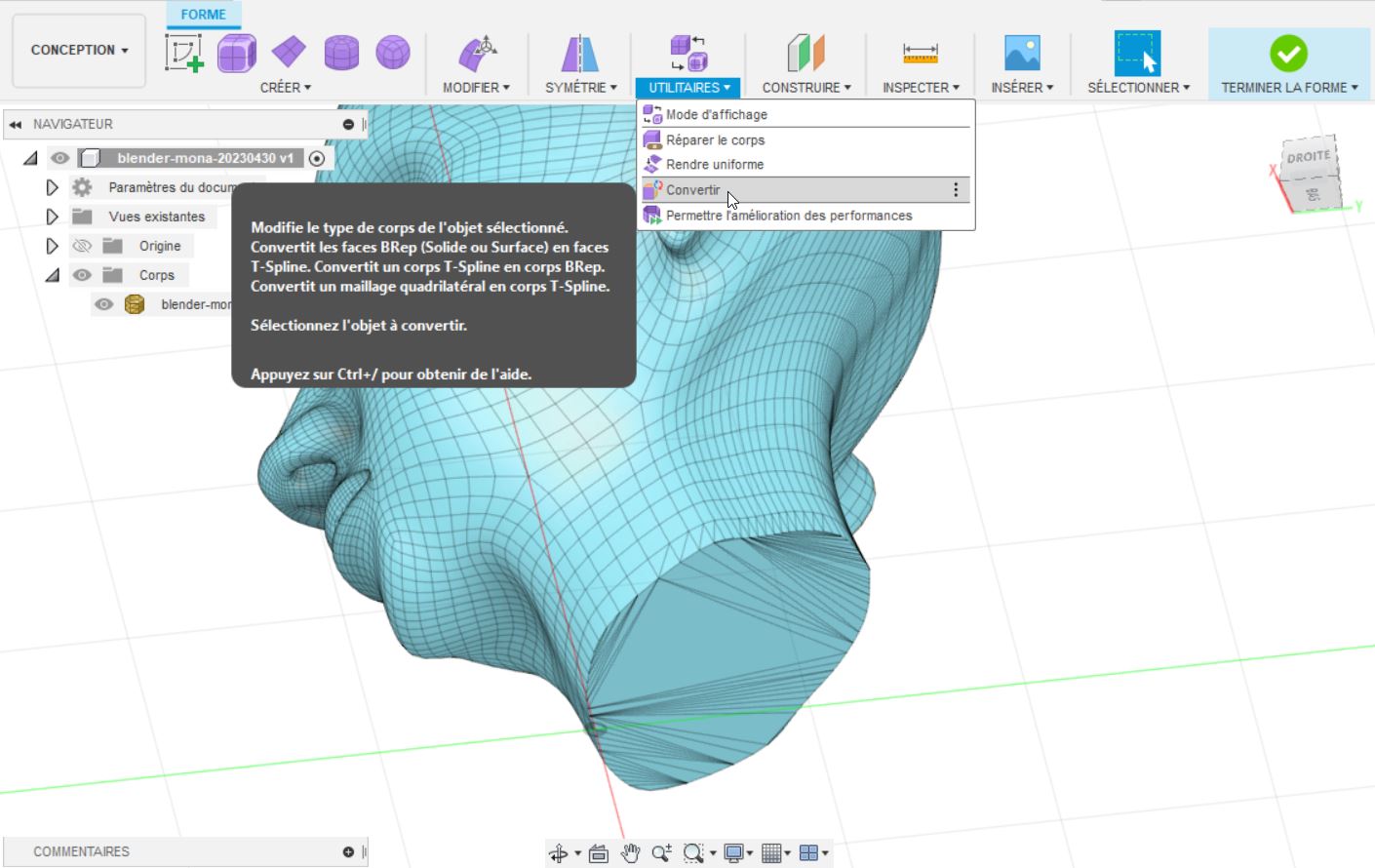

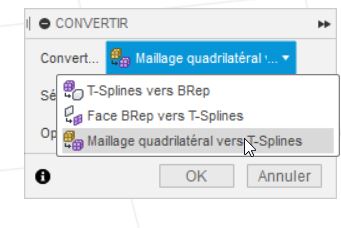

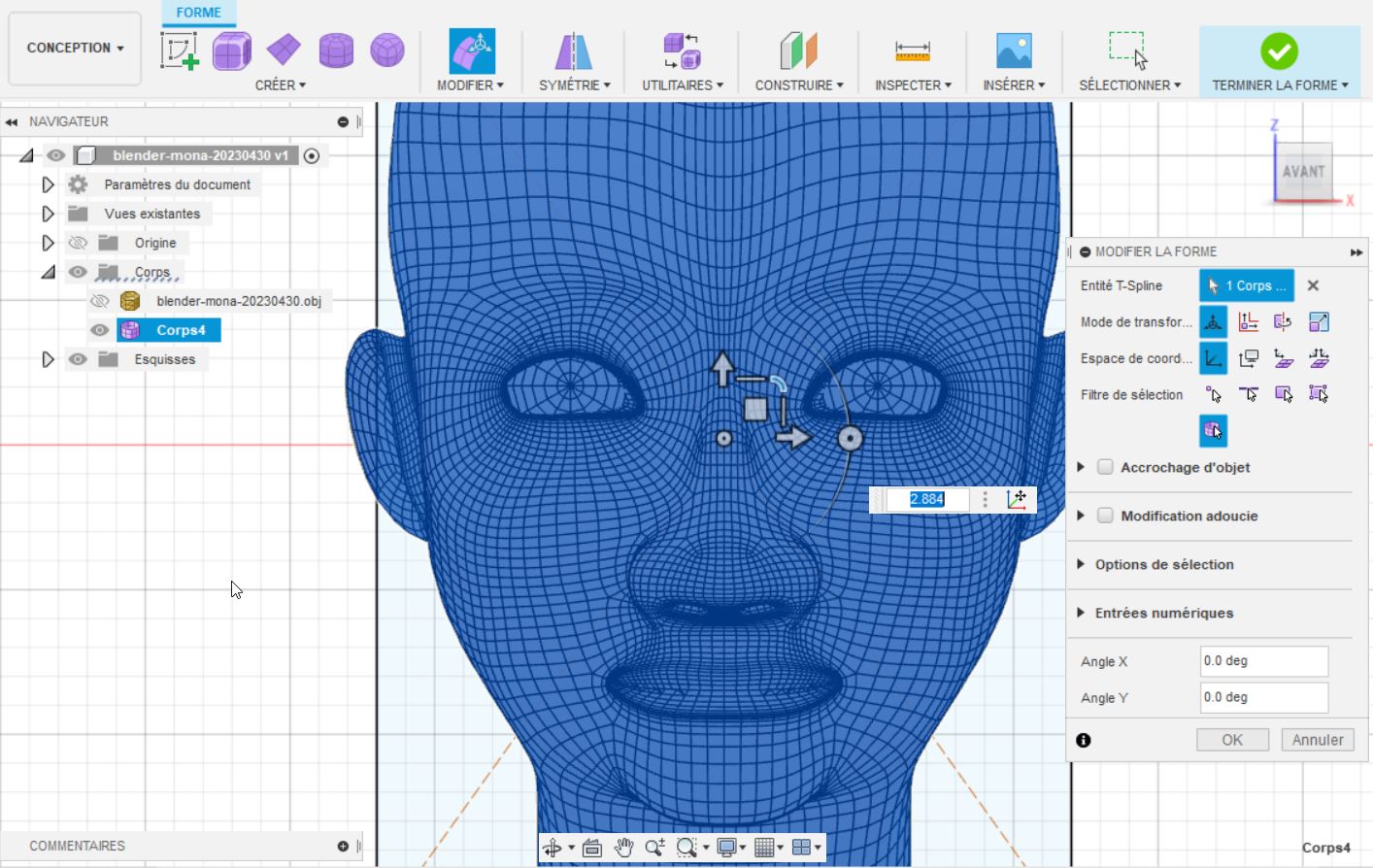

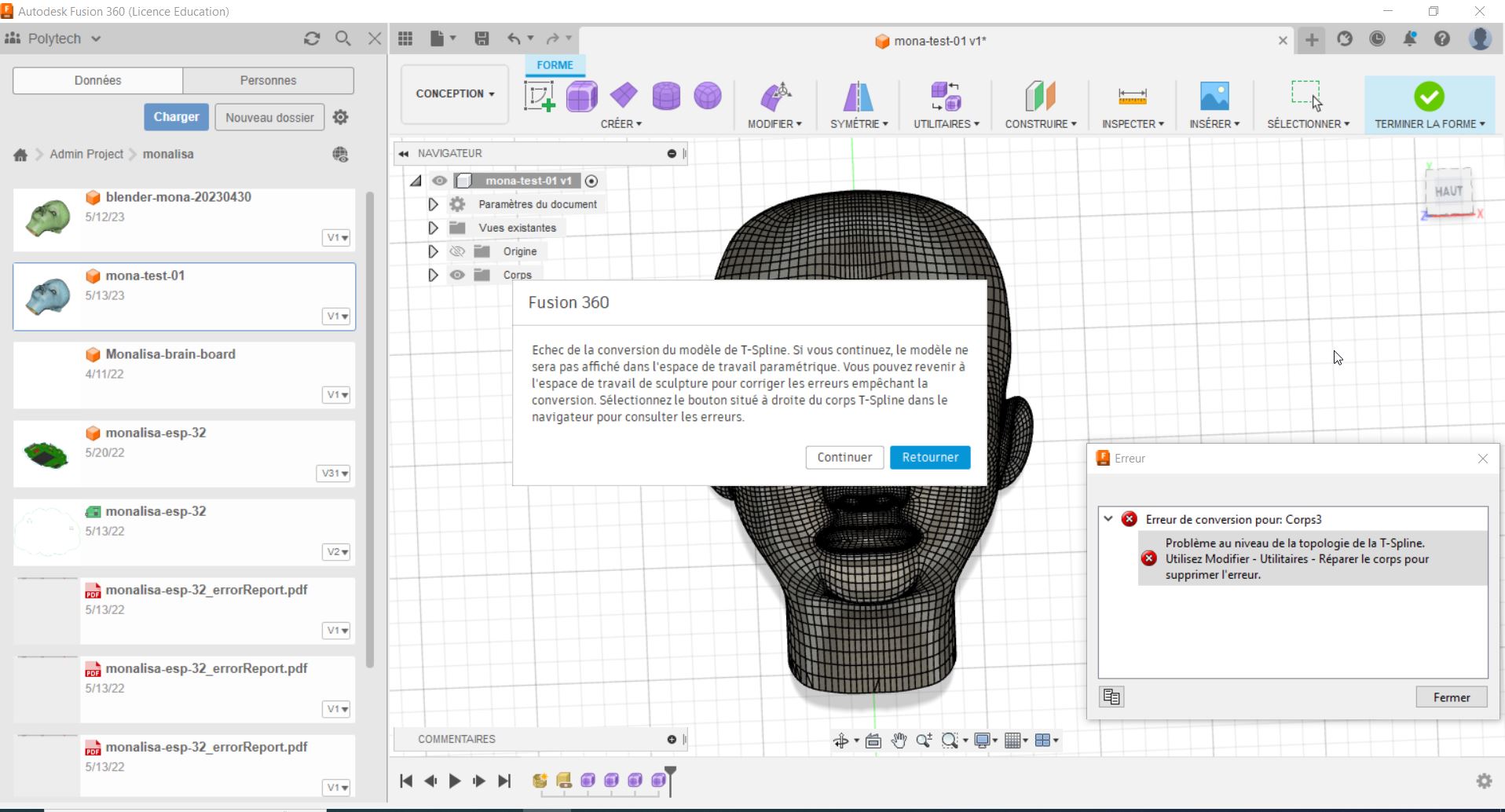

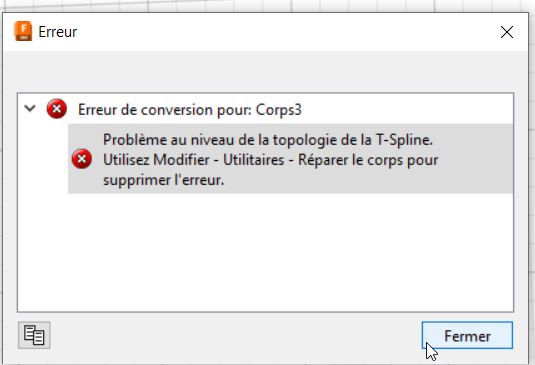

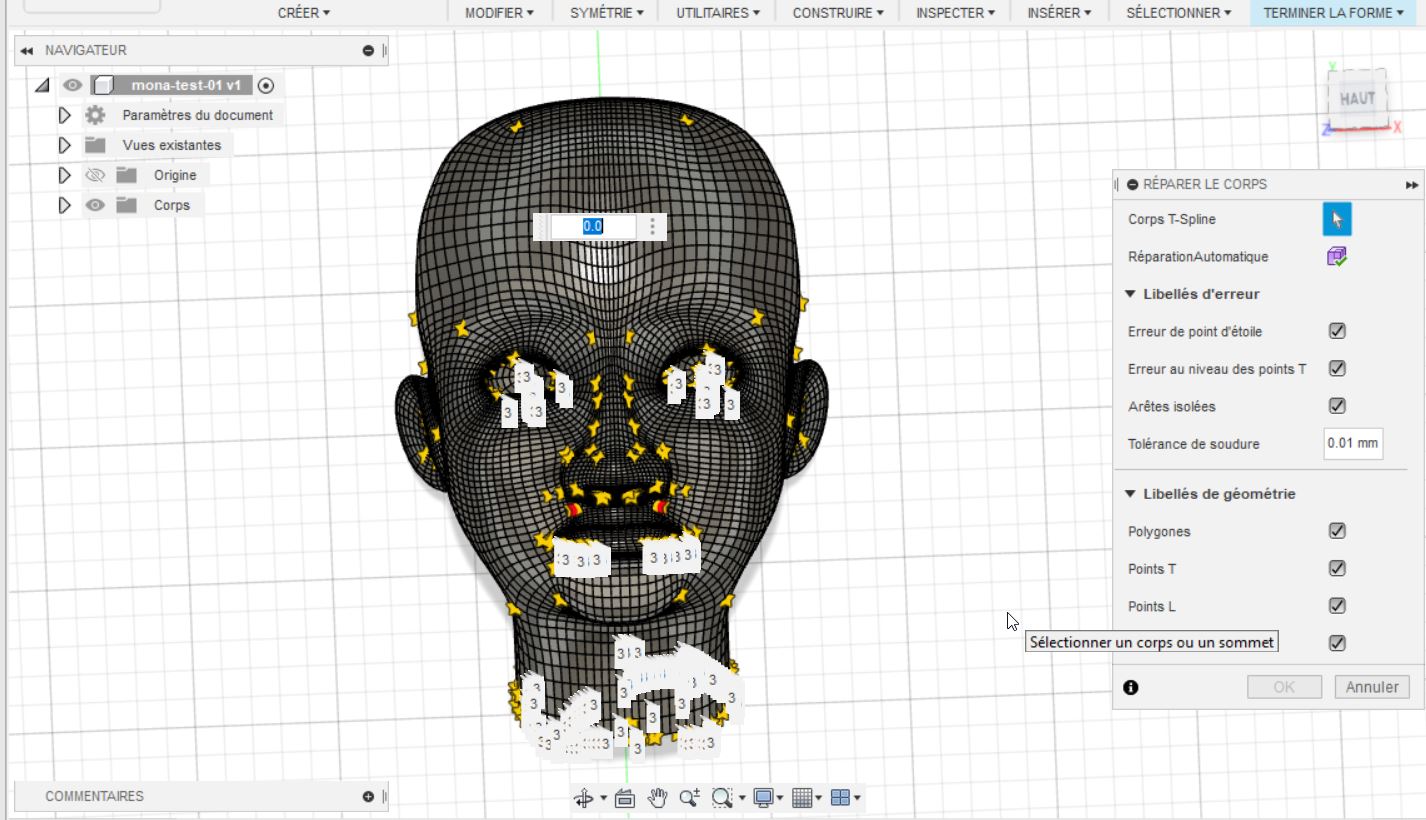

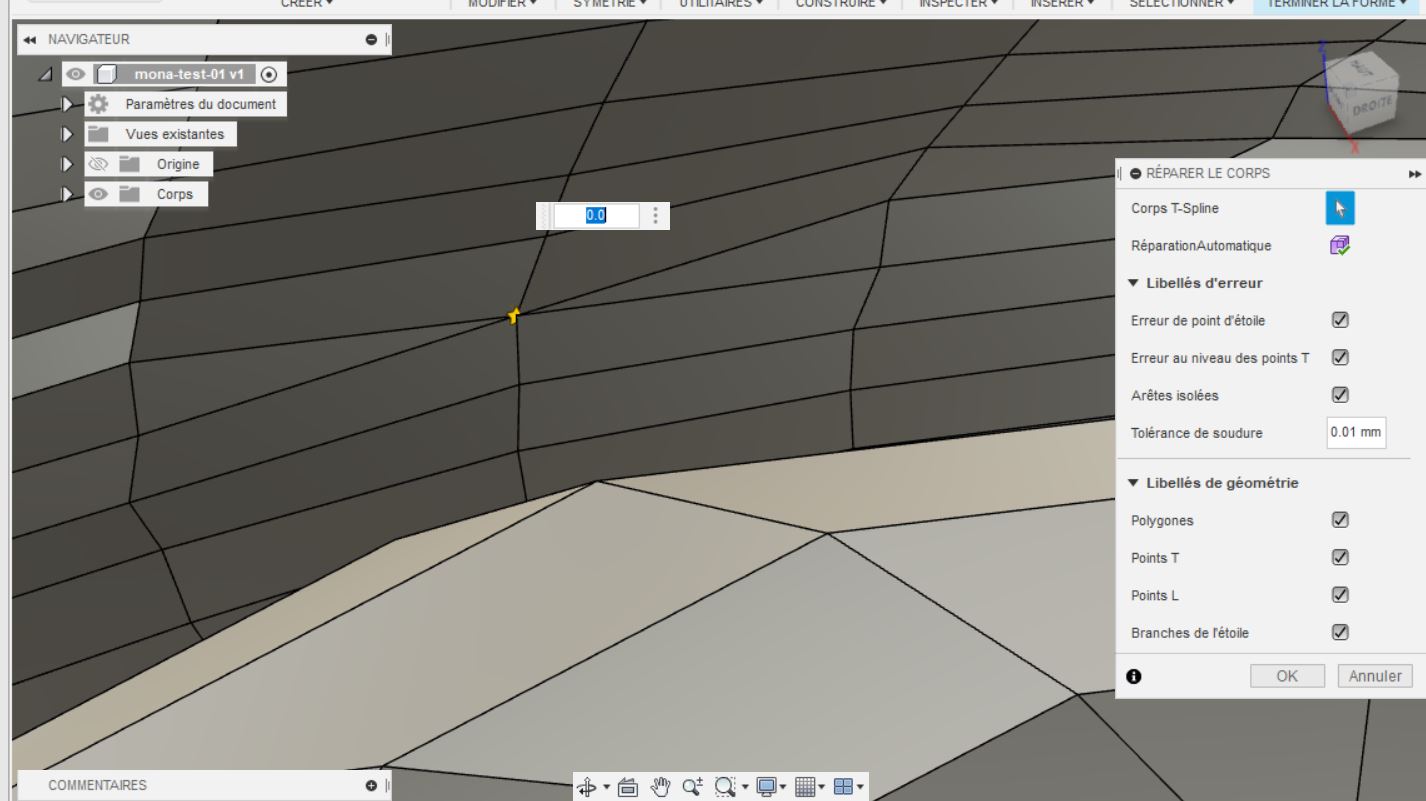

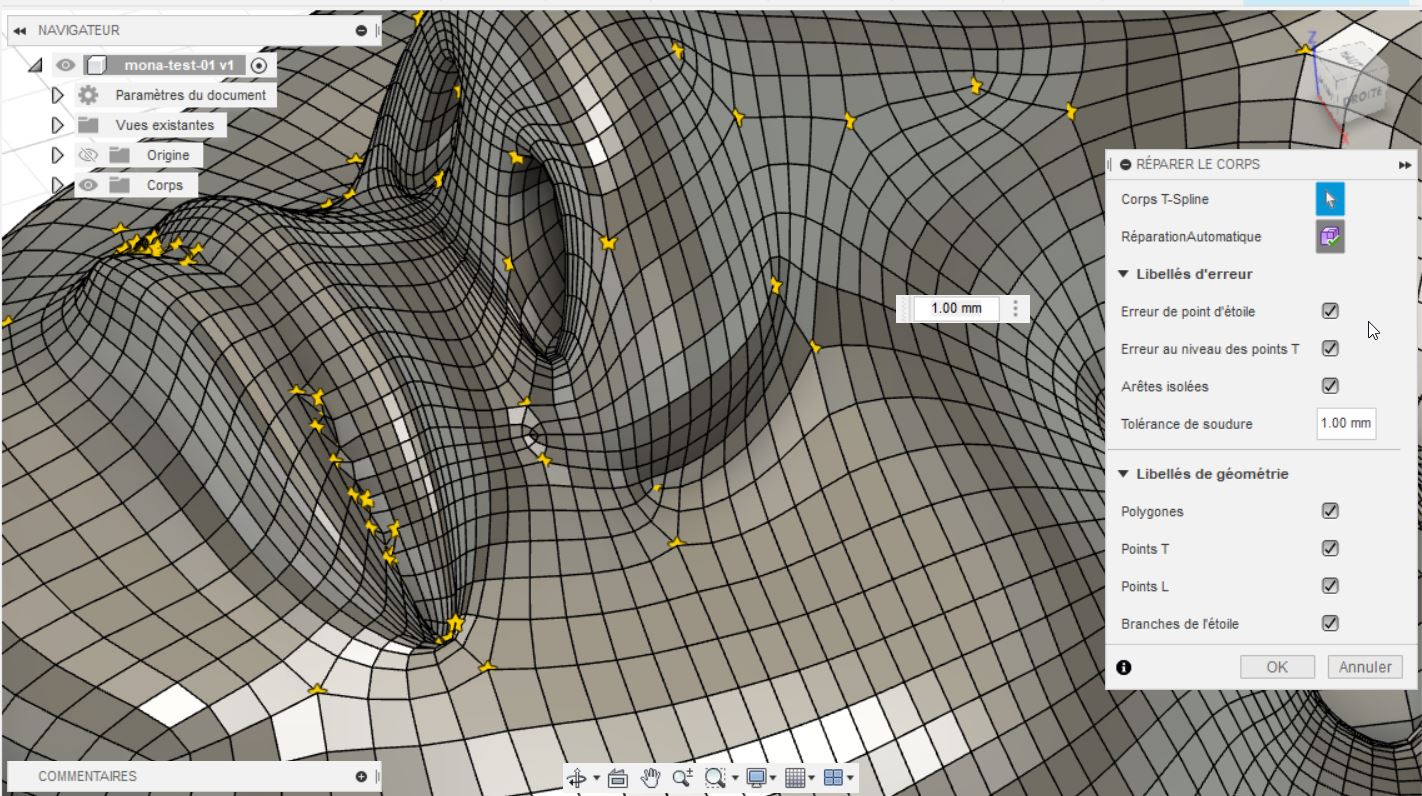

importing obj to fusion 360°¶

I have followed some tutorials to import this file. You have

[FAIL]

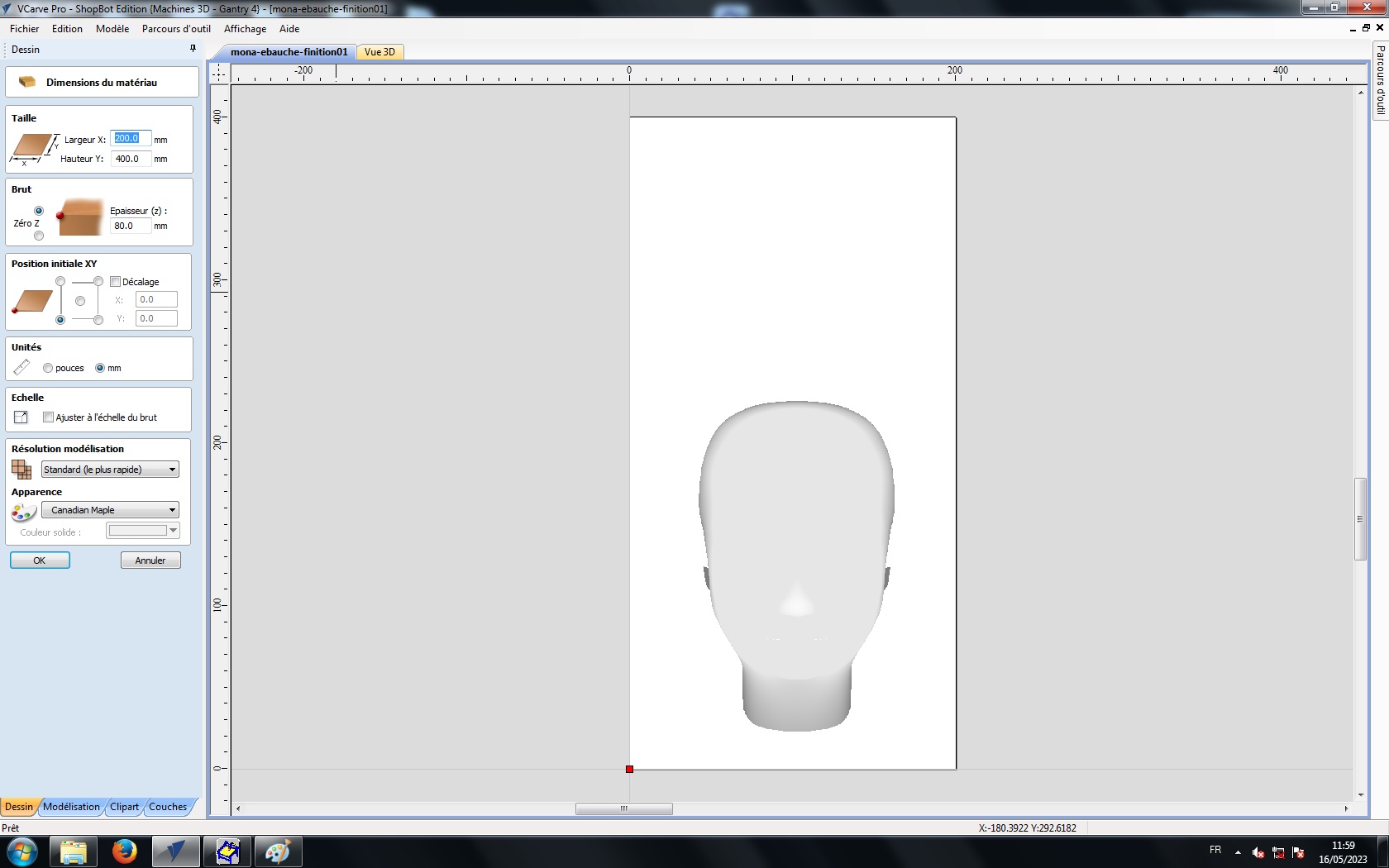

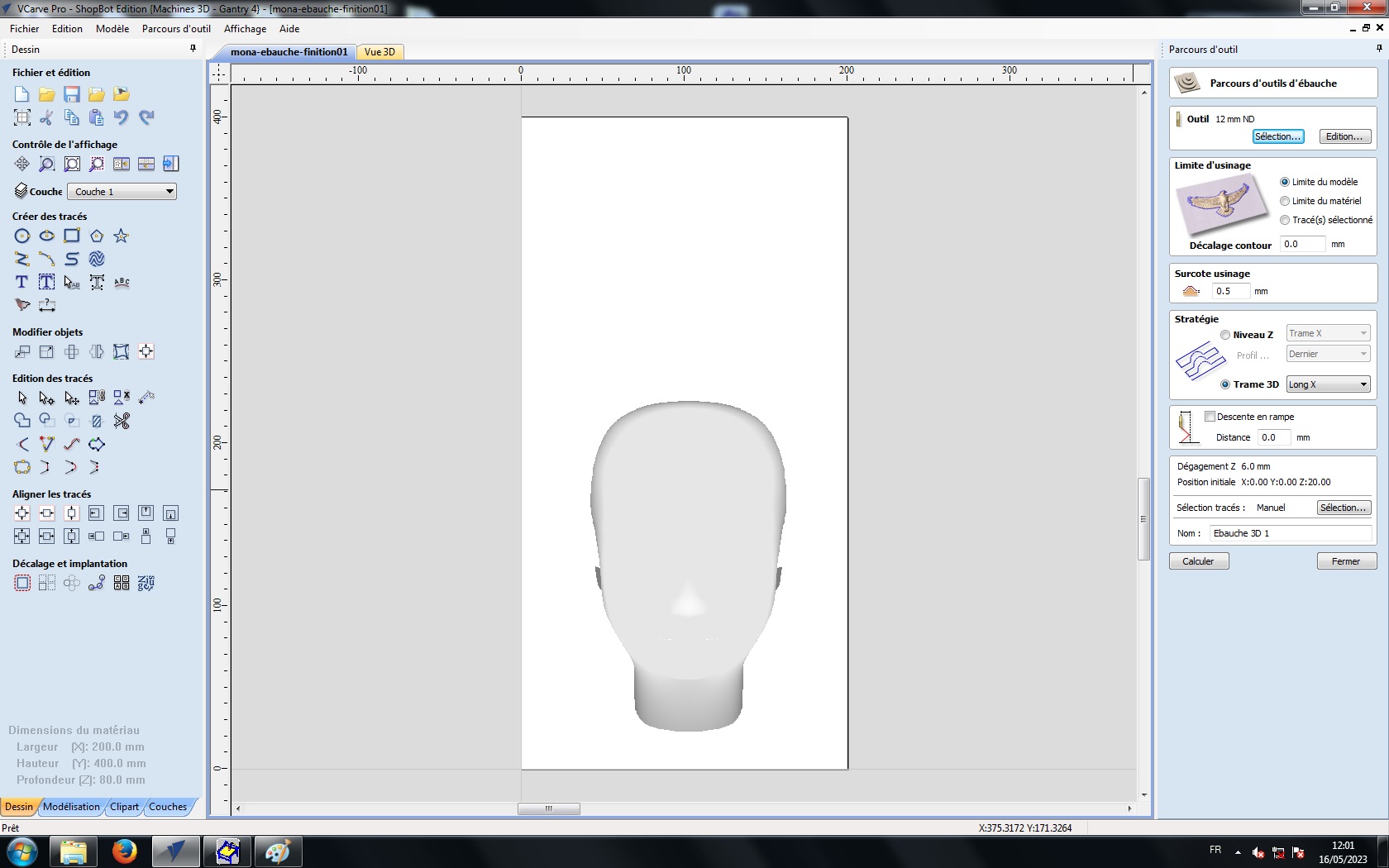

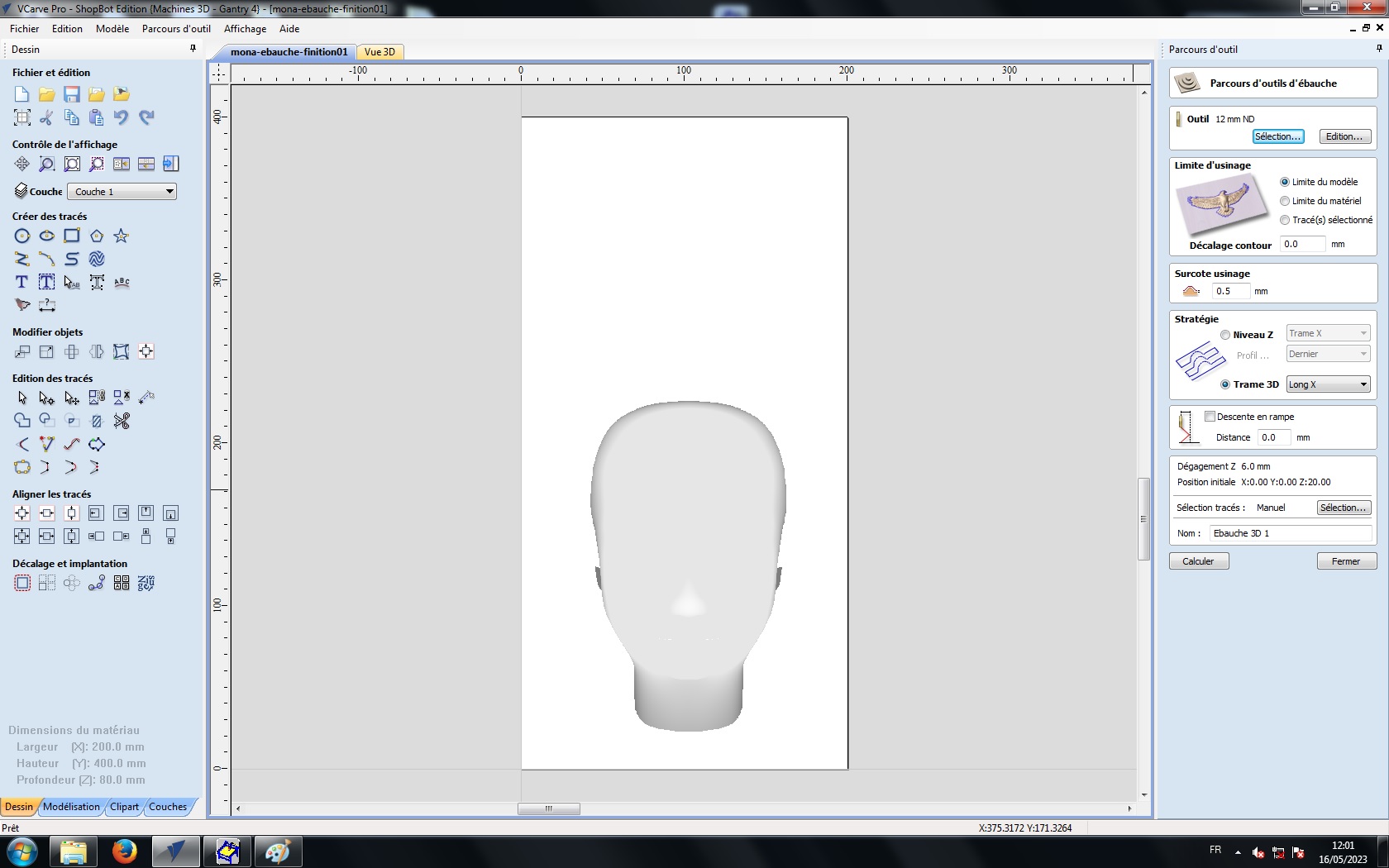

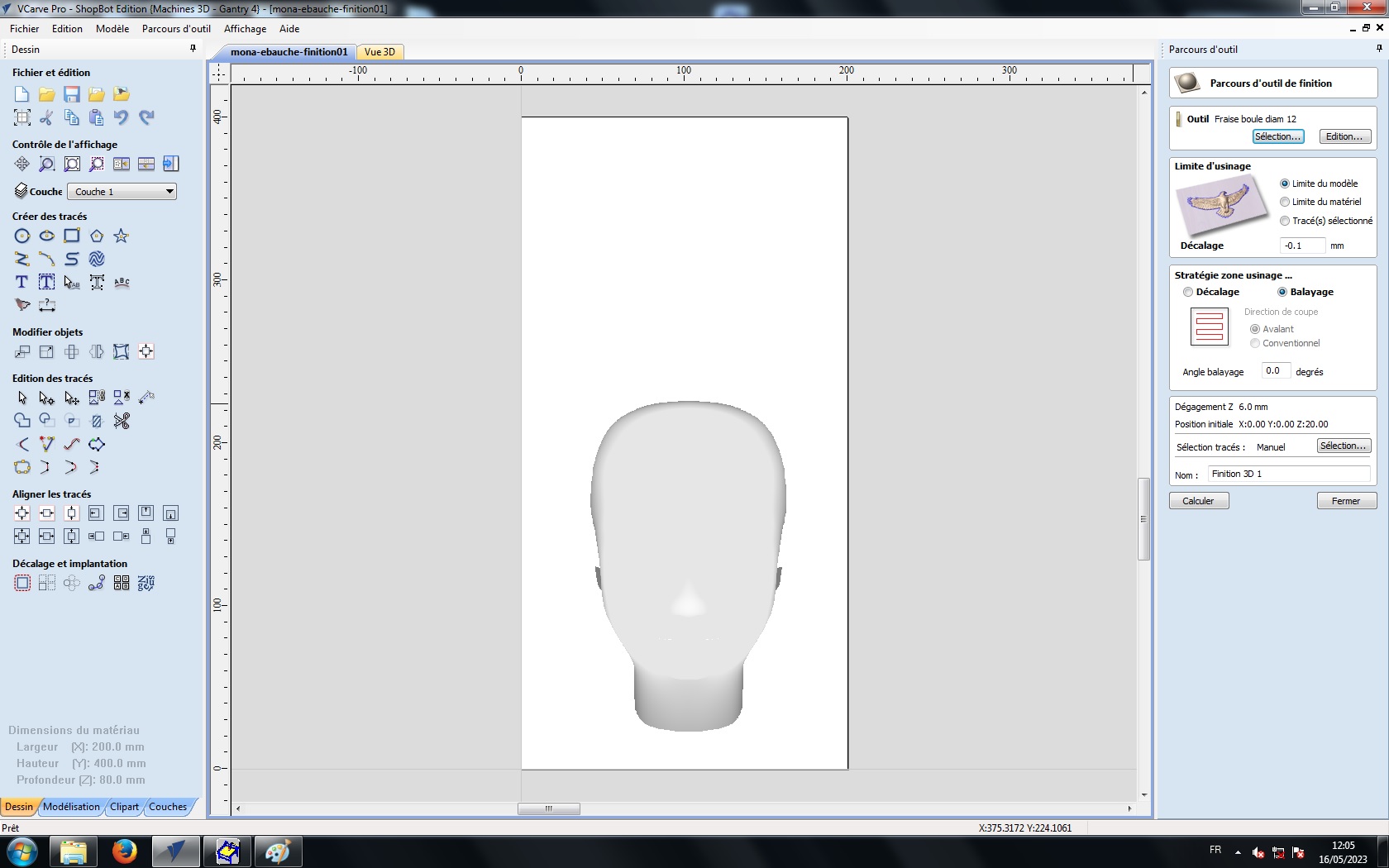

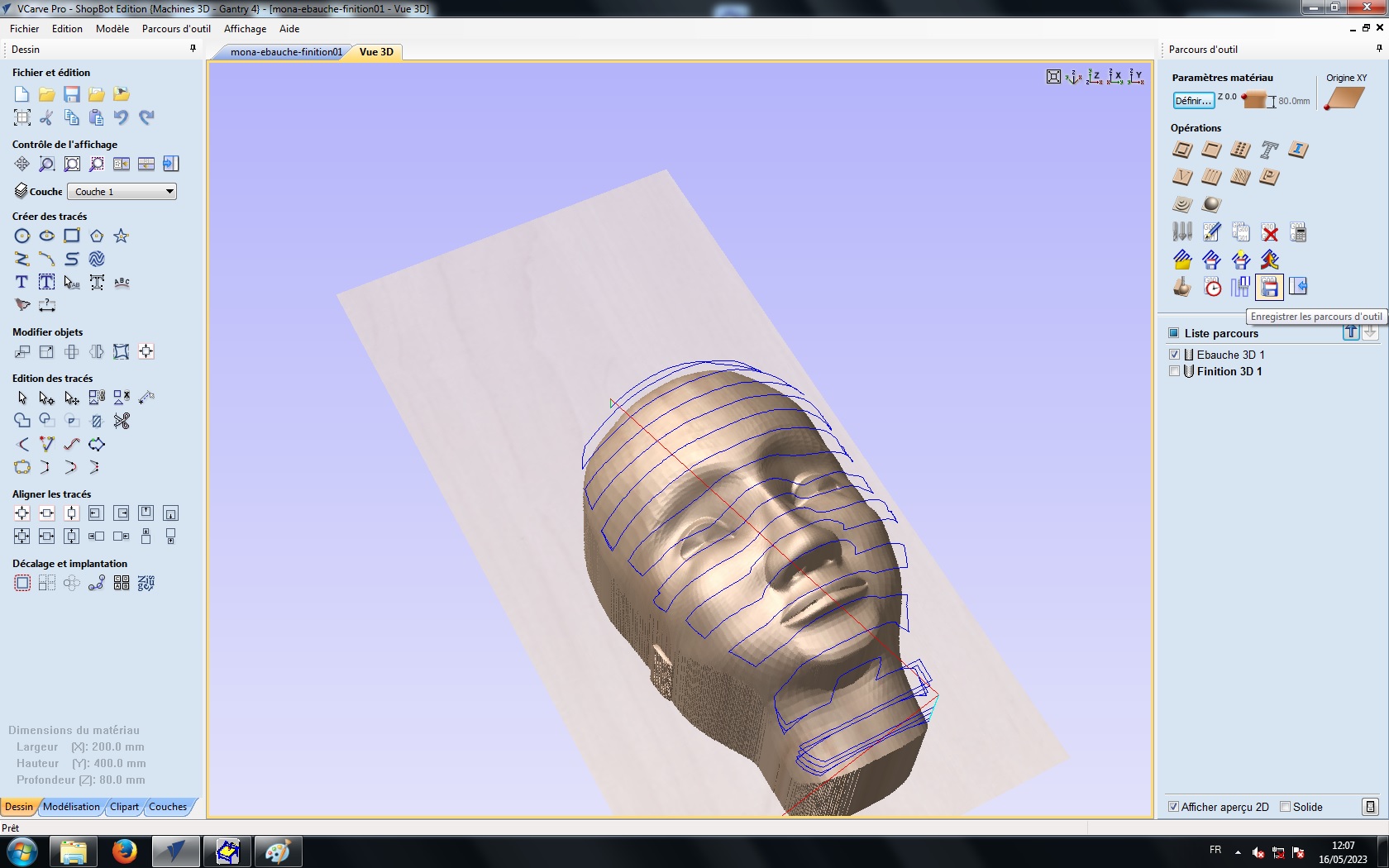

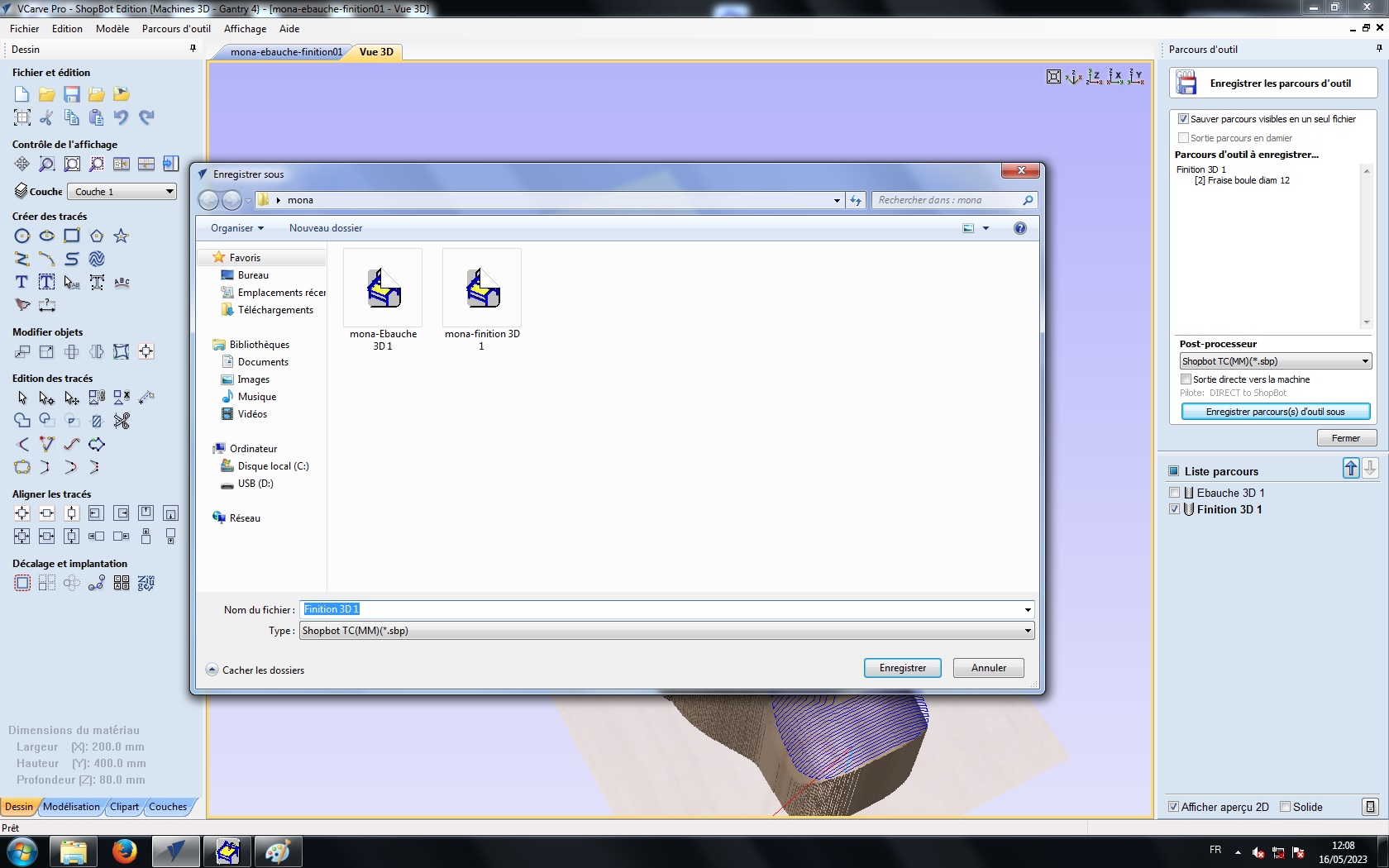

Importing obj to V-carve¶

Safety¶

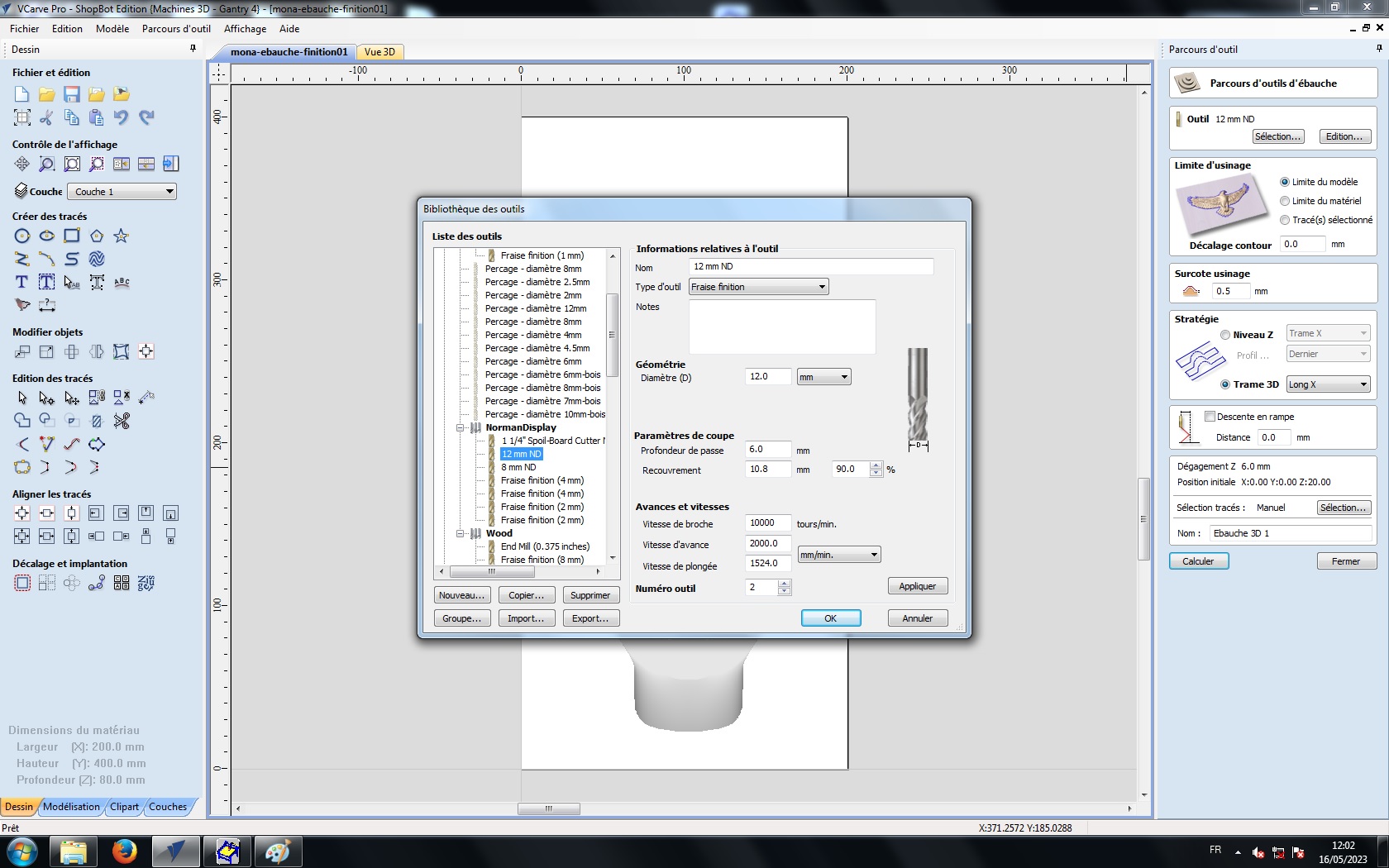

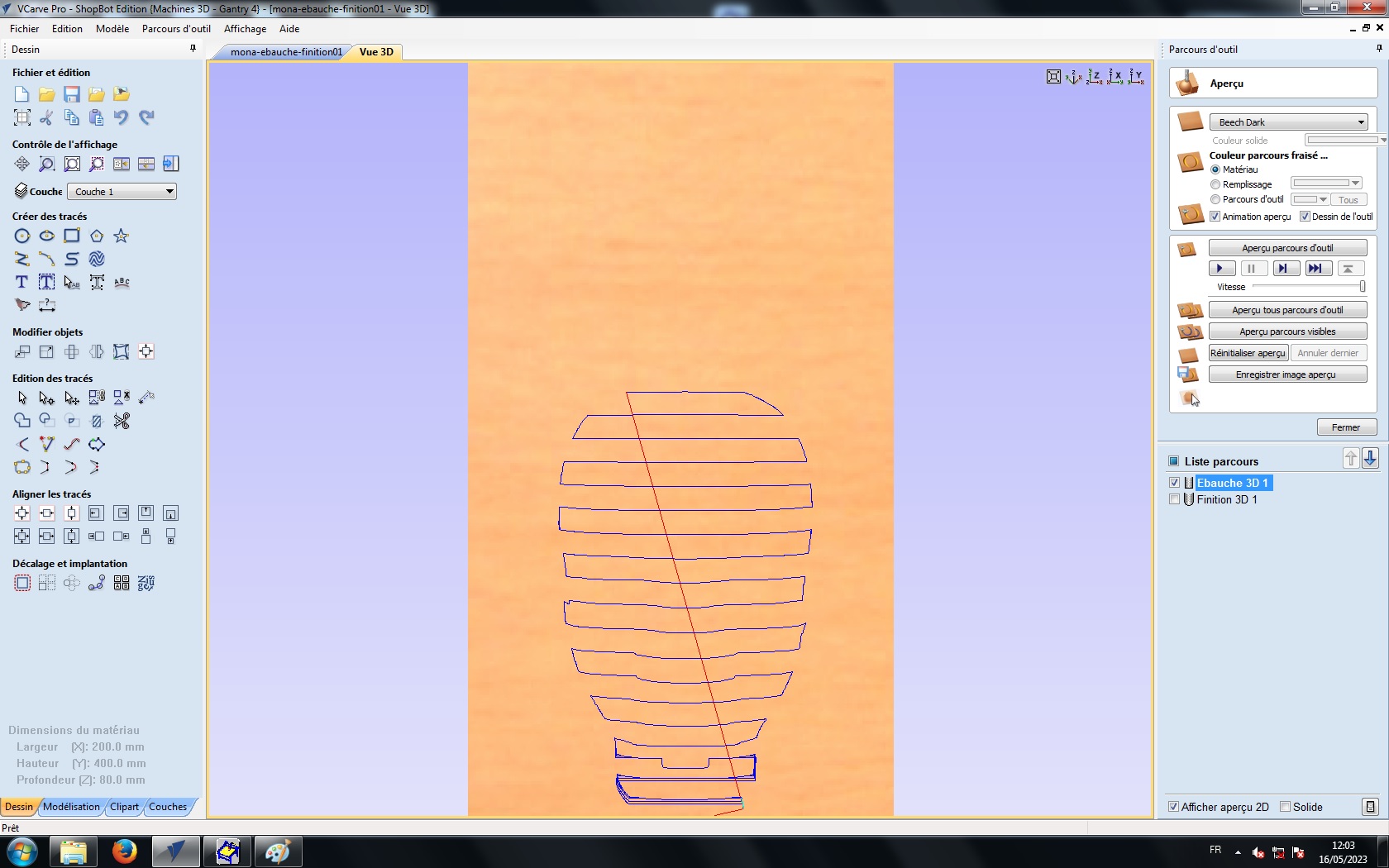

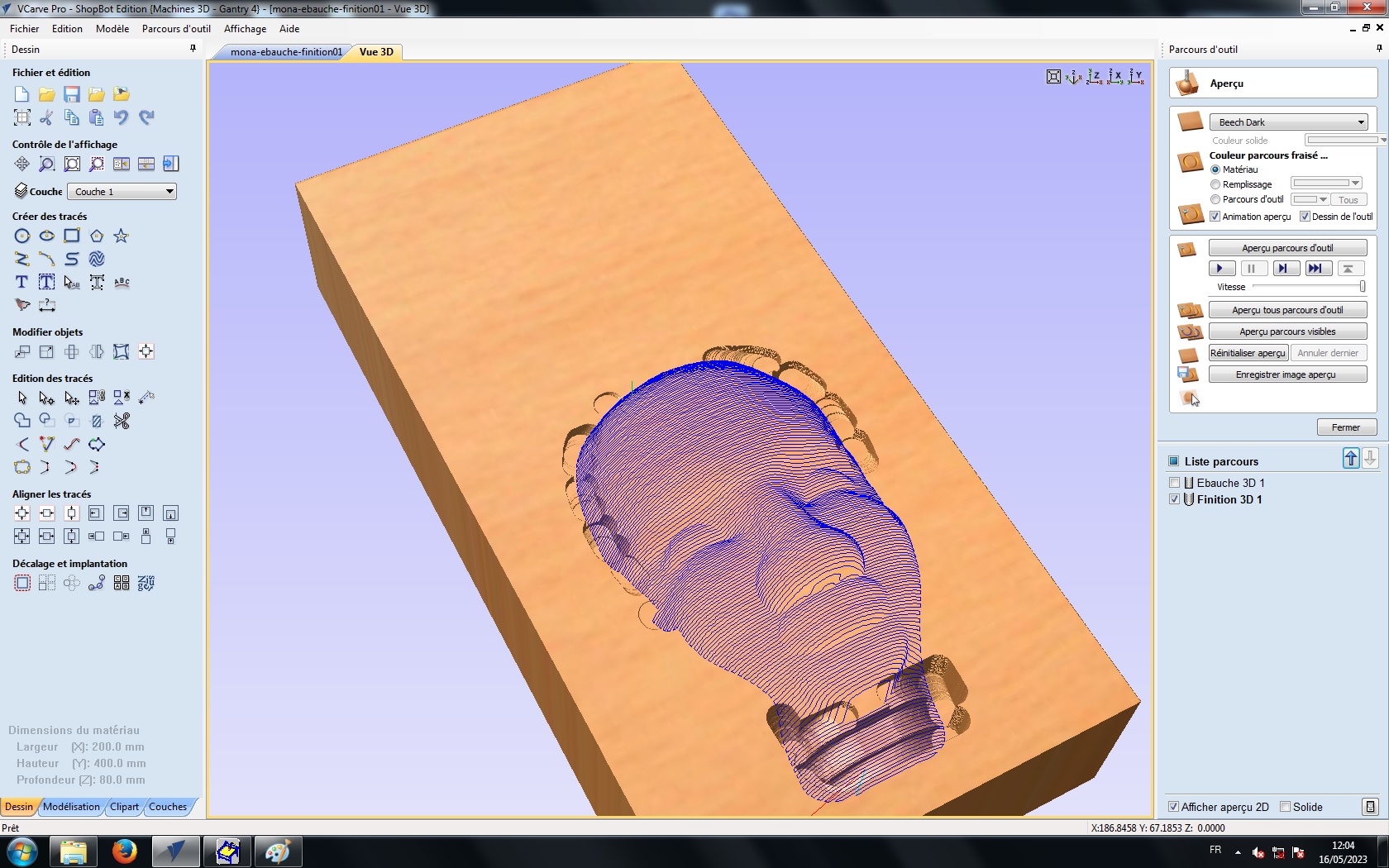

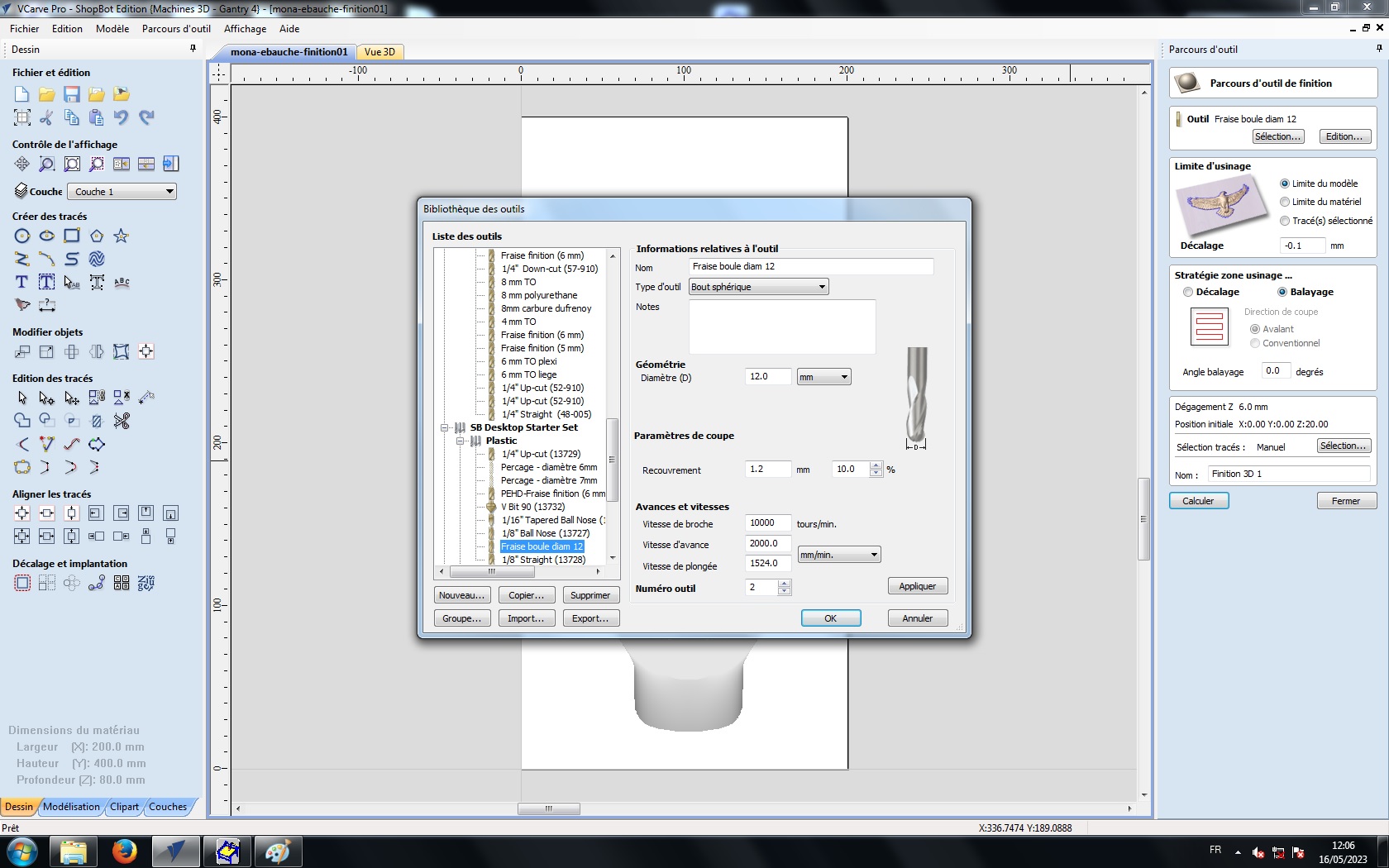

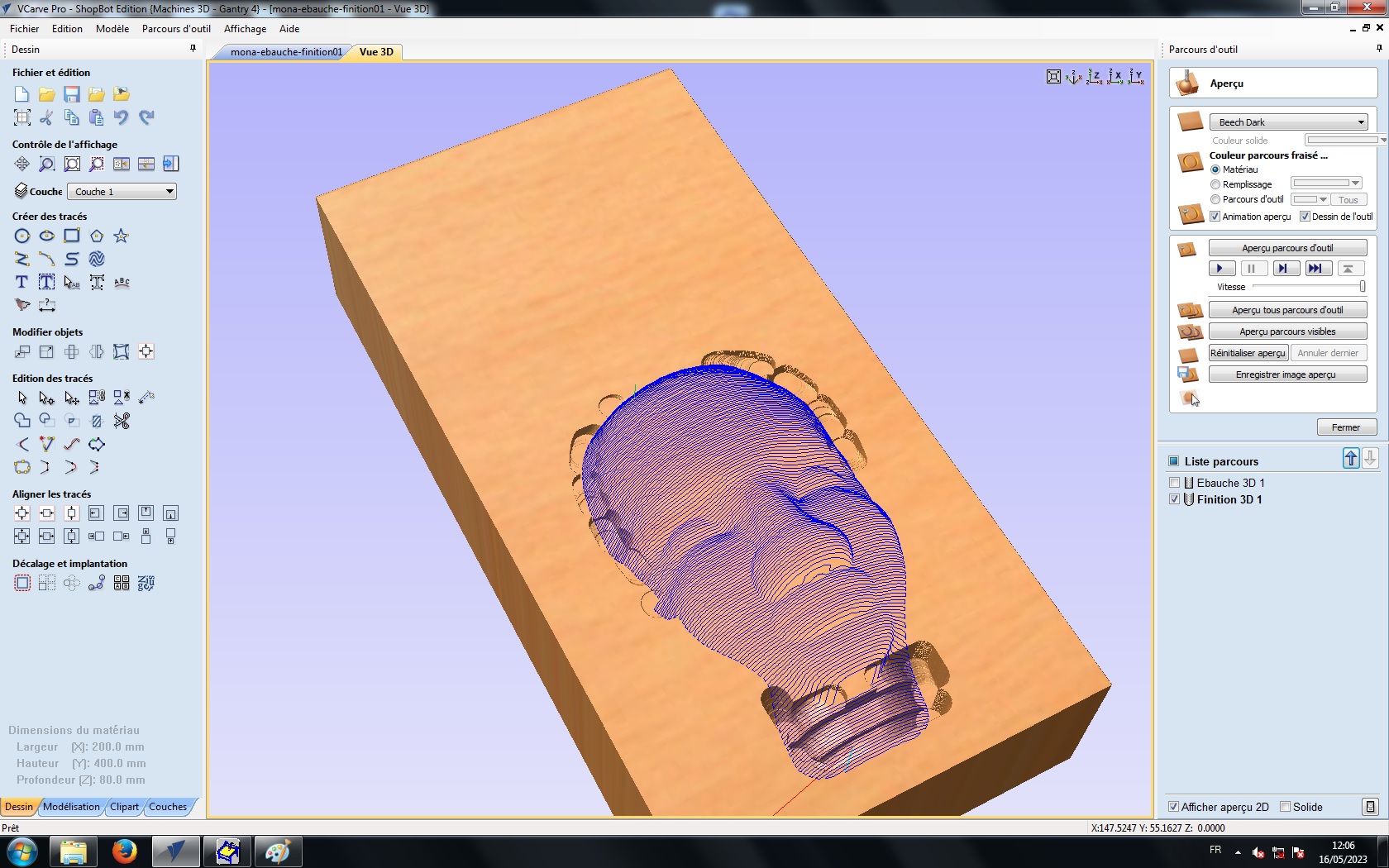

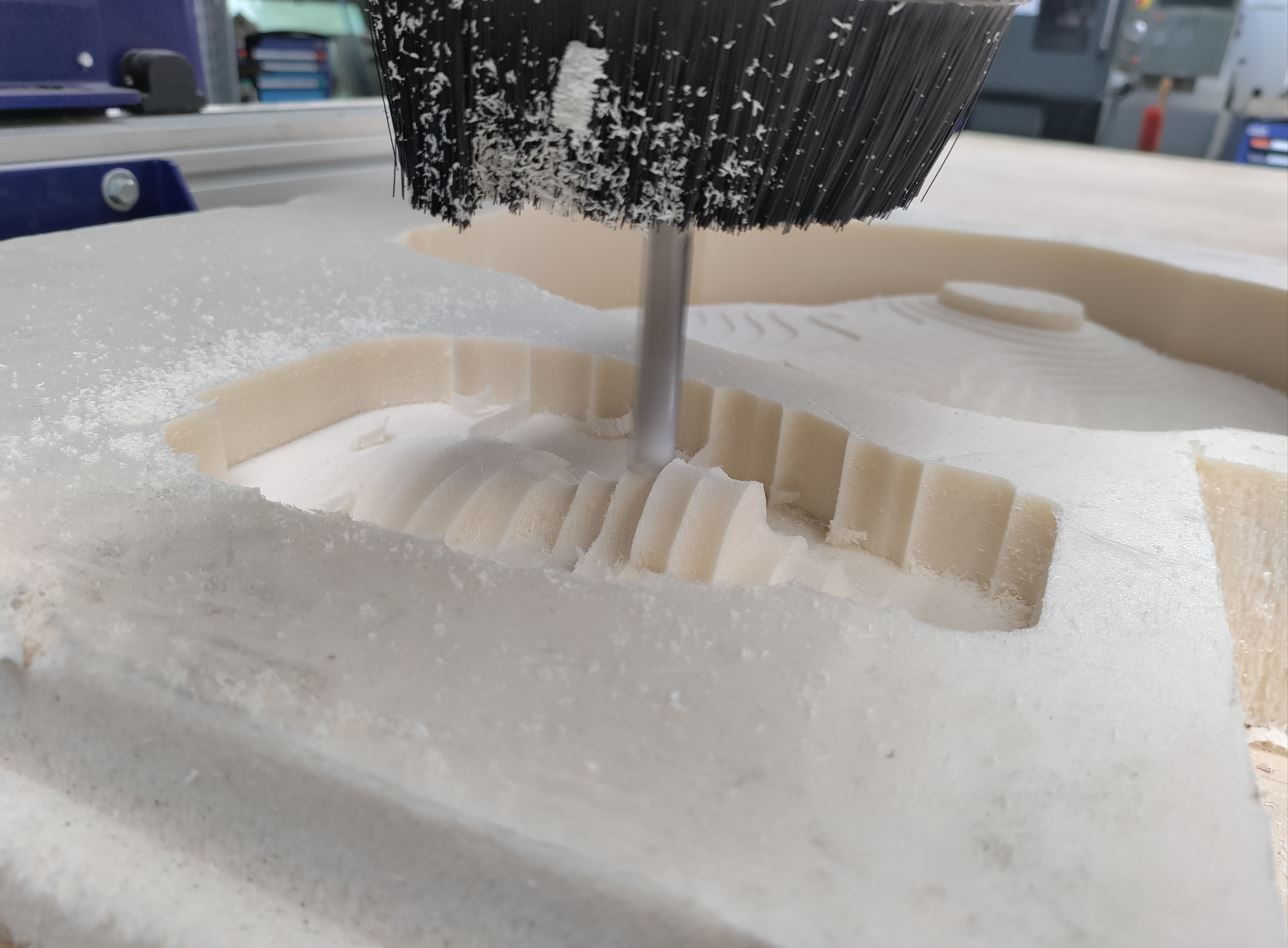

first path: Endmill¶

diameter 12

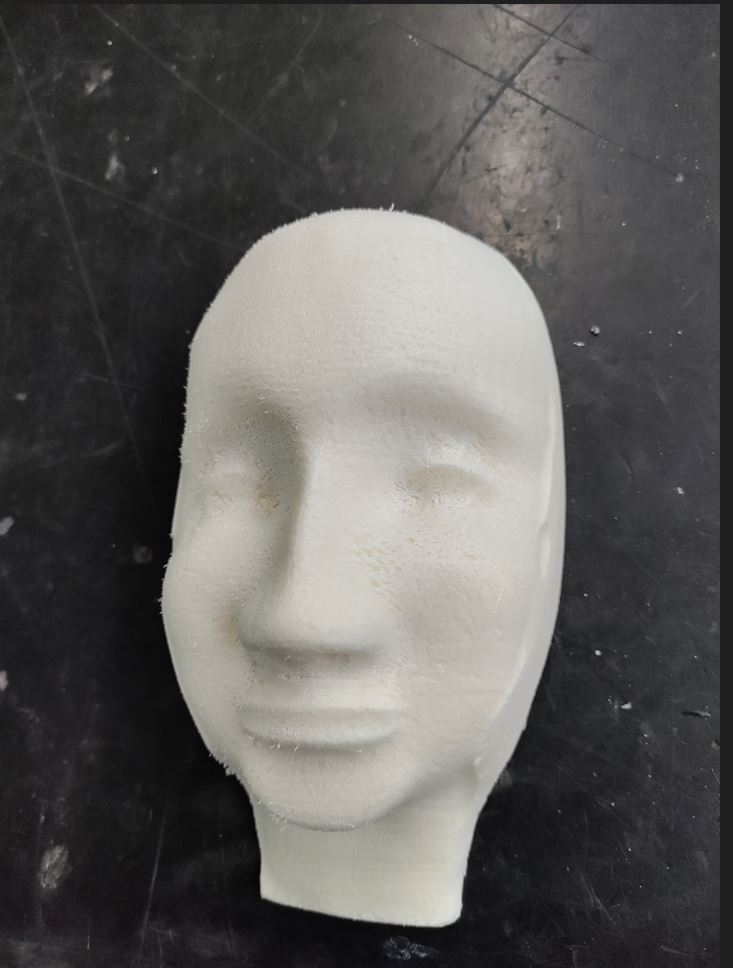

second path: ball nose¶

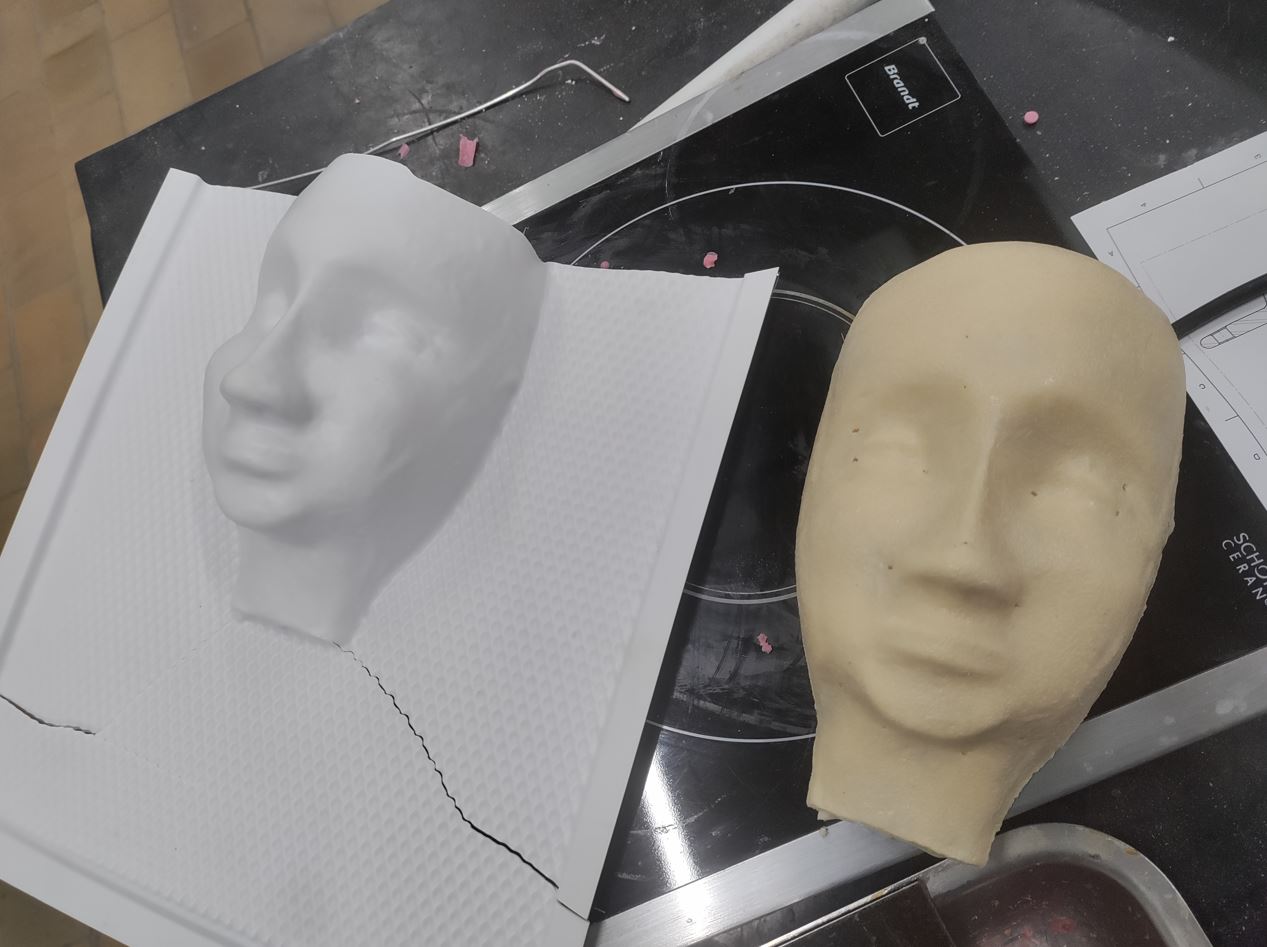

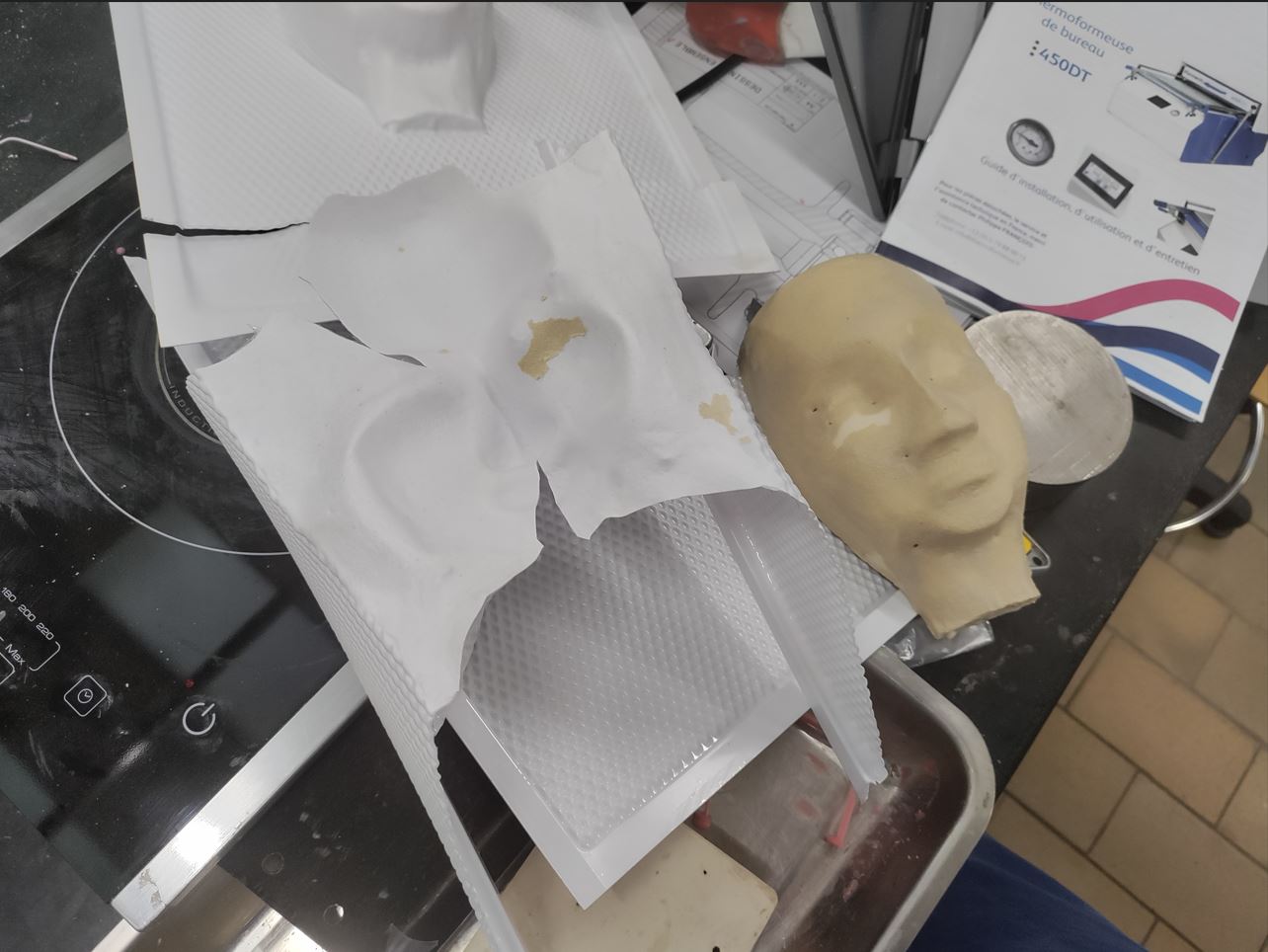

hot wire + cutting¶

Resine PU to make strong and get a heat protection¶

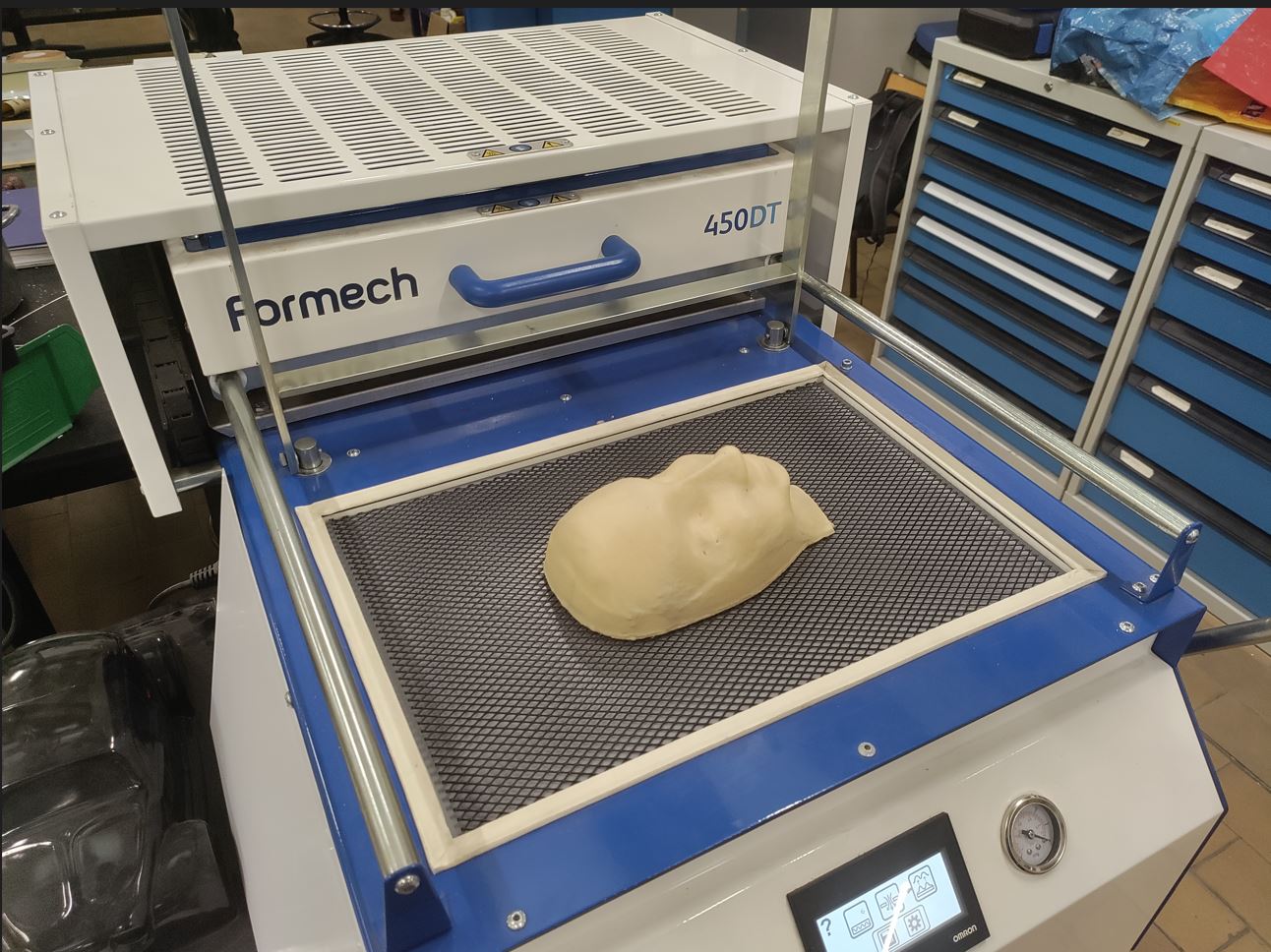

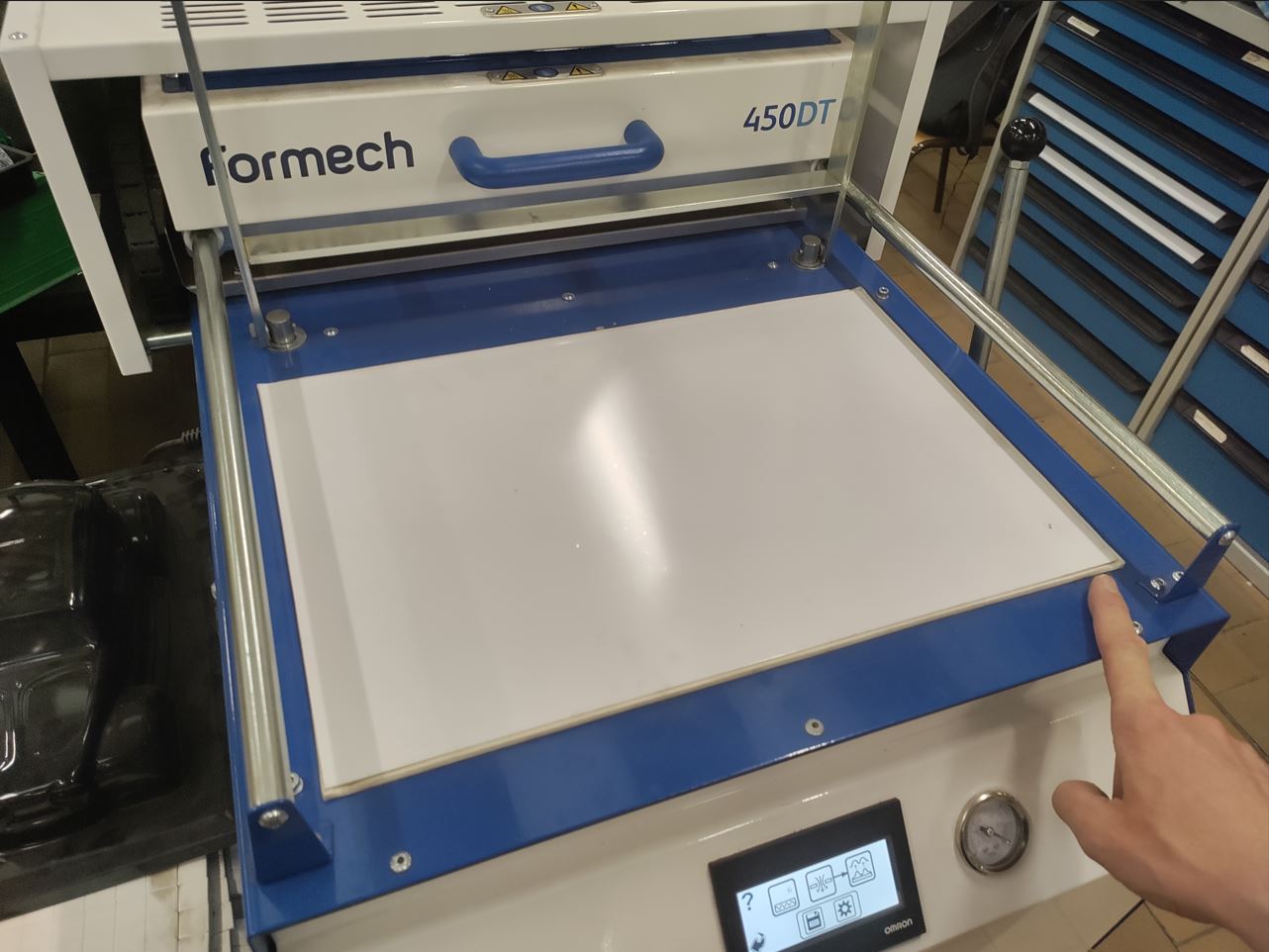

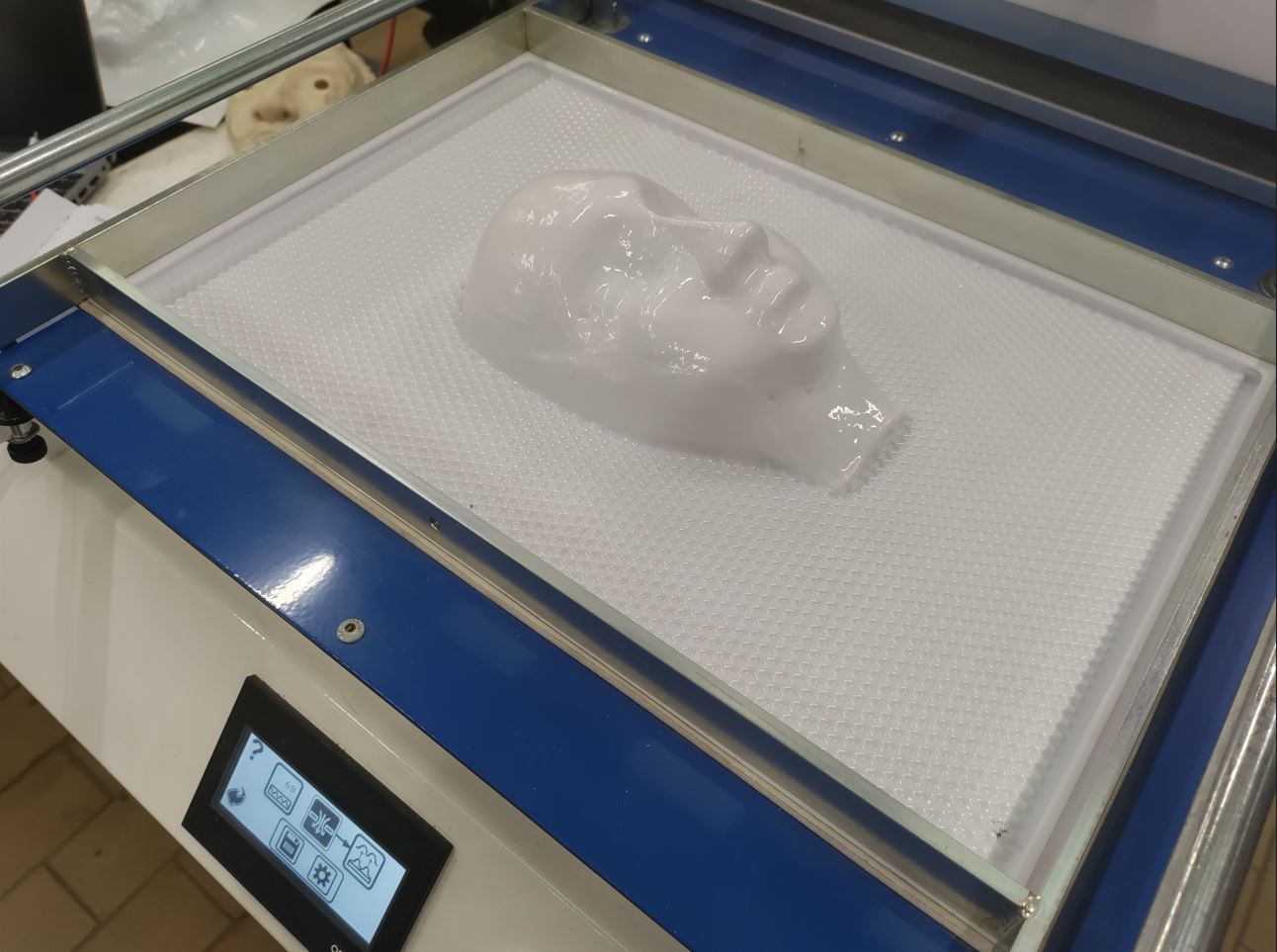

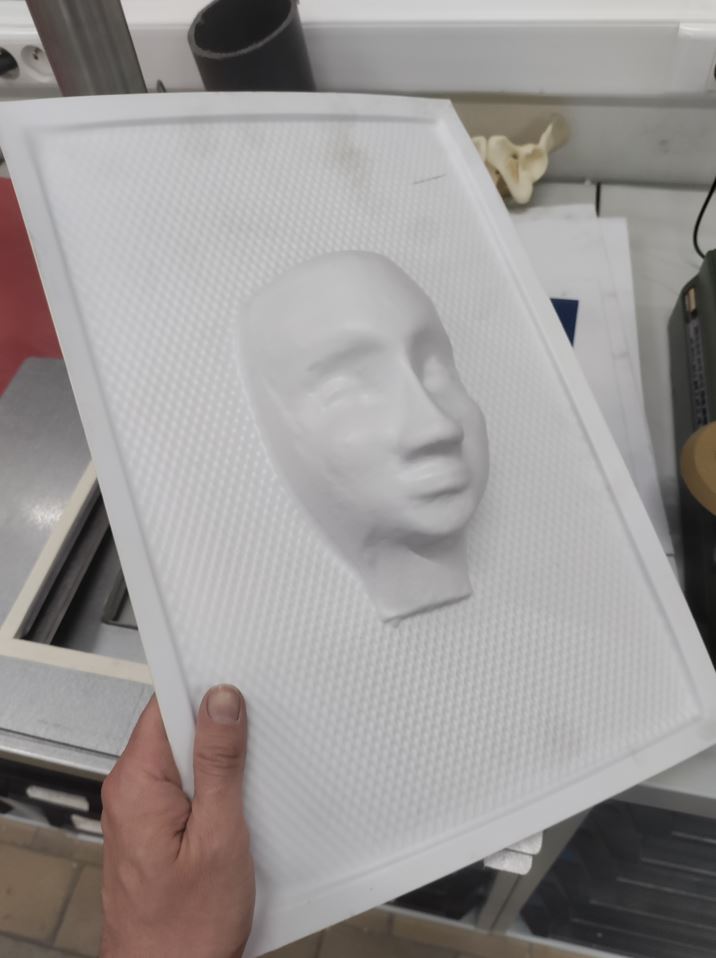

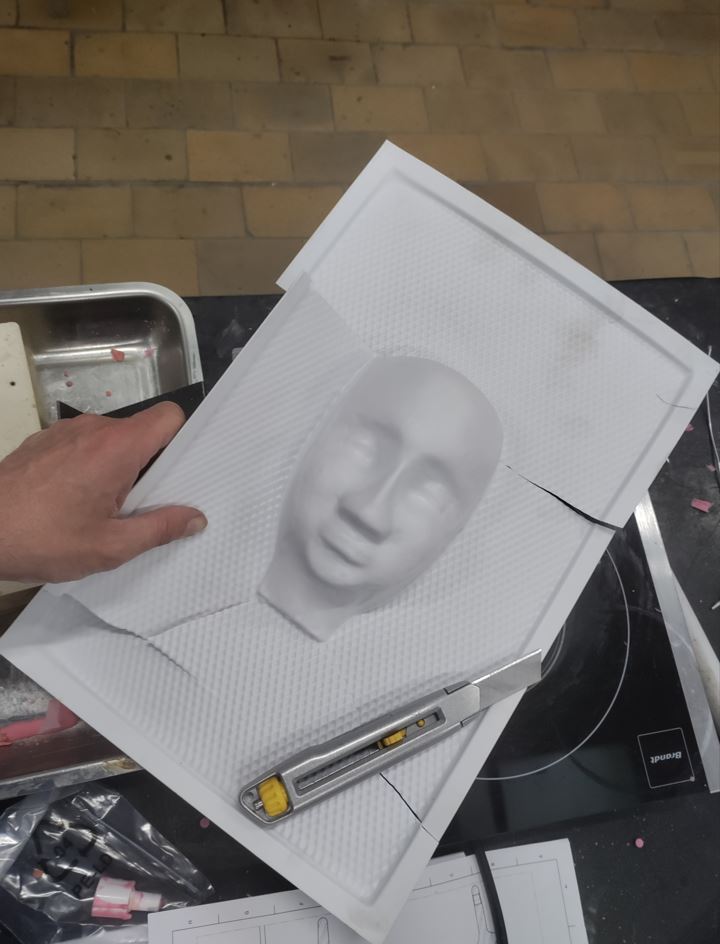

thermoforming.¶

Formech - 450 DT

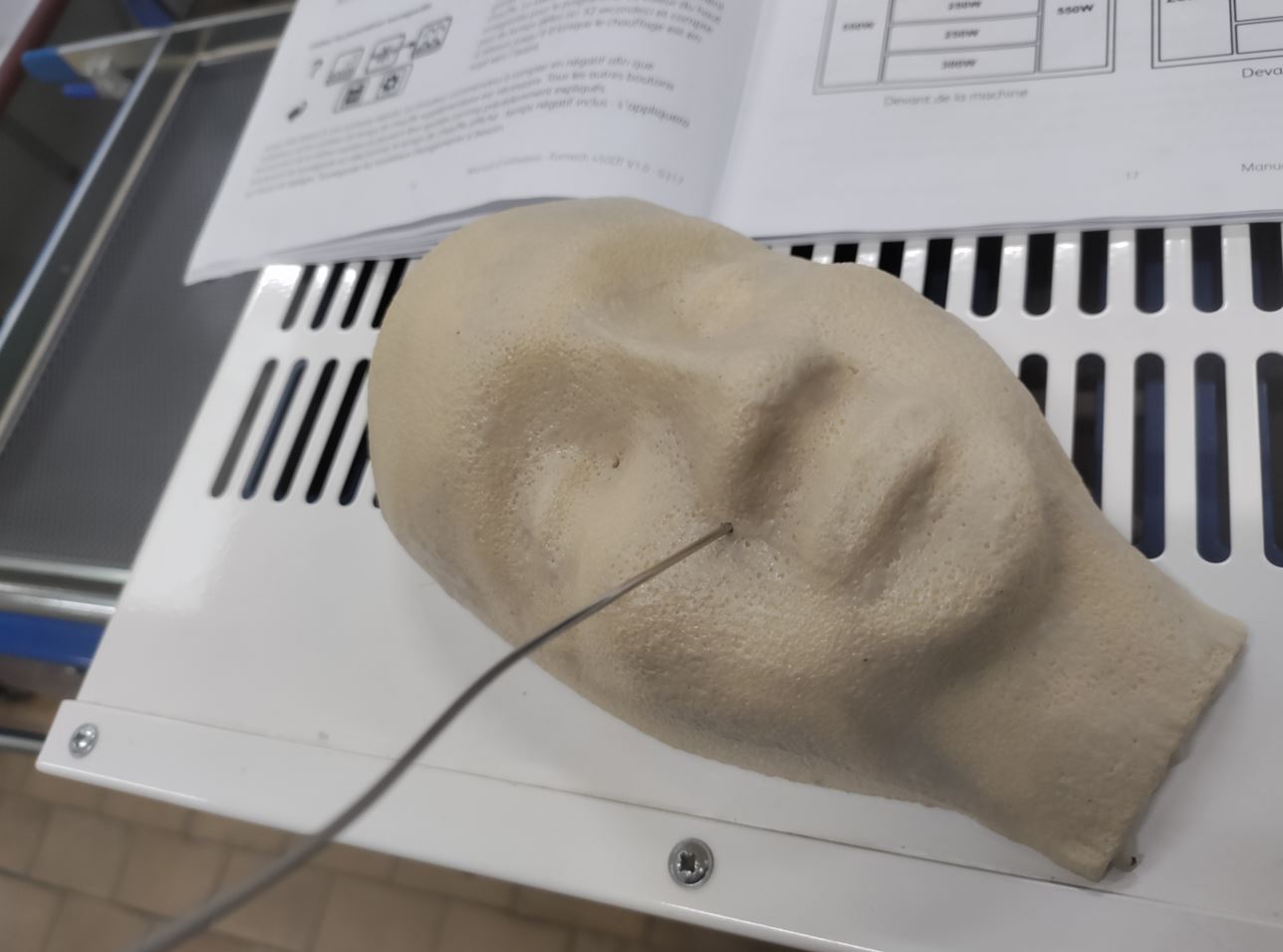

making holes for vacuum system:

thermoforming process.¶

Turn on the machine.

Material ABS 1 mm.

Turning OUT¶

Cool projects: samson: soft robot.

sheet metal fusion: https://www.youtube.com/watch?v=cgKe3JGNIEg&ab_channel=ProductDesignOnline

https://fabacademy.org/2021/labs/agrilab/students/theo-gautier/assignments/week18/