8. Computer controlled machining¶

This week I worked on building a mobile storage box for nurse.

Research¶

During the summer 2020 the fablab was busy to build stuffs for hospitals, doctors, retirment house. One of them was a mobile storage box for nurses working in a retirement residence.

Several students were interested in building research and development teams. All the communication was focused on the Discord platform.

Discord

Discord

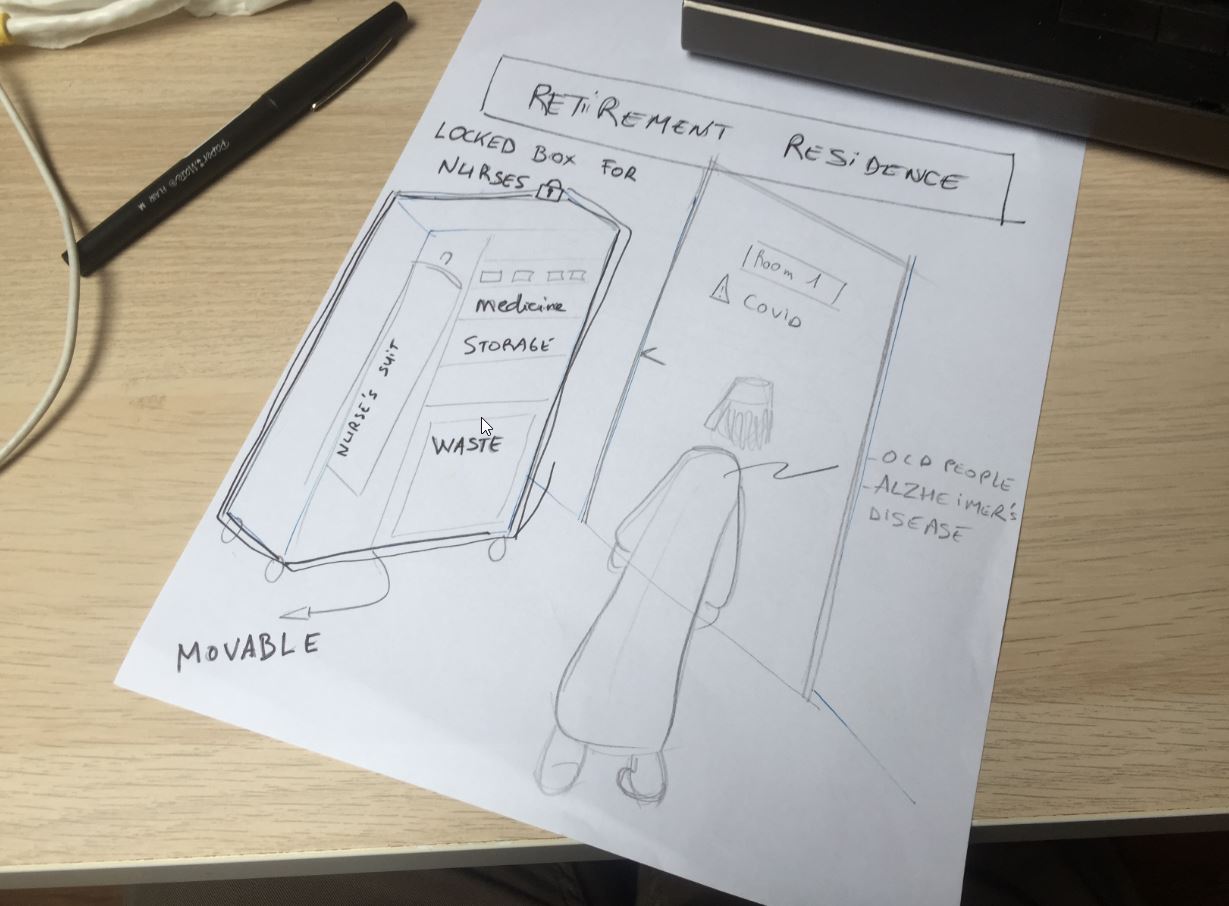

I helped them in order to simplify their solutions. When the University authorised us to visit the place. We came back with a lot of users’feedbacks. It has to be easy to move if necessary. The alzheimer’s people must have no access. Nurses has to get new suit quickly, materials easily. A basket to throw away their suit after working.

sketching

sketching

sketching

sketching

The students were not able to come to the lab, so my colleague and I built the first prototype.

first prototype

first prototype

and we fixed a lot of things such as:

3d modelling¶

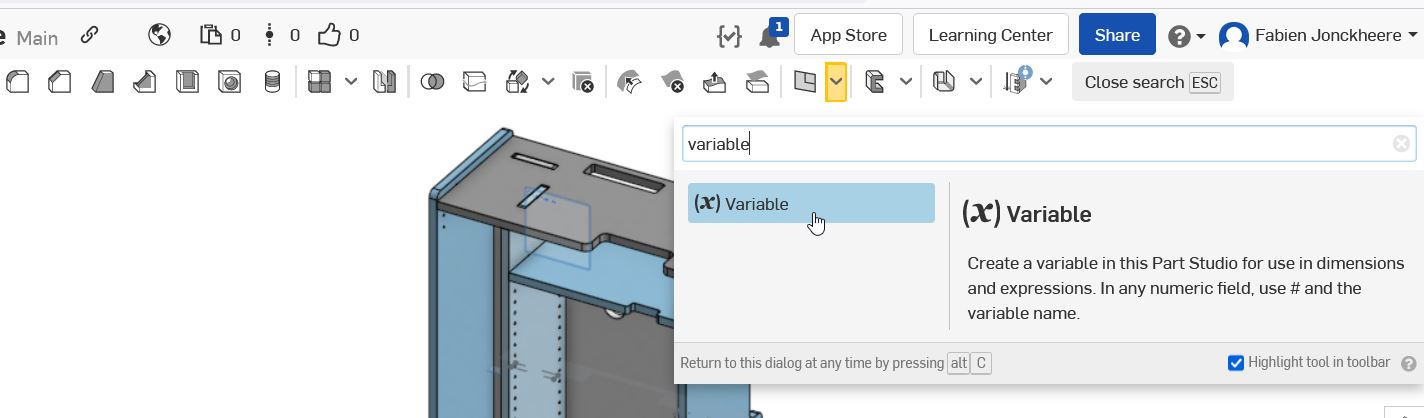

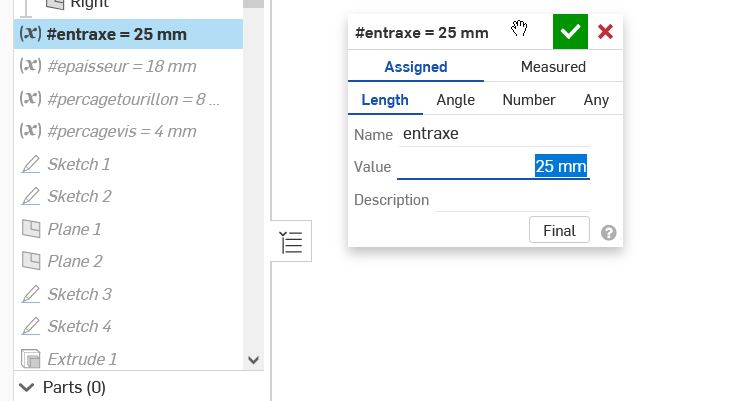

I get back on the project and I designed it on onshapde. I also created parameters for the thickness, length , width, axes…

You can look for the option in the search tools

Variable function

You can type your parameters:

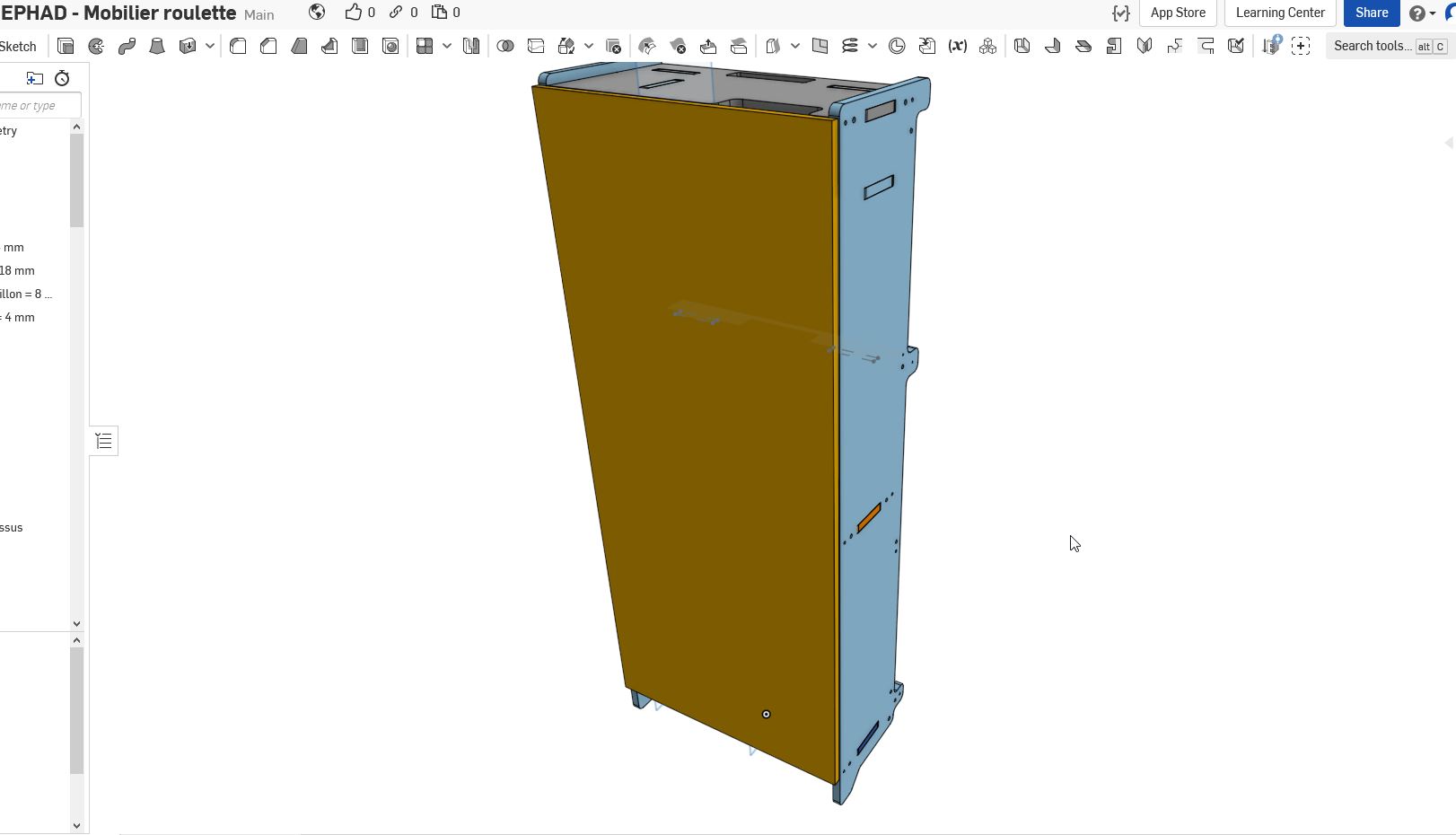

storage box front perspective view

storage box front perspective view

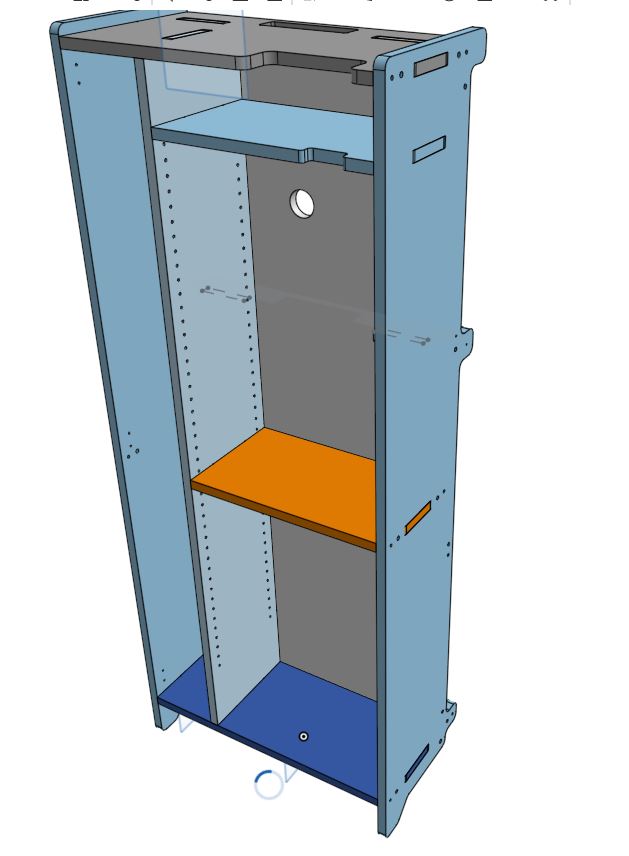

storage box /no front door/ front perspective view

storage box /no front door/ front perspective view

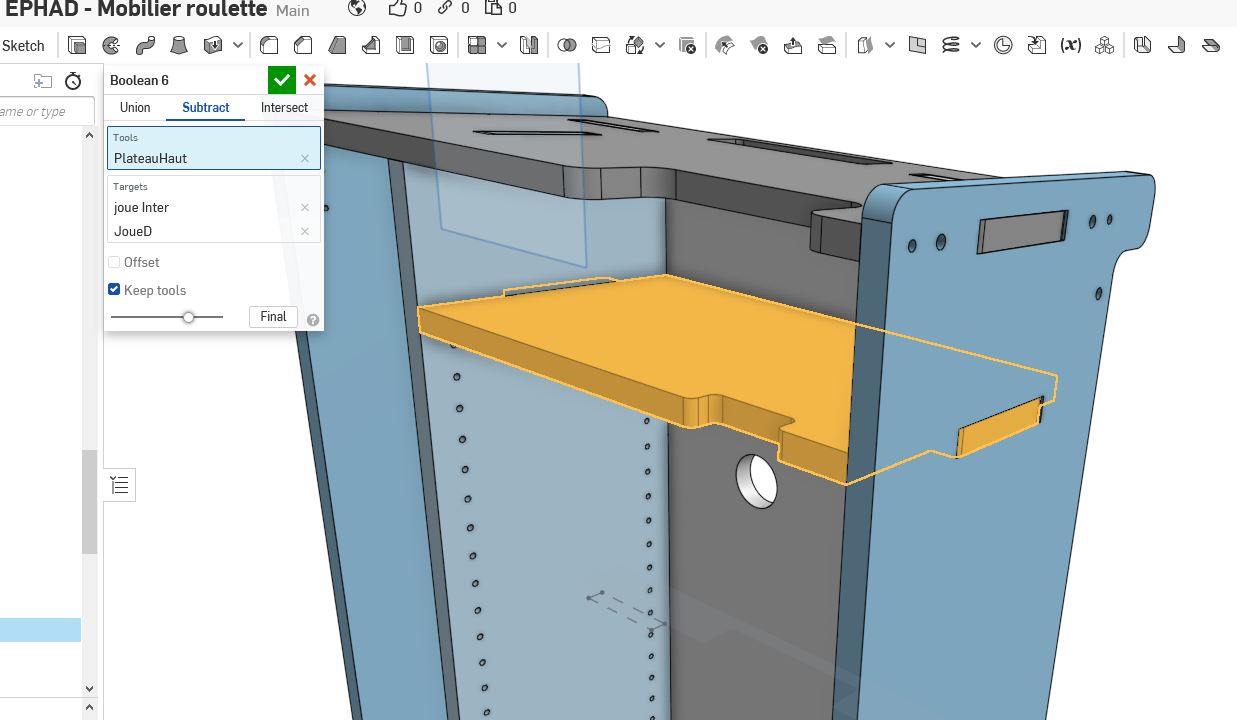

I designed the project in order to work both: in a lab and in an industrial process. I used a lot the boolean function in order to get quickly the assemblY.

boolean function

boolean function

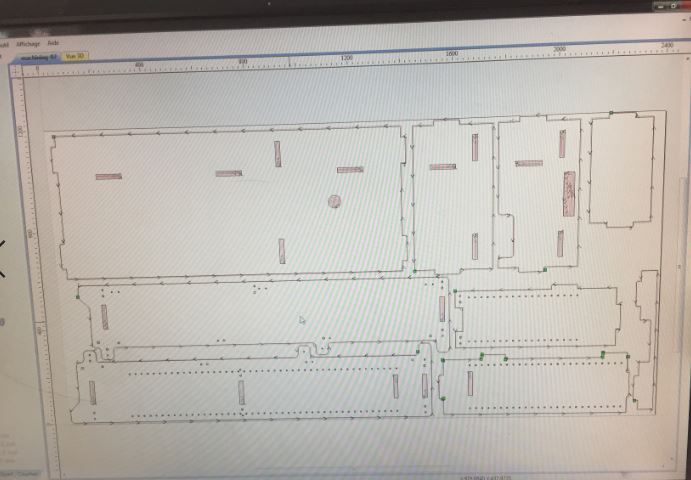

I use the “export as dxf/dwg” in order to get the tool paths.

¶

N=1000xVc /TTxd

| Symbols | Unity |

|---|---|

| Vc | m/min |

| N | tr/min |

| d | mm |

a=Nxfxz

| Symbols | Unity |

|---|---|

| a | mm/min |

| N | tr/min |

| f | mm/tr/teeth |

| z | number of tooth |

a=2400mm/min

N=14000 tr/min (maximum frequency of the shopbot)

V carve pro.¶

To make the file for the shopbot, I use VCarve Pro software. First I imported all the dxf file

routing paths

routing paths

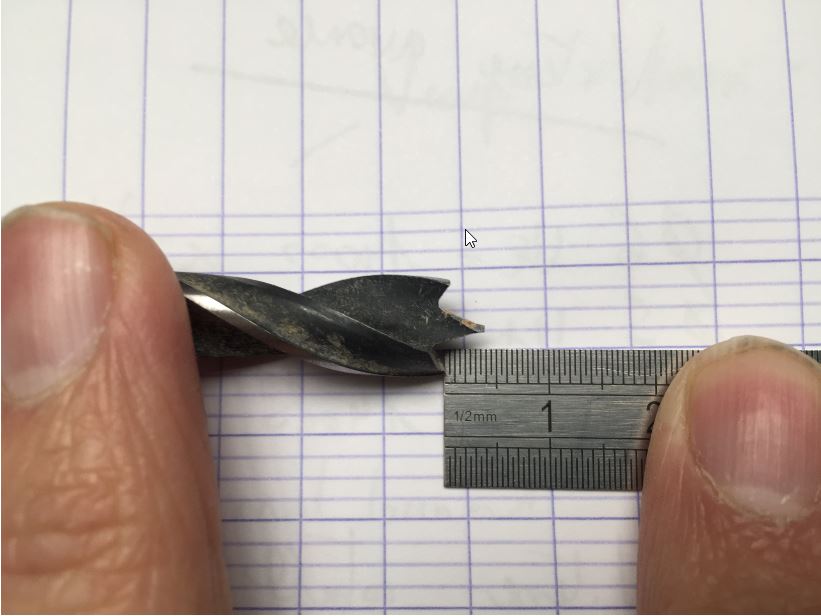

After that, I just need to select all the parts and select the tool I would like to use. Here, I choose a upcut tool of 6mm diameter. the softaware will generate all the paths for the machine. I will just add some tabs ta maintain the parts during the production.

I have selected 5.5 , 8 , 10mm drills to make the linear holes and I measured the difference between the end of the tool and the main surface.

drilling difference

drilling difference

Probe¶

2 - Milling the project¶

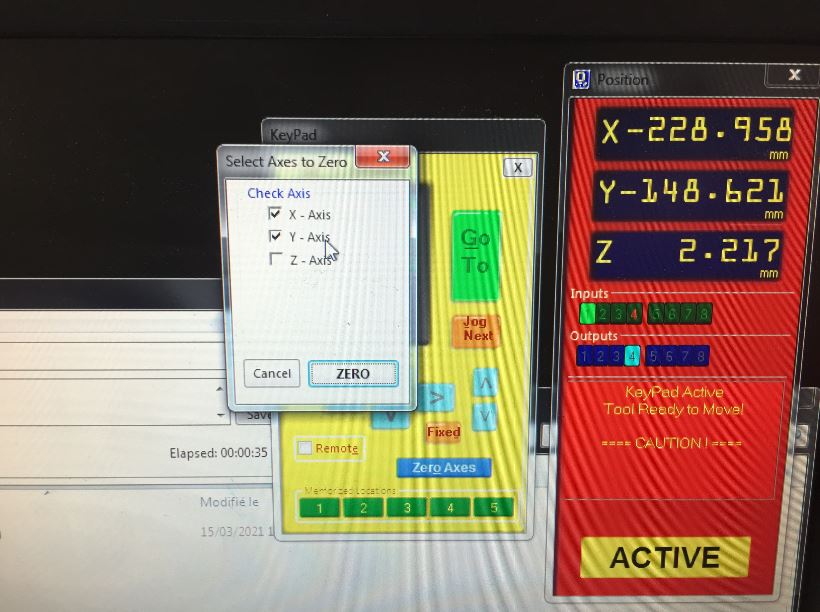

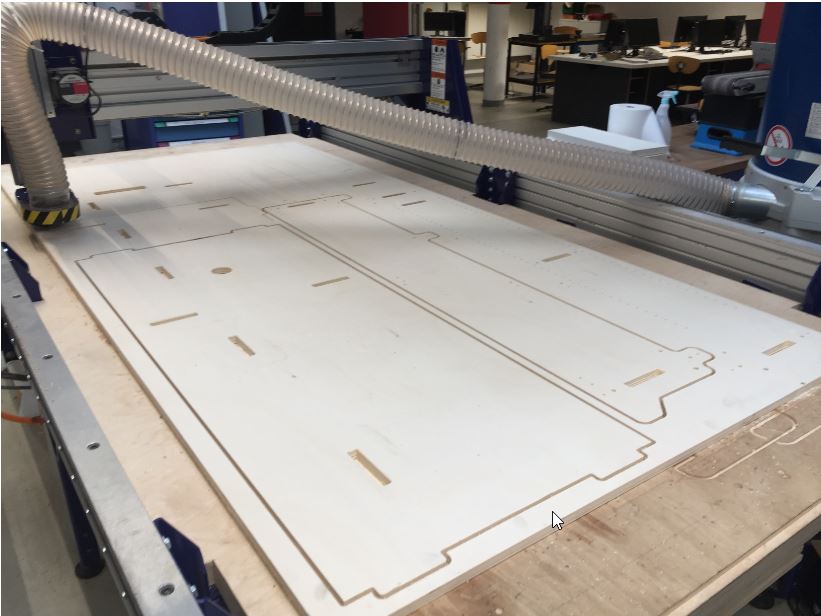

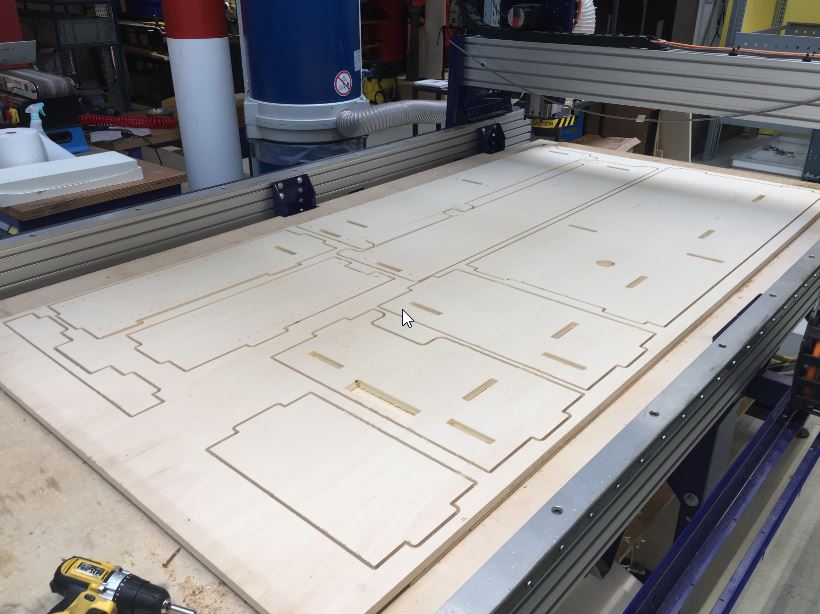

To mill my project, I use the shopbot. After putting the tool and the material into the machine, I’ve made the zero for the Z axis using the dedicated tool. I have also verified that my design fits into the machine before launching the milling.

probe

probe

processing

processing

job done

job done

wood router

wood router

Testing¶

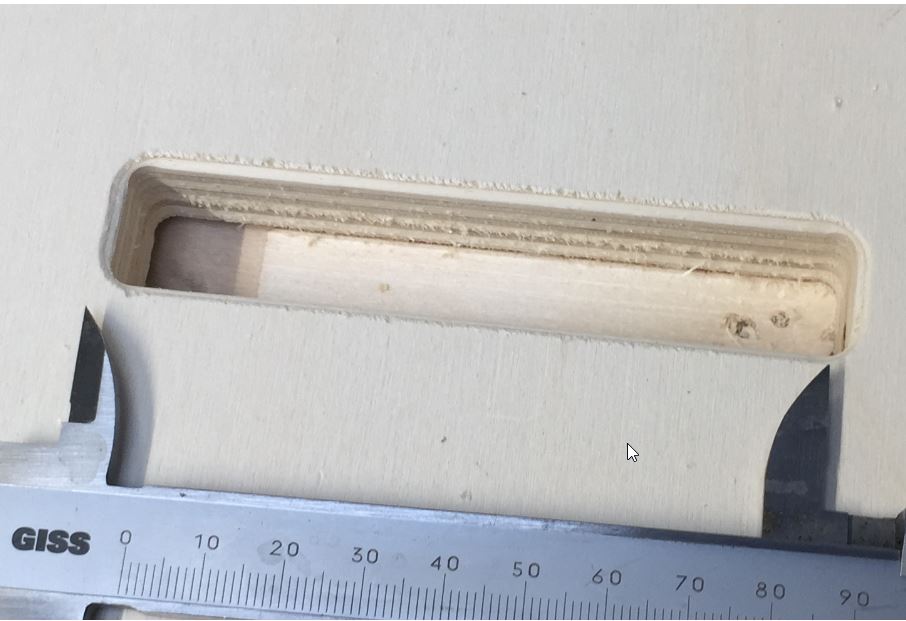

For this part, I cut three times a slot of 18 by 100 mm,

Measurements

Measurements

I got this measurements:

For 100mm 99.42 /99.56 /99.50 mm For 18mm 17.56 mm

wood router

wood router

I would like to use a hammer to make a strong assembly, so I kept it like it was.

Assembly¶

step 1

step 1

step 2

step 2

step 3

step 3

problem03

problem03

problem04

problem04

doord

doord

Sanding

Sanding

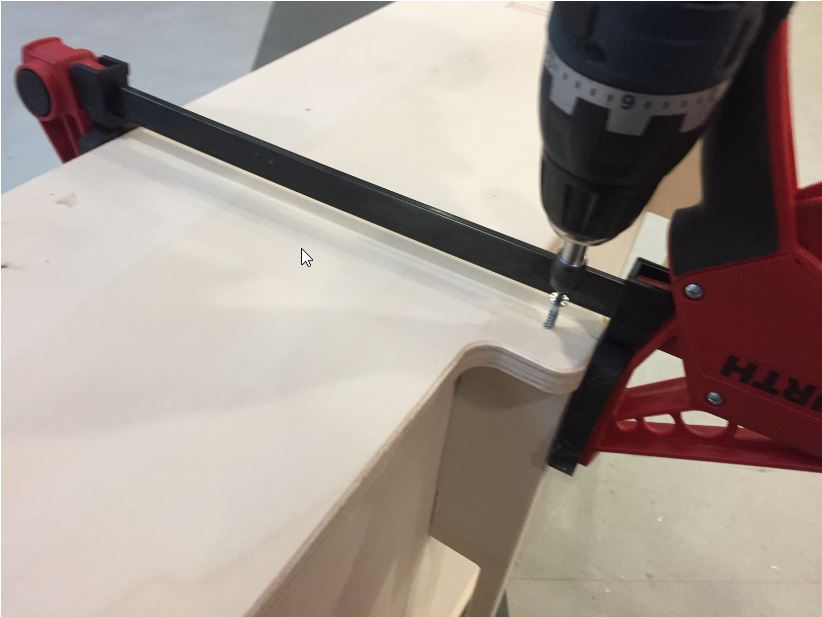

clamping

clamping

I had some issues because the standard measurements did not equall to “IKEA measurements”. I am waiting for standard hinges.

problem 05

problem 05

So, this is the comparison V1 and V2.

compared version

compared version

compared version

compared version

I will take some extra time to finish it and present to the future users.

testing

testing

Opening the door:

Let’s roll:

Final pictures.