4. Computer controlled cutting¶

I have started the fabacademy three weeks late, so I am in a rush to get my assignments documented. Right now we are week 09.

LASER CUTTING MACHINE: Speedy Trotec 400¶

This is the brand I know since 2015, I used to create toys and manual activities.

The large one (speedy 400) is perfect for small production.

The work area is 610x 1016 mm²

Laser power Co² 60 - 100

This is the brand I know since 2015, I used to create toys and manual activities.

The large one (speedy 400) is perfect for small production.

The work area is 610x 1016 mm²

Laser power Co² 60 - 100

Overview:¶

Main characterics:¶

There are 3 parameters to know: Speed (mm/s) Power (percent) Frequency : Hz

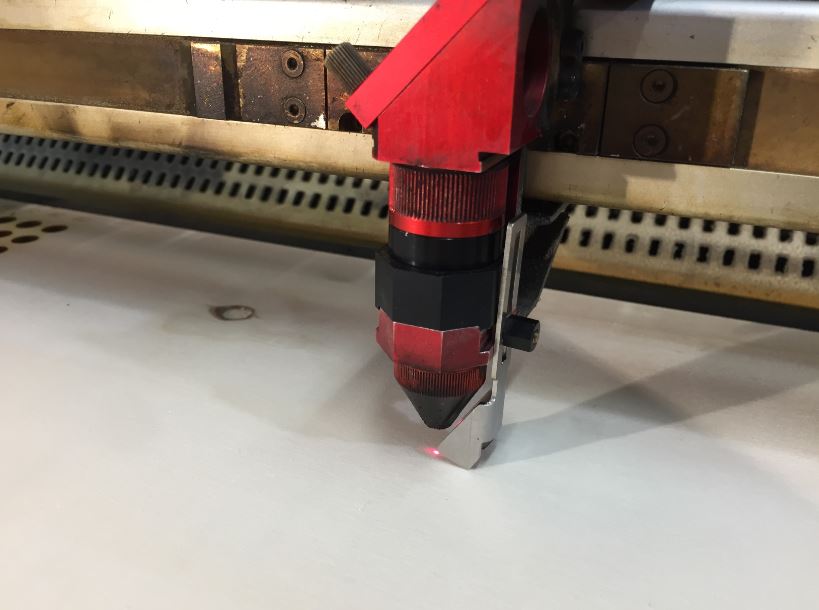

Probing¶

It is easy to probe by using the tool of the machine.

That’s the power of cut !!¶

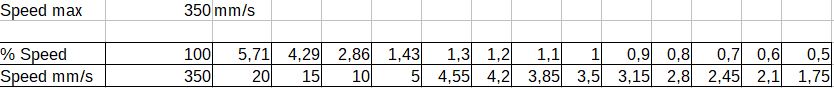

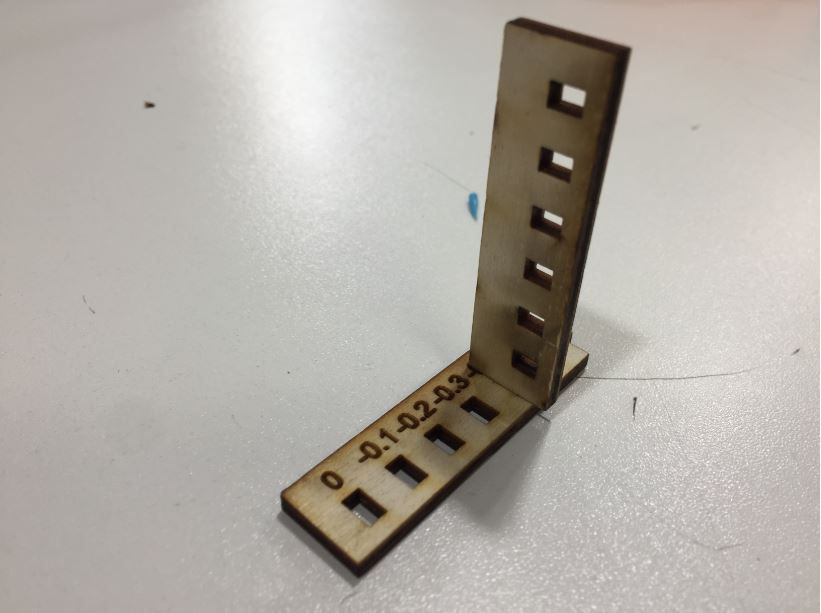

In the lab, the main material is 3mm bench plywood. According to power and speed, we are testing the ratio to know the best values to cut the material.

I cut comparison charts showing which parameters work and which not.

The ratio for a 3mm plywood bench board is around 80% of power and 1,1% of speed.

Download ratio-test

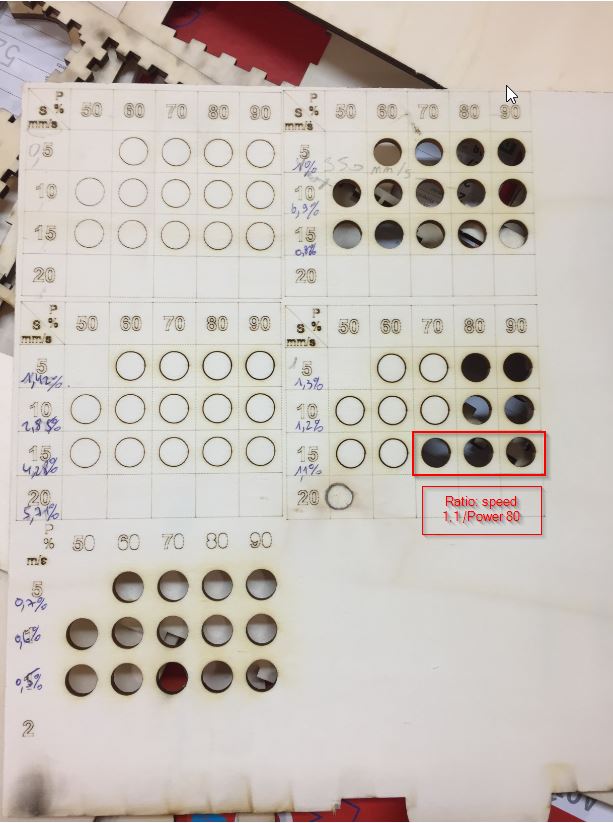

The Kerf¶

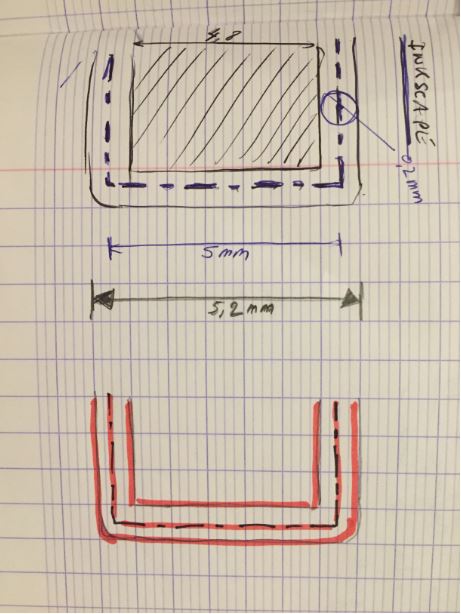

It means the diameter of the cutting beam. To make assemblies, I need to to know the tolerance between what I draw on inkscape and what I get from the lasercutting machine.

we need to use this kind of template.

I measured what I got from the lasercutting and summed up in this drawing:

On the left, the laser process. On the right, the inkscape vector.

On the left, the laser process. On the right, the inkscape vector.

You just try to fit the lug to the proper notch.

On the left, the laser process. On the right, the inkscape vector.

You just look for the perfect fit called the KERF: - 0,4

Download the kerf-test

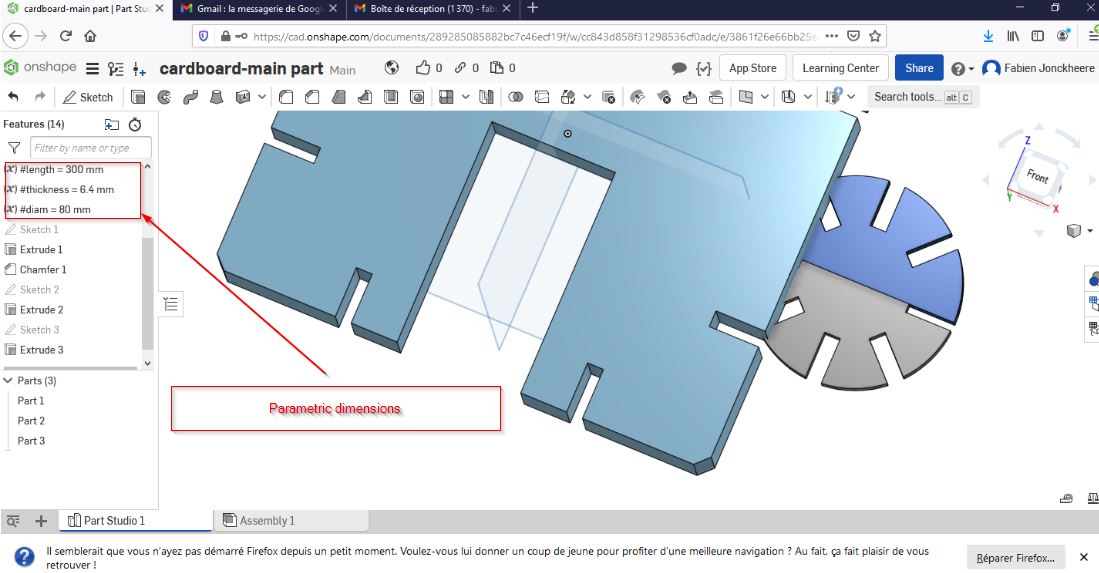

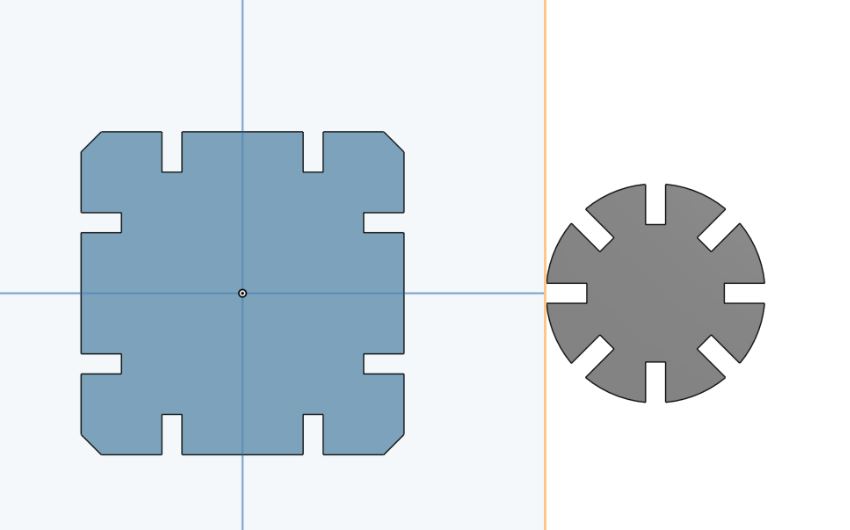

Design, lasercut, and document a parametric construction kit¶

Create something useful is my leitmotiv. Since christmas, my daughter is asking me a playmobil house, here comes my topic. Two parts have been created but it is easily to create towers, houses, flats etc…

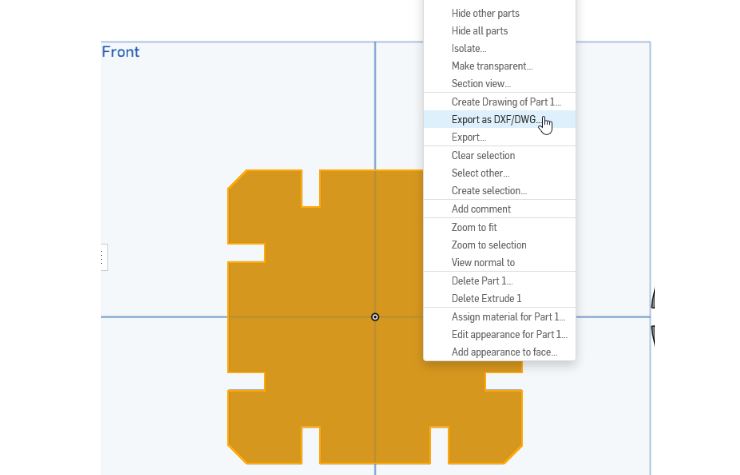

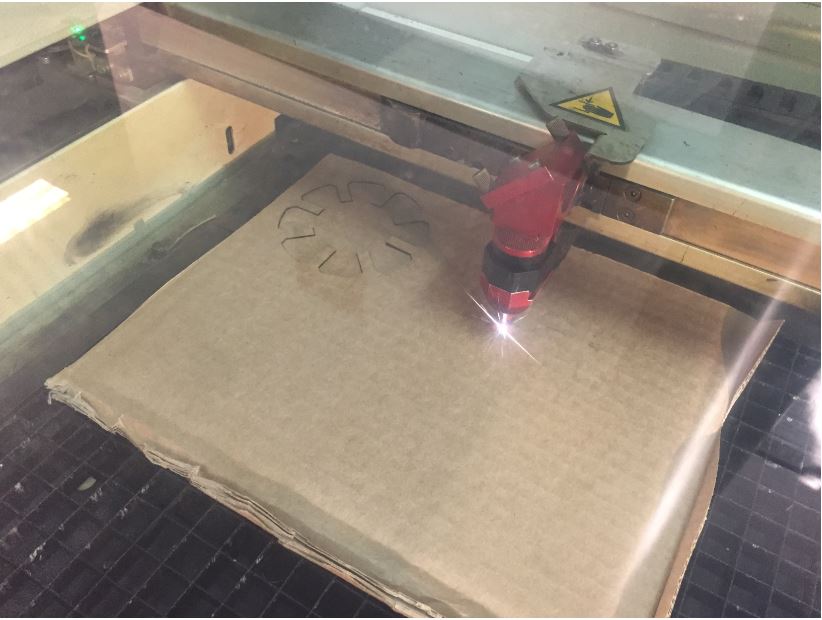

Lasercutting¶

- Material : 3mm carboard recovered sheets.

- Ratio: Power 100 speed:1.5 frequency: 1000

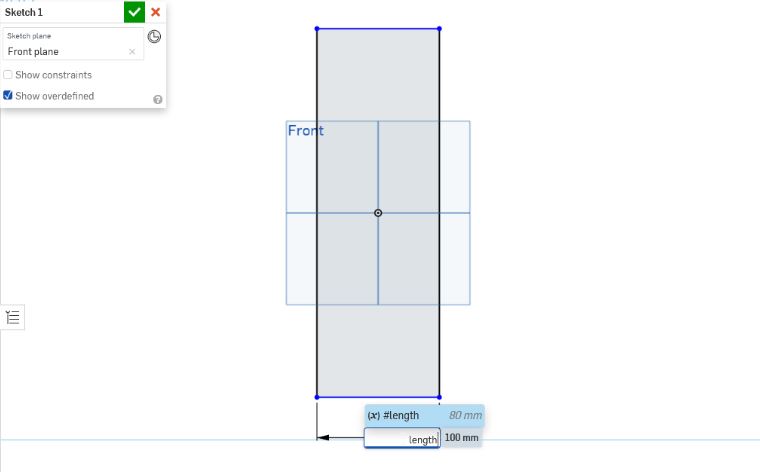

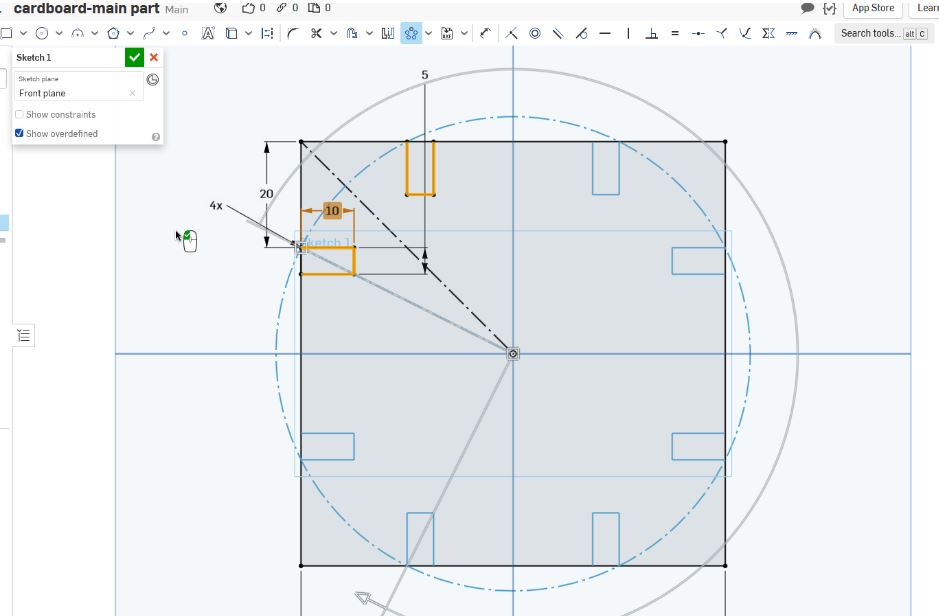

- 3D modelling software: onshape.

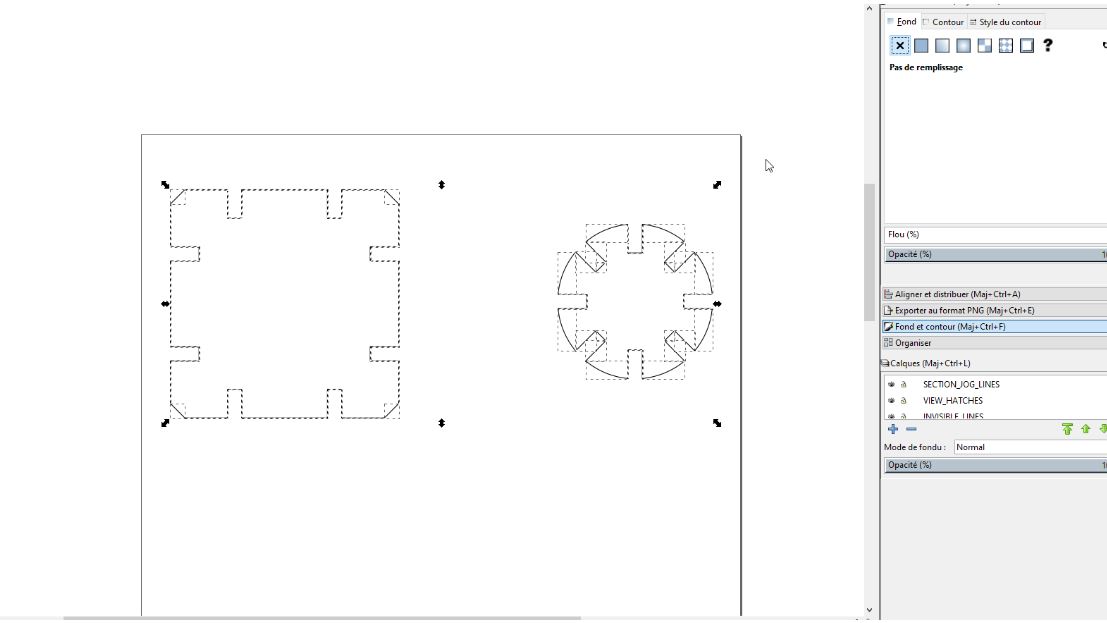

Then import the dxf into the inkscape program.

Then import the dxf into the inkscape program.

Let’s cut !!

No need to move the dimensions, the carboard parts plug themselves very well.

First playmobil tests!

You can build high or large house

You can build high or large house

Download: Playmobil House

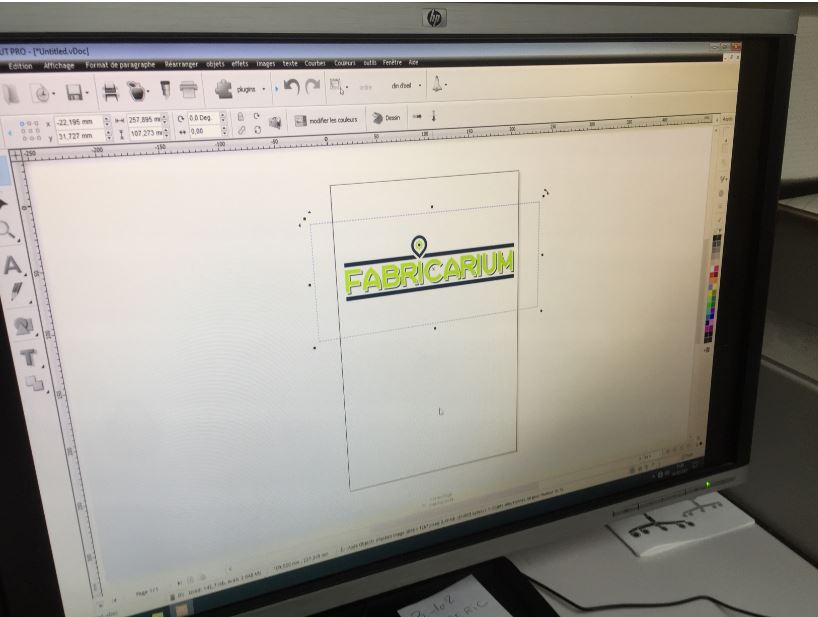

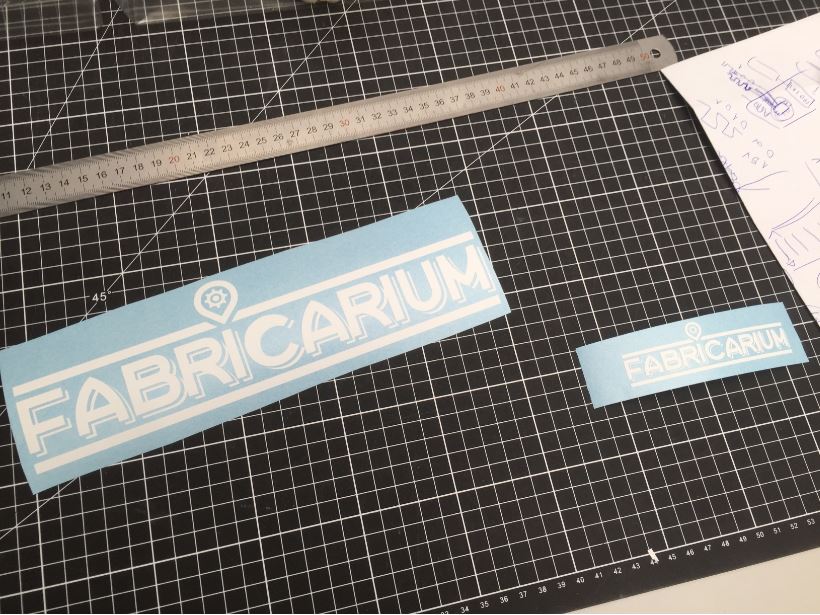

Cut something on the vinylcutter¶

Useful thing: a vinyl logo for the fabmanagers of Fabricarium.

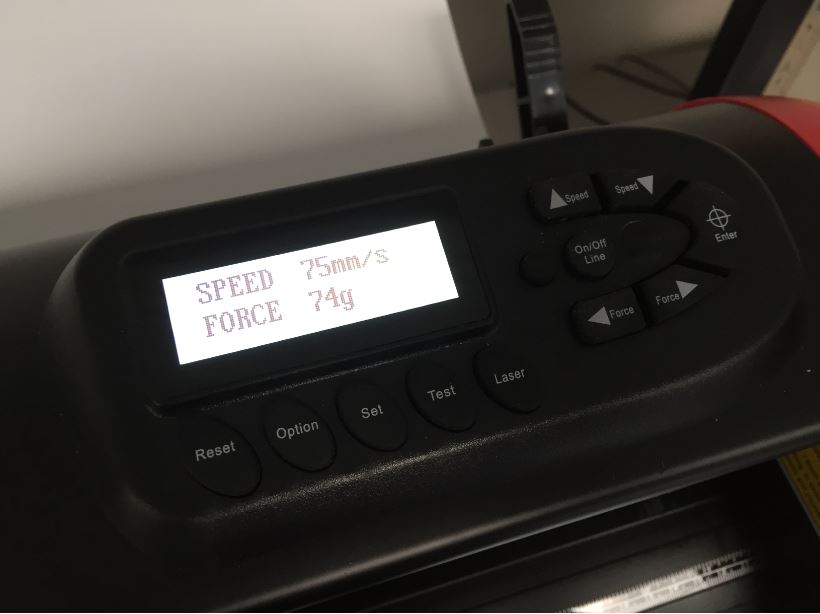

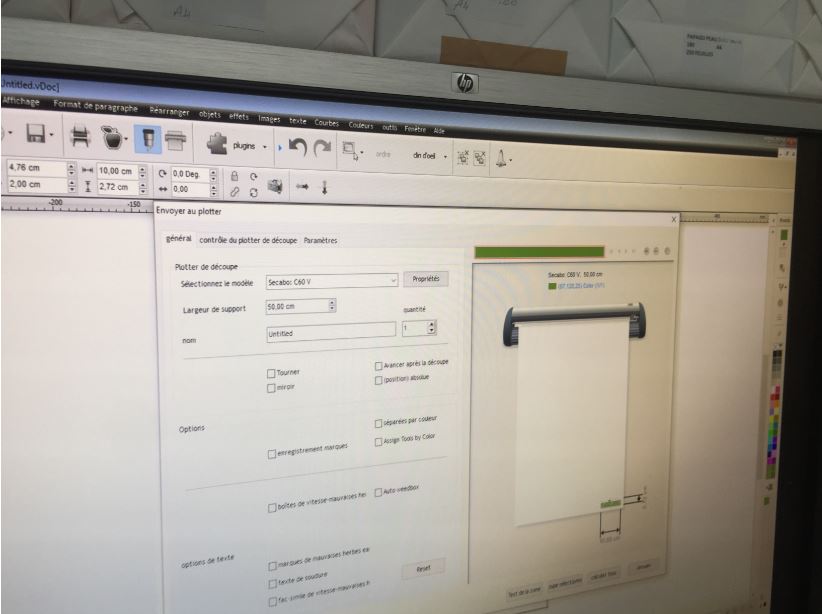

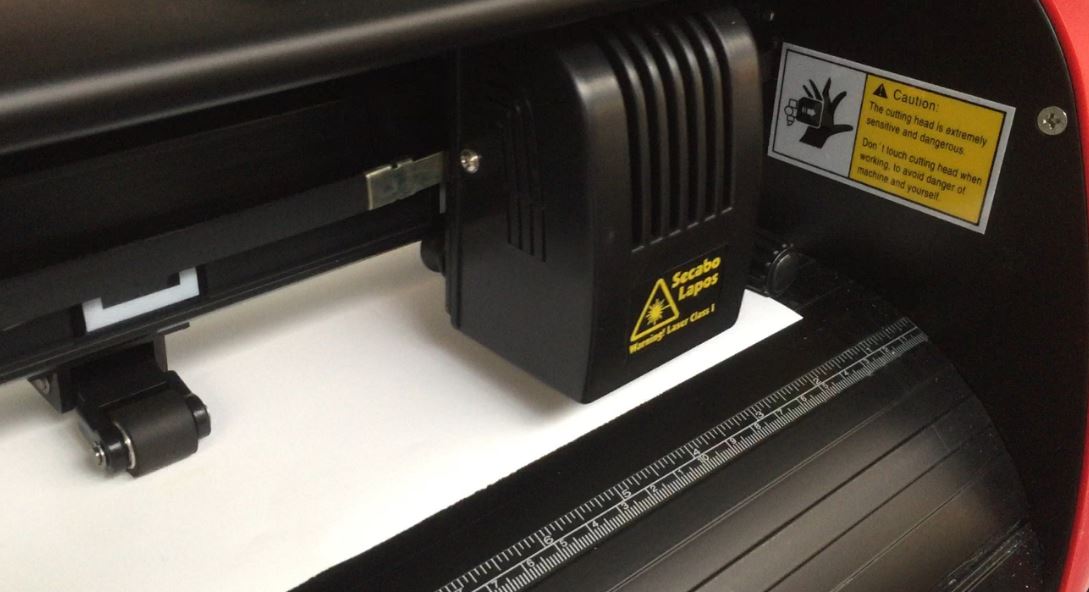

tool: Secabo C60IV vinyl cutter with LAPOS2¶

| parameters | specifications |

|---|---|

| dimensions | 92cm x 26cm x 26cm |

| scope of delivery | Knife holder, drag knife, plotting pad DIN A3, plotting pen, connecting cable, software, operating instructions |

| countour cutting function | LAPOS², 4 crop marks |

| max. downforce | 500 g |

| max. media width | 50 mm |

| min. media width | LAPOS², 4 crop marks |

| max. media thickness | 1 mm |

| max. cutting size | 630 mm |

| max. cutting speed | 600 mm/s |

| mech. resolution | 0.025 mm |

On photoshop, illustrator, inkscape, whatever you know, you just print by using the proper machine.

The plotter has already cutting parameters, and it works very well.

It is really easy. Then, you choose the place and the numbers of copies you need.

It is really easy. Then, you choose the place and the numbers of copies you need.

Remove the vinyl part you do not need.

Apply an adhesive transparent tape

Lock your target and stick it!

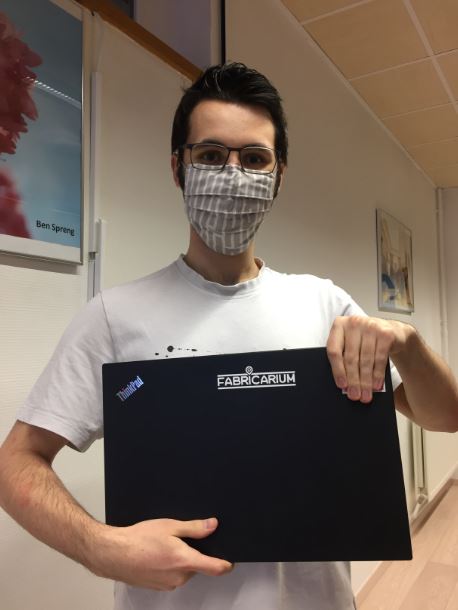

_First sticker on Axel’s laptop.