Skulina Hlif Kjartansdottir

How to make [almost] anything

Week 12: Composites

This week we are learning about composites. This is our agenda for the week. We will get aquainted with various materials, fibers and resins. We will work with various processes, compaction, compression, infusion and open or closed moulds. Safety in handling different materials will also be on the agenda, as some of these materials require ventilation and protection, with respirators, goggles and gloves.

Week 12: Assignment

The assignment for this week is to to make a 3D mould and to produce a fiber composite part in it. Different types of fiber might be tested and multiple plies of fabric will be used, imbued with the resin, to test the strength of the form.

We had an introduction of the materials that we had available in the workshop.

We are making use of Finnfoam for the moulds. The fiber we are using is burlap or other natural fibers, which is supported with Polyester batting when doing the open vacuum moulding.

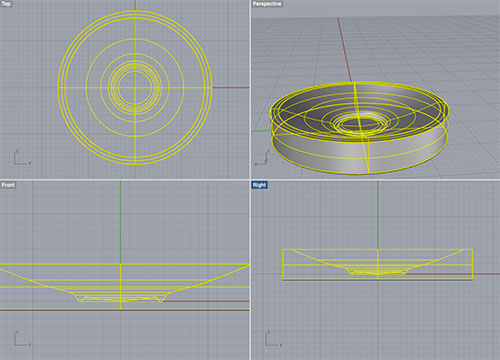

I designed a bowl in Rhino, with a relatively shallow form and a foot.

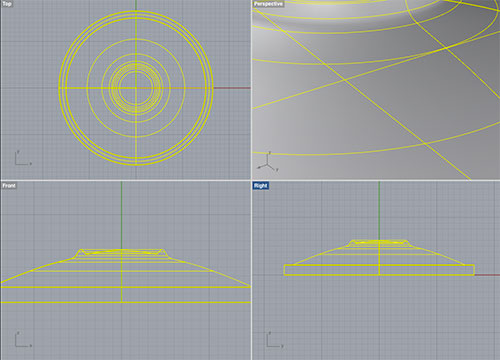

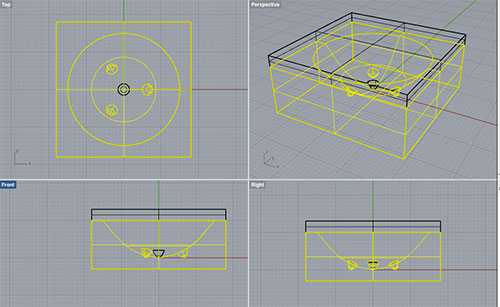

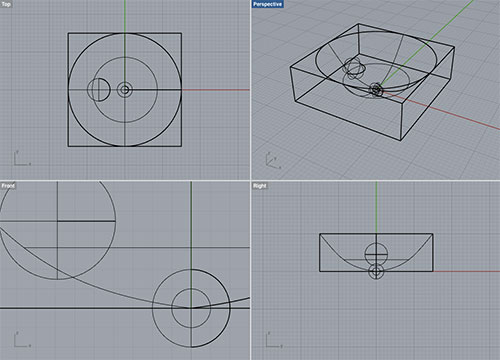

A reverse open form was created that I intended to use as a mould and to vacuum pack later on. I saved the bottom and top parts of the mould in a .stl file format. These files were opened in Partworks 3D and checked that the top is selected on the model. See a more description of settings and saving of toolpaths in my notes:

More designs were attempted that were not carried out to any completion.

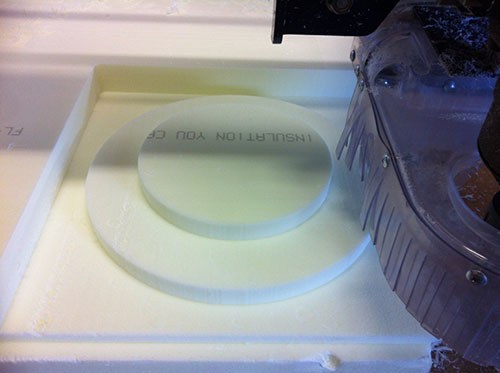

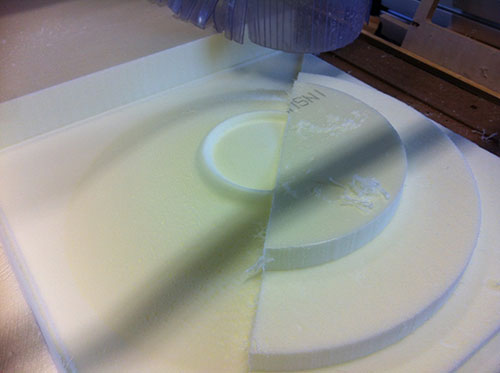

The mould was cut on the Shopbot - see wiki and instruction on techniques. For the roughing toolpath a 0.5 inch endmill was chosen and a ball nose 0.25 inch for the finishing toolpath. The pass depth was set to 0.78 inch, stepover to 0.2 or 40%. The spindle speed was set to 12000 (default setting, judged according to the material qualities) and feed and plunge rate was first set to 3.0, later to 6.0.

When the rough cutting had taken place the mill cleaned near the edges of the cut. Then the tool had to be switched for the finishing round.

The mould was prepared, by painting the top surface with an Acryllic Gesso Primer. This was left to dry overnight.

In preparation for the compositing we checked out Zitek Scott's guidelines. I prepared and cut the five burlap layers and the batting, prier to mixing the resins.

The mould needed to be covered in plastic film, which was painted with vaseline.

The epoxy resins I used were mixed 1:2. They need to be stirred together carefully as not to create bubbles.

The burlap or fibers are dipped into the mix and layed on top of the mould. A layer of plastic film and batting is put on top of the fibers and spiked roller is used to pierce the plastic film for the air to escape.

The mould is then placed in the vacuum bag, which needs to be tightly sealed.

The sealed bag has to wait at least overnight.

This is the shape as it looks when it was freed from the mould. The edges need to be touched up a little.

Plans for next Week

Experiment with different fibers.

Notes

My Notes from this week.