Photometric:

Robotically-Controlled Responsive Facade System

photometric from Kelly Zona on Vimeo.

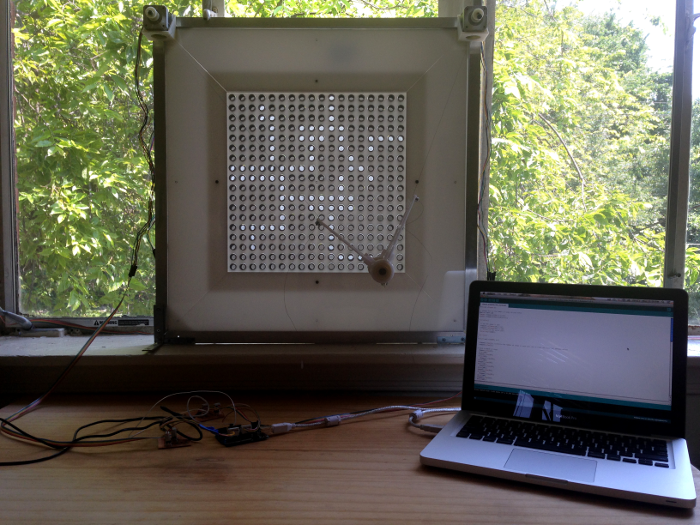

Final project with interface control

Final project with interface control

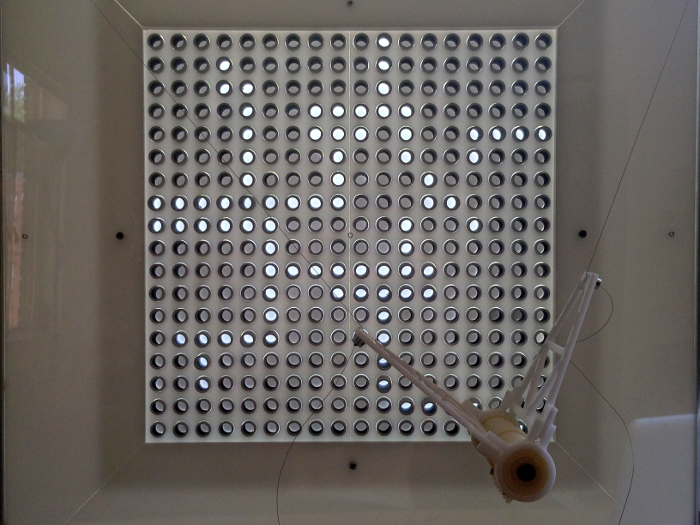

Closeup of screen

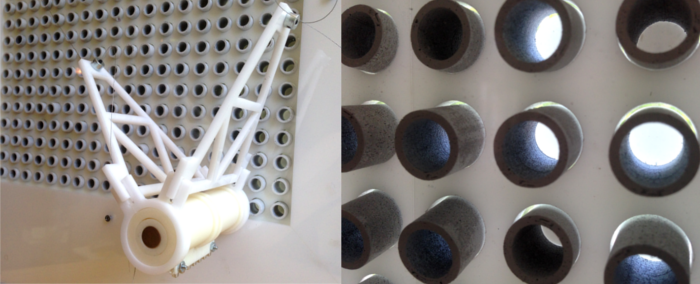

details

details

Overview

Photometric explores the emerging role of robotics in architecture, beyond tools for construction.

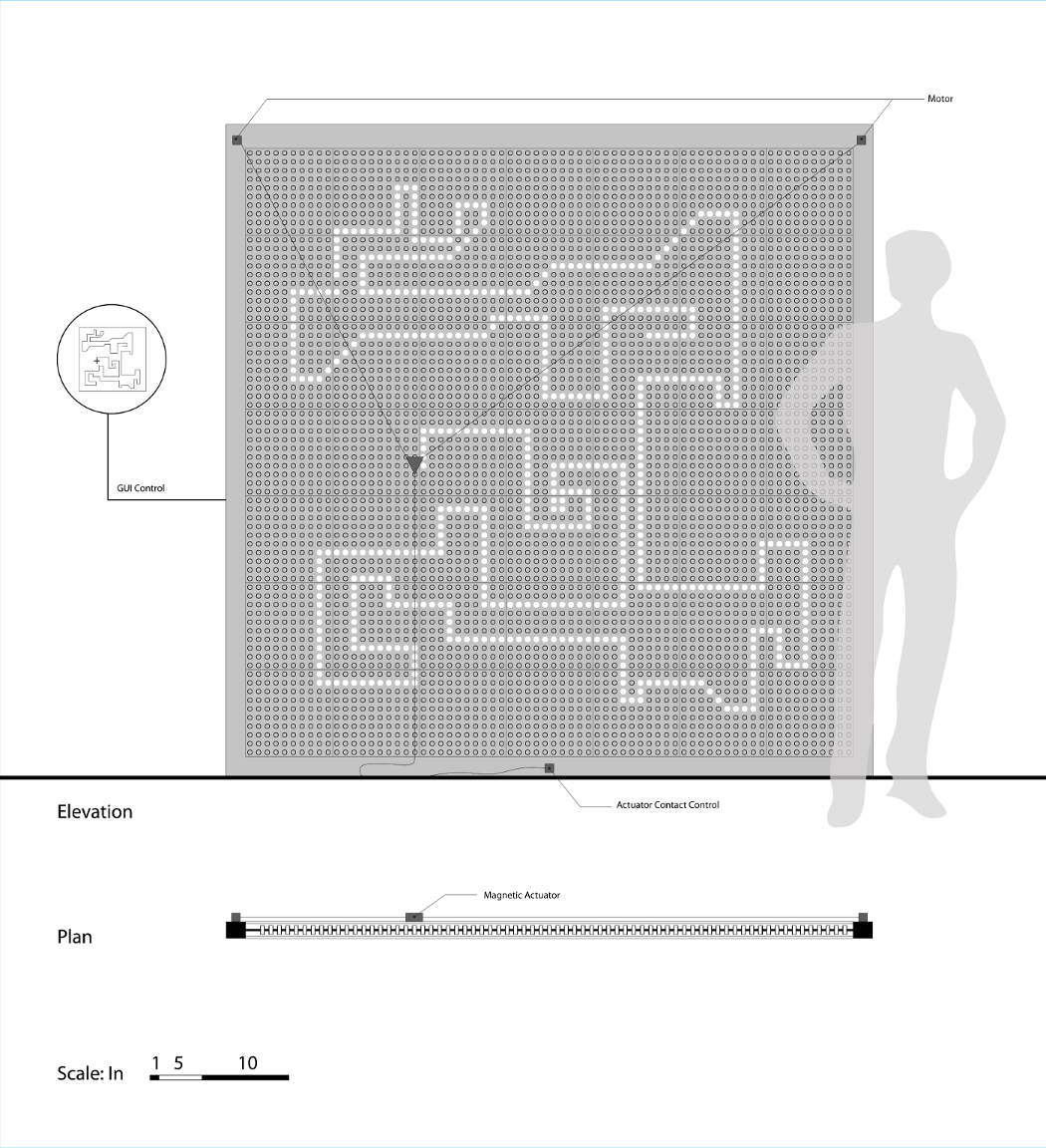

The project is a robotically-controlled responsive facade system that modulates daylighting levels, resulting in graphic visual patterns. It is an interactive work of art as much as it is a practical, low-cost display and sunshading system.

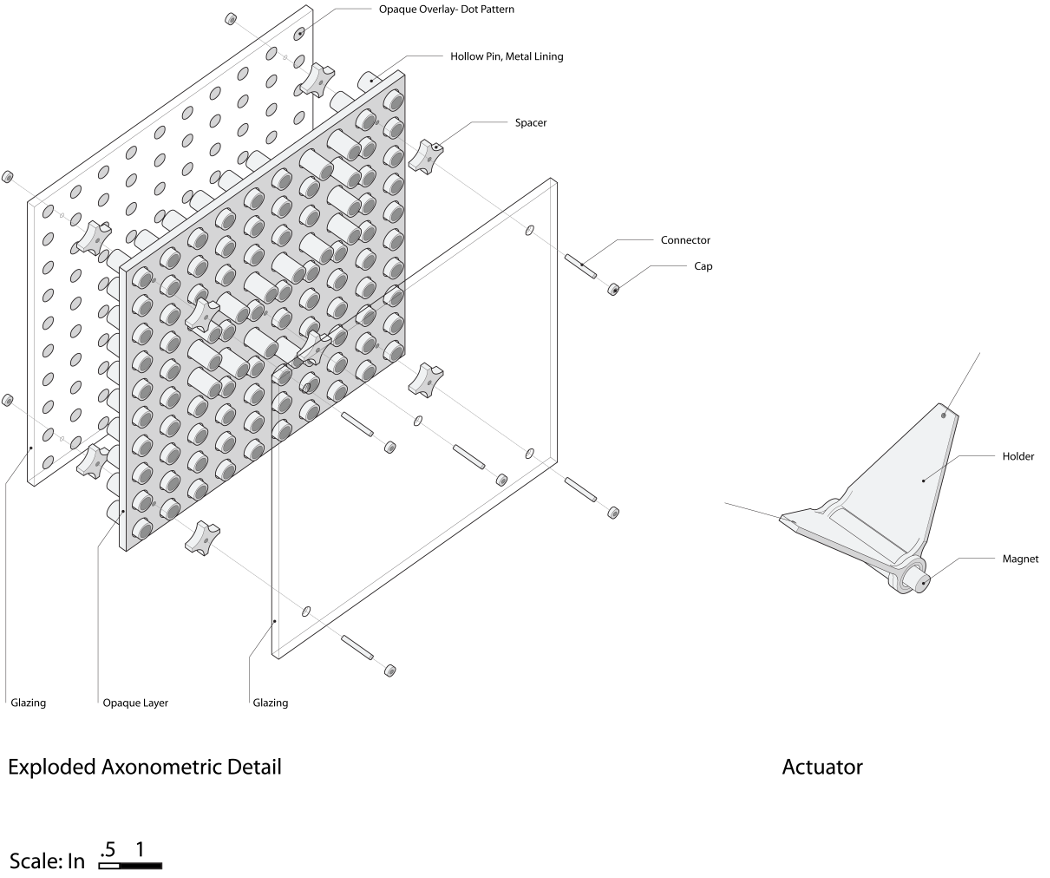

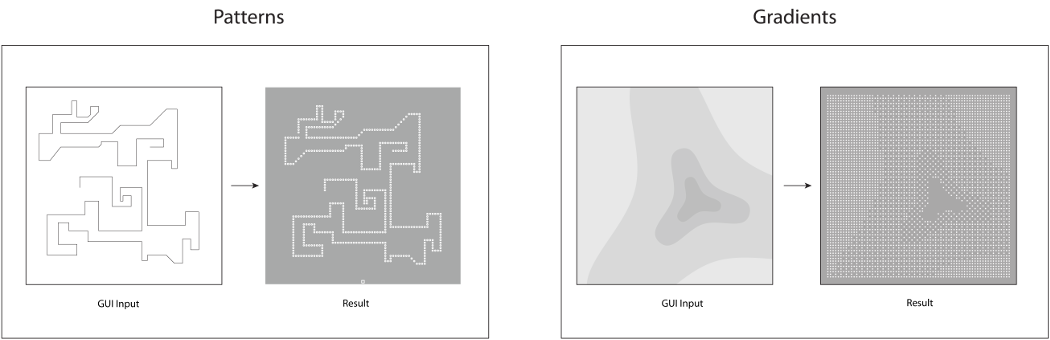

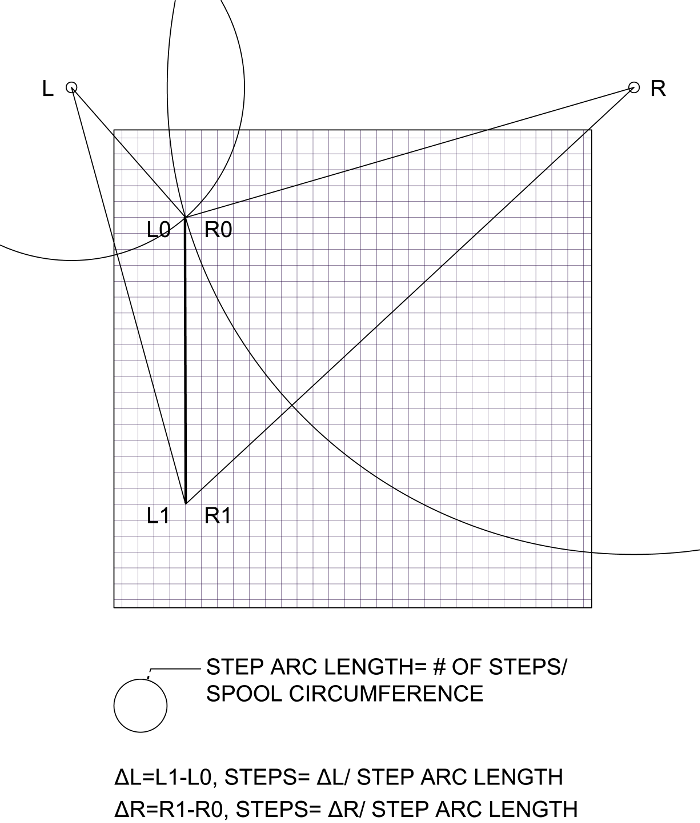

The system operates by digital user input; code is translated into patterns. A multi-layer screen is controlled by a magnetic actuator hooked up to two stepper motors. The screen consists of a perforated inner layer filled with freely-sliding hollow metal pegs. This inner layer is bound by two exterior layers of clear glazing. The back layer has opaque pattern of dots corresponding to the pegs. As the actuator moves across the screen’s surface, the pegs are pulled forward to their open position, generating patterns of natural light. A similar mechanism on the backside “resets” the pegs to the closed position.

Softly illuminated patterns of natural light gradually emerge from a blank canvas, and new patterns can be generated continuously. It is about the experience as much as the final result. The system emphasizes parametric performance over static parametric design

Drawings

x

Operations Diagram

Mechanics

Operation

Mechanical Details

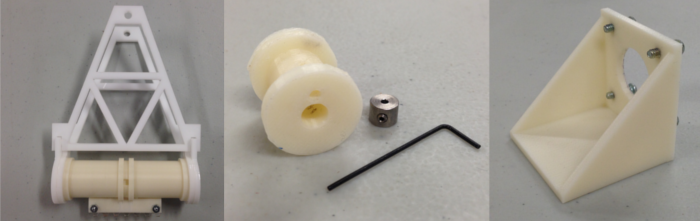

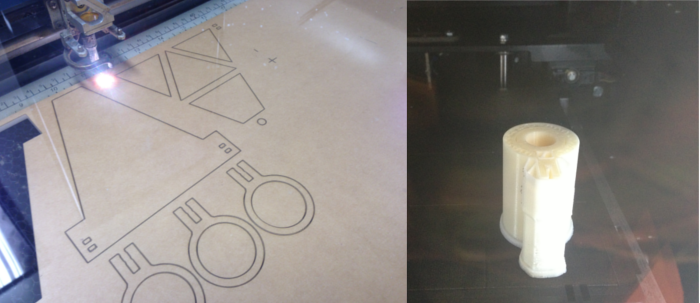

Fabrication

Laser-cutting and 3d printing of mechanical details

Files, Materials, & Specs

Actuator 3D Print and Laser Cut files

Miscellaneous hardware- McMaster-Carr

Stepper Motors- Jameco Electronics (standard Fab Lab inventory)

Epilog 40 Watt

1/4" Acrylic Sheet

Speed: 7

Power: 100

Frequency: 5000

Electronics & Coding

Interface

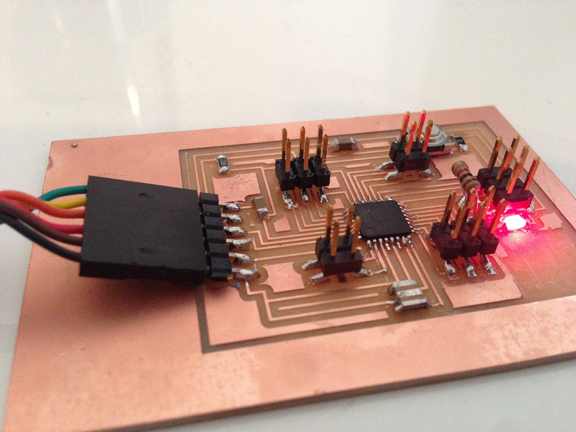

Testing the Fabduino. Uploaded a simple code to blink the LED.

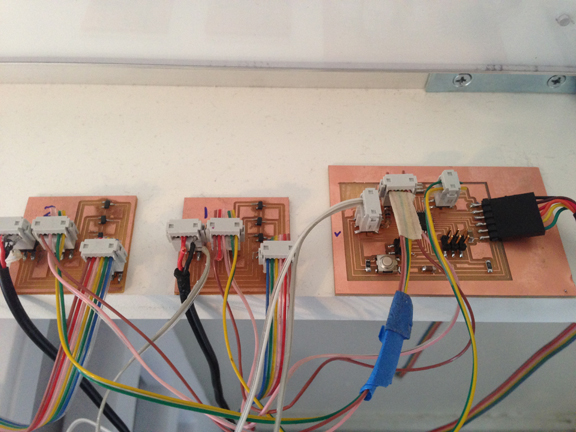

Testing the Fabduino and both stepper drivers simultaneously

Operation logic

Design

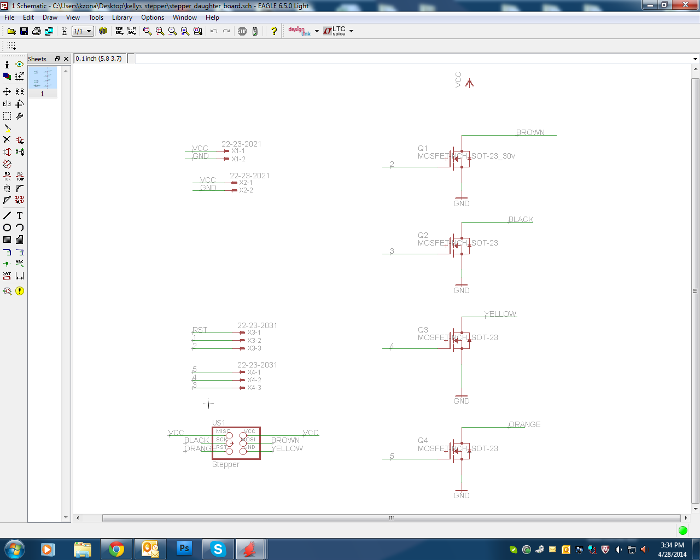

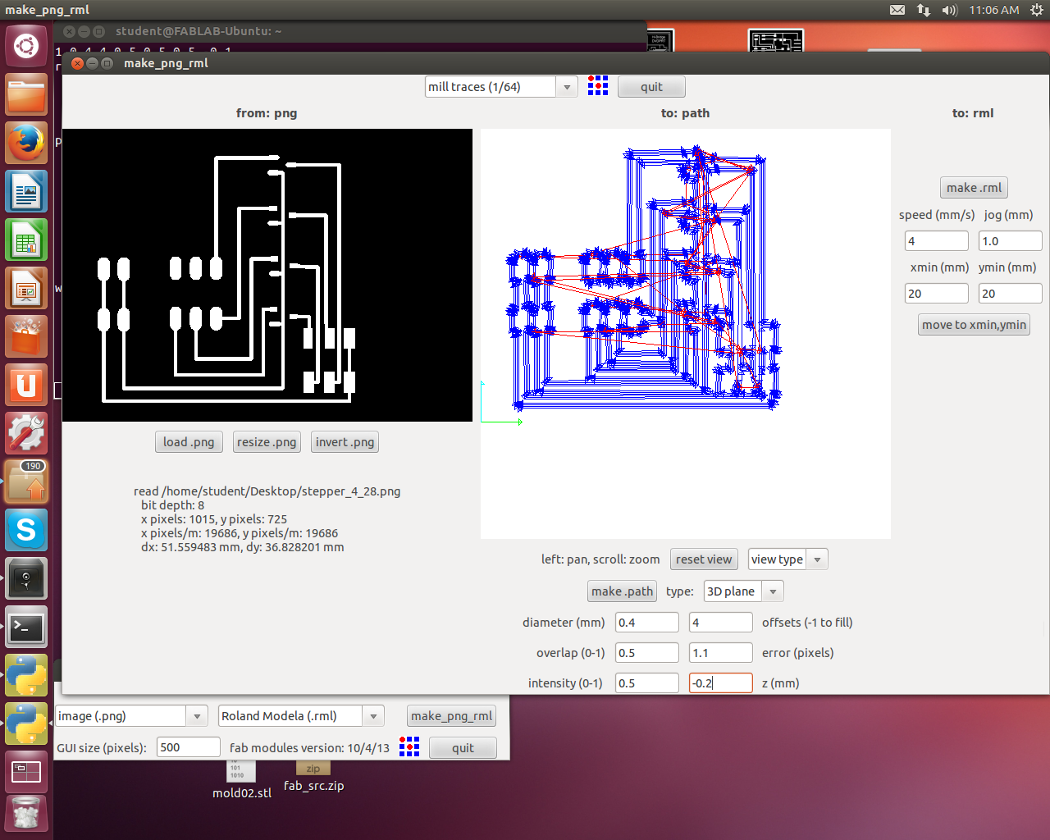

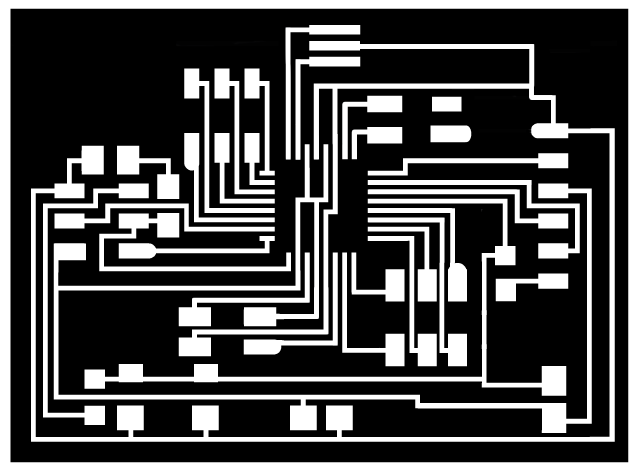

Stepper driver board design in Eagle

Fabrication

Milling the Fabduino and driver boards on the Modela MDX 20

Files, Materials, & Specs

Stepper Motor Driver schematic and board files available here

Fabduino Code (for blink test) available here

Code to run the Fabduino + Motor Drivers available here

Microcontroller board- Fabduino (main board)

PCB material and components- DigiKey (all components in the standard Fab Lab inventory)

1/64" bit

Diameter (mm): 0.4

Overlap (0-1): 0.5

Intensity (0-1): 0.5

Offsets (-1 to fill): 4

Error (pixels): 1.1

Z (mm): -0.2 (I found that -0.1 might not cut all the way through if the board is not perfectly level)

Speed (mm/s): 4

>Make Path

>Make rml

>Send It!

Screen & Frame

Assembling the screen, building the frame

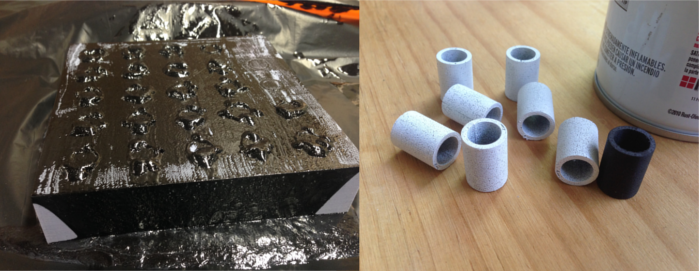

Casting and painting the pins

Files, Materials, & Specs

Screen 3D Print and Laser Cut files available here

Resin/metal cast pins- Smooth On (resin and silicon- standard Fab Lab Inventory), Alpha Chemicals (iron oxide)

Laser Cutting

Epilog 40 Watt

1/4" Acrylic Sheet

Speed: 7

Power: 100

Frequency: 5000

Casting

To make the mold:

After printing the mold_2 .stl file, cast silicon rubber to create the mold

Smooth-On OOMOO 25

To make the pins:

Smooth-On Smooth Cast 305 & black iron oxide

Mix a ratio of 6 parts resin to 1 part iron oxide by volume