Computer Controlled Cutting

Kinetic Structure & Press-Fit Universal Joint

kinetic structure from Kelly Zona on Vimeo.

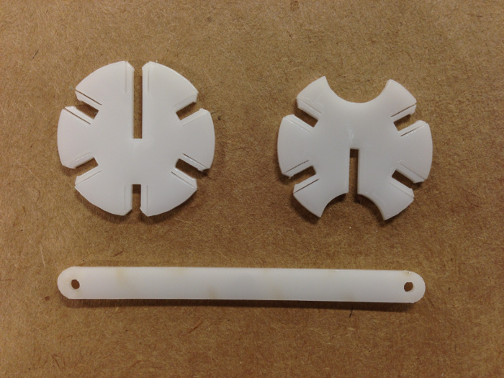

For this assignment, I was interested in creating a kinetic press-fit structure. I focused on creating a type of press-fit universal joint that would allow for members to move in any direction. The two round pieces fit together to create a spherical joint. Individual structural members connect to this main joint via press-fit pin connections.

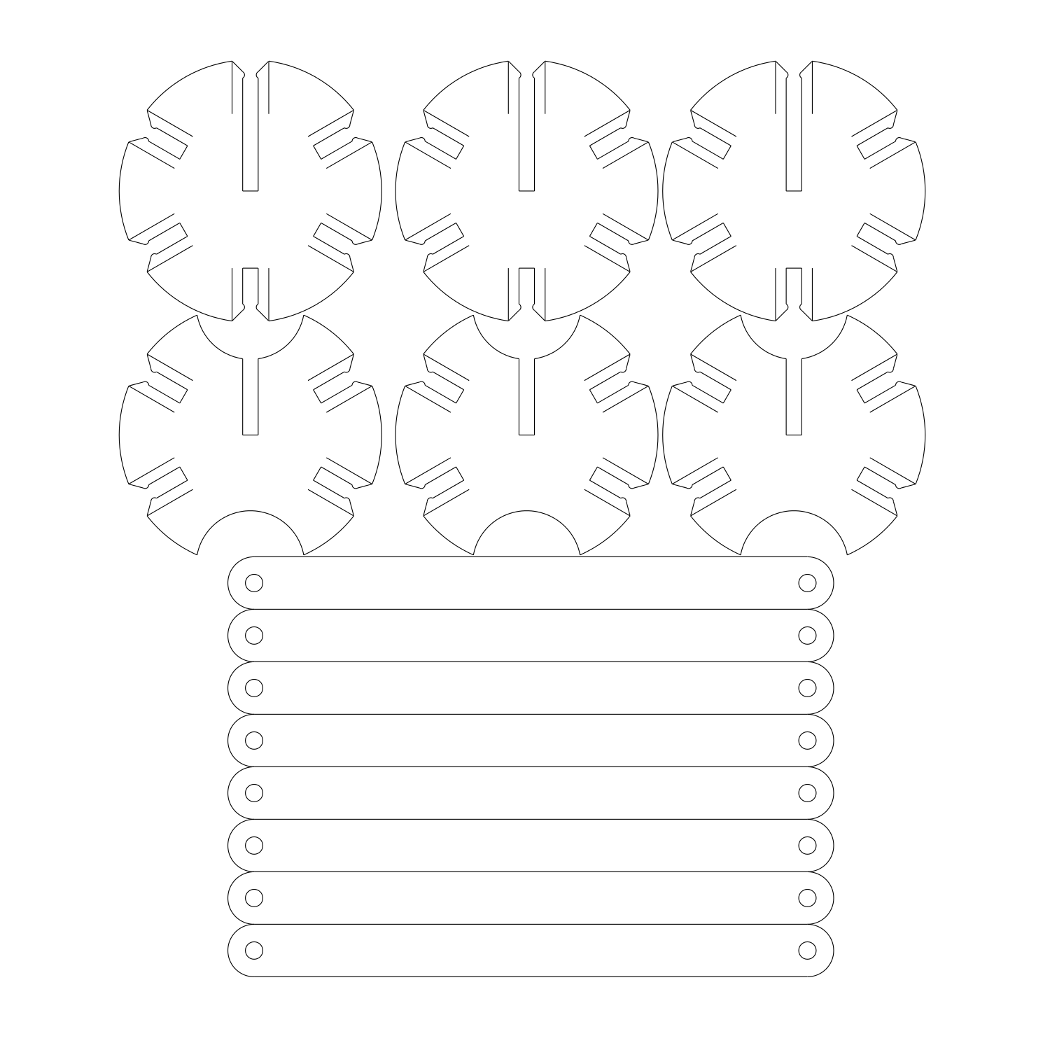

Kinetic Structure/ Press-Fit Universal Joint: laser-cut components

Kinetic Structure/ Press-Fit Universal Joint: laser-cut components

Laser Cutter File available here

I chose acetal resin (Delrin) due to its combination of flexibility, rigidity, and scratch resistance. It also cuts well on the laser. I think that this material works especially for "snap-fit" construction (in my case I would call this a "snap-fit" system as opposed to "press-fit" or "friction-fit" since the components hold together by forces other than friction).

The biggest design challenge was to get the sizing of the "teeth" correct. Tolerance was in the range of thousandths of an inch. Too large and it was almost impossible to get them to fit, too small and they would easily pull apart.

Specs

1/16" Delrin, Epilog 40 Watt laser, Speed: 15, Power: 100, Frequency: 500

To run the files on the laser, I cut directly from a PDF.

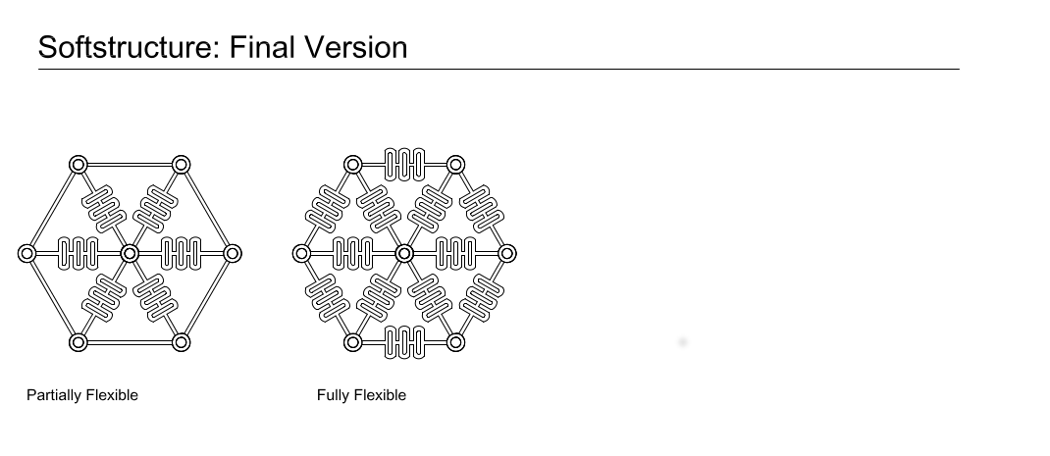

Flexible Structure using Flexural Connectors

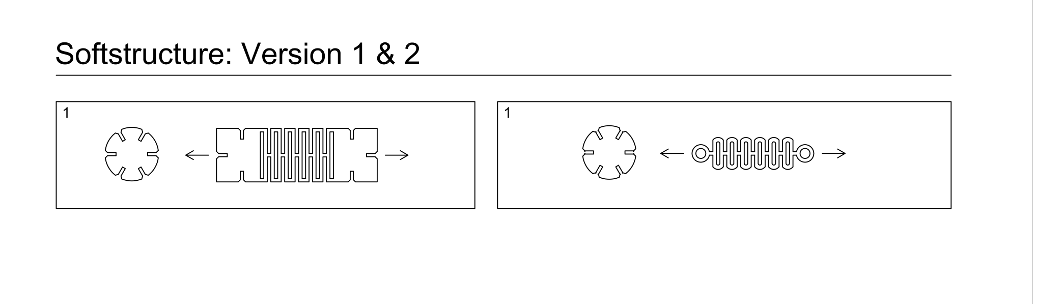

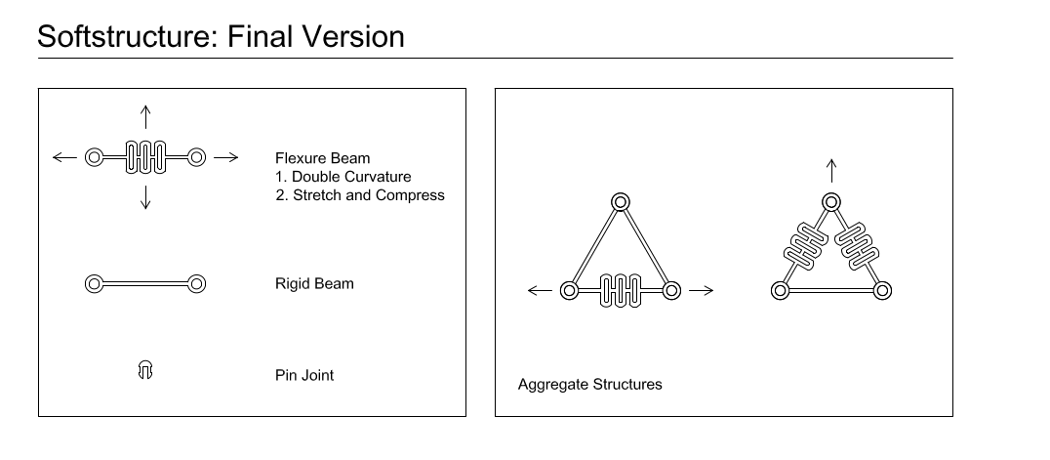

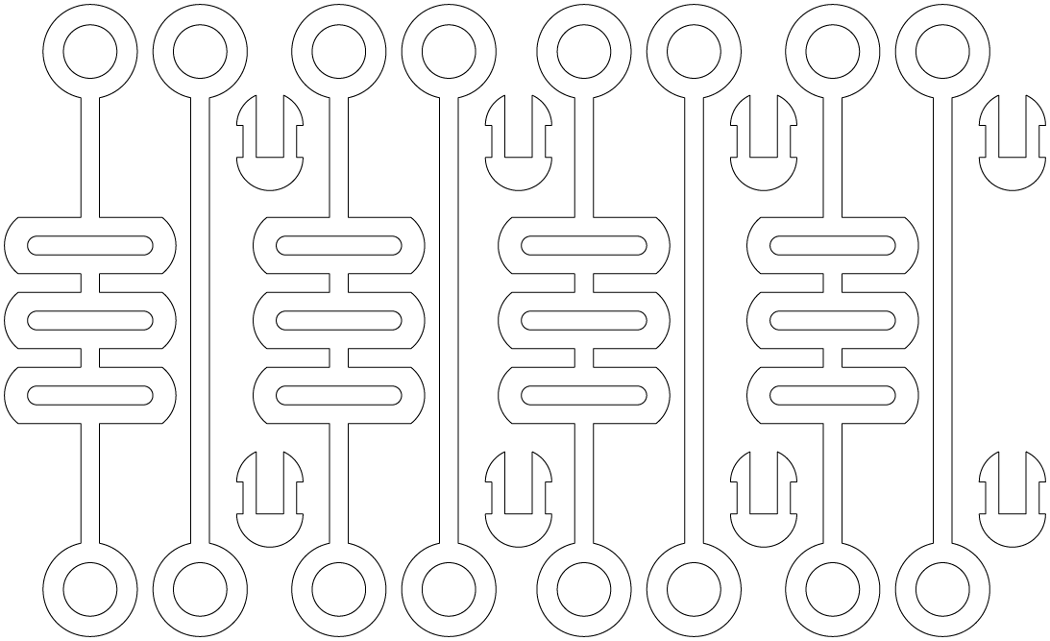

I also decided to experiment with flexures in order to create a flexible construction system. I created two initial versions of the design before settling on a pin connection system. Both flexible and rigid members can be used in combination.

Prototypes cut from Delrin and cardboard

Prototypes cut from Delrin and cardboard

Laser Cutter File available here