Computer Controlled Machining

CNC Zen Garden

cnc zen garden from Kelly Zona on Vimeo.

For this week’s assignment, I built a CNC Zen garden. Our lab’s ShopBot dust collector accumulates tons of sawdust each week, so I thought it would be interesting to create a project that does something with this refuse material.

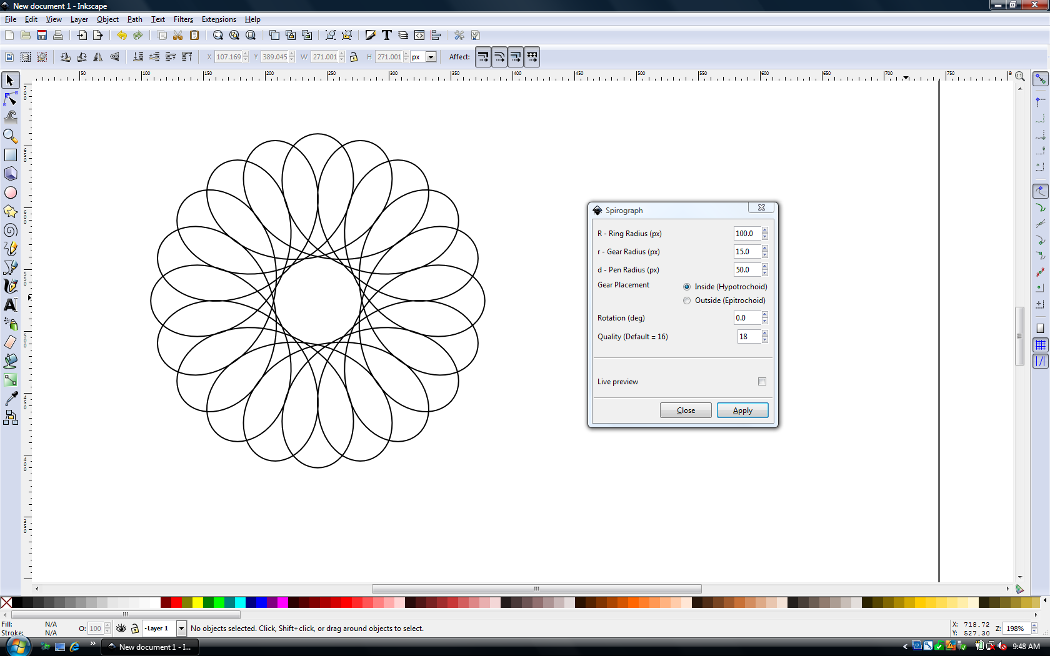

I created the pattern in Inkscape, using Extensions> Render> Spirograph.

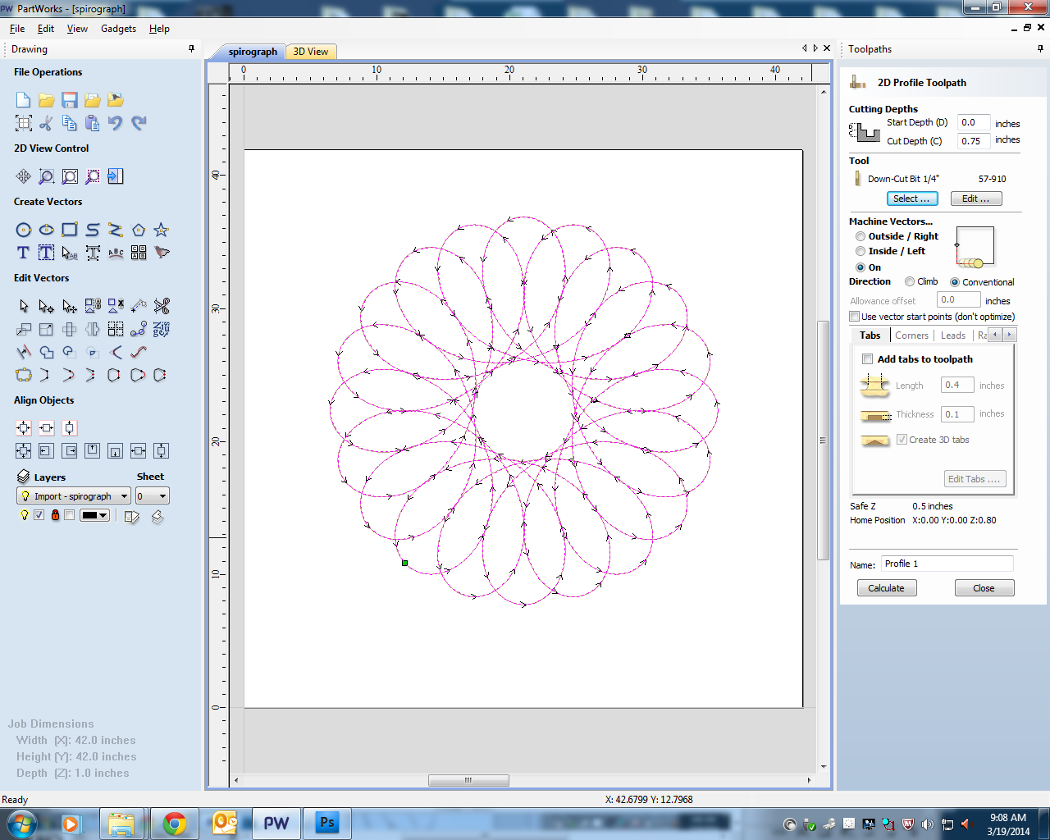

I used Part Works to set up my file to run on the ShopBot CNC Router. Most of the input values are inconsequential since I ran the machine with the spindle off, but I did set my tool diameter to .25 inch, feed rate to 102 ipm, and plunge rate to 30 ipm.

Spirograph pattern file available here

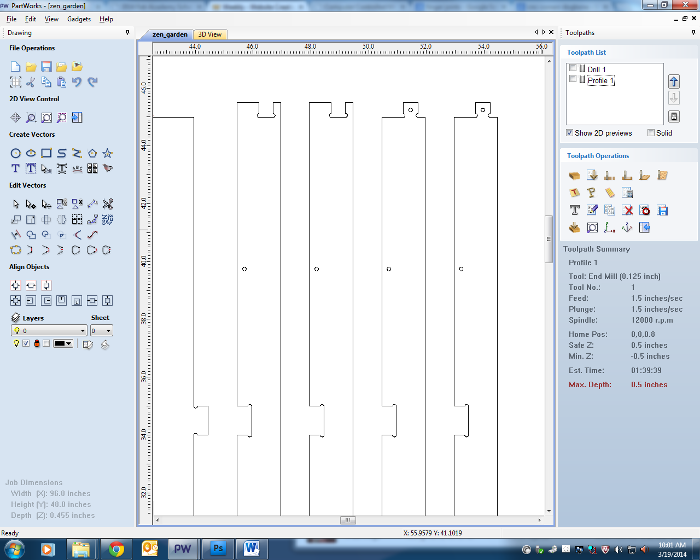

I made a simple box to contain the garden. My strategy was to use finger joints to join the parts together. I did have to add notches to the corners since the diameter of the tool would naturally create rounded corners, making it difficult to fit the corresponding pieces together.

Settings:

Bit: .125" endmill; Pass Depth: .1"; Spindle Speed: 12,000 RPM; Feed Rate: 1.7 IPS; Plunge Rate:0.5 IPS; Stepover: 40%

Applications

I thought it might be interesting to somehow capture the pattern once it is made. I could see this as a way to turn sawdust into wood composite panels. I tried a few experiments, mixing sawdust with a binding agent. So far, no luck- the pattern looks awful when cut into a damp mixture.