Applications & Implications

What will it do?

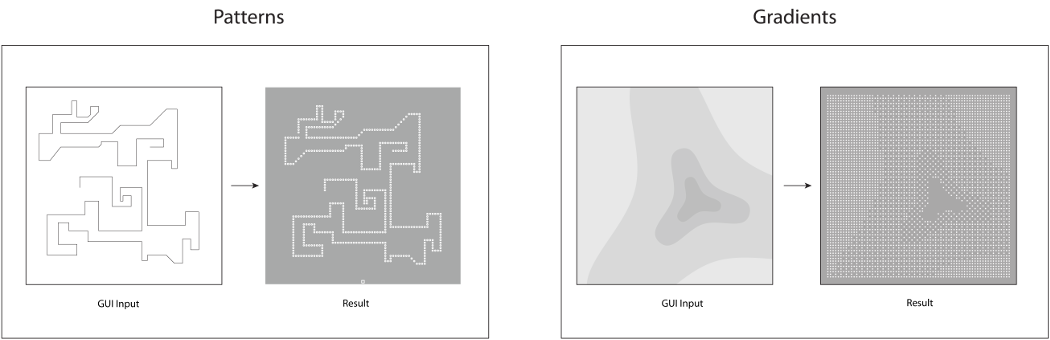

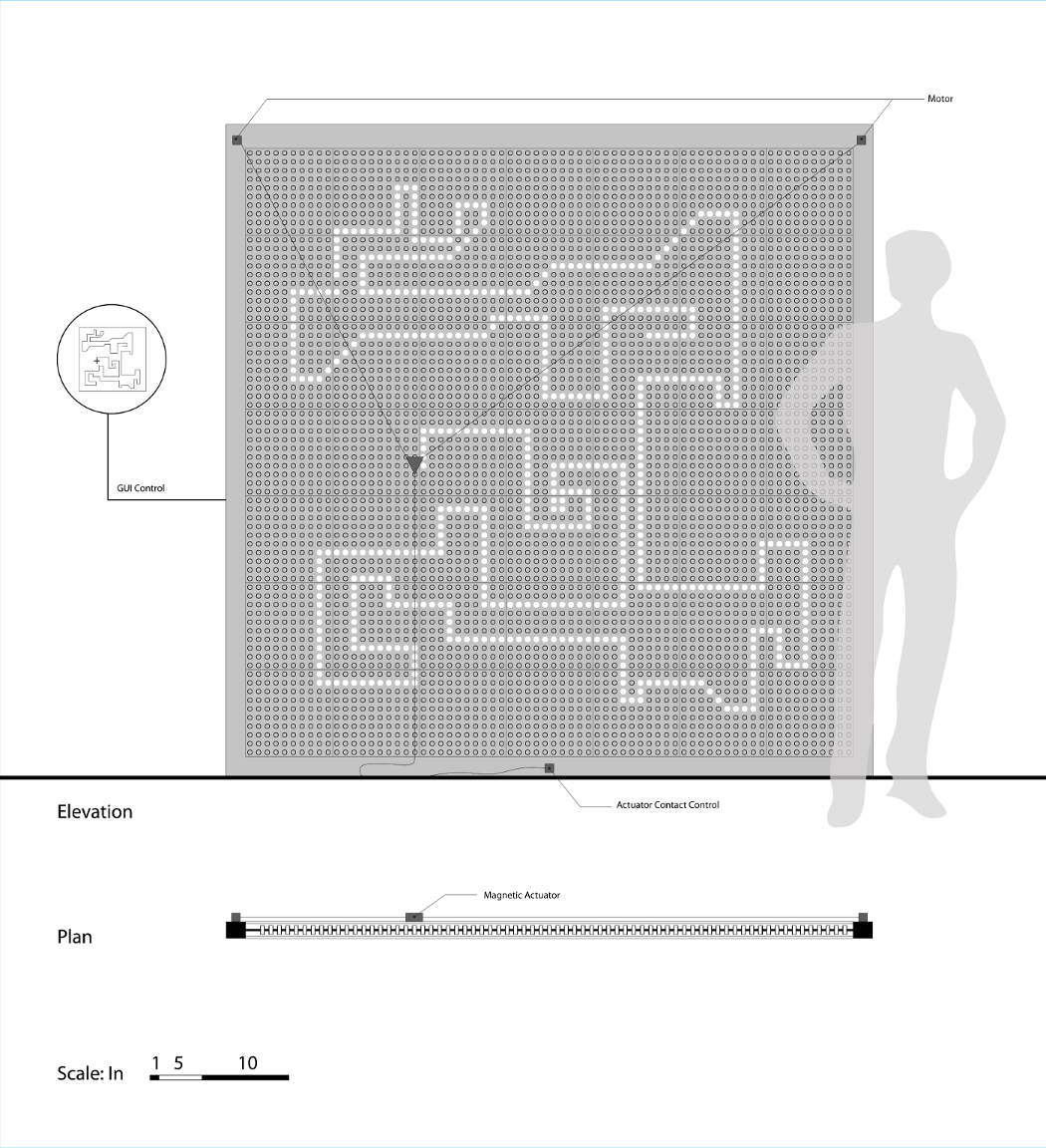

Mechanical operation of the system

What materials and components will be required? Where will they come from? How much will it cost?

Miscellaneous hardware- McMaster-Carr

Acrylic sheet- white and clear- Pioneer Supply or McMaster Carr

Resin/metal cast pins- Smooth On (resin), Alpha Chemicals (iron oxide)

Microcontroller board- Arduino (main board)

Stepper driver electronics- DigiKey

3D printed items- actuator, stepper mounts, bobbins- in house

Stepper driver boards- in house

Motors- in house

Acrylic sheet- white and clear- Pioneer Supply or McMaster Carr

Resin/metal cast pins- Smooth On (resin), Alpha Chemicals (iron oxide)

Microcontroller board- Arduino (main board)

Stepper driver electronics- DigiKey

3D printed items- actuator, stepper mounts, bobbins- in house

Stepper driver boards- in house

Motors- in house

Who's done what beforehand?

Technorama Facade

Responsive Awning, MIT Kinetic Design Group

Flare Facade

Institut du Monde Arabe

Hyposurface

Responsive Awning, MIT Kinetic Design Group

Flare Facade

Institut du Monde Arabe

Hyposurface

What parts and systems will be made?

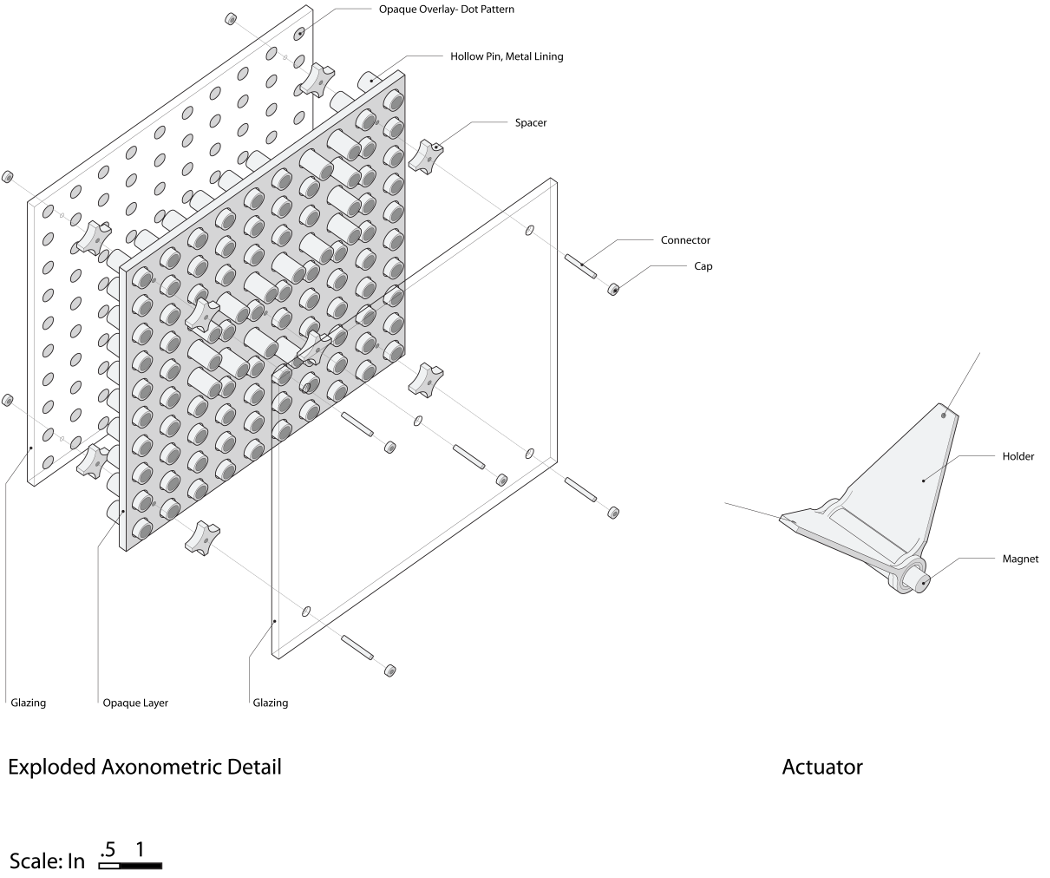

Multi-Layer Screen

Resin/metal Cast Pegs

Aluminum Frame

Stepper Motor Drivers

Motor Mounts

Bobbins

Actuator Mechanism

Resin/metal Cast Pegs

Aluminum Frame

Stepper Motor Drivers

Motor Mounts

Bobbins

Actuator Mechanism

What processes will be used?

Laser-cutting

Molding and casting

CNC milling (PCB fabrication)

3D Printing

Vinyl Cutting

Molding and casting

CNC milling (PCB fabrication)

3D Printing

Vinyl Cutting

What tasks need to be completed?

Cut and assemble the screen

Finish casting the pins

Work on electronics application

Refine stepper motor code

Finish casting the pins

Work on electronics application

Refine stepper motor code

What questions need to be answered?

How can I get the motors to run in unison?

How can I maximize the contrast between light and dark (open and closed) pegs?

How can I maximize the contrast between light and dark (open and closed) pegs?

What is the schedule?

Already completed- actuator mechanism

May 14th- complete the screen

May 17th- complete the frame

May 21st- complete the electronics and coding

May 28th- complete all of the pins

June 4th- complete miscellaneous outstanding tasks

May 14th- complete the screen

May 17th- complete the frame

May 21st- complete the electronics and coding

May 28th- complete all of the pins

June 4th- complete miscellaneous outstanding tasks

How will it be evaluated?

Artistic merit and practicality should be given equal weight in the evaluation process; it would be unfair to separate one from the other. It is my hope that this project sparks conversation for new ways to incorporate robotics in architecture.