About the assignment: computer controlled machining

Make something big!

the sculpture-chair....big!

For this project I am going to work with a similar shape I have in mind for my final project: a seat system - sculpture that can support different seating positions for the human body.

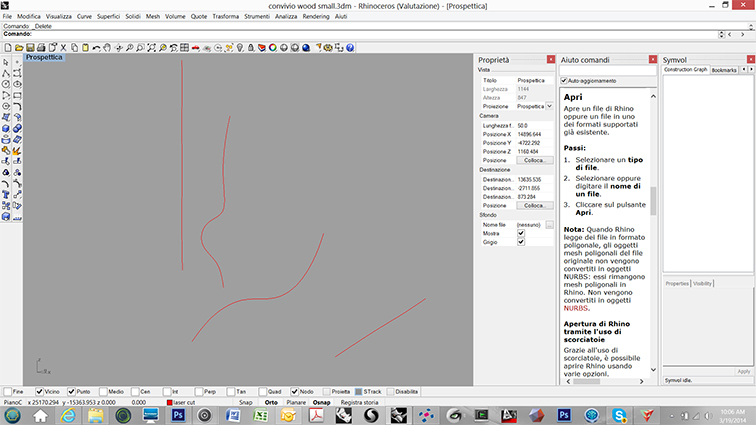

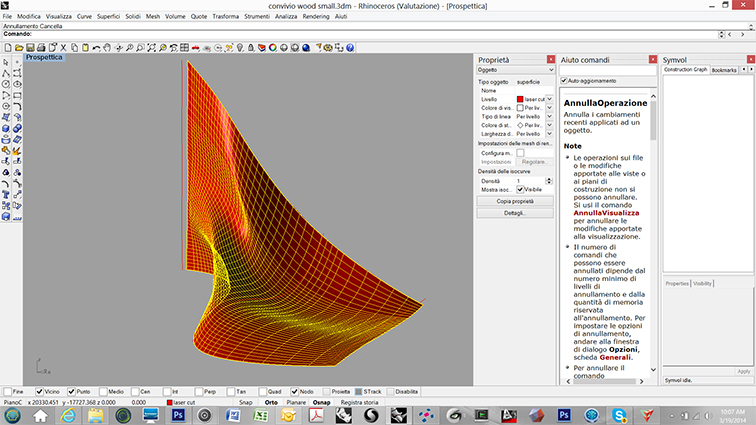

I started with similar vertical sections using Rhino.

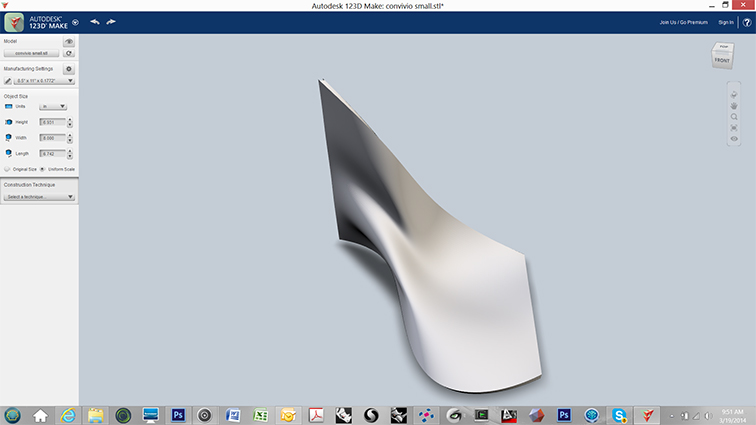

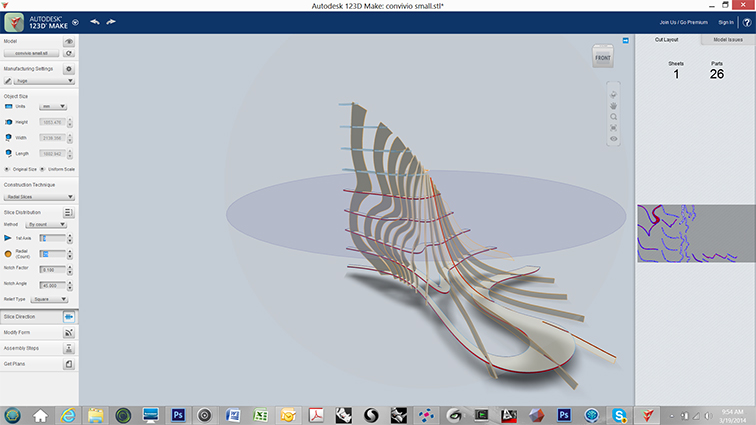

Autodesk 123D Make is something fun to use and sometime you can create very cool stuff with it.

I imported the mesh created in Rhino in Autodesk 123D Make.

I played with 123D Make with radial slices limiting the number of pieces to use only three 4x8 plywood board of 1/2 inch ($140).

After a couple of tests, I found the right size for the press fit connections.

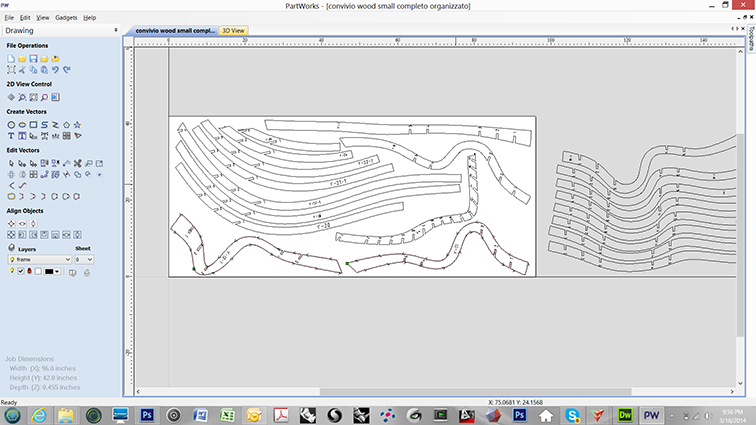

I organized all the pieces with Shop Bot Partworks 2.5V and set two tools one for engraving (letters) and one for the cutting adding taps each side.

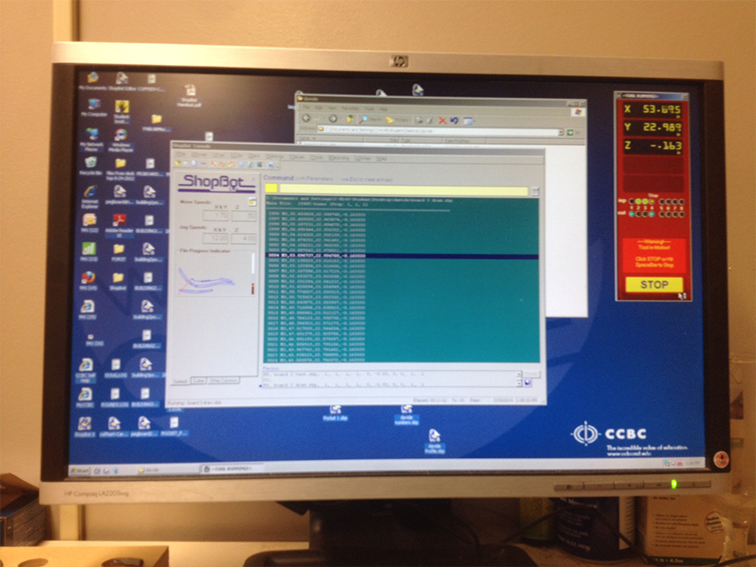

I set the ShopBot, set the plywood with screws, switch to cut mode, secured the bit, check the conductivity, set the Z, set the XY center, load the file, wear protective glasses, turn on dust collector and....

cut the boards....

After sanding all the elements I started the assembling of the sculture.

![]()

All the elements were perfect!

and finally the sculpture is done!....sorry the mess in my studio!

I will prepare a nice photo with a nice background!