THE FAB ACADEMY 2014

CIRO MEJIA ELIAS

|

THE FAB ACADEMY 2014

|

|

|

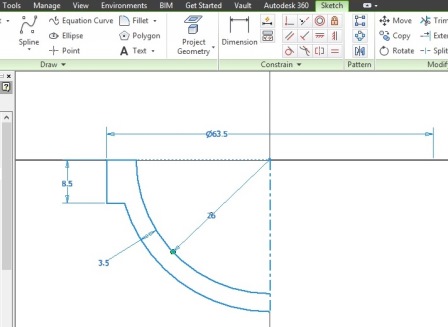

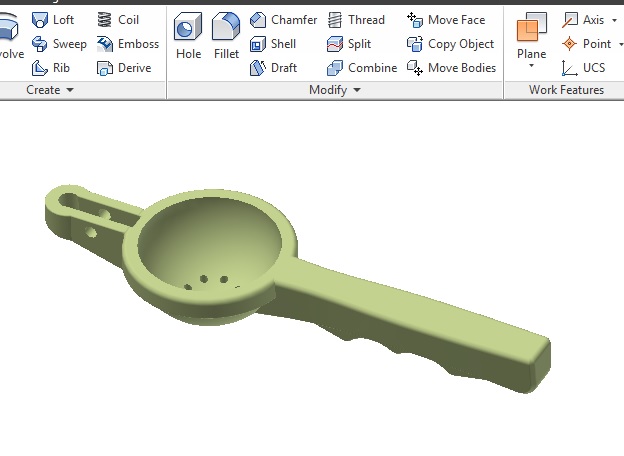

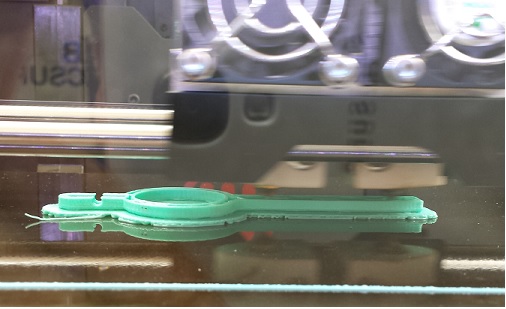

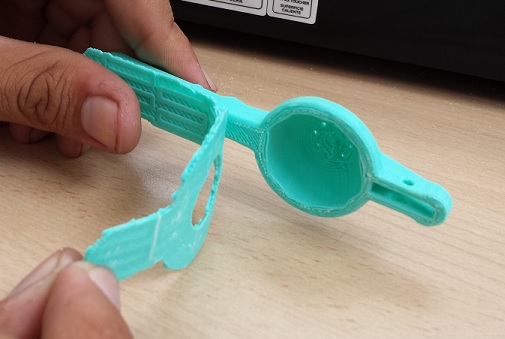

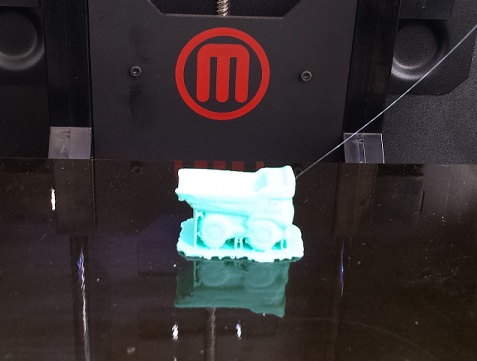

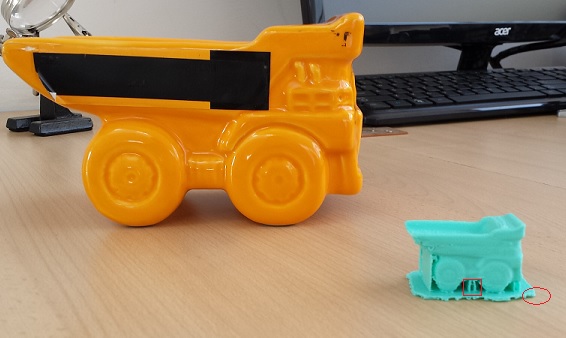

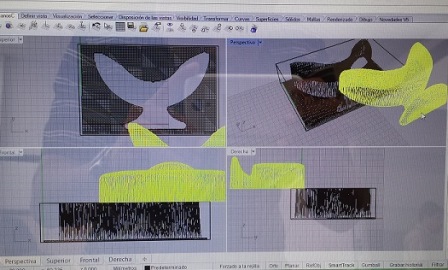

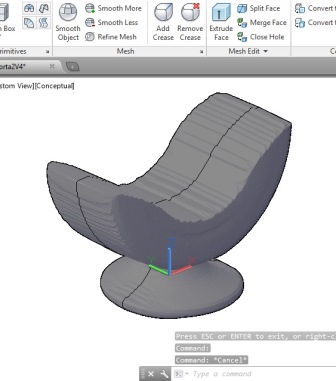

3D Scanning and Printing Design and printing of an object This task is to design and to print a lemon squeezer, this object can not be created by subtractive methods due to internal channels and circular shapes. Design: The design was done in Inventor Professional, having a bit of difficulty in the handle of the juicer because it is an irregular shape, it works with the "LOFT" command. It shows the main steps of the modeling:         General considerations of the task

baseless based  Extracting the basis

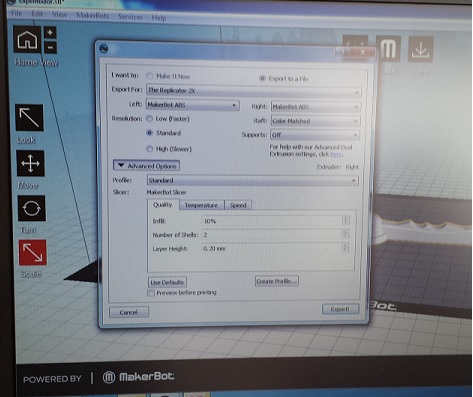

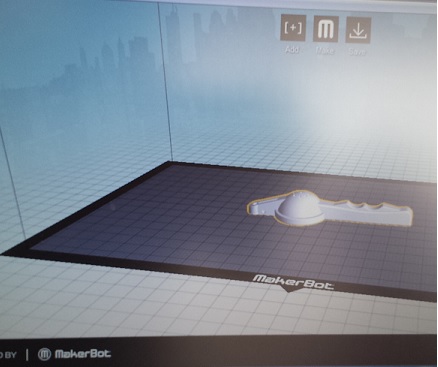

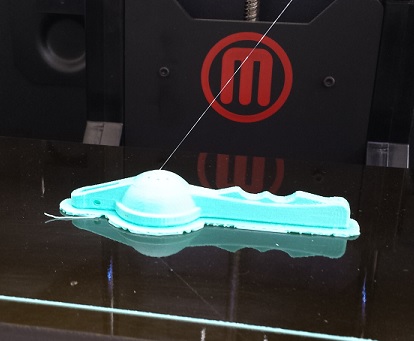

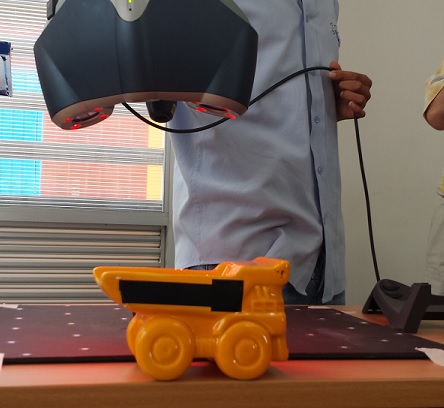

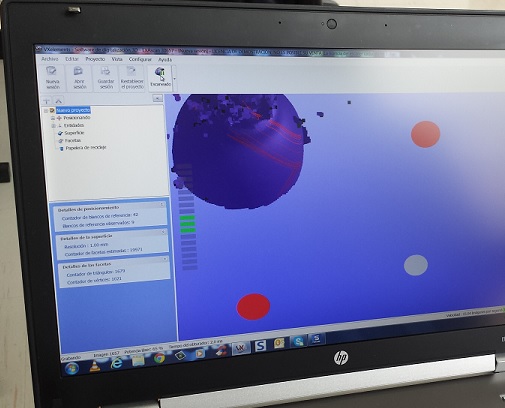

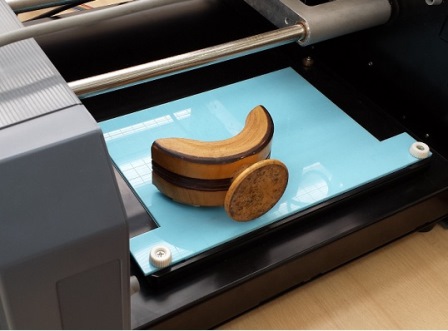

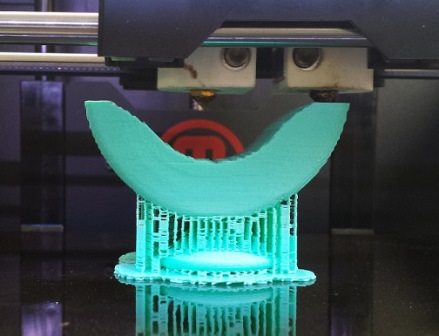

Two methods of scanning are considered : 1) 3D Laser Scanning : This method has higher accuracy in the shape of the object , time is much lower than other methods , it had no problems with bright colors. The equipment used was the brand EXAscan CREAFORM. It exports STL and OBJ files.   In this case printing the scan was done quickly, I only had to fix some edges with Meshmixer . The Printer Software settings had to be considered in addition to a support base for the cantilever model parts .   "In a square the support shown"

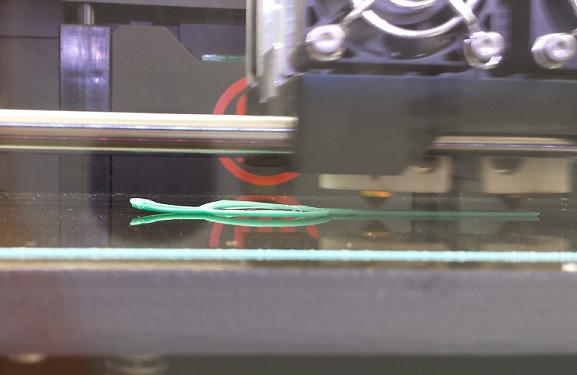

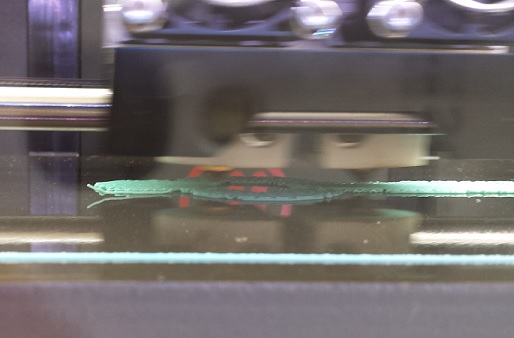

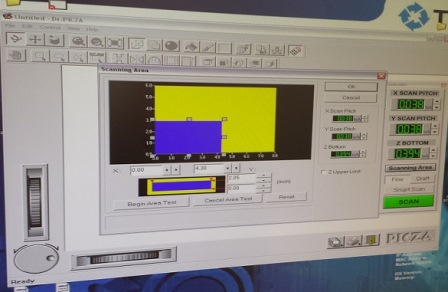

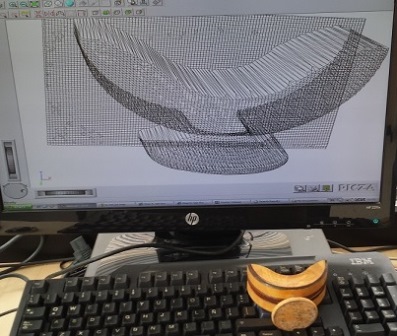

"In a circle the base is shown" 2) Scan contact : With this method an approximate shape of the object is obtained, the time is your disadvantage because it takes too long , in my case it was about 5 hours . No scans and low internal parts of the object. The equipment used was the MODELA MDX -20. The extension was STL files and IGX .   Object stuck with double-sided tape Scanning softrware   Scan Start Scan result (mesh) In order to print this case I had to make several modifications to the scanned model . a. Court symmetric model with Rhinoceros  b . Mirror model with Autocad .  Printer the model:  | |