THE FAB ACADEMY 2014

CIRO MEJIA ELIAS

|

THE FAB ACADEMY 2014

|

|

| In

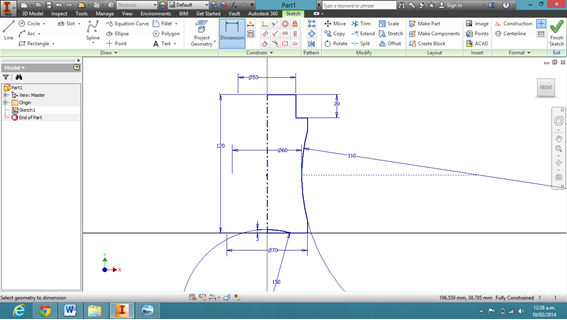

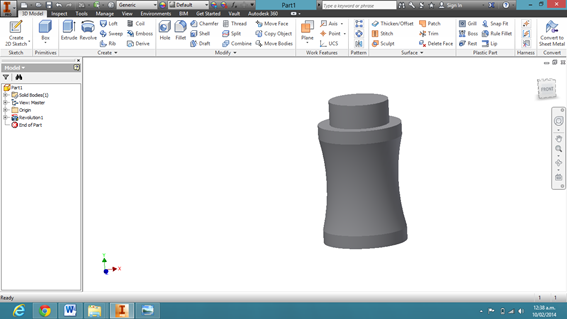

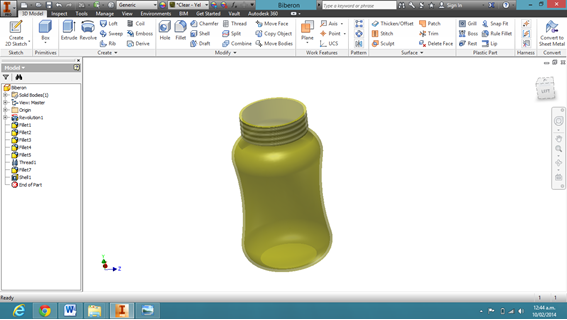

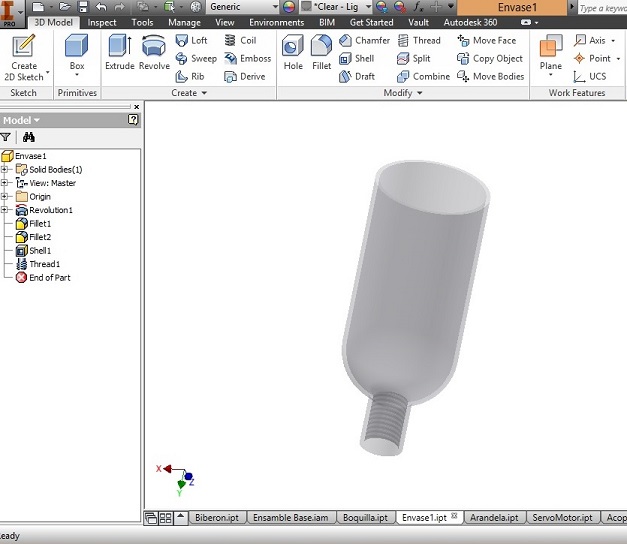

this activity I tried two software, Rhinoceros and the Inventor, the

first is not suited to my project and it does not handle mechanical

assemblies, it serves more to surfaces and shapes of great difficulty. The

inventor manages libraries of bolts, pipes, nuts, valves, etc.., Plus,

you can assemble easily. I started my work with the construction of the bottle; so, first I generated the 2D Figure and then I used the 'revolution to generate solid' command, the process is similar for all parts or machine components.    Similarly, the other components of the machine are modeled easily.

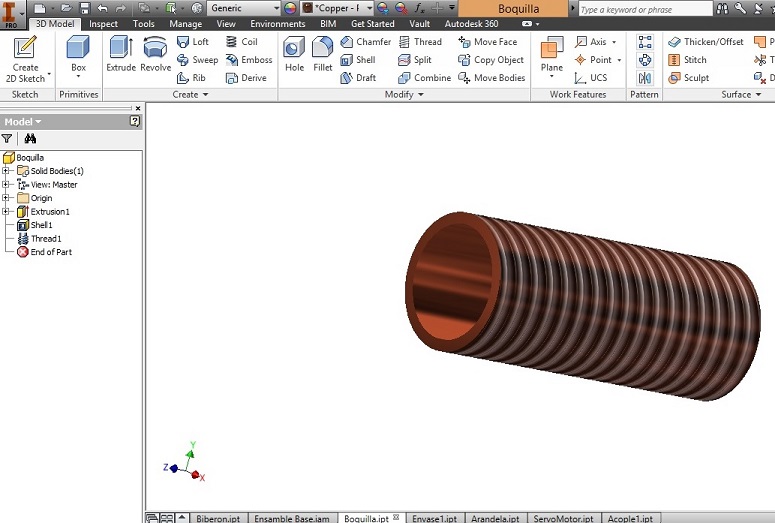

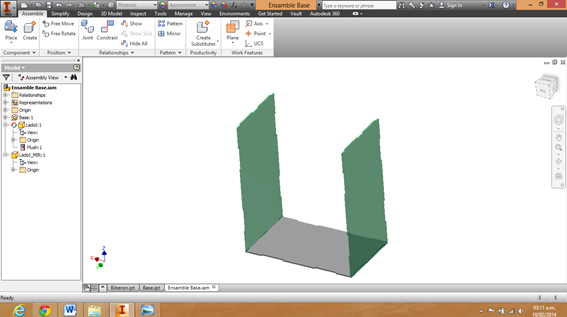

Then

we proceed to the assembly with all the components created. In this step,

restrictions for mounting between parts must be taken into account,

these restrictions may be the faces, edges, vertices, etc.

|