THE FAB ACADEMY 2014

CIRO MEJIA ELIAS

|

THE FAB ACADEMY 2014

|

|

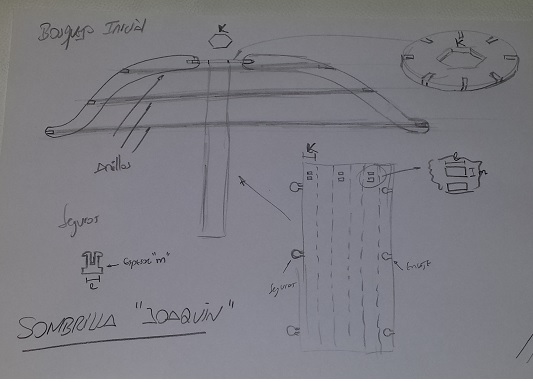

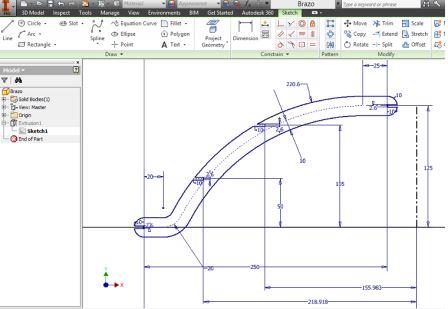

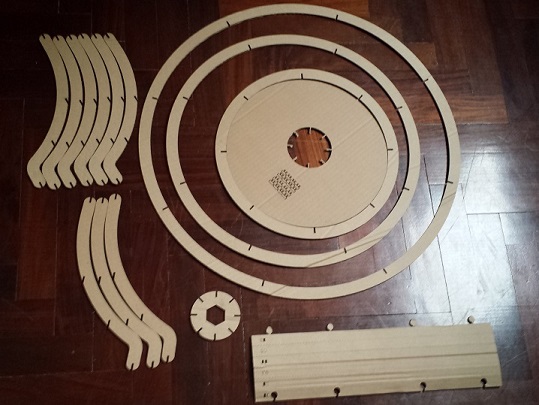

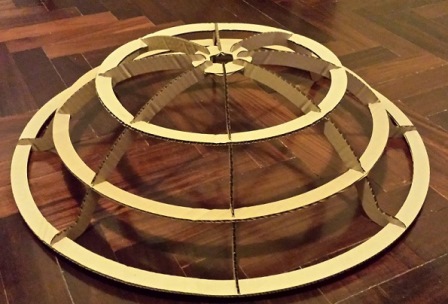

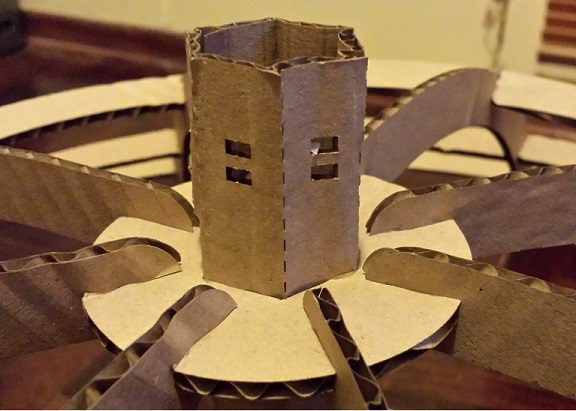

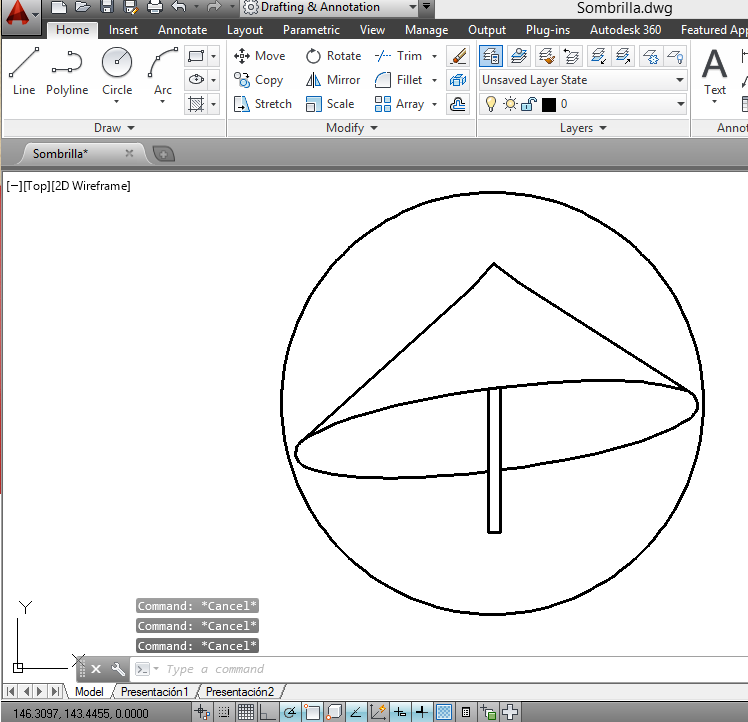

Umbrella Joaquin In this project snap wanted to create something to use in my daily life, umbrella bag for my son. Perform the initial freehand sketch, taking into account as of the umbrella dimensions height and diameter of my son. I had some drawbacks to draw splices or joints. Also I thought of a basket to store eggs and table, the curtain will projects in the following weeks. Below the plane of the umbrella shown.    I

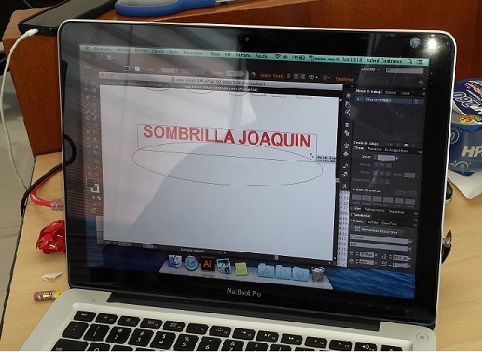

had enough trouble importing the " dwg " format file to " Corel Draw" ,

apparently the problem arose when extruding parts in Inventor, I should

have just generated or 2D Sketch , then I had problems on the version

of " Autocad (2014 ) " , the" Corel Draw " installed version could not

stand , I had to record a version of the 2004 extension" dxf " . The

conclusion is that best done directly " autocad " or " rhino" .

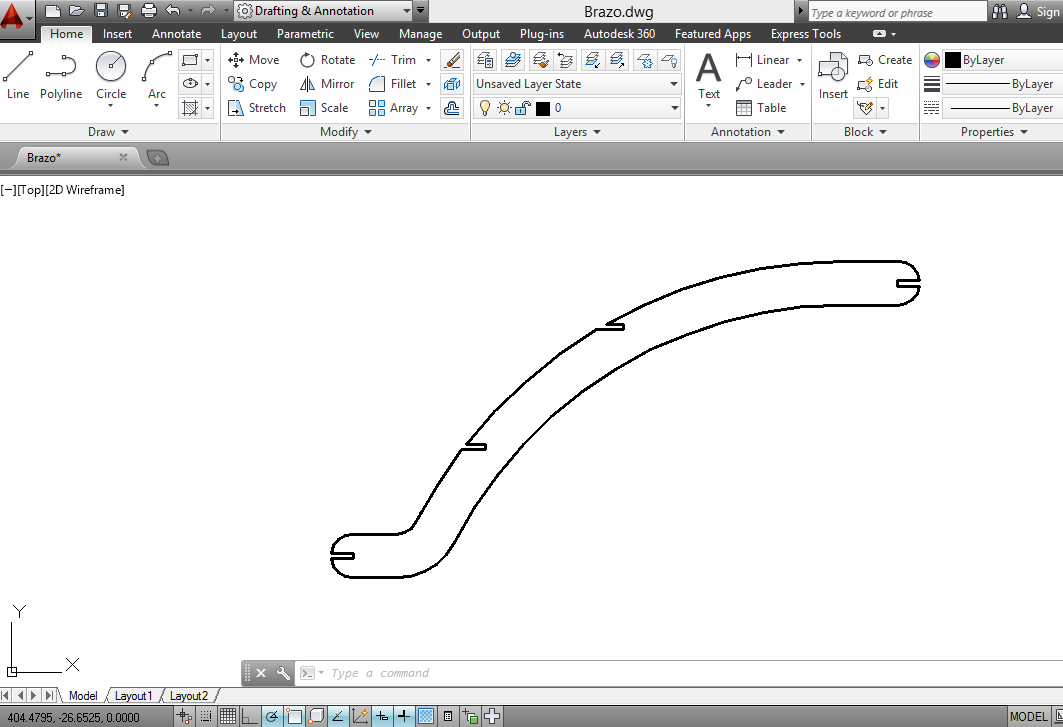

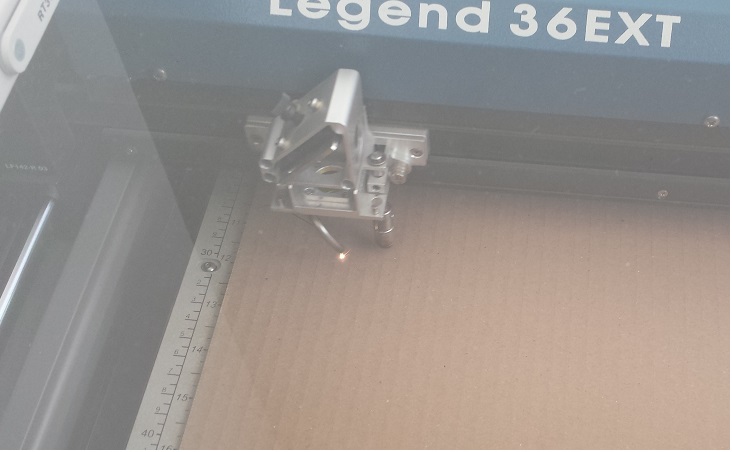

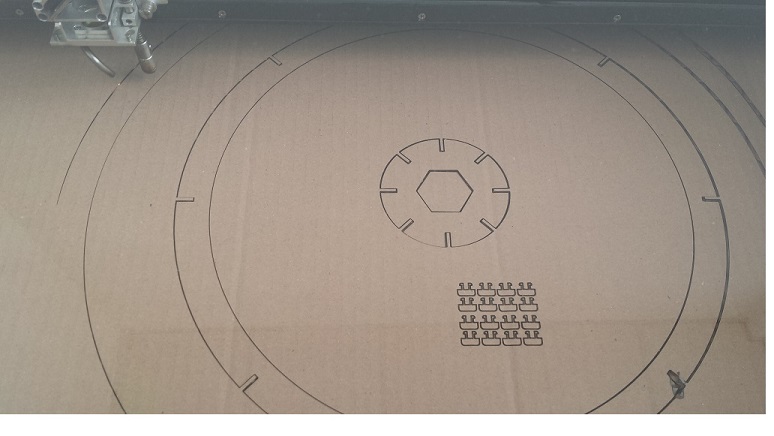

After much stress and with the support of the support of my FabLab achieve sending the job to the laser machine. Download cutting files   By printing the parts in the laser cutter.

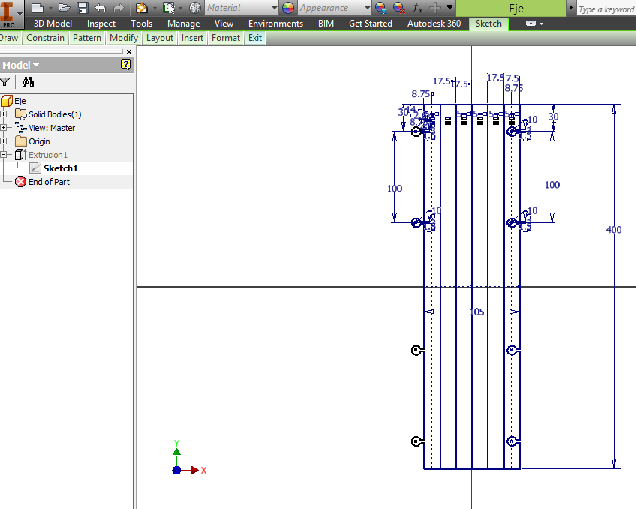

Aca show insurance and I could not insert the holes where they should go in the corner.

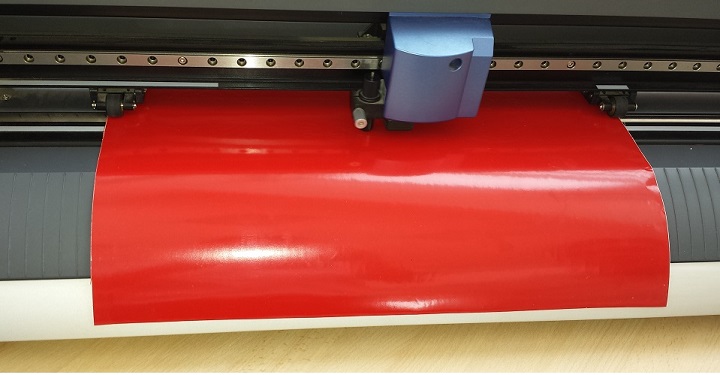

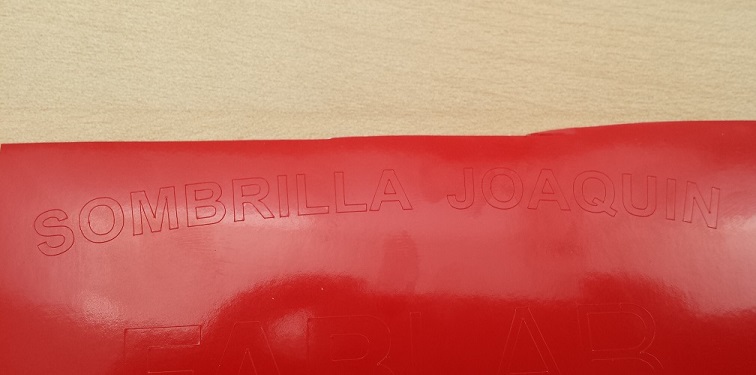

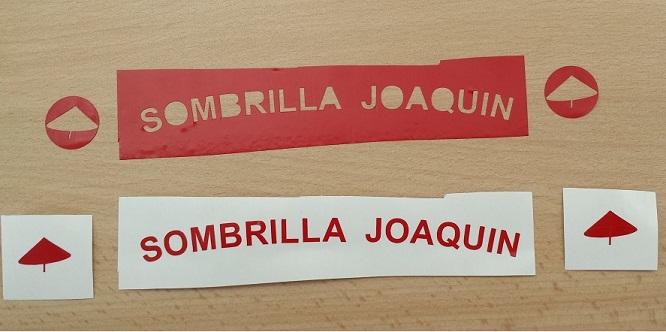

It should be noted that the thickness of material considered in all joints, seams and channels is 2.6 mm, ie slightly less than actual thickness of the material, this is done with the intention that the piece is assembled with pressure. Now my model proves "MDF" I'll be posting the results Vinyl cut The next job was to create a form, as a sign and then cut in the "Roland GX-24" on vinyl. The way I generated was a sign to place on the umbrella. It was extremely easy, the sign it worked in "Illustrator" and how autocad. I had to be careful when taking off the sign and shape of its base because it moves.   Results in Roland.

|