16. wildcard week¶

Vaccuum forming¶

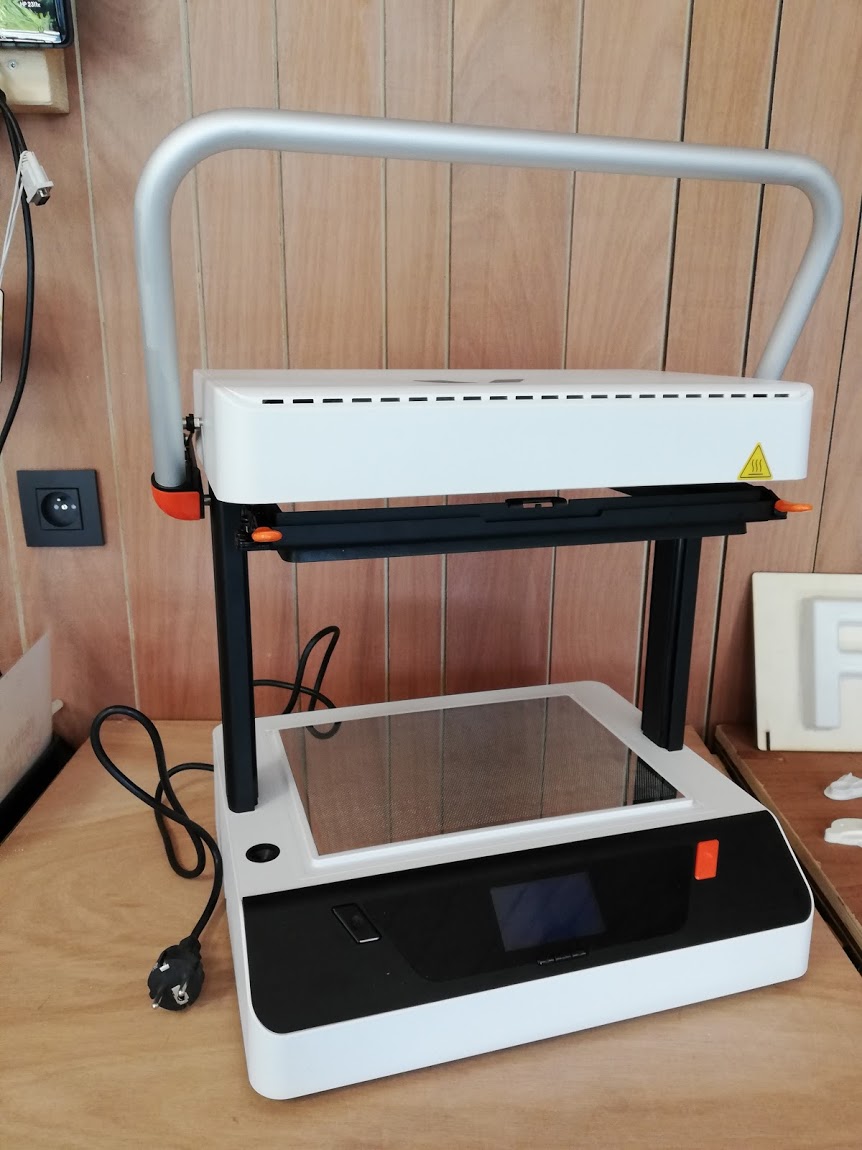

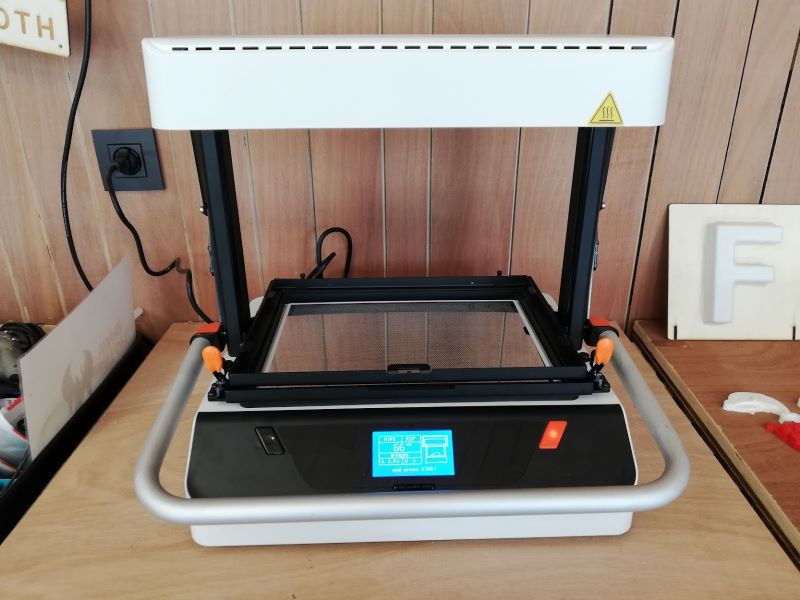

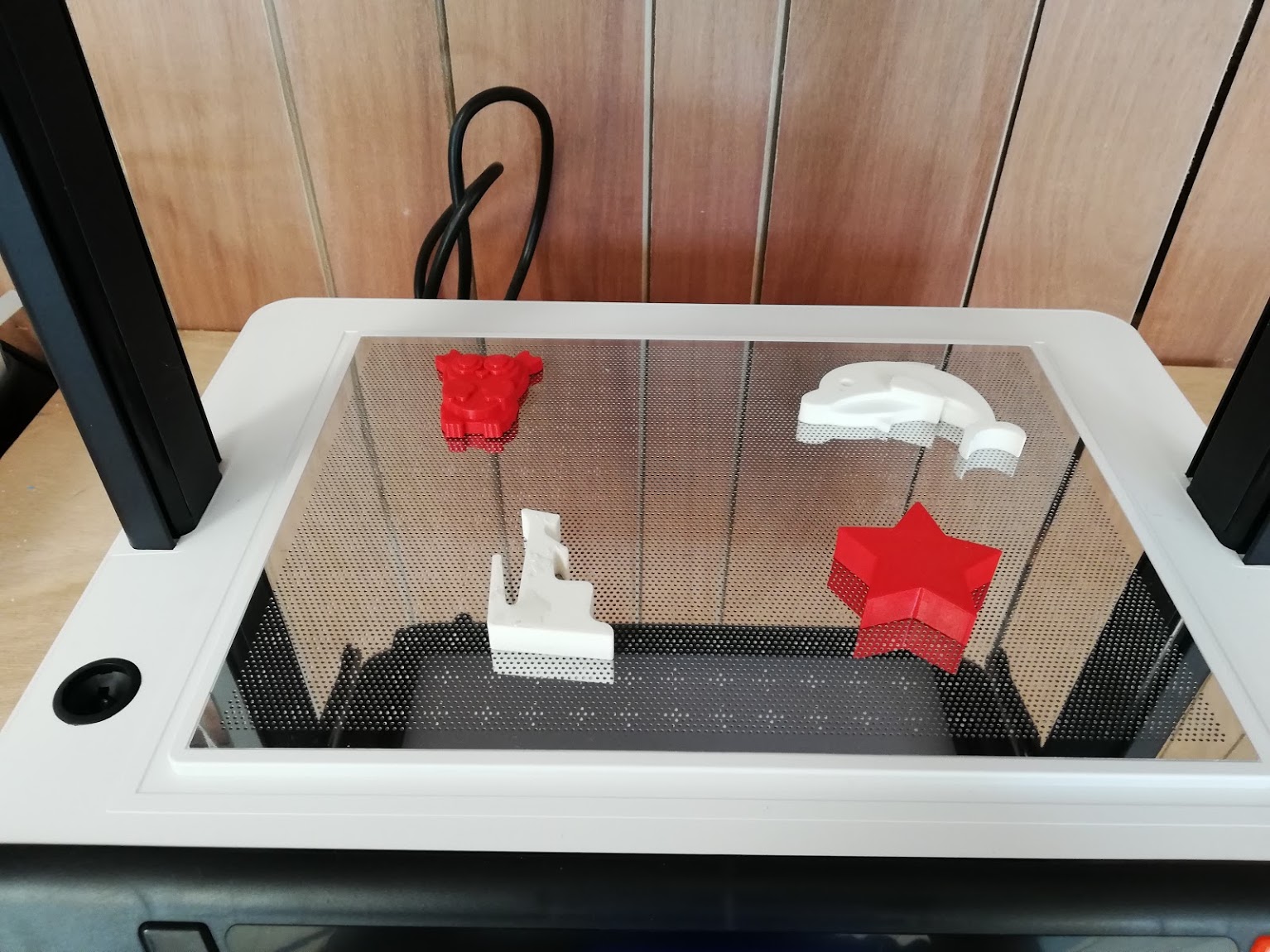

The machineI would like to discuss is the vaccuum former i will use this machine with children in our lab during a workshop. In the lab we have a small machine A3 format. We have the vaquform . This is a tabletop model it is very compact an easy to use.

The principle:¶

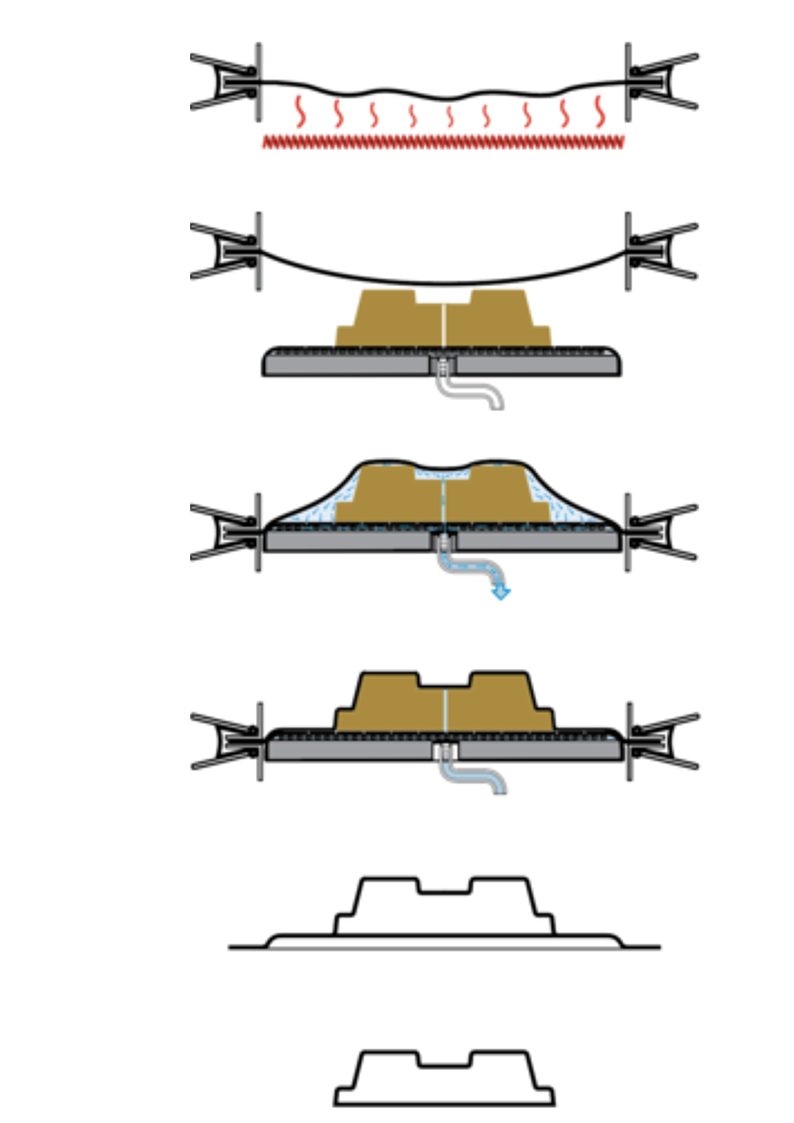

The thermoplastic plate is being heated and then the air beneath it will be sucked away. Underneath it is a negative form.

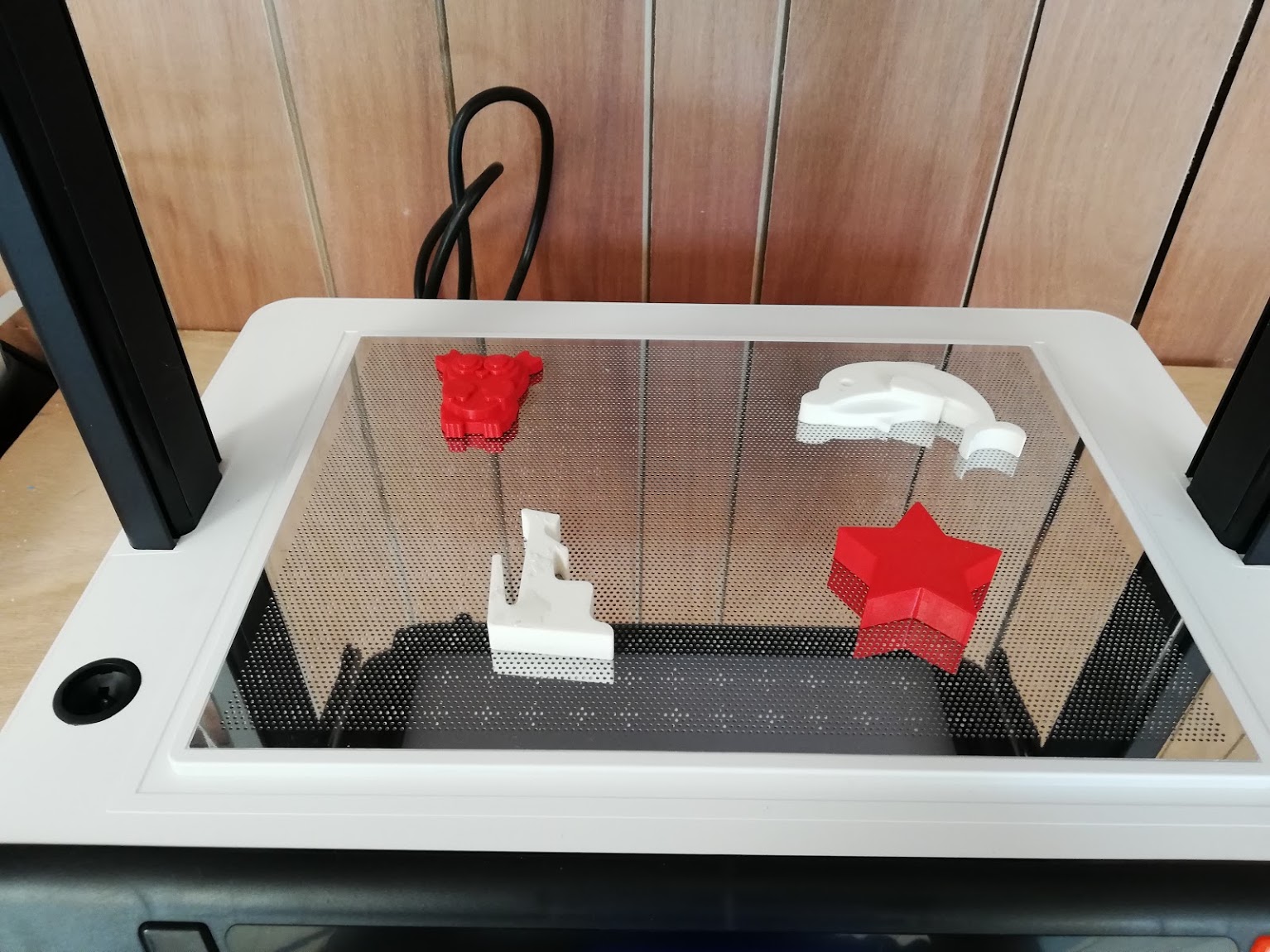

This is a technique I use a lot during workshops with children in our lab. First we design a form in tinkercad and 3D print it. After that we use the 3D printed objects to make a mold with the vacuumvormer.

One of the products we made was a nightlight. This way there was also a bit of electronics during the workshop.

designing a motherobject.¶

I design them in a cad programe like fusion360 or tinkercad. I explaned this in week3

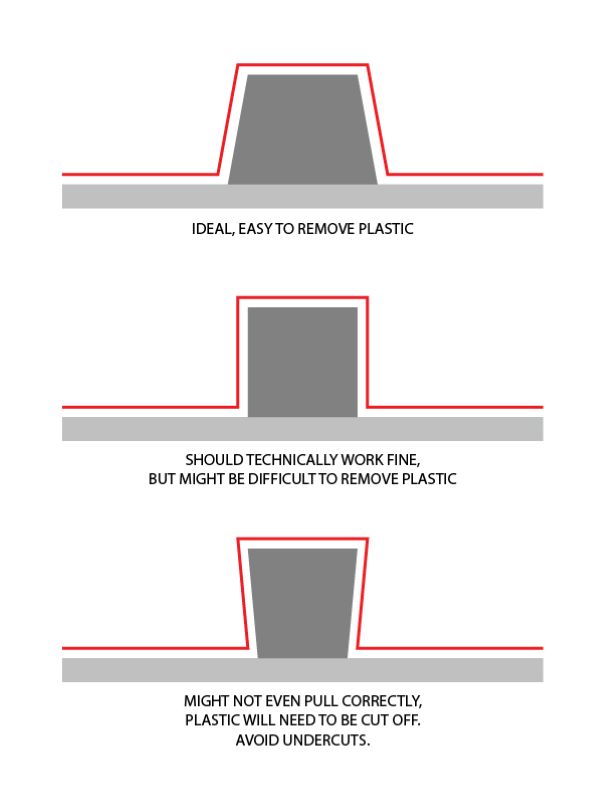

The mother mold is the basic model around which the heated plastic will draw. This mother form can be made in different ways. This can be printed with a 3D printer, modeled with clay or cut from a potato. The most important thing to consider when designing the master mold is that one should be able to demold the object and the plastic should not crack during this process. This results in the following points for attention: no sharp points, no undercut, no too high shapes, round corners, if possible make the shape conical.

setting up the machine¶

This machine we have in the lab is a very friendly tool to use, since we give a lot of workshops for kids it is neccesery.

start with turning on the machine on the back

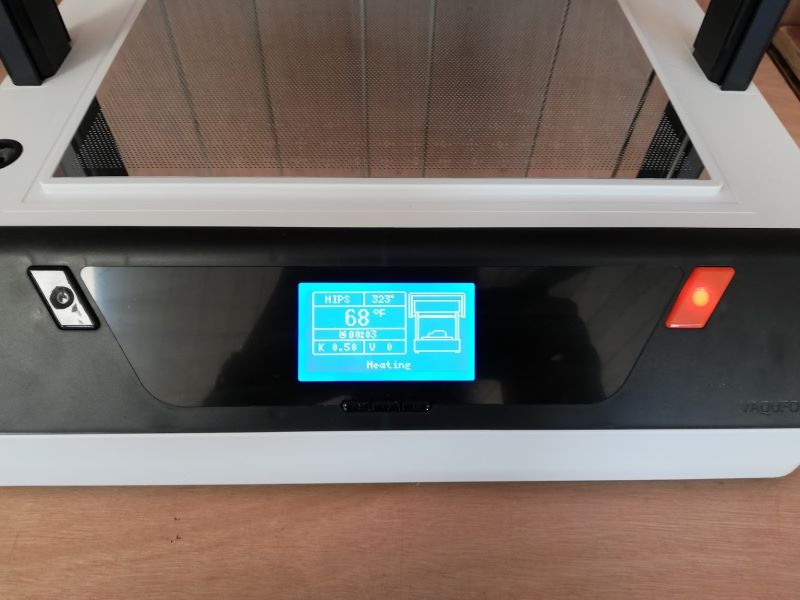

select the material and the tickness off the sheet you are going to use. The machine will calculate how long it will need to heat before it starts sucking air.

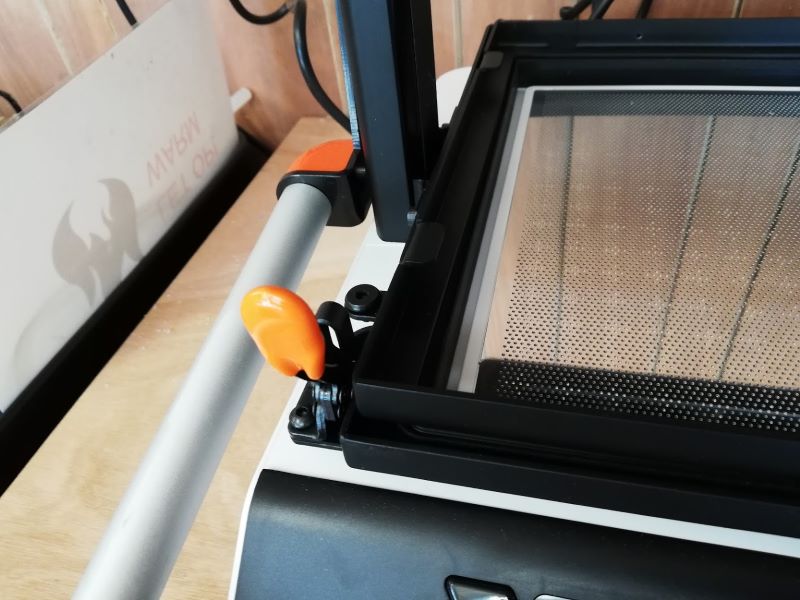

fix the material under the handles

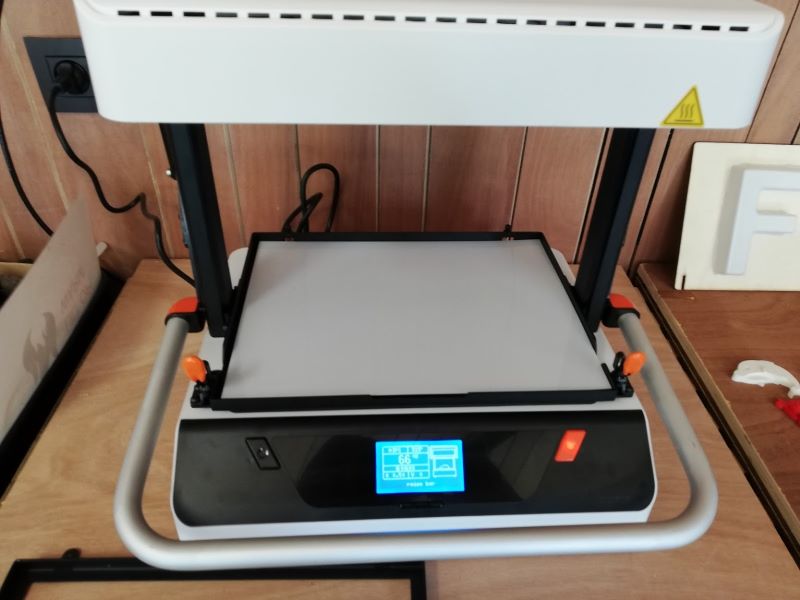

Press the orange start button an take the material to the top with the handle.

Now you have ( depending on the material) 2 minutes to place the object you want to vacuum mold on the bed.

When the material is heated the machine will start to suck the air away. When this happens take the handle down.

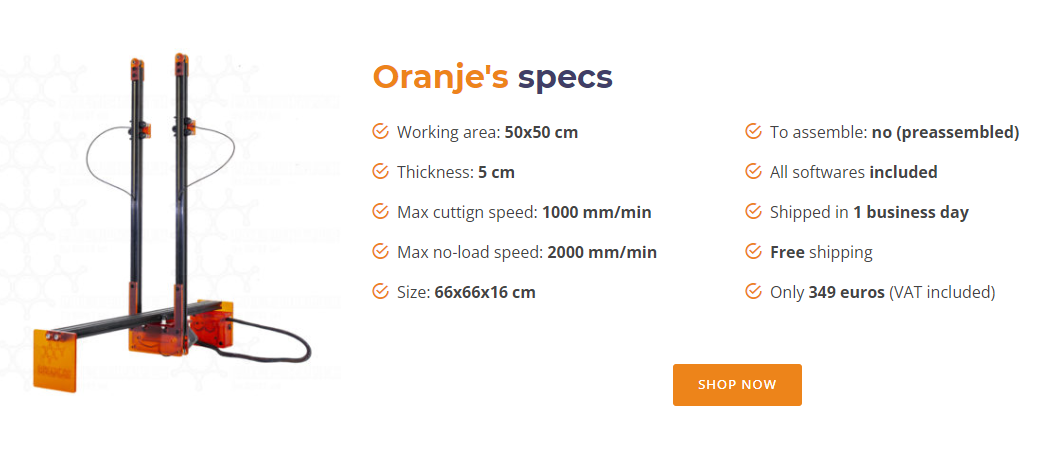

polyshaper / hot wire cutter¶

PolyShaper: hot wire polystyrene cutting machine

Download the programe¶

It is important tho first instal the driver and then ShaCo Both can be found here

material¶

-

Depron : One of the thinnest commercial materials that can be cut with our machines (2 - 4 mm thick). Excellent for creating folding writings and 3D puzzle

-

Extruded polystyrene : The most durable material among those that our machines can cut. Preferable for indoor signs and furnishings or in any case for gadgets with high added value.

-

Polystyrene : The most common material among the workable ones. Depending on the density chosen it is suitable for multiple uses, from personalized packaging to the creation of products and gadgets.

-

Expanded polyethylene : The elasticity, the excellent surface finish and the softness make it an excellent material for the creation of alternative decorative elements even without applying surface finishes.

making the files¶

The machine needs .svg files I use inkscape for this. I explaned this in week3