3. Computer controlled cutting

Assignment

Group assignment

- characterize your lasercutter's focus, power, speed, rate, kerf, and joint clearance

- document your work (individually or in group)

***Group Project here***

Individual Assignment

- Vinyl cutter - make a laptop sticker design, vectorize, cut using vinyl cutter

- Laser Cutter - Parametric modeling of Press-Fit Kit, cut Press-Fit pieces out of cardboard

Table of Contents

1. Vinyl Cutter

2. Laser Cutter

2-1. Group Work Result

Parametric Design

2-2. Fusion360

2-3. K2 LASER SYSTEM

Problems

Solutions

File

1. Vinyl Cutter

Use illustrator to draw up a laptop sticker for cutting on a vinyl cutter

Used polygon to make hexagon , divide it into 3parts and give the line thickness, convert it into outline stroke, and then delete .

Made logo!!!

After converting to a dxf file, use the vinyl cutter

Open the 'Grahpic Studio' and bring the dxf file

Click 'Open The Cutters Window'

Typing Cutter's Speed, Acceleration, Cut Force

Place the sheet on the 'Vinyl Cutter' and fixed it.

Setting origin

Try test

It cuts well. I think we can cut it with this setting.

Cutting logo

Remove the surrounding area

Place transparent grid tape on top of the logo

Transparent grid tape is very useful. It positions the separated stickers and can be removed as they are cut.

This tape is weak in adhesion, so only the grid tape can be removed.

Like this.

The place I want to attach is on top of my MacBook computer case. Whenever I see this, I will think about my first intention.

Stick them on my laptop and take them off only tape.

FINISH!

Vinyl Cutter DXF File here

2. Laser Cutter

2-1. Group Work Result

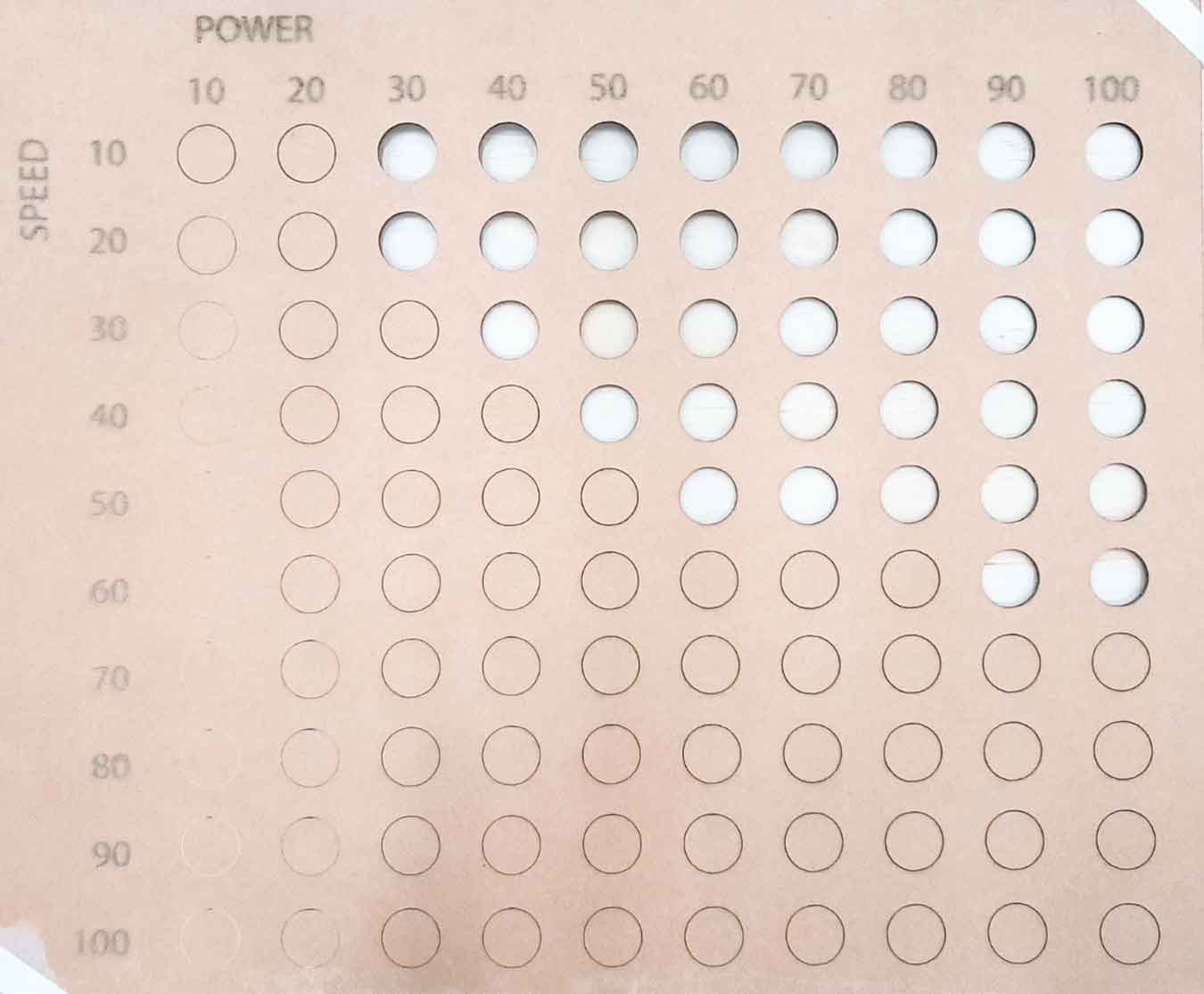

RESULT - Speed 60 and power 90 look the most ideal. The result is the fastest.(CardBoard 2mm)

- Parametric Design

- Parametric design is a process based on algorithmic thinking that enables the expression of parameters and rules that, together, define, encode and clarify the relationship between design intent and design response.

- - As I understand, parametric design is a design in which the overall shape and figures change to suit the situation when designed with figures as variables.

2-2. Fusion360

Use Fusion360 to draw up Parametric Design cutting on a laser cutter

Make Parametric Design 2type to using Parameter Tool

- Explain My Design

- I designed the pressfit kit that can make various shapes using parametric design. There are two square-shaped pieces, and each has a different number of slots, so the more the pieces, the more various the shapes.

Using Fillet Tool 1mm

For 2mm thick cardboard you used a clearance of -0.2 to account for the laser kerf. So you end up with a 1.6mm slot size to create your press fit. It won't come out easily and will be firmly fixed. This is interference fit.

About types of fit

Save as DXF file

2-3. K2 LASER SYSTEM

Modify file in illustrator and align

Open the file in GoldenLaser Cut

Refer to the setting values identified in the group project. Type 'work energy', 'min energy', 'work speed'

- Setting Value

- Work energy : 90

- Min energy(work energy-5) : 90-5=85

- Work speed : 60

↓K2 LASER SYSTEM(JG-10060)

Cutting..

-

- We have to pay attention.

- You can watch the laser cutter cut, but it's not good to see the laser with your naked eye. - Wear protective glasses.

- If the laser cutter is too slow or powerful, it may ignite. Please note this and set the value.

- If you open the cover right after you finish working on the laser cutter, it's not good for your health. The cut material burns and smoke comes out. The smoke is bad for your health, so open the cover after the ventilation machine has removed some smoke.

All the pieces I designed were cut off.

Finished assembly shape

This pressure kit that I've never made before is really fun. The shape changes every time I put it in the slot I want among so many slots. It's like a Transformer. It makes me happy like a robot that changes variously. I'm very satisfied.

FINISH!

Problems

Problem1

Problem2

Solutions

- Distance between slots is too close. Here's the solution to this.

- Double the distance between slots.

- ake the piece larger, and increase the number of slots on one side.

- Make the size of the smaller piece smaller.

- Create more diverse pieces and add more slots.

File

Laser Cutter DXF File here