16. Wildcard Week - Composites

Assignment

Group assignment

- Produce test coupons for your composite fabrication process(es)

Group Project here

Individual Assignment

- Read the safety data sheet (SDS) and technical data sheet (TDS)for the resins that you're using design

- Fabricate a 3D mold (~ft2)and produce a fiber composite part in it, with resin infusion and compaction

Table of Contents

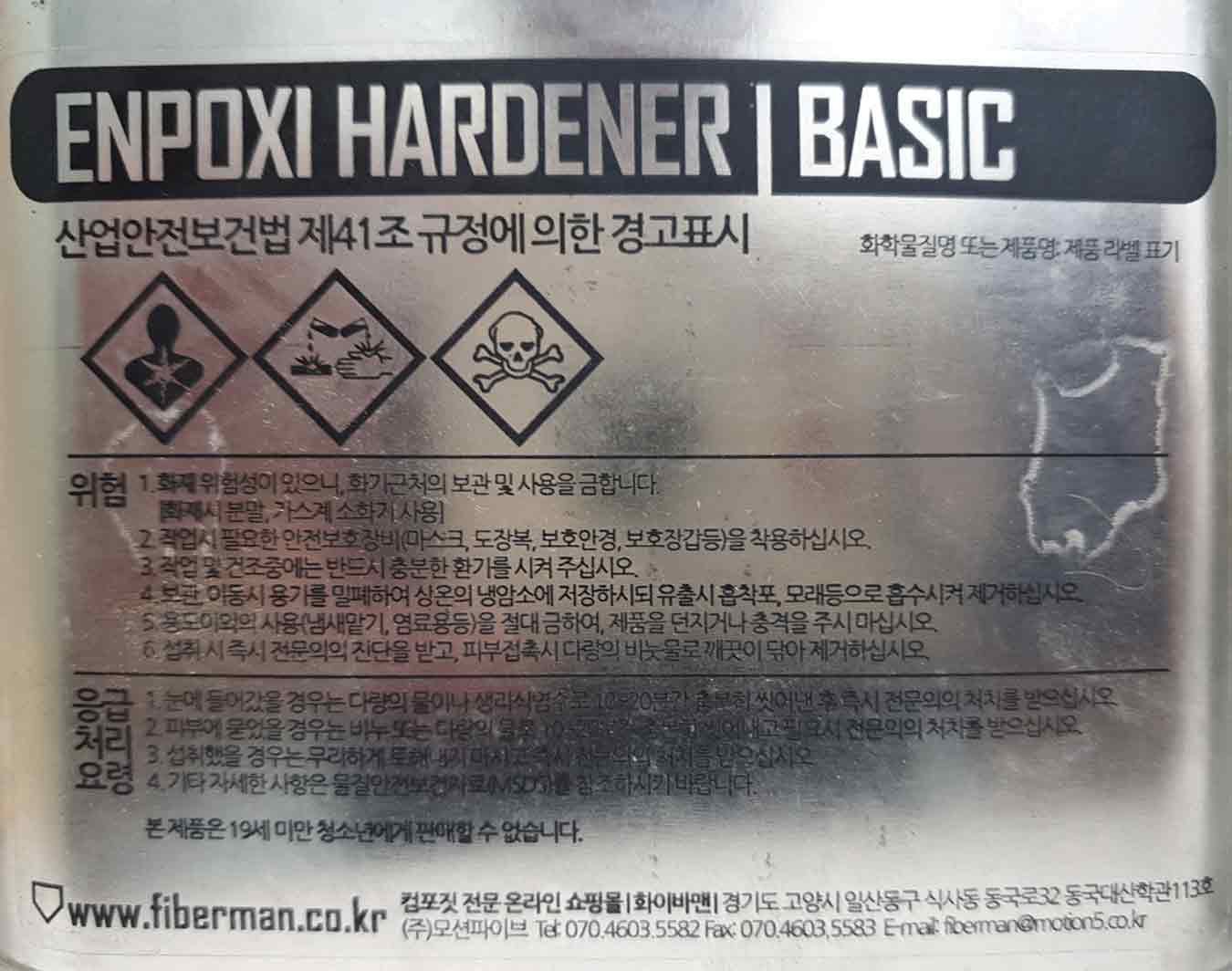

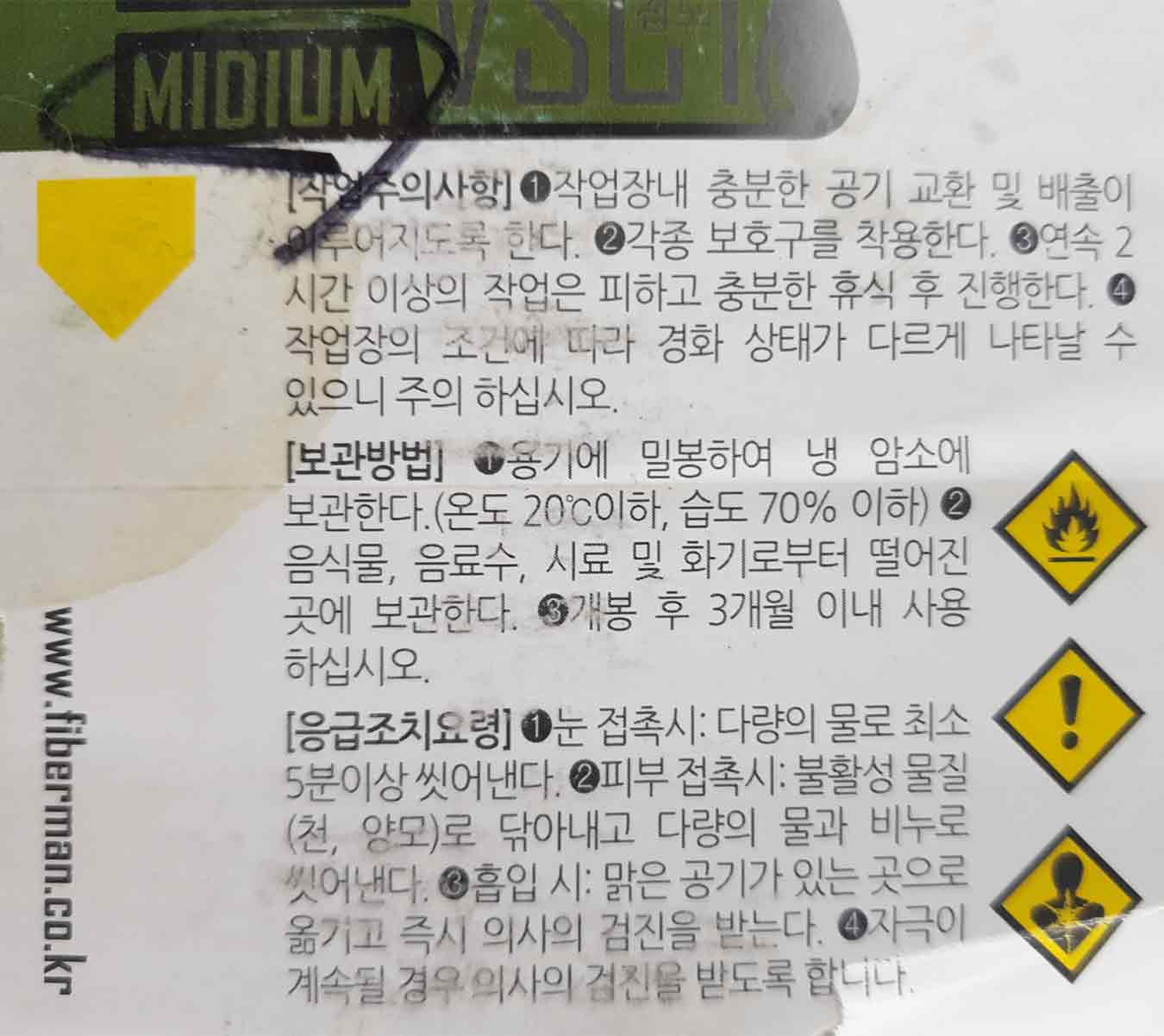

1. ENPOXI BASIC

1-1 SDS and TDS

1-1 SDS and TDS

2. Process

1. ENPOXI BASIC

1-1 SDS and TDS

- I chose the BASIC between ENPOXI BASIC, which takes 10 hours to cure, and ENPOXI ART, which takes 48 hours.

- Characteristic

-Ratio 100:13

-Geltime : 30 minutes

-Cure time : 10 hours

- Be sure to work with protective gear.

- Sufficient ventilation is required during the working.

- I got to know other precautions and started working on them.

2. Process

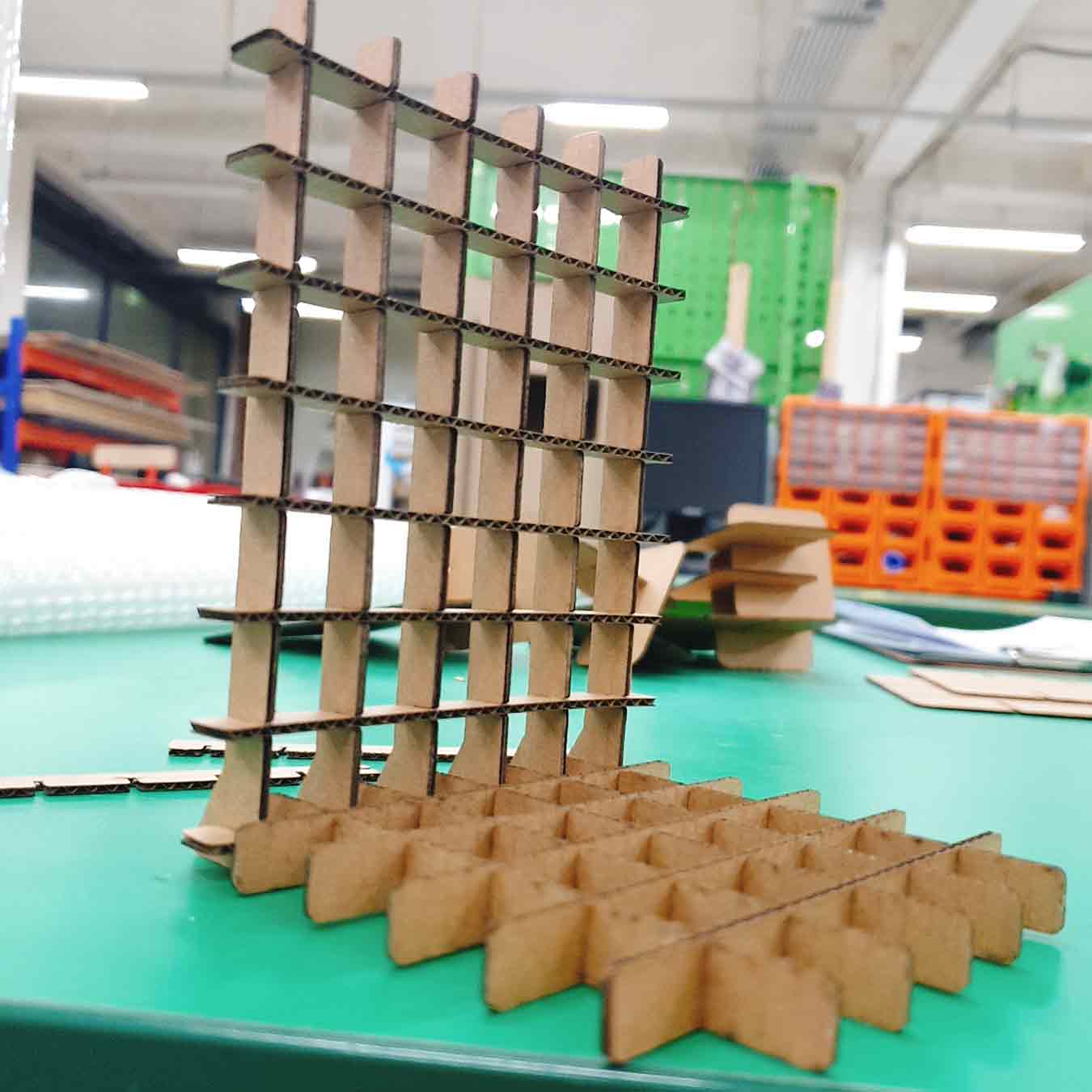

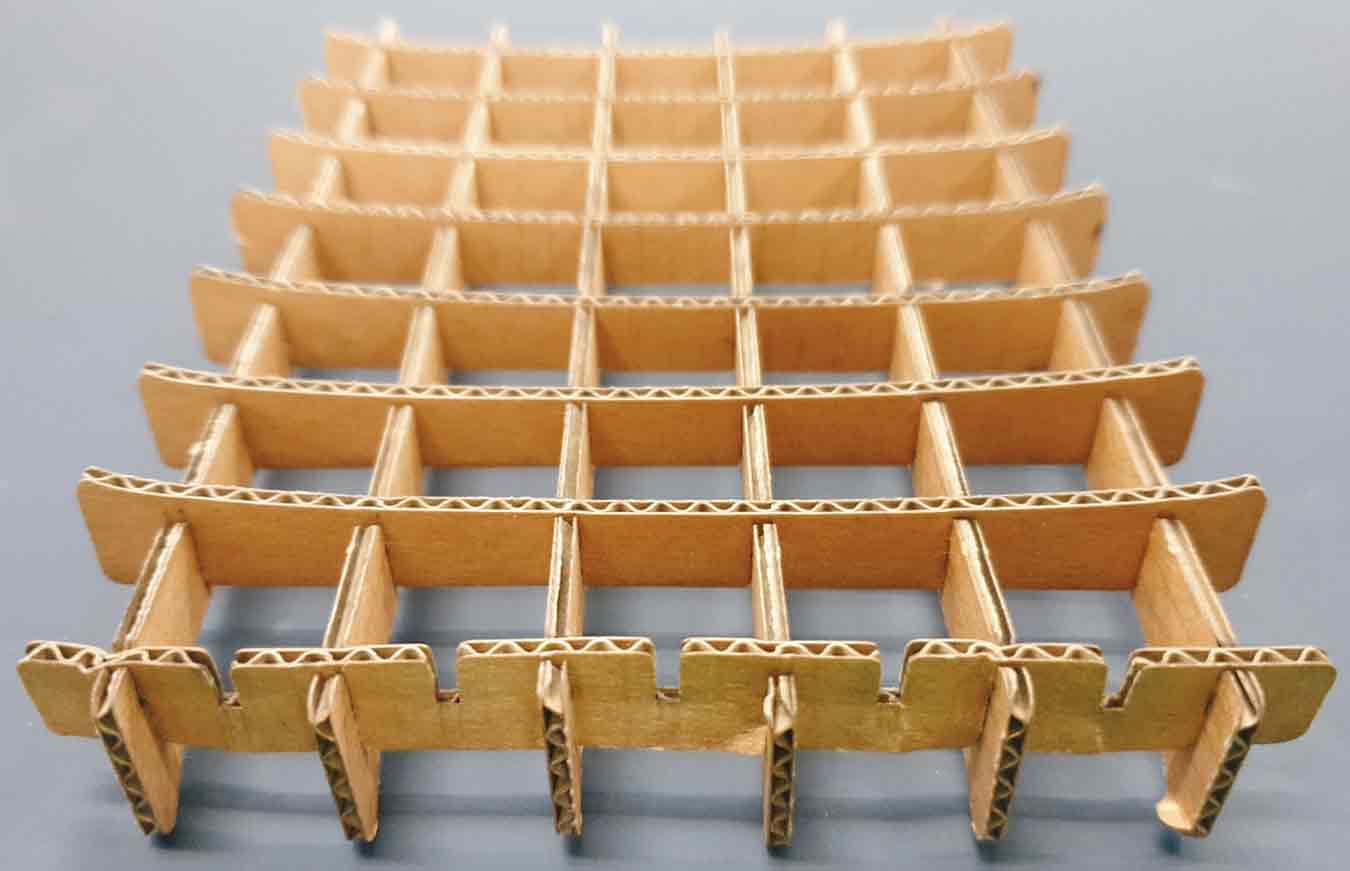

- First, I am going to make a cover using the mini-seating chair model that I made in the third week.(This chair is used on the floor, so it has no legs.)

- As composit materials, I used ENPOXI BASIC(resins) and hemp cloth.

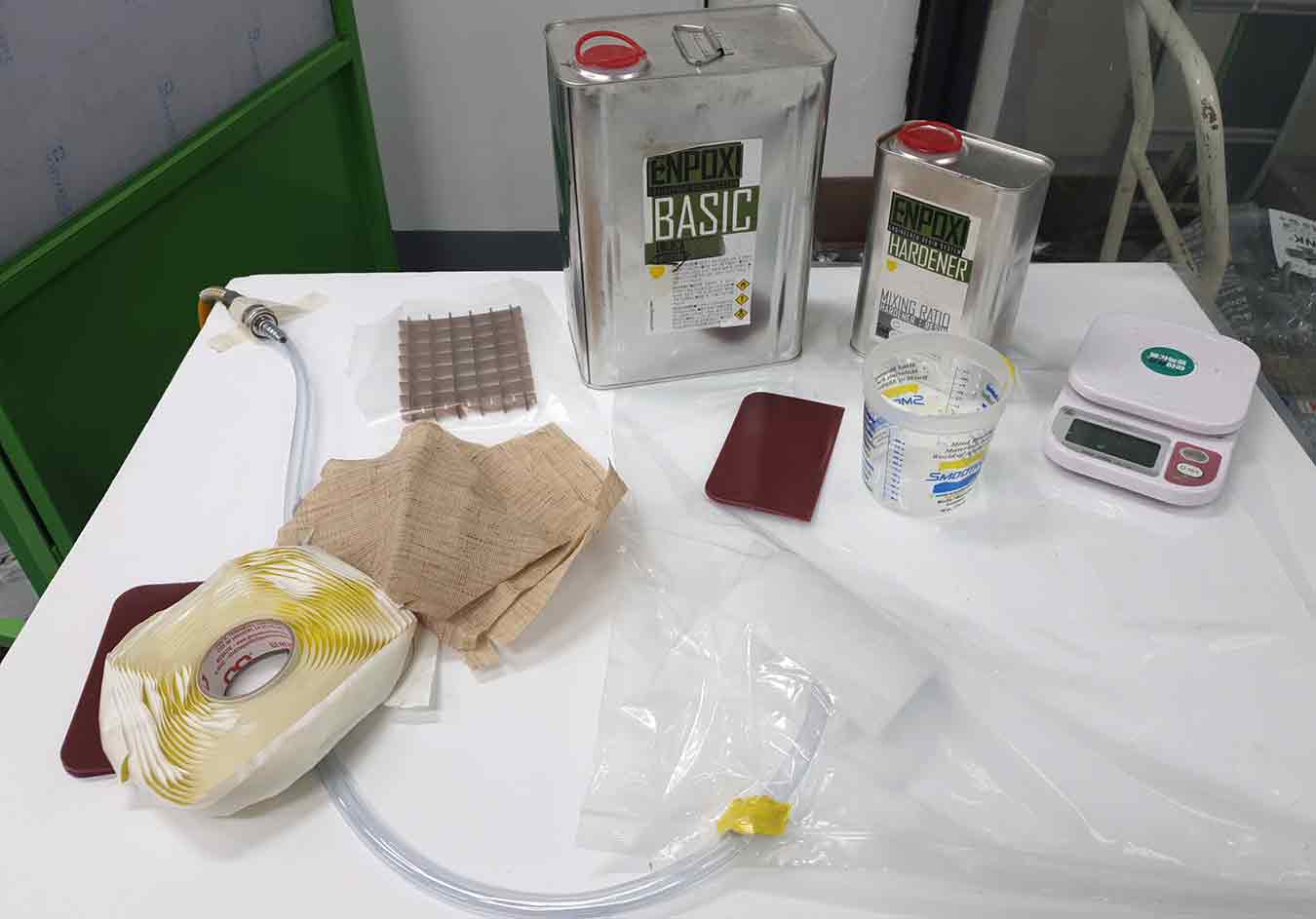

- Preparation materials

- Ziploc bag, resin, hemp cloth, hose, sticky tape to block holes, vacuum

- First, I decided to put 100g:13g of epoxy as I thought I would need 100g at random. Check the weight with a scale.

- Mix them evenly. The gel time is 30 minutes, so mix it up for 5 minutes.

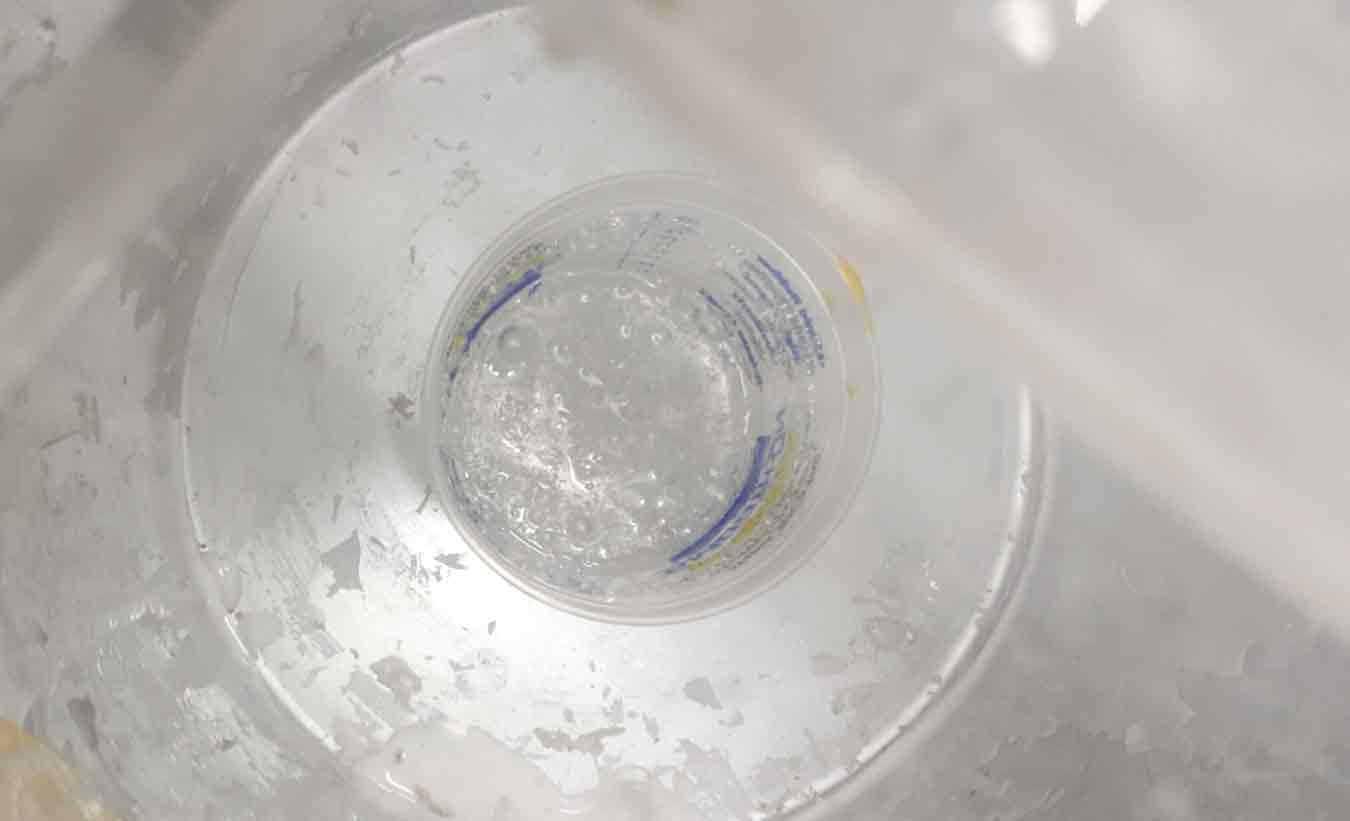

- Go to the vacuum and drain the air in the resin for 15 minutes. The method of deflating the material using the vacuum can be found in the moulding and casting group work.

- Checking for air loss

- The release of the resin air (wait until the bubbles subside).

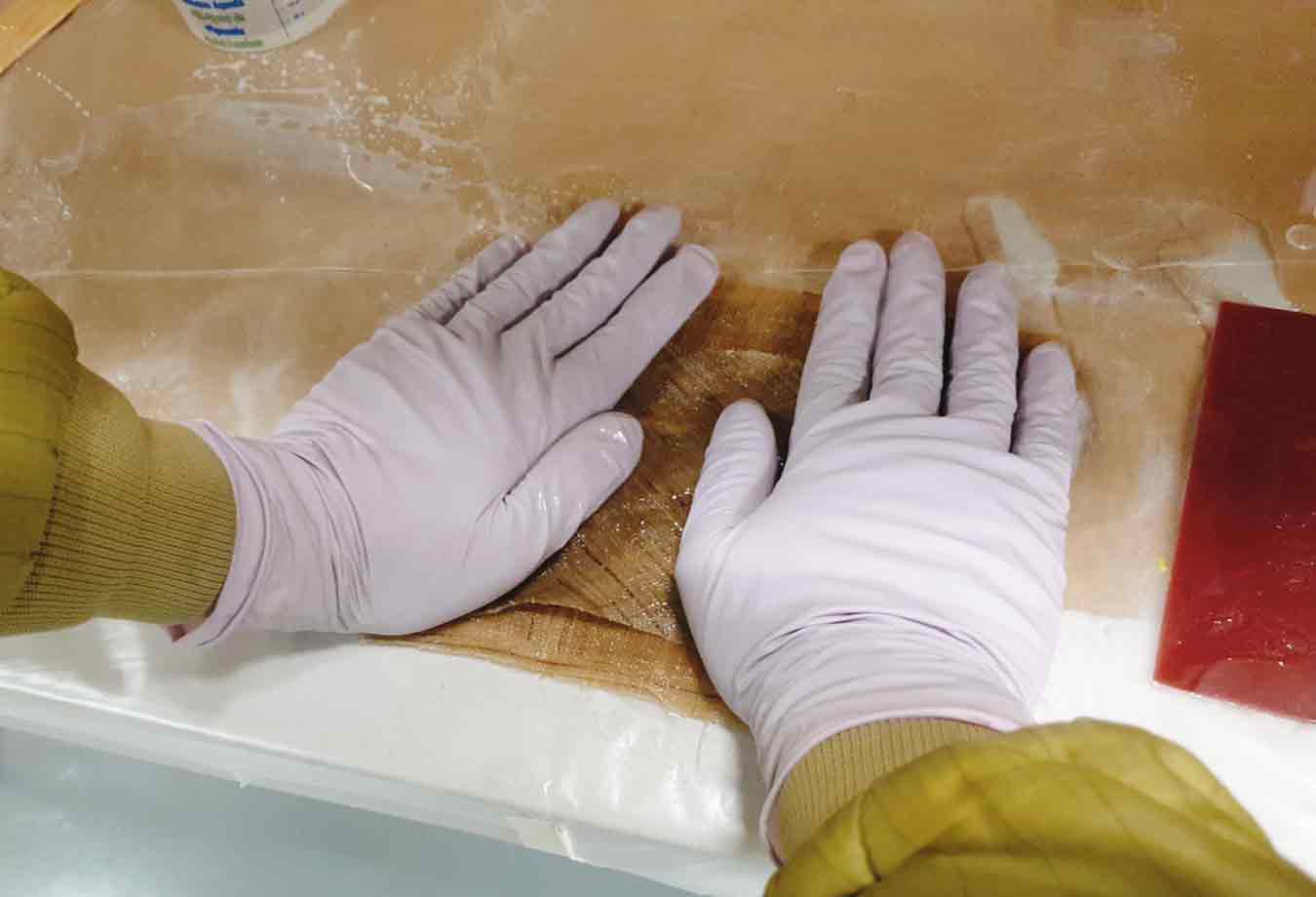

- Move the resin and spread evenly on the hemp at the working table.

- Then, pile the materials in layers. I stacked the material in three layers, each with a different direction. Then, use my hands to press hard so that the material is spread out evenly.

- Now take off the resinous gloves.

- Take care not to stain other gloves. Put the work piece piled up in layers into the ziploc bag.

- Close the ziploc bag tightly and drain all the air out of the ziploc bag using vacuum.

- While the air is drained, make sure that the ziploc bag on the work piece is not wrinkled. After removing it, keep the vacuum in the vacuum and turn off the vacuum.

- If this continues, there will be a wonderful piece of work. Please.

- But... this week, my bad luck hit me again. There was a problem with the vacuum and the air went in between and ruined.

- I cut the side extra materials with scissors. The shape is not bad, but the resin has not permeated well in between, so it is stained.

- I cut the side extra materials with scissors. The shape is not bad, but the resin has not permeated well in between, so it is stained.

- If you work again next time, you'd better leave the vacuum on.

- This time the compose was not successful but I found it attractive. If I have time later, I would like to use compose to protect the lower part of the legs of my final project.

File

AI

- Design files of works made with laser cutters used this week here