4.Computer-Aided Design & Manufacturing¶

File preparation¶

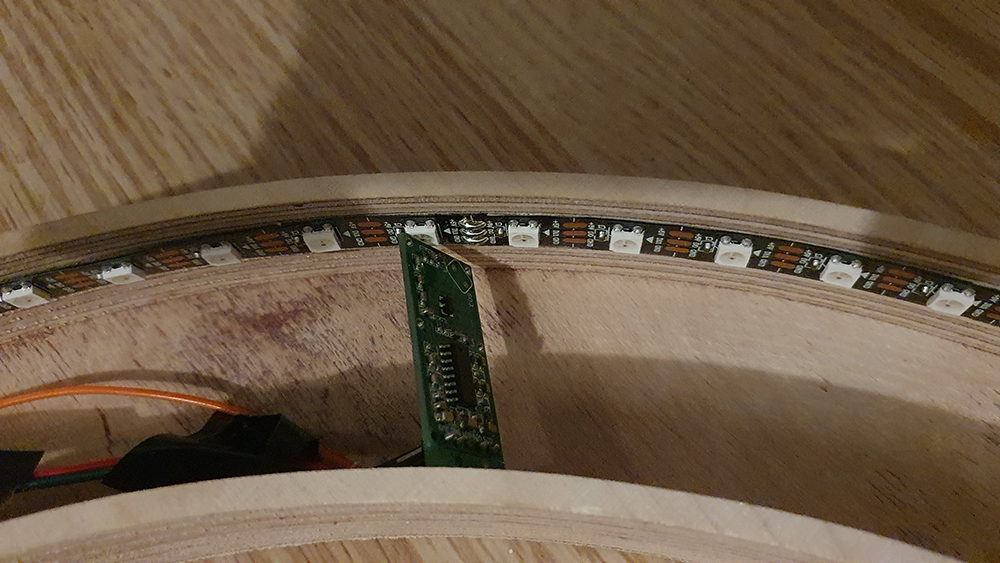

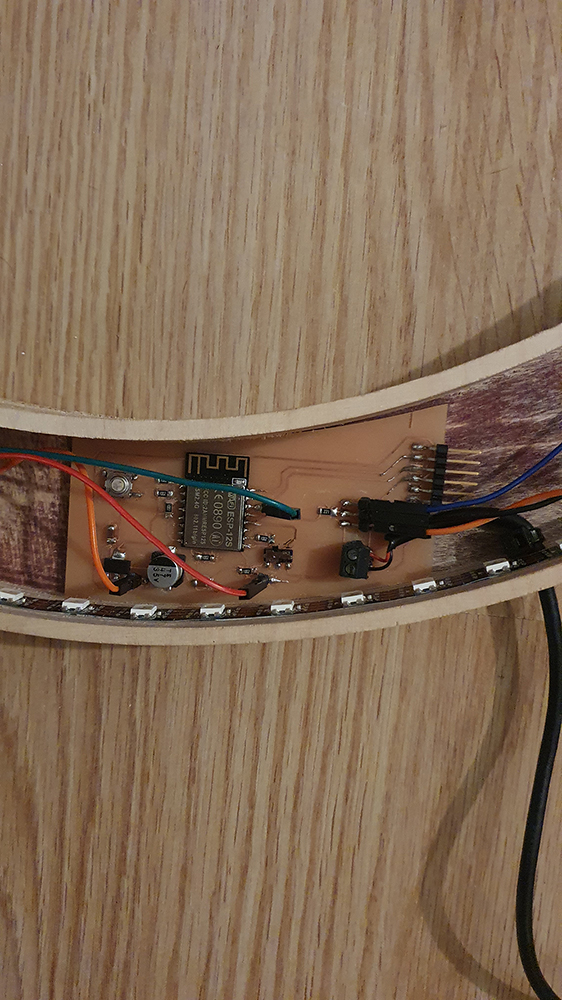

That was my first interaction with the CNC machine. I loved it! The only thing I regret is the wasted material since I had to pocket a 2.5 mm piece of wood. The file is quite simple. Two cocentric circles.

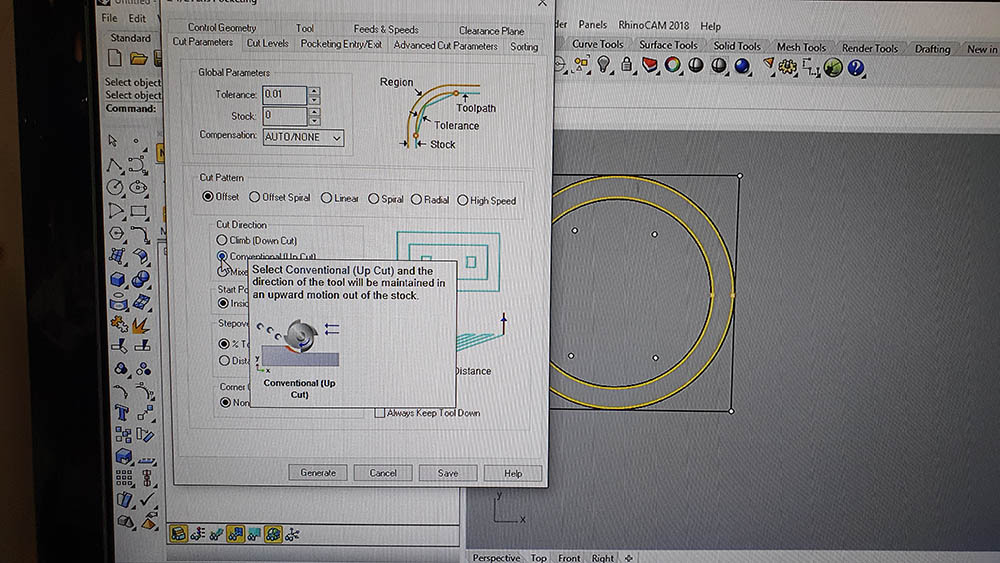

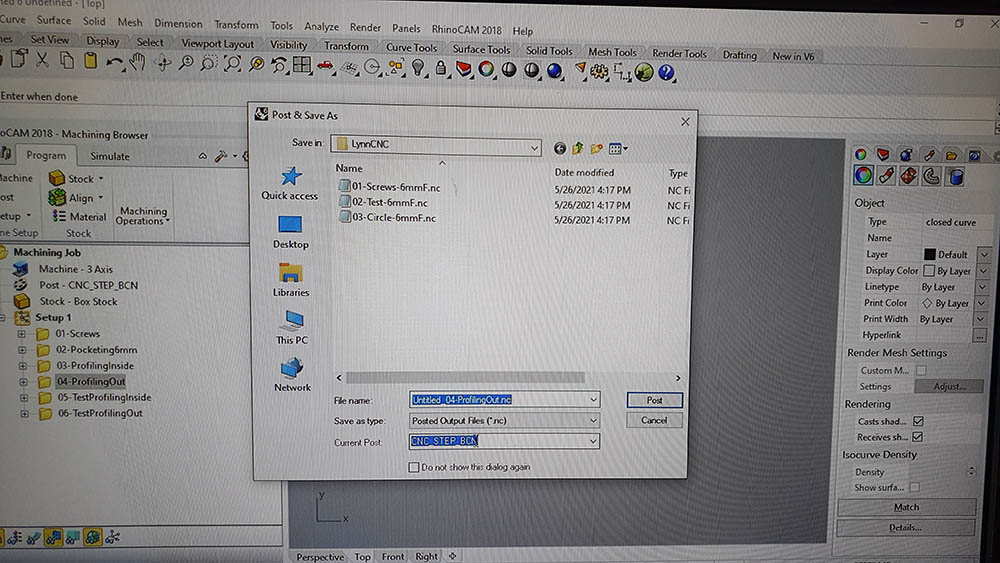

The CNC preparation is interesting. We had to generate separate .nc files.

We also make a test before to make sure that with the speed we chose, the walls are sustained.

I use a 6mm Flat End Mill, and we make sure that to use conventional cutting since our walls are too thin and it might create pressure on the walls.

Some other parameters we followed to make sure we dont break the walls are: - using a clearance plane for transitiong in cuts. - making sure the cutting is not too fast that the pocketing is not smooth, and not too slow so that the pressure isn’t too heavy.

Cutting in CNC¶

I actually documented pretty well the computer-controlled machining and we can find all the steps there, considering we even used to the end-mill but a different material, which affects the feed rate.