10. Molding and casting¶

Design¶

Design Files¶

To download the file Please Click Here

-

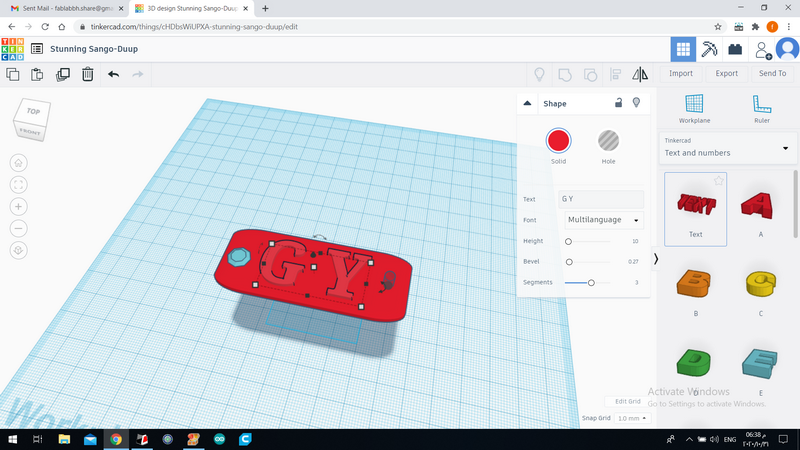

I used tinkercad to design the model here I used the text to write the first two litters of my name

-

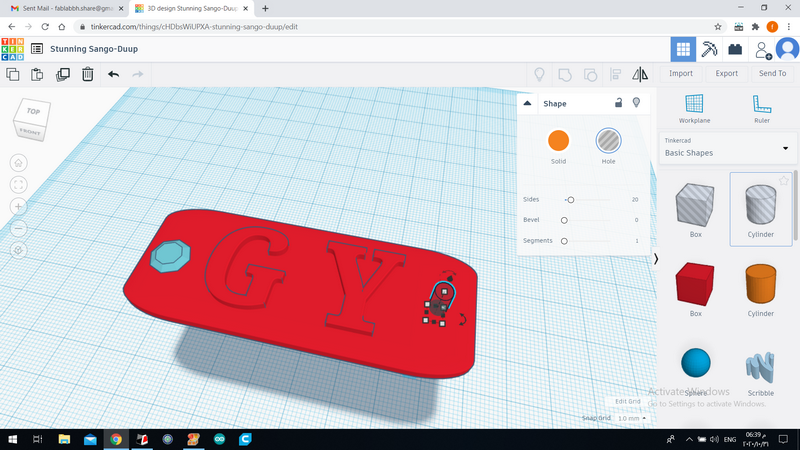

To make a hole I used the basic shapes cylinder as a hole creator

-

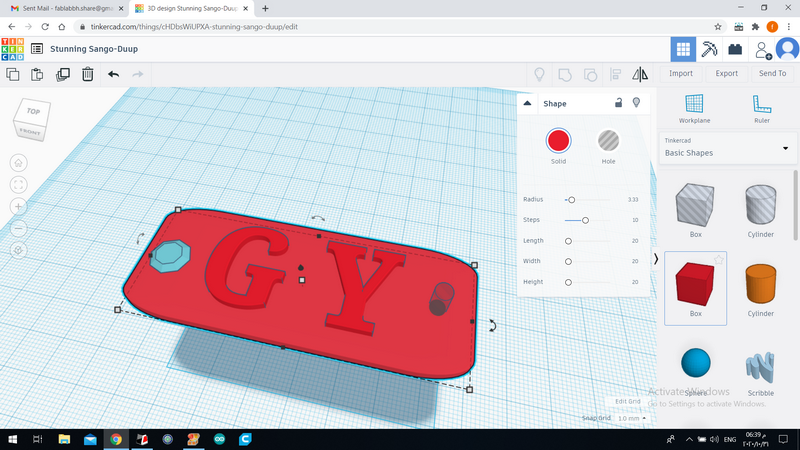

to create the base I used the box and then rounded the edges

-

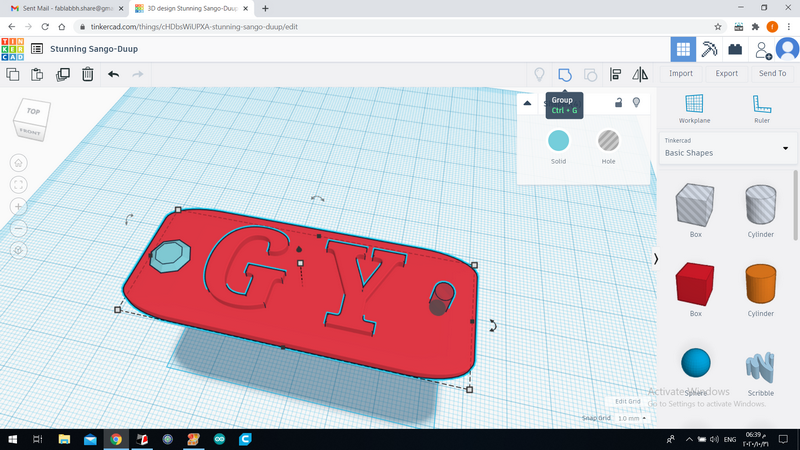

to finish and combine all parts together I used the combine tool

-

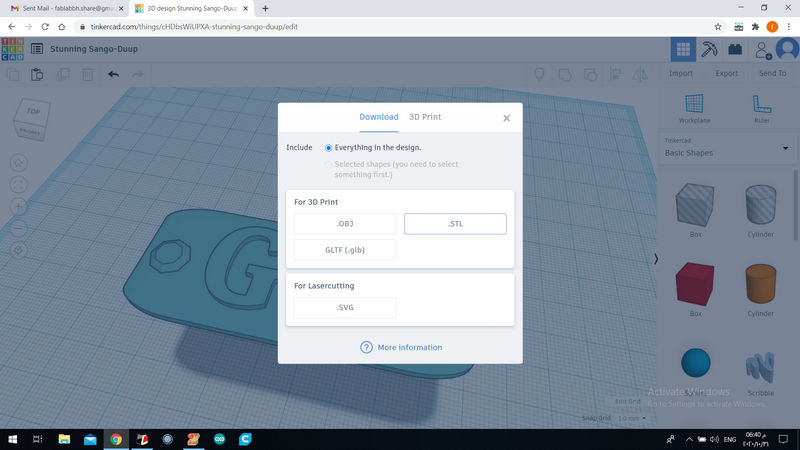

then click on export as .stl

Milling software¶

-

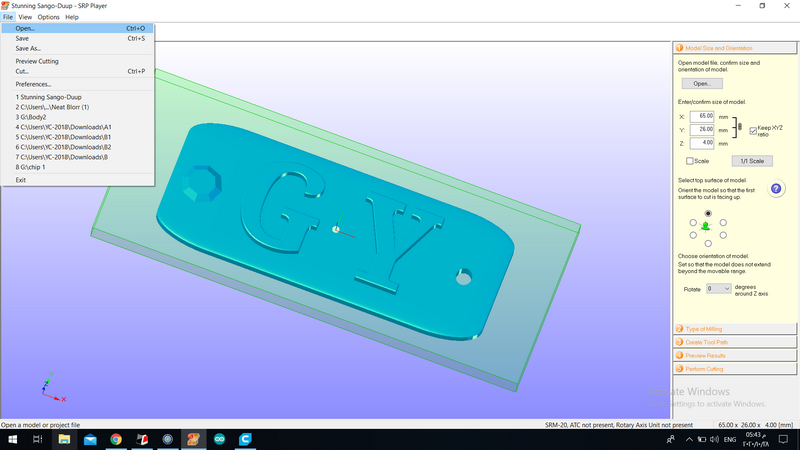

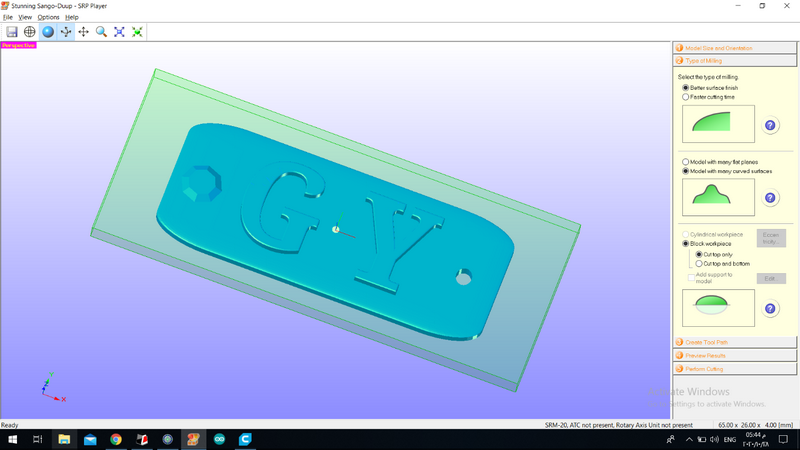

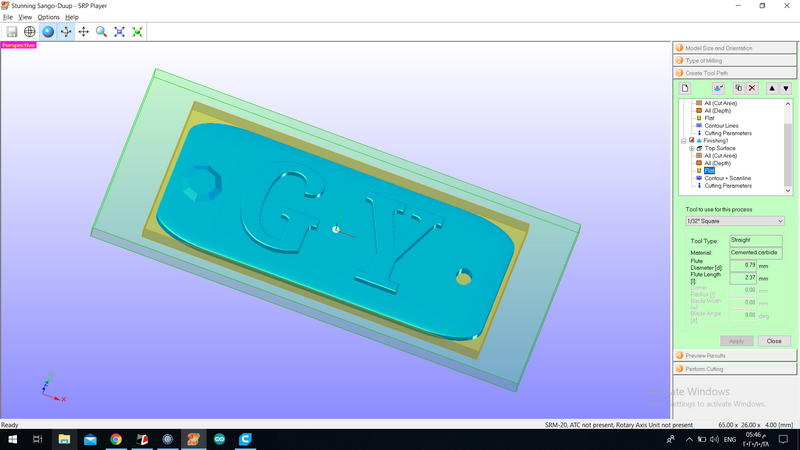

I uploaded my model from file >> open ,we made sure that the orientation is correct and the dimensions too

-

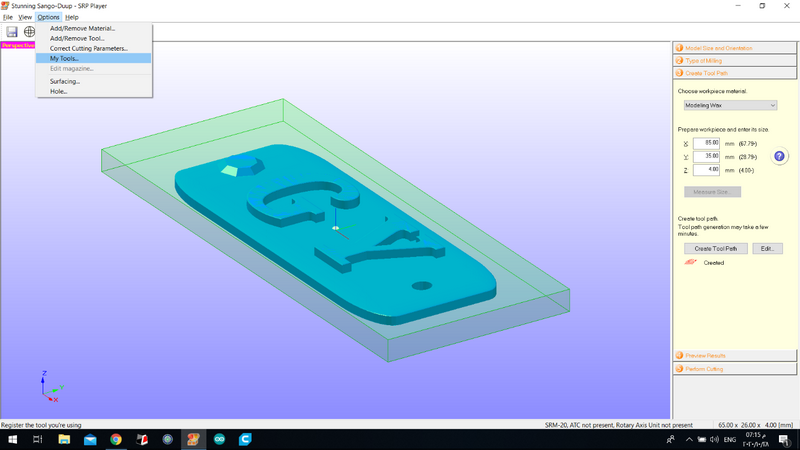

To start we added the tools for milling the wax from Options >> my tools

-

-

After that we chose the type of milling

-

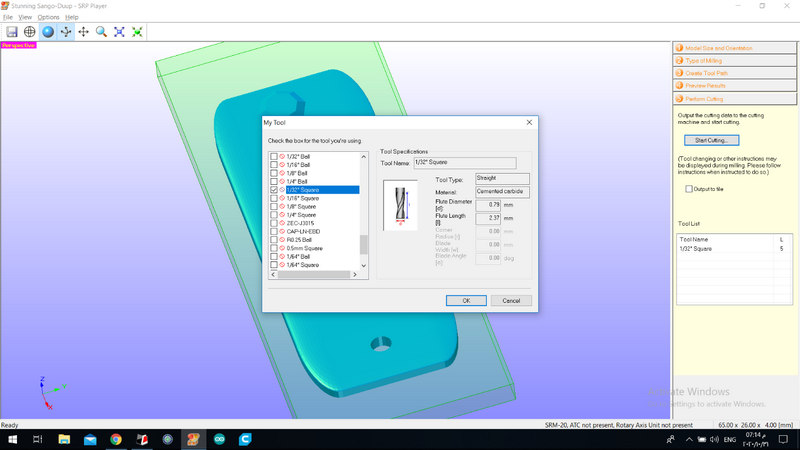

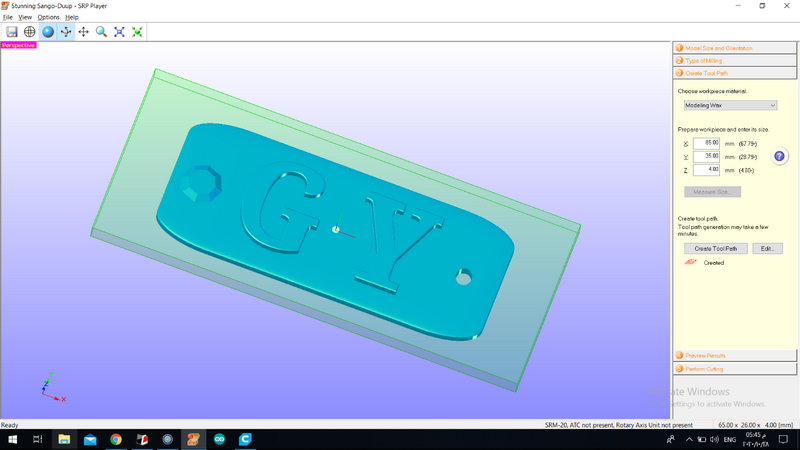

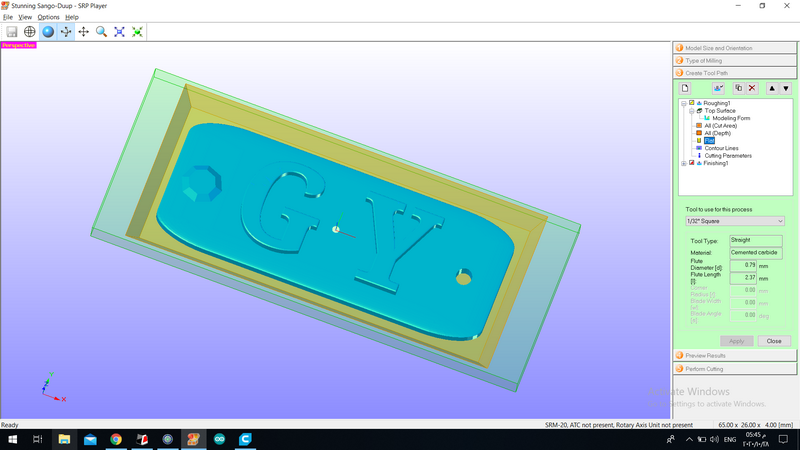

click on create toolpath ,then edit it and set the material to mill so that the software would generate the feeds ,speeds settings. Moreover, I chose the milling bit

-

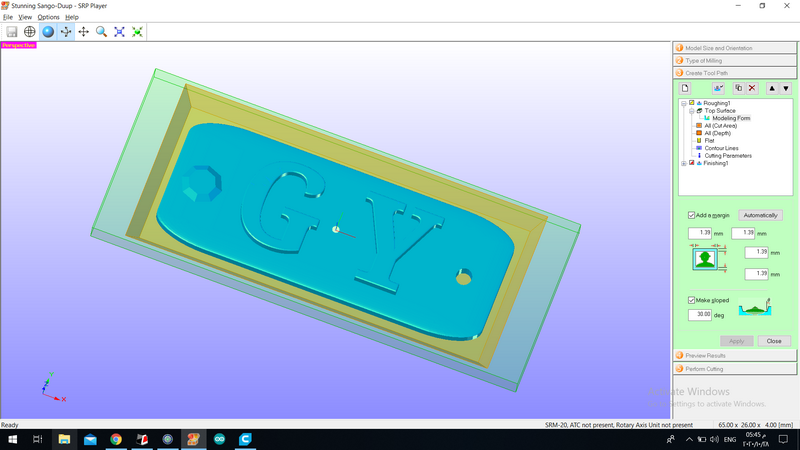

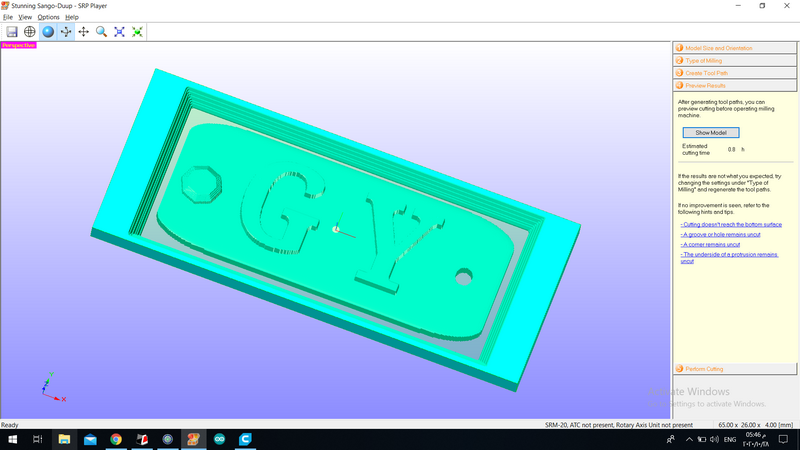

for roughing and finishing we will use the same milling bit which is 1/32 ball nose

-

To make sure that the milling in the edges will happen I added a slope of 30 degree

-

For the finishing I used the same milling bit 1/32 ball nose

-

Then to preview the final result I clicked on show model this will indicate if I will have to adjust or change the milling bits

-

I zeroed the x,y axis to the middle of the wax and z on the top of the wax

-

Finally I clicked on start cutting

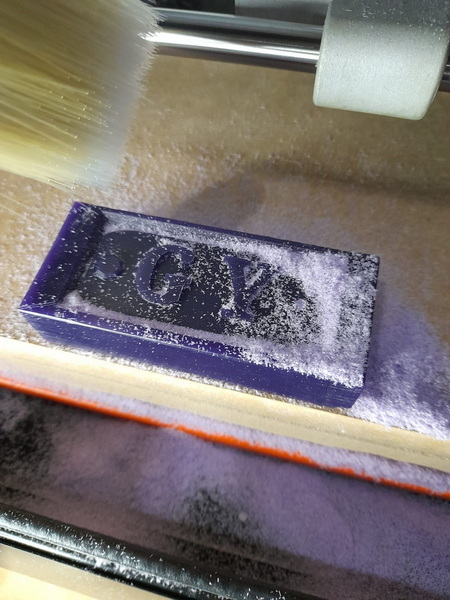

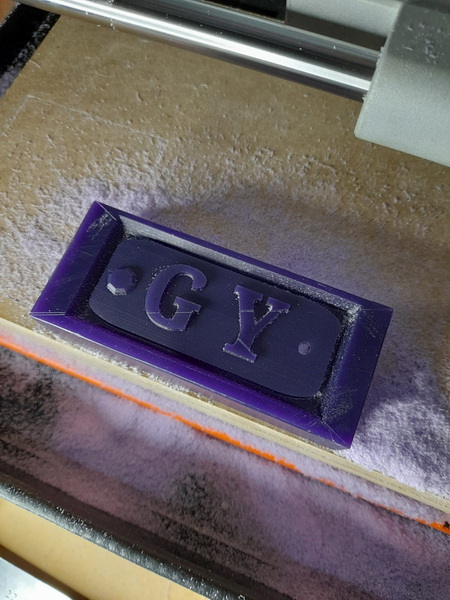

Milling¶

-

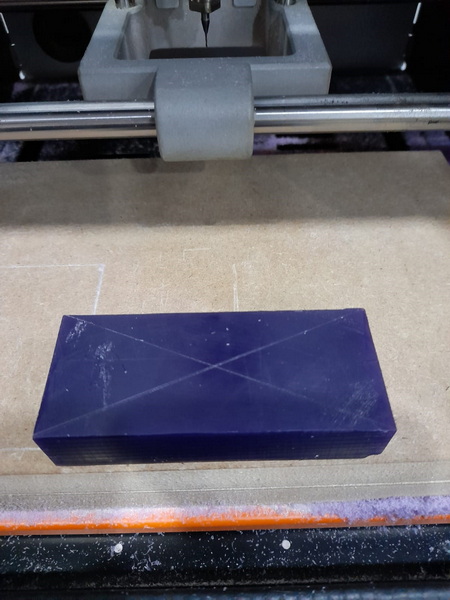

I draw a X to find the center of the wax

-

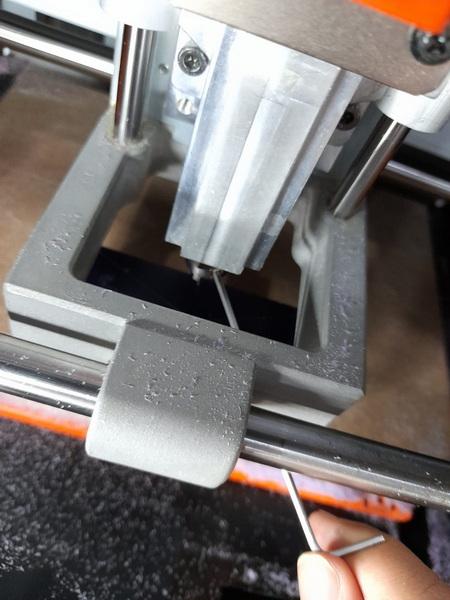

I changed the milling bit to 1/32 ballnose

-

this vid shows the start of the milling

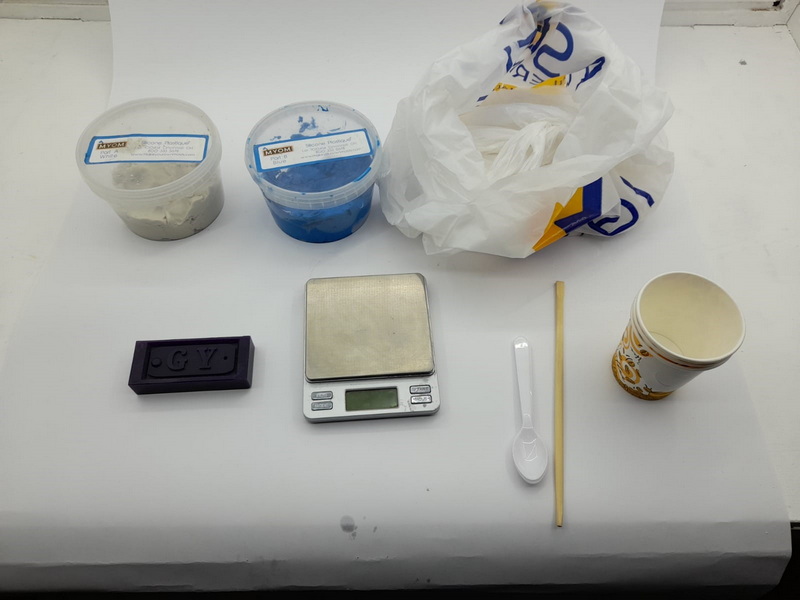

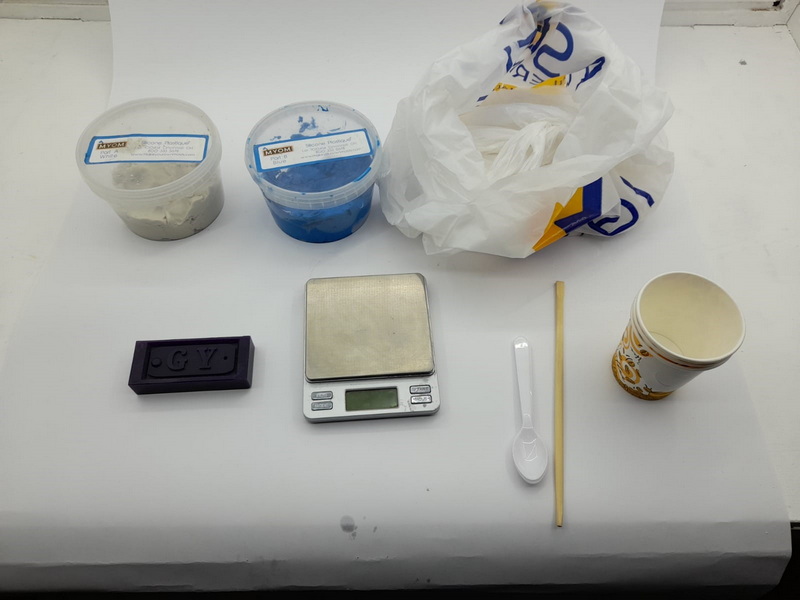

4.This was the materials and tools I needed

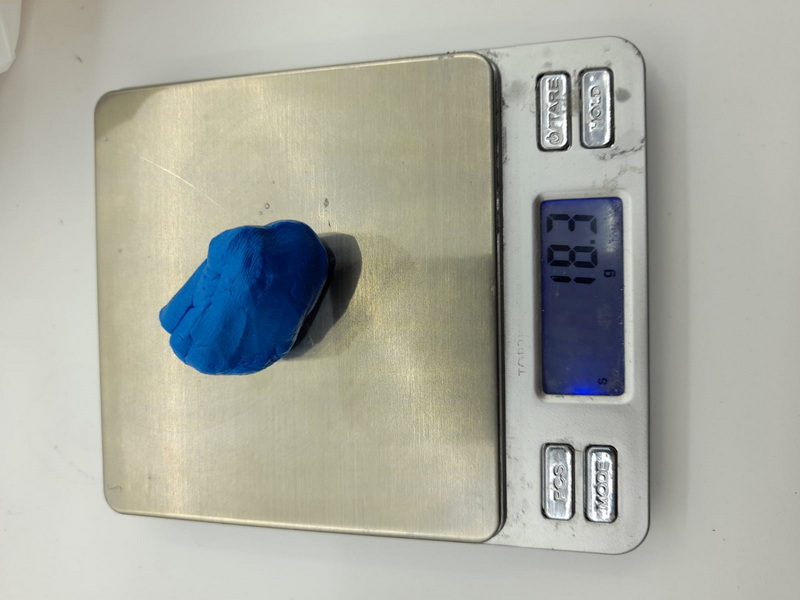

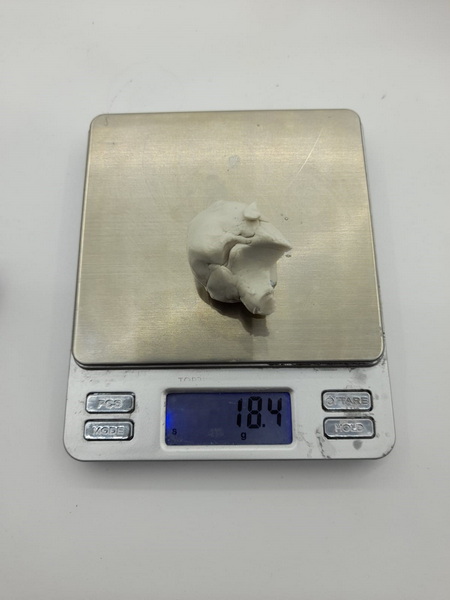

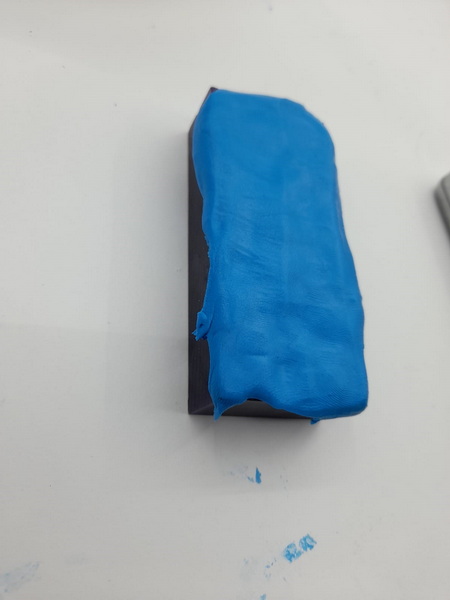

5.for this material I had to mix 18.3g “1-1 ratio” to make the negative mold

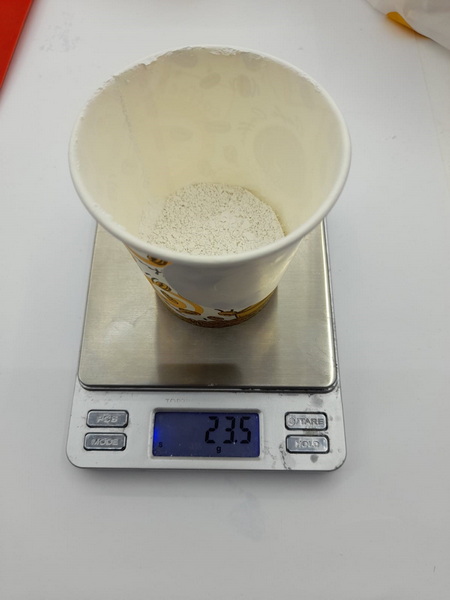

- for the cast I used jepsum with 1-1 ratio with water

Group Assignment¶

Please Click Here