Project Development

For this week there was not any assignment but we are supposed to work on our final project. These are questions we need to be answer for this week

Final Project Concept:

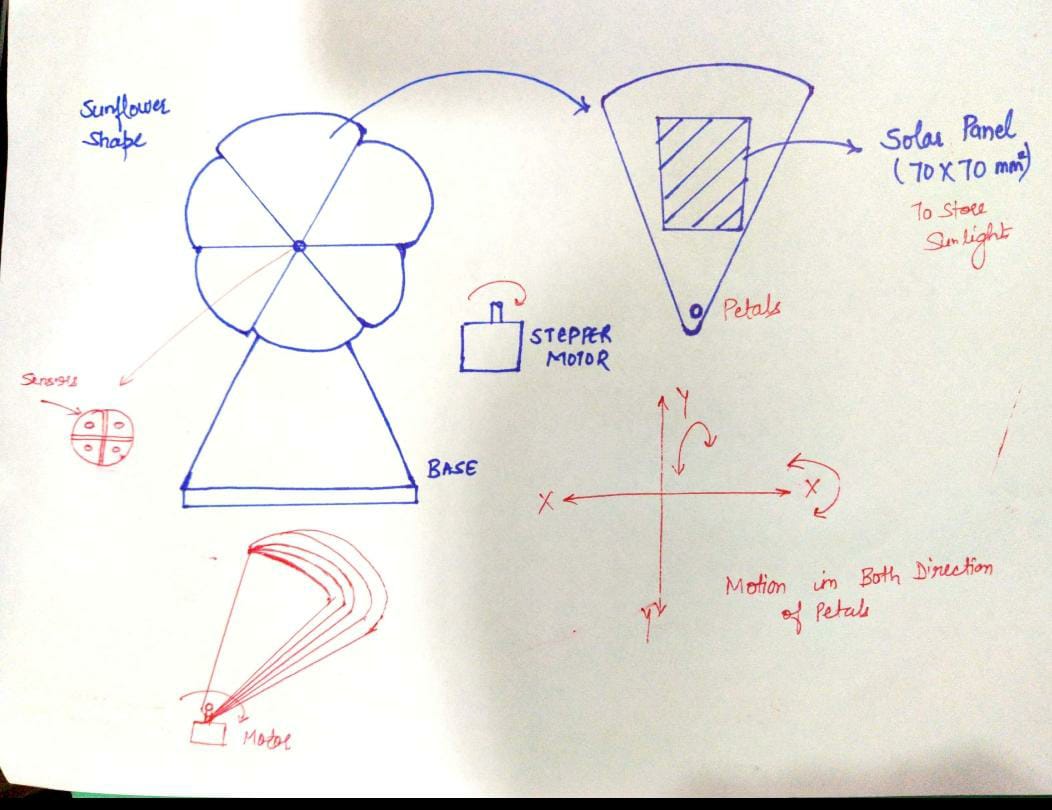

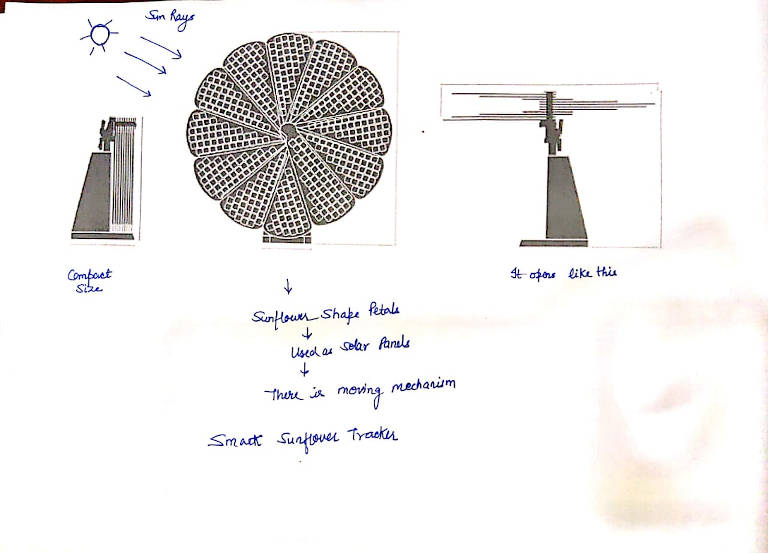

This project aims to capture maximum intensity in minimum possible space (flower shape) and rotate whole set of solar panel in sun moving direction so that efficiency can maximize. It tracks sun movement and changes its face toward sun just like sunflower

Smart sunflower solar tracker uses Nema-17 stepper motor with assistance of A4988 stepper driver to open up all the petals of sunflower which are folded initially with the help of Real Time clock module DS3231. Under this design, One Petal has its own motor which moved at the sunrise in the morning and rotate the whole set of petals. These characteristics make it a better fit for the irregularities and obstacles in tracking sun rays. Sunflower Petals having five solar panel mounted on it which moves from east to west direction and north to south direction .When Light Dependant Resistor(LDR) sensor got sufficient light in that direction. The motion in both the direction takes place with Metal Gear MG-90 Servo Motor.

Sketch Ideation

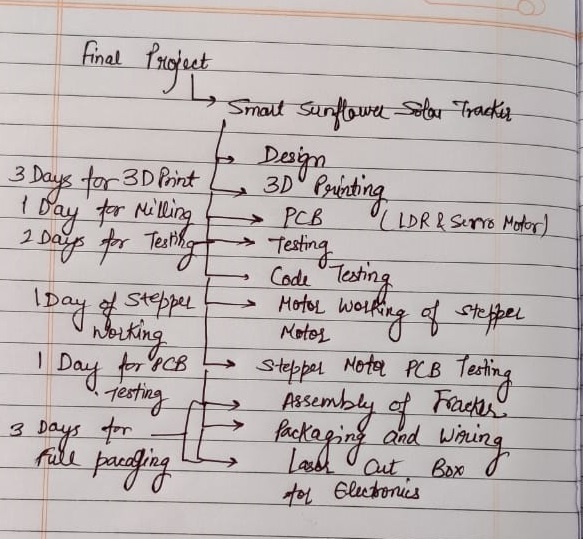

Deadlines

I have already presented my Final Project in front of Neil.Due to the time I had apart from pandemic situation I have completed my Final project with minimum goals.Yeah lot more is required to reach out the goal which I set initially.

From the day one after lockdown of few months.The things really dint work perfect.I had to do lot of work in the field which I was very unaware of ie electronics part.

But yes at the end I can say I got valuable experience with good result.

What has worked?What has not

The basic requirement of the project done including:

In my solar Tracker I have sucessfully give the motion to petals left,right,Up and down directions with the help of Two servo Motor and LDR sensor.

But the part of opening all the petals has remained due to unavailability of stepper driver.I have checked the code and stepper motor working but on actual model. I was not able to work on it due to unavailability of resources.

What questions need to be resolved

How much power will solar panel generated by this mechanism.Management of wires and Packaging of system.

Placement of components to make it fully fabricated product.

What will happen when

I will test my pcb with other stepper drivers to get that motion of opening petals.

What you have learned?

I have learned how to design and fabricate a PCB incorporating Input and Output Devices,Embedded Programming and how to prototpye a Design.Time Management and developed a product having mechanical design and electronics design both.

Project Plan

I was planned to do my final project development part with assignments related to my project.For CAD I made preliminary design which I made without considering electronics and other components which need to be assembled on it.Just made a thought of mine in form of CAD and animation.But due to coivd pandemic there was lockdown and the lab access is strictly prohibited and the part in which I am extremely week is electronics. After unlock one we got partial lab access and in lockdowntime I made one pcb related to my final project input and output devices.With lack of experience I did mistakes in pcb designing and after mlling I had failures related to holes and padding outline but after attempts. I rectify this and for CAD I Improved the design and Printed the petals on PLA and that attempt got failed and there was scope of improvement in that.

As the final project presentation dates came I tried my best to do all the tasks within time limit.So its important to plan accordingly for each part of project.

We can also use the Final project pcb for output and input device as our pcb for input and output devices so thats how I managed to complete final project pcb as well as input and output assignment pcb and on other assignments I worked after the project completion

Have a look on my checklist which I planned two weeks before my final presentation for fabrication.

When I was working 3D Prinitng I also working on design on Eagle as well.This time I defined after I have tested pcb with failures.

As soon as the time came for presentation we need to work hard due to limitation of time for lab access and pandemic.At some times I used to work alone as there was no one available in lab.Making videos and photos was a tedious task to do that time.Thats why I did not have photos and videos of some failed attempt.But last not the least I was able to present in front of Niel.Thanks to my regional instructor and local instructor and my fab Mates PULKIT AND NEERAJ SIR