7. Computer-Controlled Machining - Week 7¶

7.1. Assignment¶

Computer-Controlled Machining

group assignment

do your lab’s safety training

test runout, alignment, fixturing, speeds, feeds, materials,

and toolpaths for your machine

individual assignment

make (design+mill+assemble) something big (~meter-scale)

extra credit: don’t use fasteners or glue

extra credit: include curved surfaces

7.2. Group Assignment¶

7.2.1. CNC Machines¶

In our lab, we have following:

7.2.2. Safety training¶

always look for/hear the mill

FIRE!!

keep flex low -> longer milling mill sticks out, more flex -> as short as possible, as long as necessary (flute length)

keep a distance and safety gear!!

hair, weary cloth -> 20k RPM of mill -> HURTS BAD

stuff (work-piece, chips, MILLS!) flies away -> especially mill -> carbide -> hard -> kick-back -> work-piece throw

no gloves!!

7.2.3. Machine Properties and Parameters¶

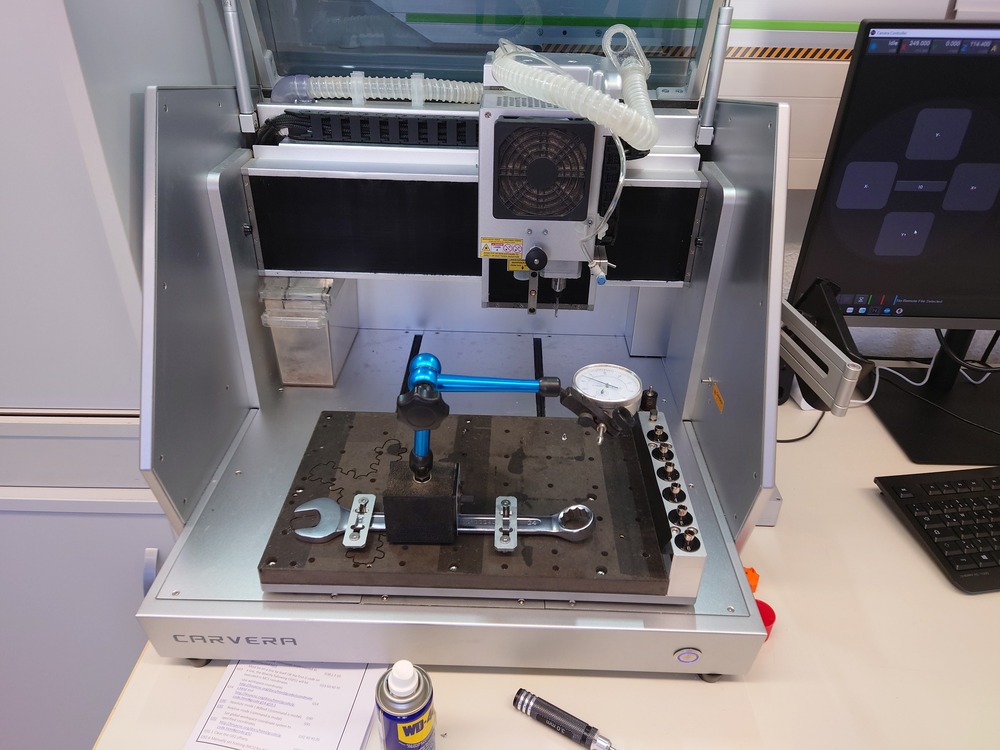

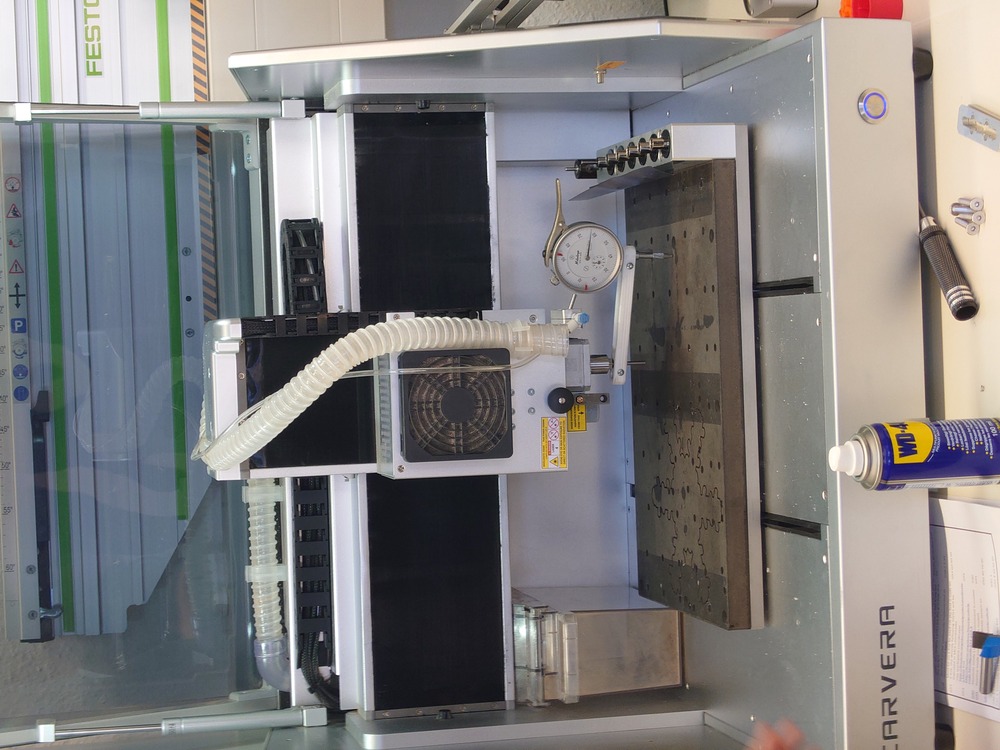

We used the Carvera in our Lab to learn about those parameters and test them out, because this is the one we will use the most.

7.2.3.1. Conventional(CW) vs Climb-Cut(CCW)¶

Conventional : Movement direction of the workpiece and rotation direction of the mill are opposite.

Consequences:

not that good edges but the machine does not need to be that stiff

Climb-Cut : Movement direction of the workpiece and rotation direction of the mill are the same.

Consequences:

good edged but machine needs to be stiff

much force needed for cuts

7.2.3.2. Run-Out¶

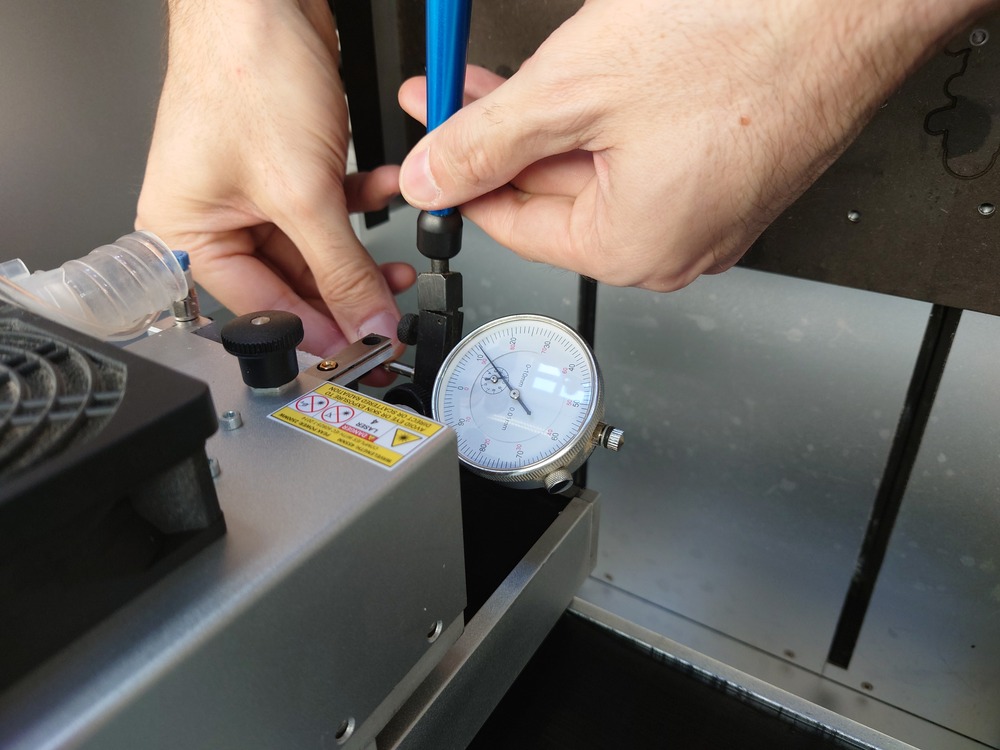

Run-Out : The movement the Drill/Mill does around its rotation axis, which is never perfectly concentric.

Measuring

Using a dial-indicator we clamped on something rigid:

we gently touched the mill with it

set the scale to zero

and rotated the mill and looked in the changes of distance

Outcome

In our Case, event at the tip of the machine, we couldn’t measure a real distance. The distance we measured were just errors resulting from a not stiff mounting

7.2.3.3. Alignment¶

Following 2 Properties are important:

Steps per mm¶

Meaning in the distance given in my G-Code should be the same as the actual distance the CNC travels.

Measuring

Just move in all available axis a distance and measure the actual traveled.

G1 X0 Y100

G1 X100 Y0

Perpendicularity to bed¶

The mill should be perpendicular to the bed for optimal milling results, but in reality, there is always a little angle between mill and bed.

Measuring

For a rough measure, use a right angle. Better: Attach an dial-indicator on the Z-Axes (Mill-axes) and drive around the bed and if the needle does not move, it is very perpendicular

7.2.3.4. Fixturing¶

Fixturing the workpiece is very important because of the possibly strong force that acts on it.

Possible Methods:

Clamps (T-slot, Nuts, Mitee-Bite)

think about overlapping!!

avoid using!!

Screws (better)

Vacuum Table (good for 2 sided milling)

Tape (see Electronics Production Week)

Also for positioning Alignment Bits are very useful, because they are measured in and guarantee, that the workpiece is in the right orientation.

7.2.3.5. Speeds and Feeds¶

Very dependent on the material and used mill. Should be determined with LISTENING.

Feed-Rate : Movement of the mill cutting in the material

should not be to high -> resulting in the translative force into the material to be to high -> moving it

should not be to low -> more friction of the mill and material -> burning/melting

Speed/RPM of Mill

not to slow -> increase in translative force resulting in the movement of the workpiece

not to high -> increase of friction resulting in burn/melt

How to find the optimal Speeds and Feeds¶

Use the machine defaults and test it with the mill on the material and LISTEN

If it melts/burns:

stop, clean

turn RPM down

manually step, if chips are produced, good

use reasonable feed-rate

Look at the chips and adjust the speeds accordingly

increasing the feed-rate (same RPM) results in longer chips

increasing the RPM (same feed-rate) results in shorter chips

Chips should be in a reasonable length and the machine should not sound horrifying

chips should be:

not too short -> material gets pushed more then chips are produced -> high rubbing -> short chips stick to the mill

not too long -> chips get tangled in the mill -> no good

7.2.3.6. Up-cut vs Down-cut Bit¶

up-cut : Flute direction like a drill, resulting in an upwards movement

Consequences:

gets chips out but no clean edge

down-cut : Flute direction opposite to a drill, resulting in a downwards movement

Consequences:

pulls chips down but clean edge

cross-cut : does both (split in flut direction), on the tip up-cut and down-cut on the rest of the flute, but usually more expensive

7.2.3.7. Step-down and Step-over¶

Step-down : Different depth-steps into the material to not mill the whole workpiece in once

usually the diameter of the mill

Step-over : The radius/diameter the mill is moved into the material/overlaps with the last path

7.2.4. Milling the Fixture Test Comb¶

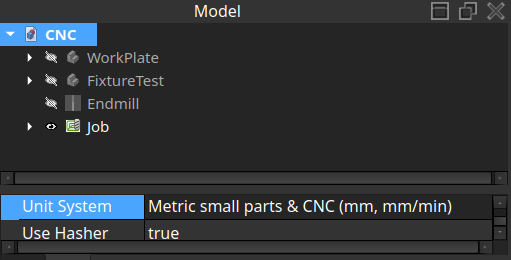

I use Freecad for modelling and also for milling with the Carvera, and Fusion for the CNC from CNC-Multitool.

7.2.4.1. Makera Carvera Desktop¶

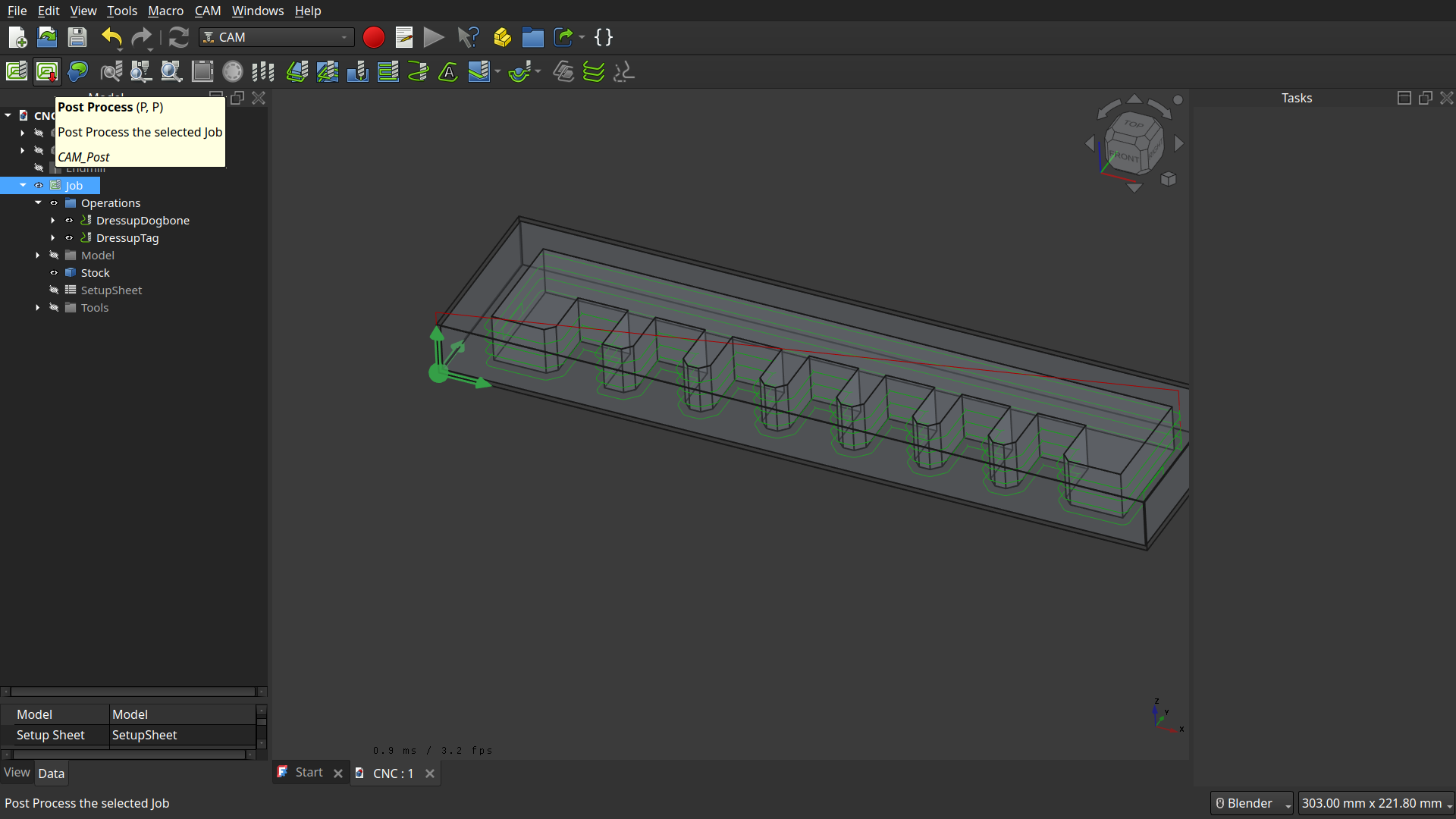

G-code generation¶

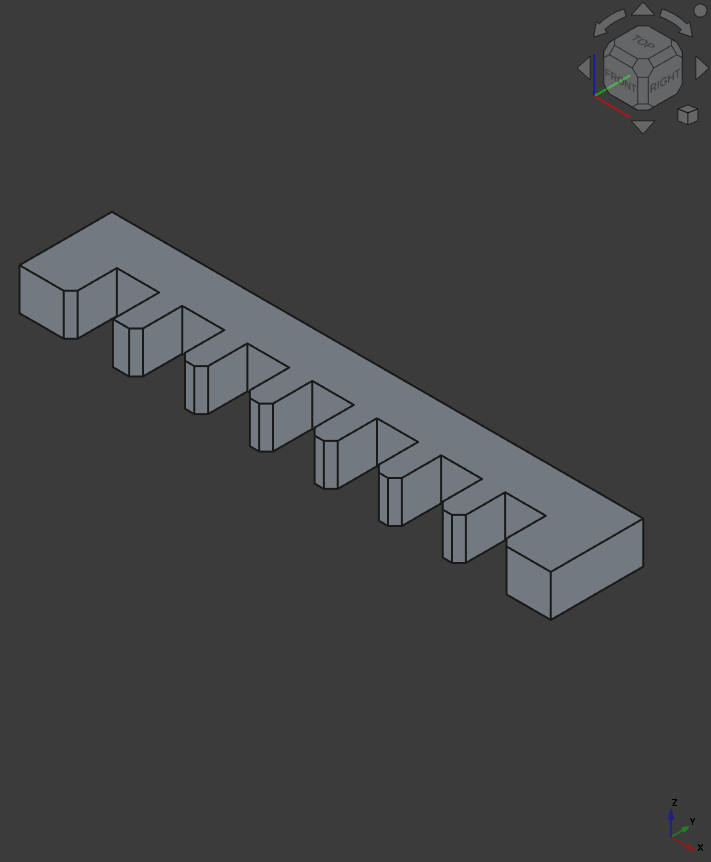

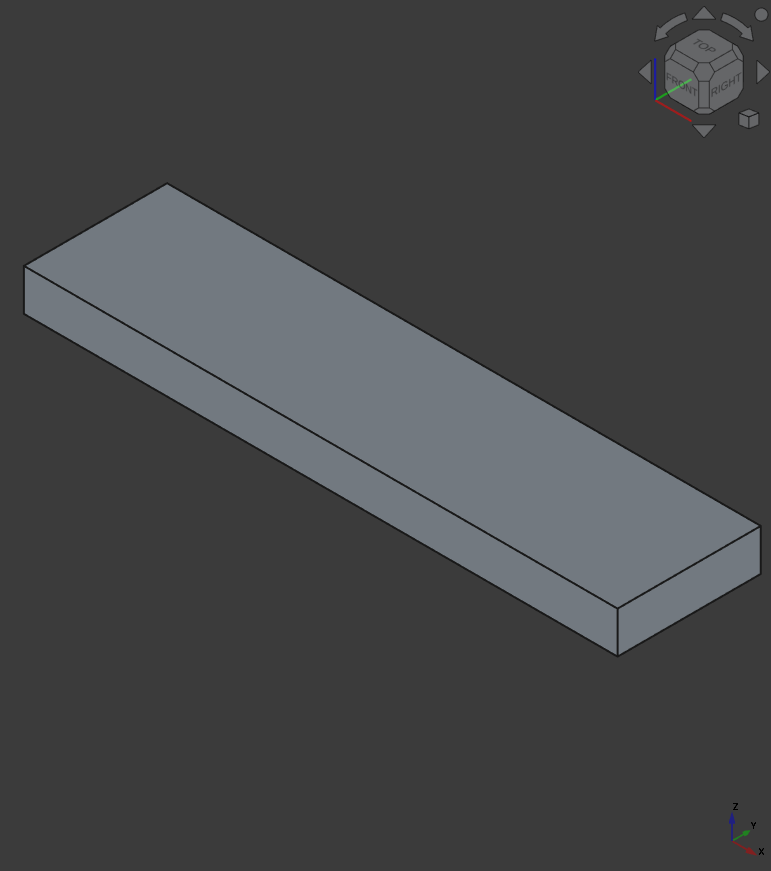

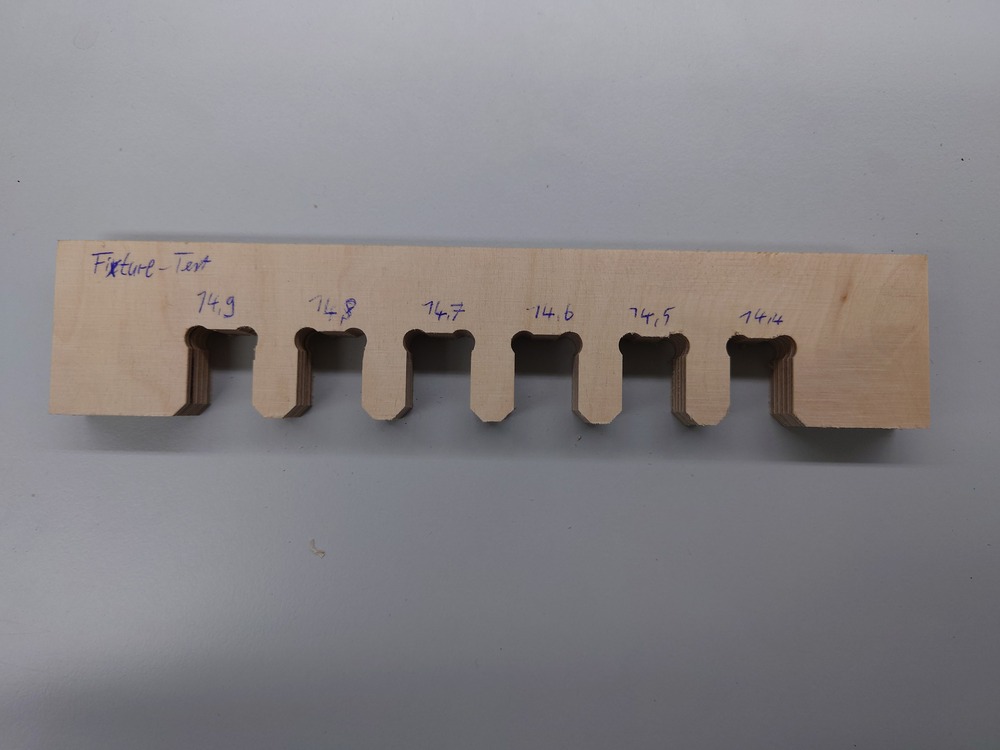

For our Test-wood (15mm depth) I designed a small comb with distances between 14.9mm and 14.4mm in a 0.1mm difference (I forgot to add 15mm and also values above -.- but in the end it was the right scale for this wood). Also I also modeled the workpiece to use as stock for the job. We tested the real wood on the bigger CNC.

Then to create a path, I first changed the units of the Project (and in general) to mm/min (for the RPM).

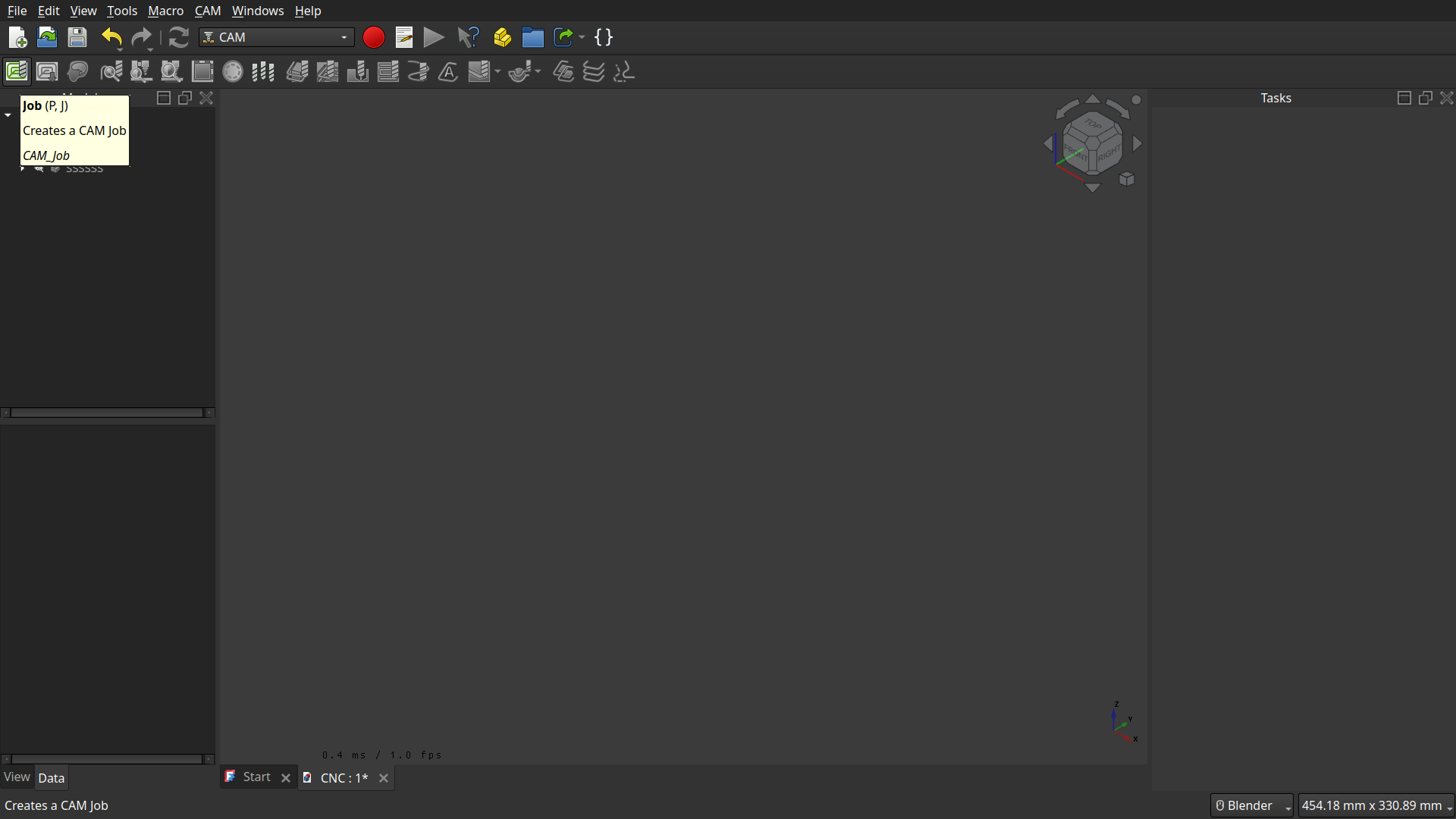

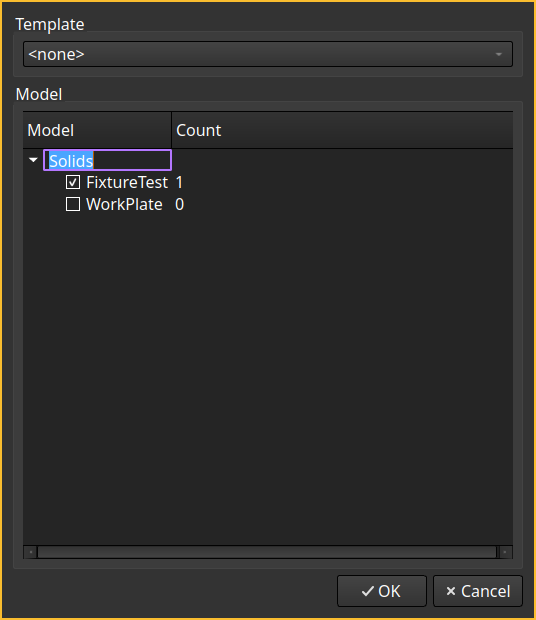

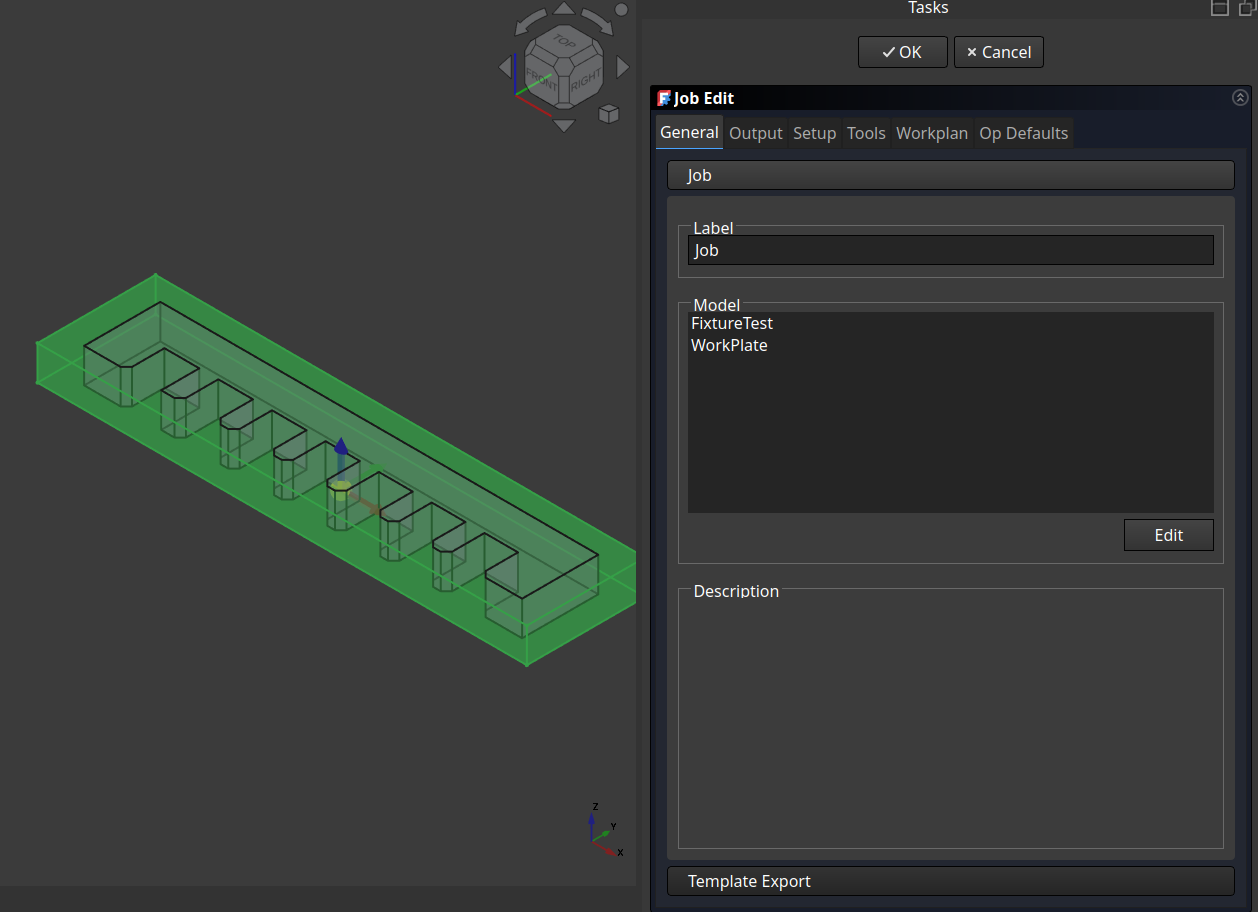

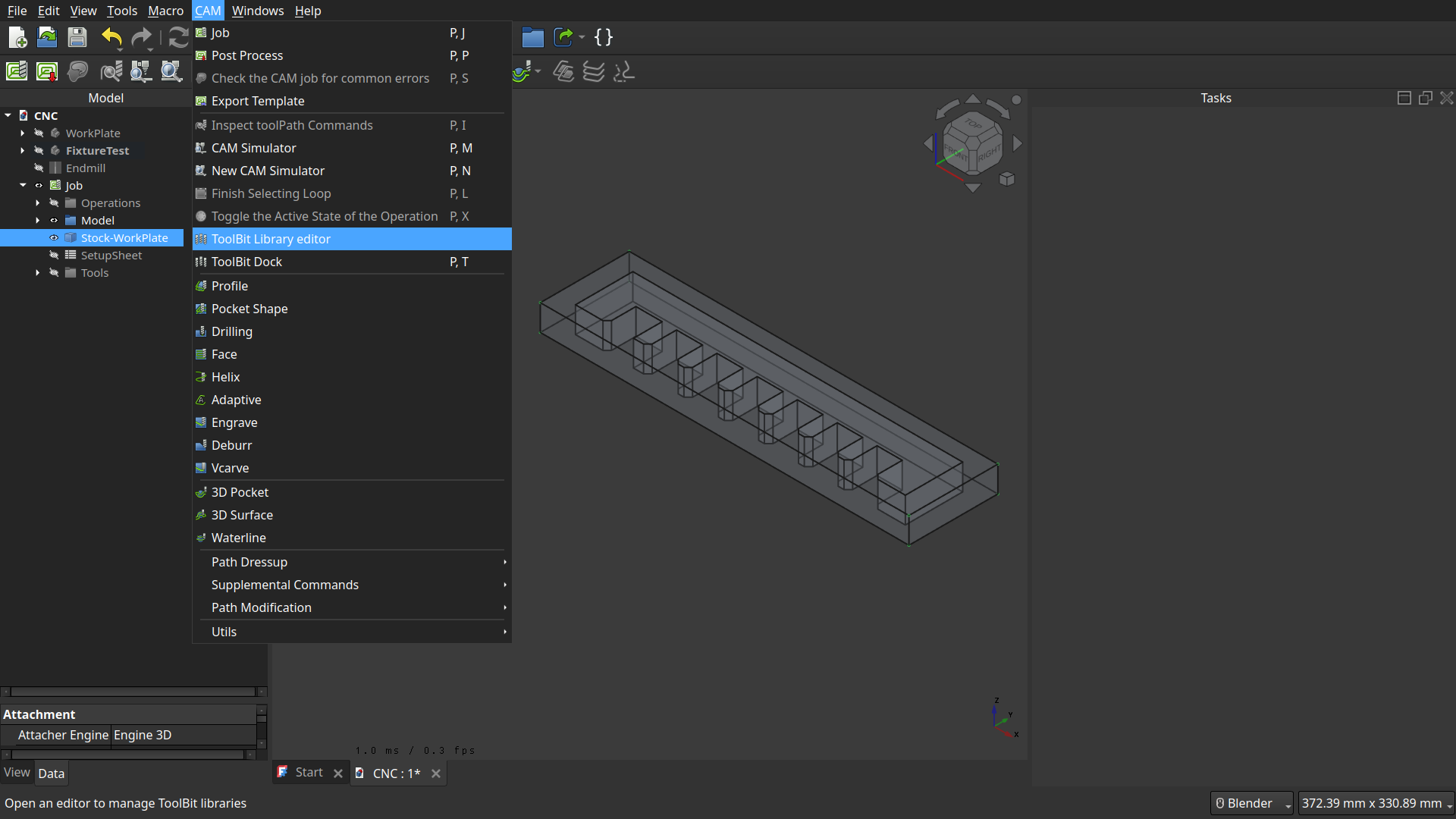

Then I switched to the CAM Workspace and started a job and added the models to it:

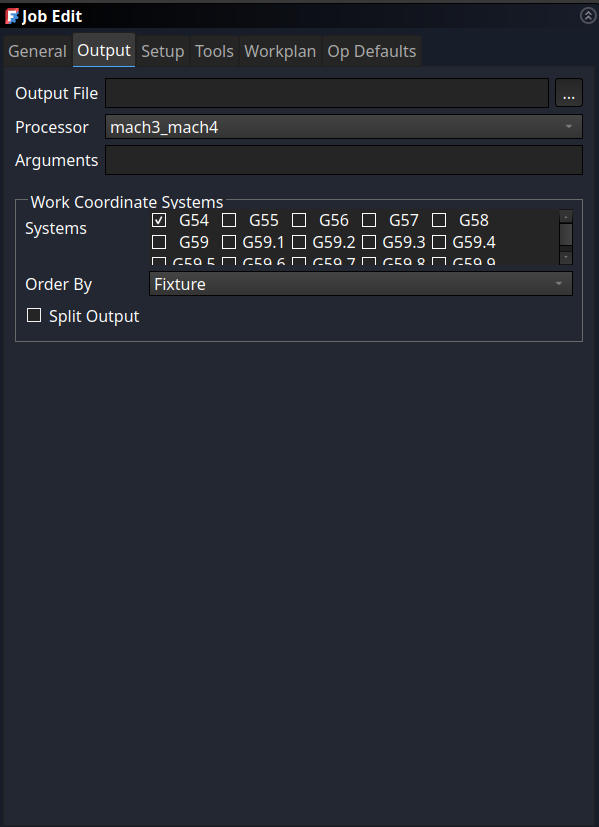

In the ‘Output’-Tab I first set the processor to mach3,mach4, which is needed for our Carvera.

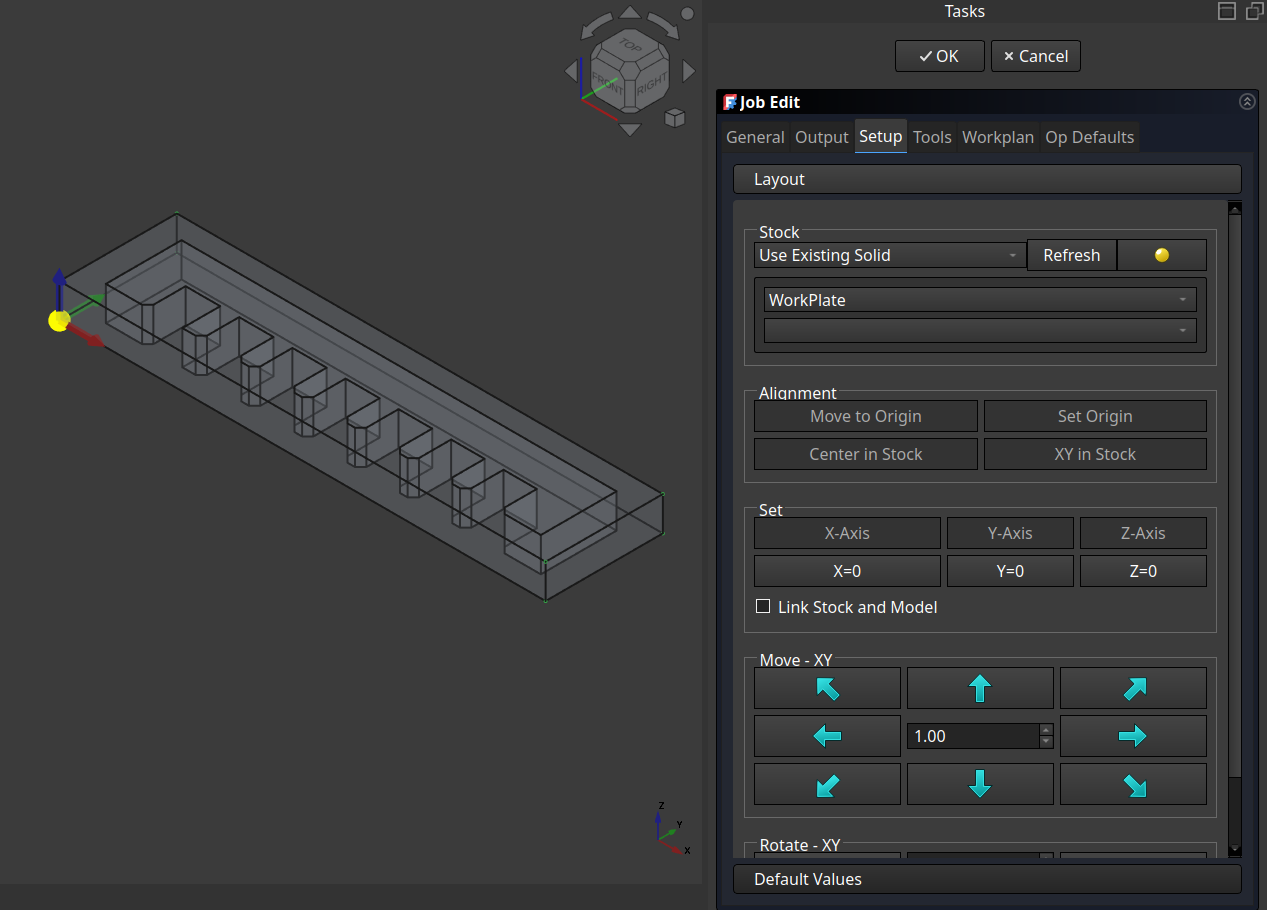

Next in the ‘Setup’-Tab I selected my workpiece as stock (‘existing solid’) and chose the bottom-left corner as the origin (in the ‘Alignment’-Section).

Note

It is also possible to use just a ‘bounding box’, I used that at the CNC from a friend of mine.

Also for the later images I used the ‘Extend Models Bounding Box’-Stock accidentally (the black lines around the stock), so don’t mind those lines.

Also important but can be done later is to create and adjust the used tool.

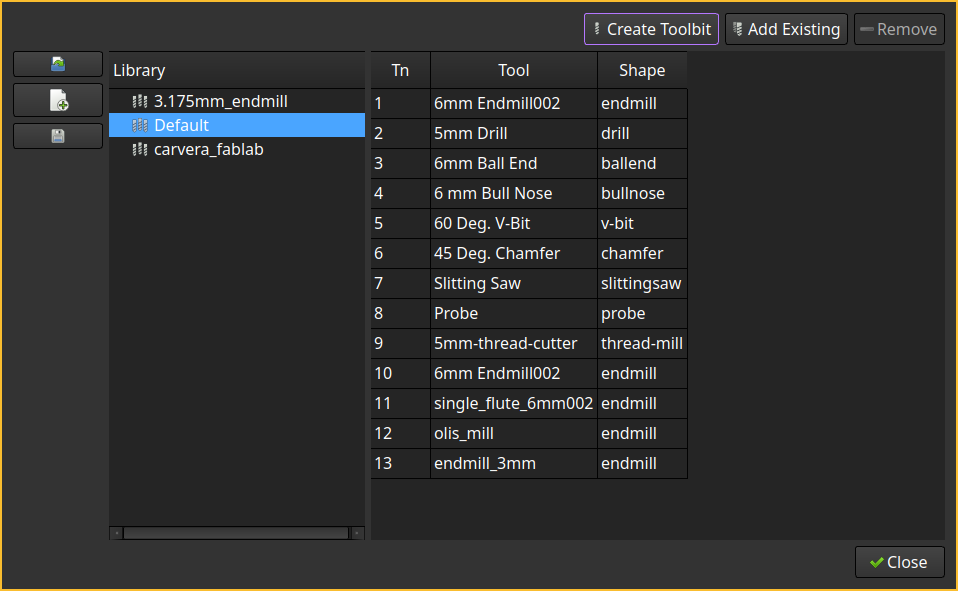

Go to the tool library

Here go to ‘Create Toolbit’

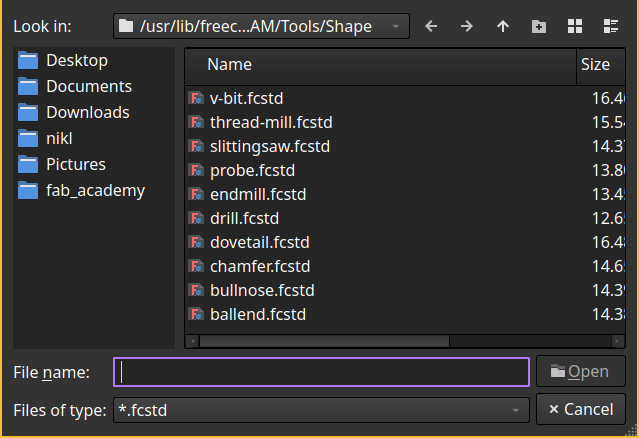

Choose the Tool Shape

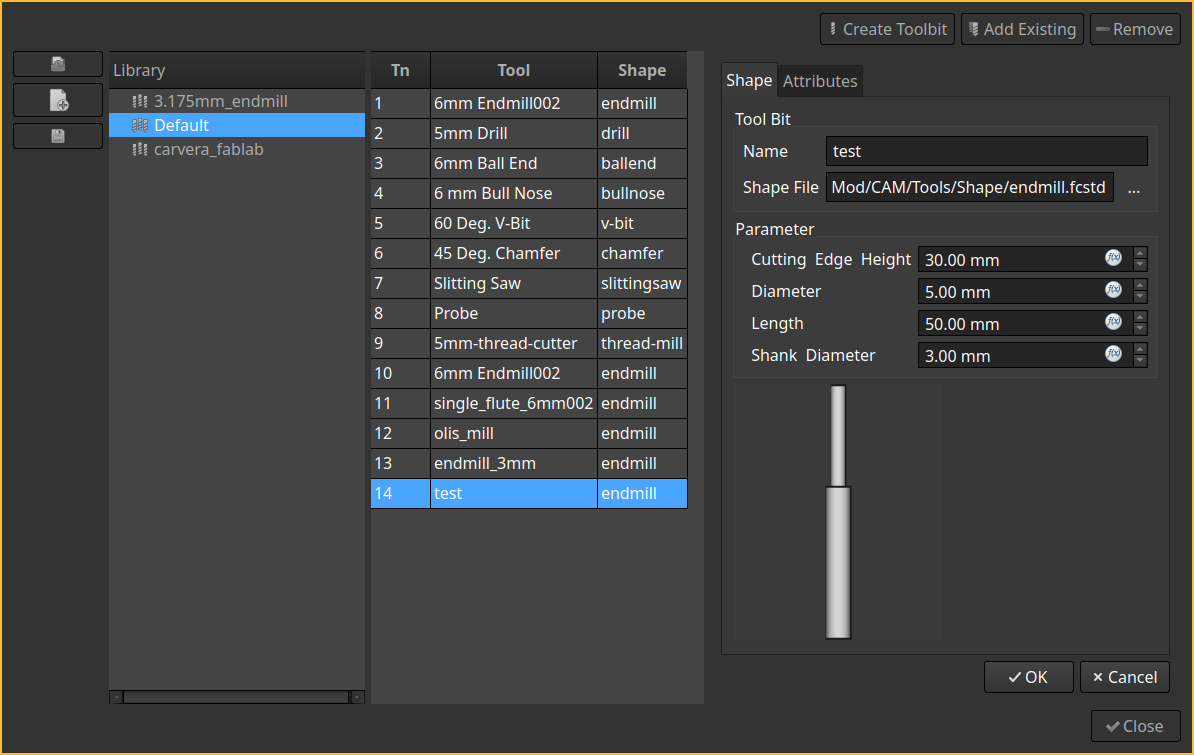

And adjust the settings

There you need to set all distances and flute number of the tool (‘Attribues’ Tab).

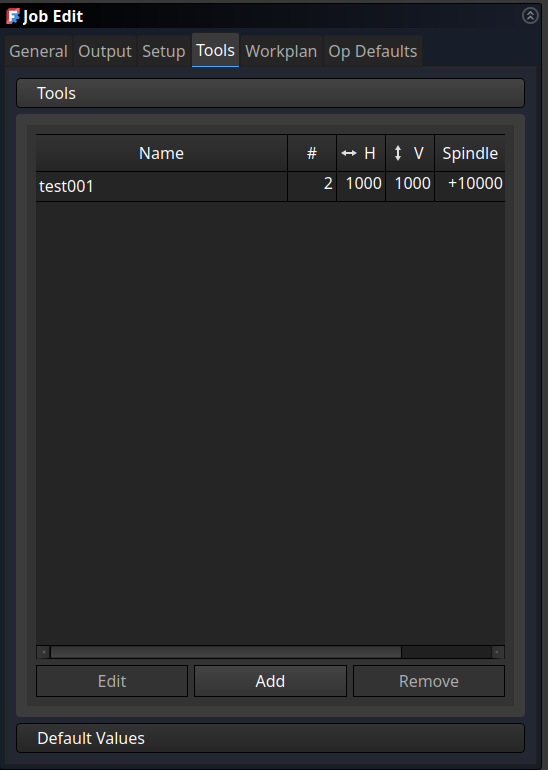

And then add the tool to the job:

Important

Also important is to set the Speed (Spindel RPM) and Freed (H(orizontal) and V(ertical)) there!!

Also note the tool ID is important for the Carvera, because there are a total of 6 tool slots the machine can switch between.

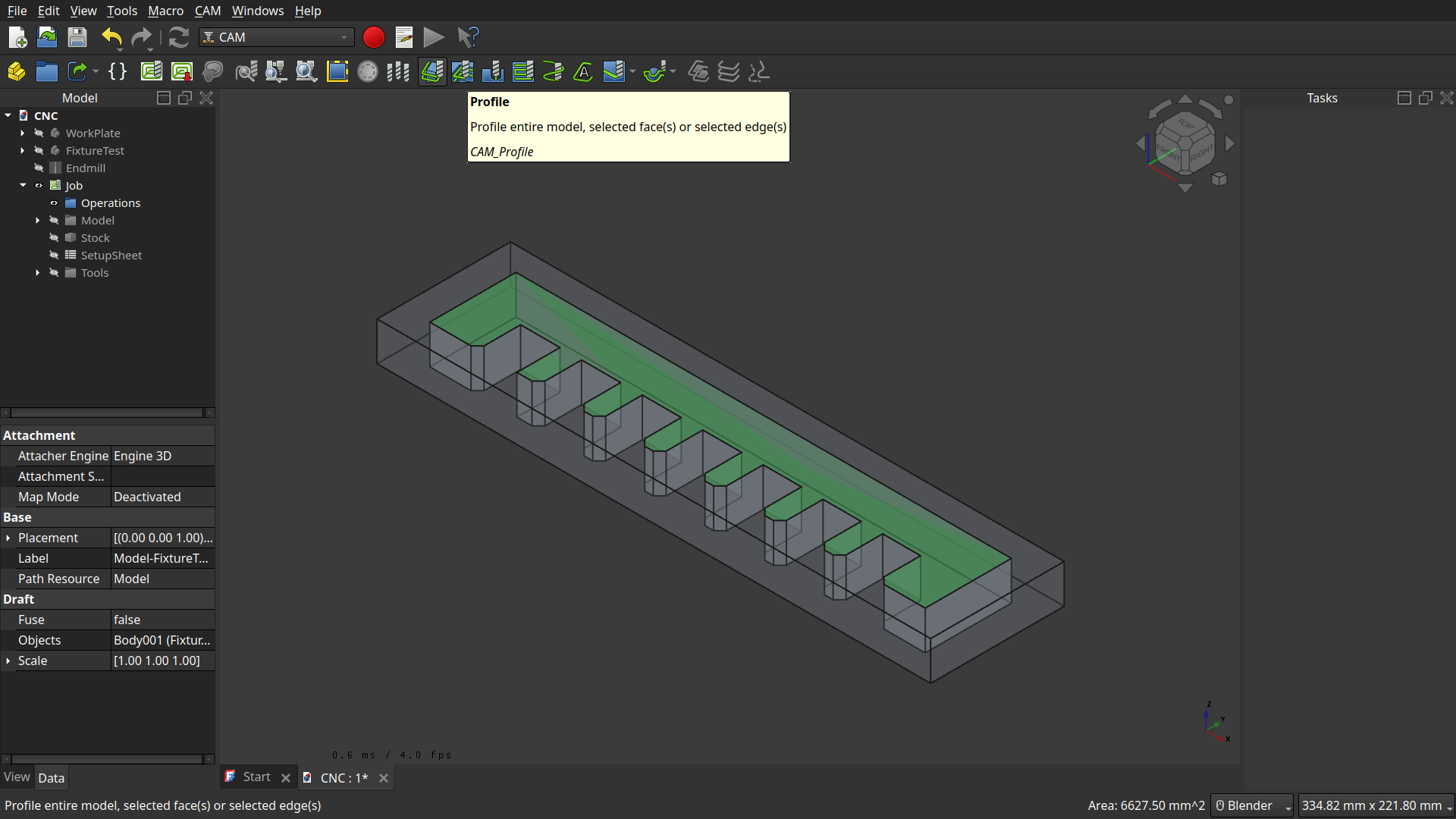

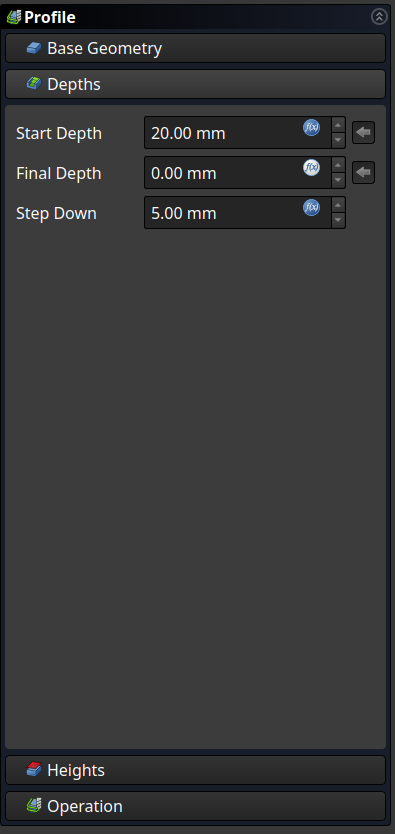

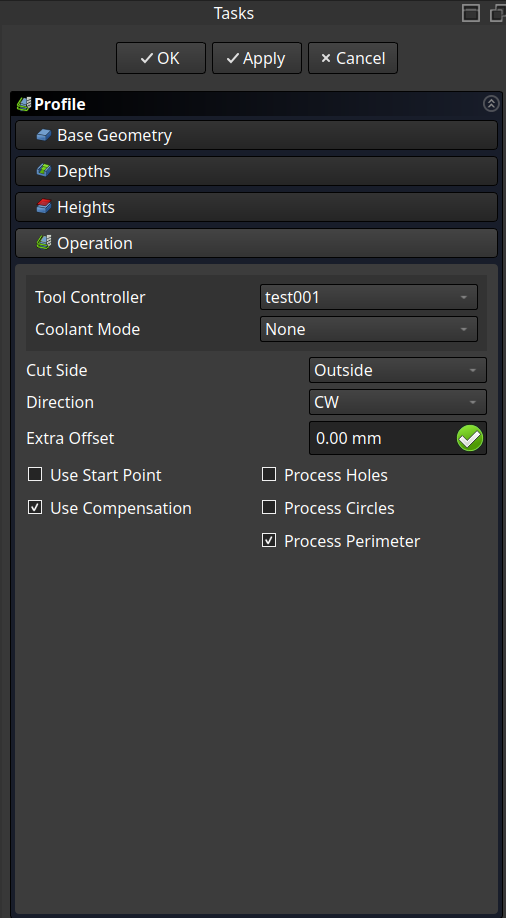

Next I started a ‘Profile’ tool-path and selected the shape I want to mill around.

<- Important there is the start and final Depth (also step-down, which uses the tool diameter initially).

Important here is to choose the tool.

Note

Also important to note, we model, that Z==0 on the bottom of the workpiece, which inherently constrains the tool to move into to bet. Also in the ‘Heights’-Tab the Safe Height and Clearance Height (travel distance to bed of CNC) is configured.

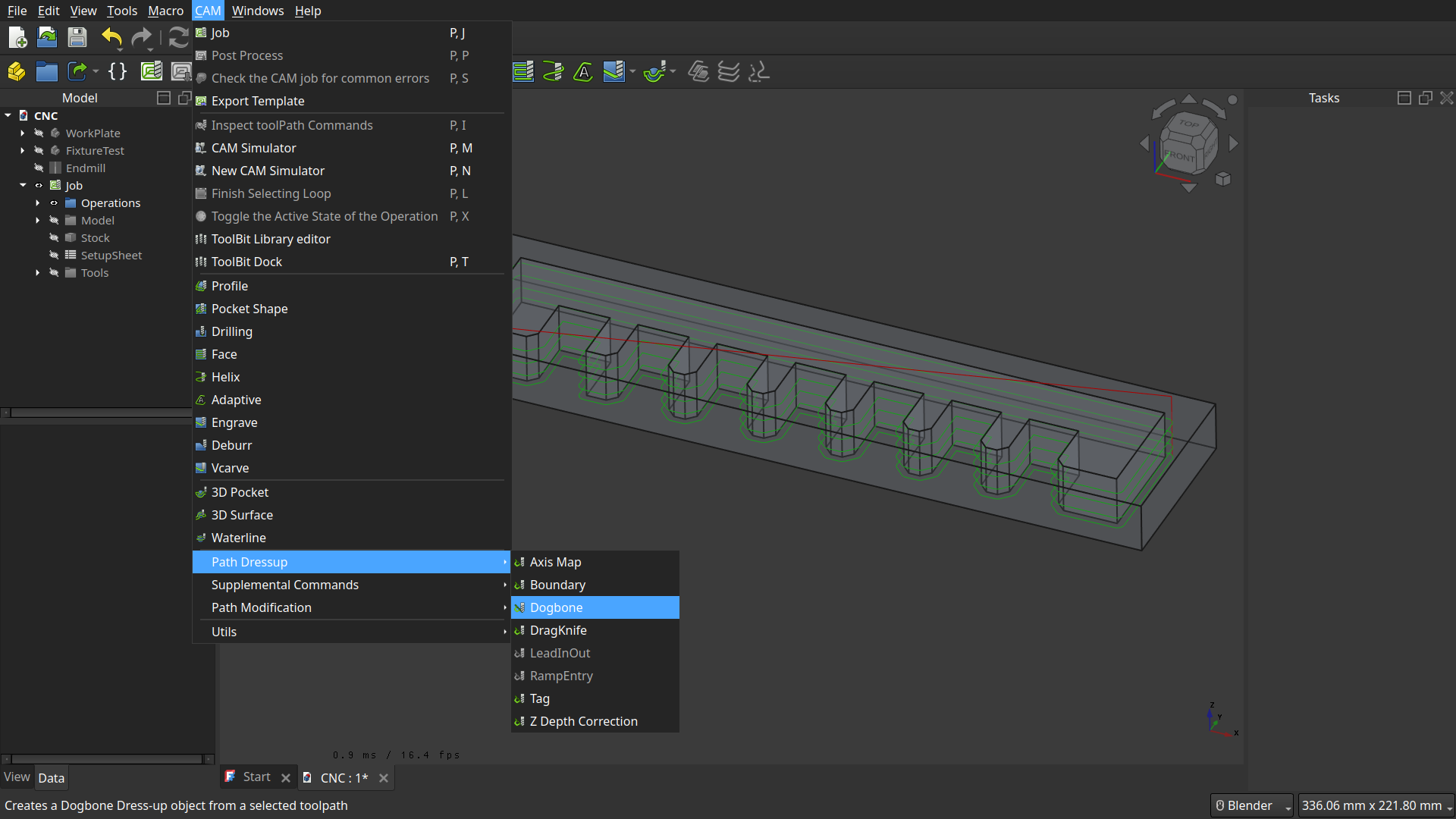

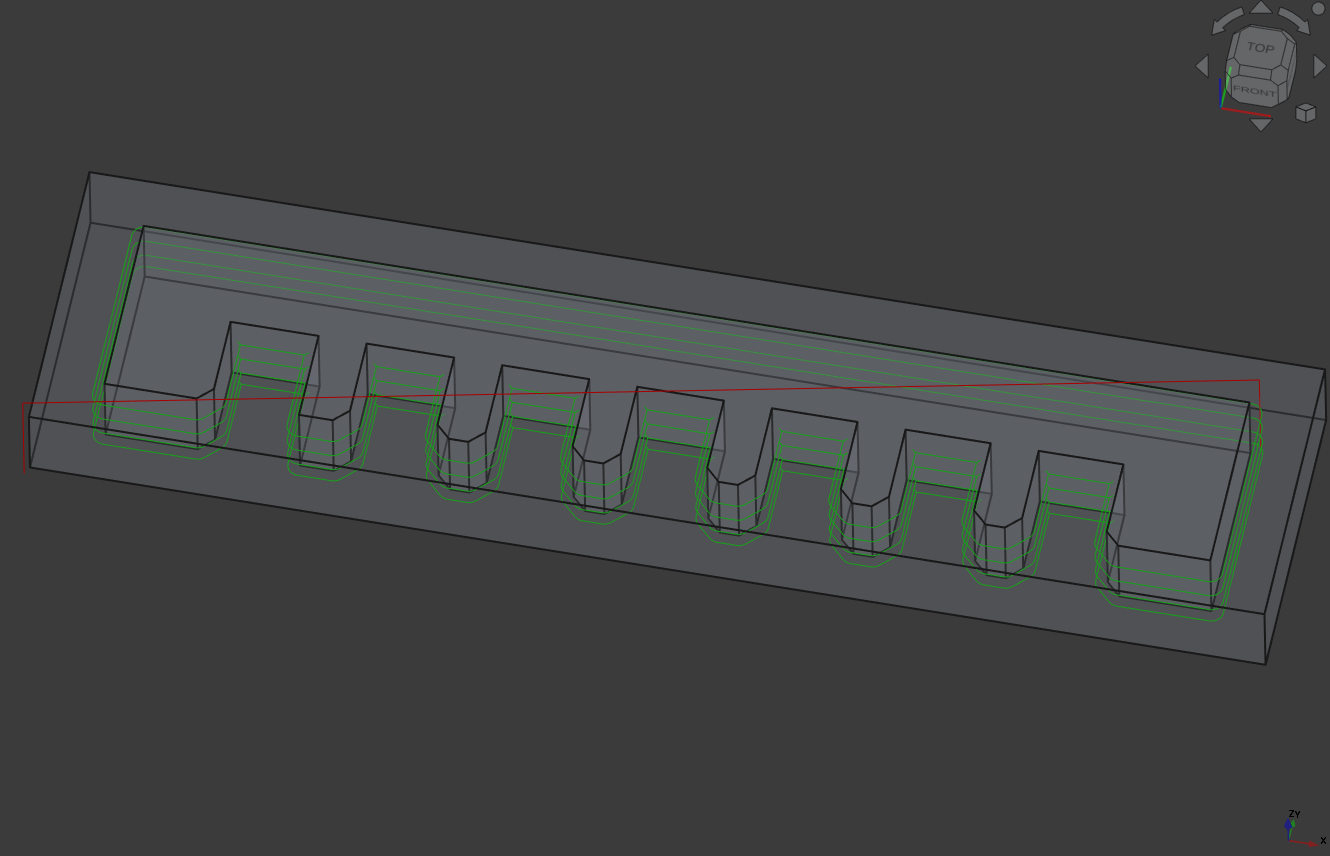

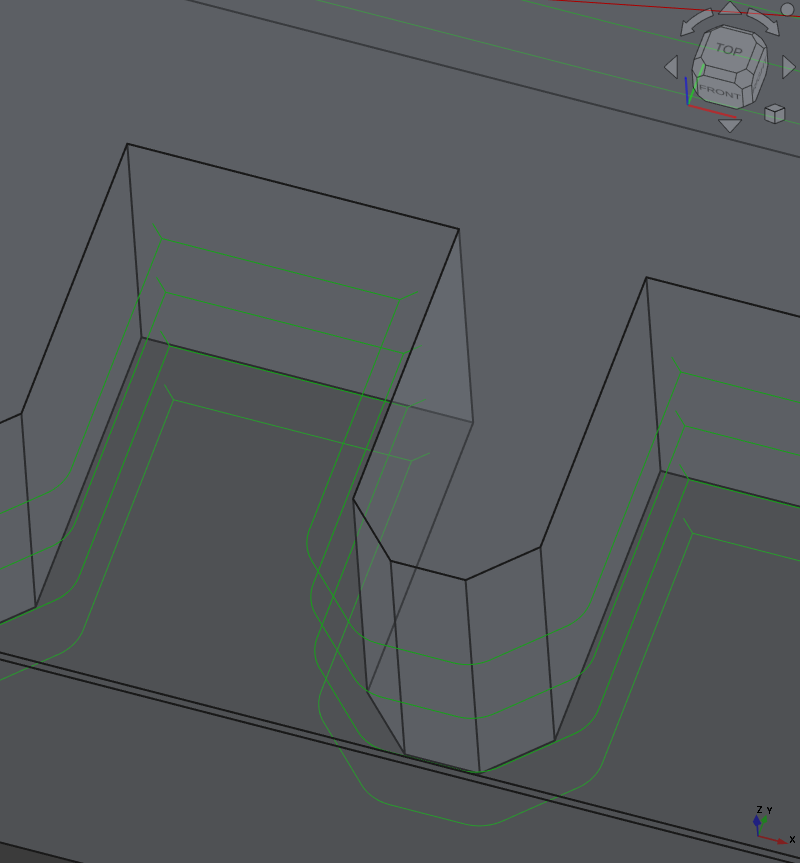

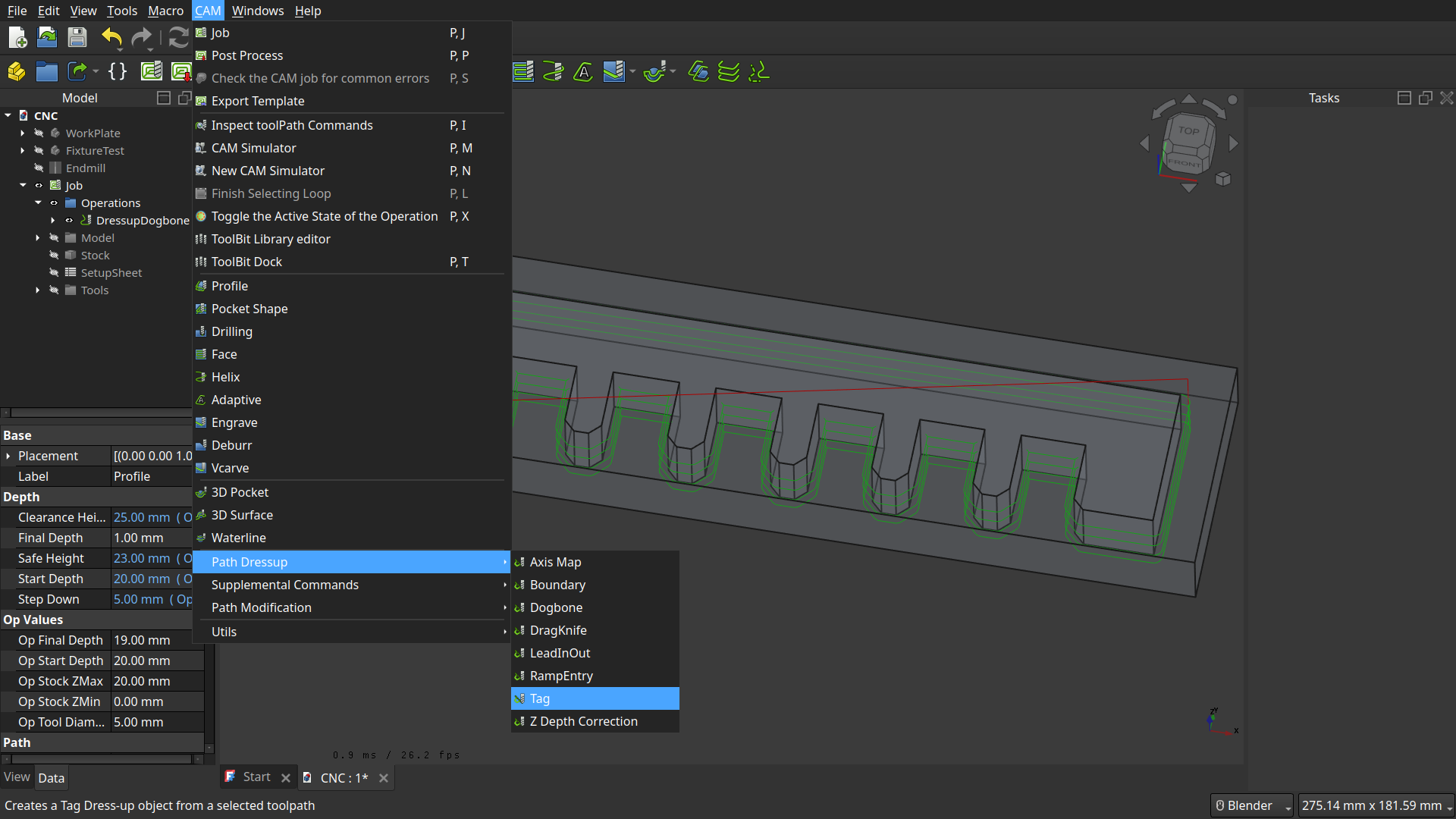

Dog-Bones and Bridges (in FreeCAD called ‘Tags’) are a dress-up and can be found in the CAM menu under ‘Path Dressup’.

Important

First select the path you want to apply the dress-up to!

Dog Bones

It just generated dog bones on inward corners.

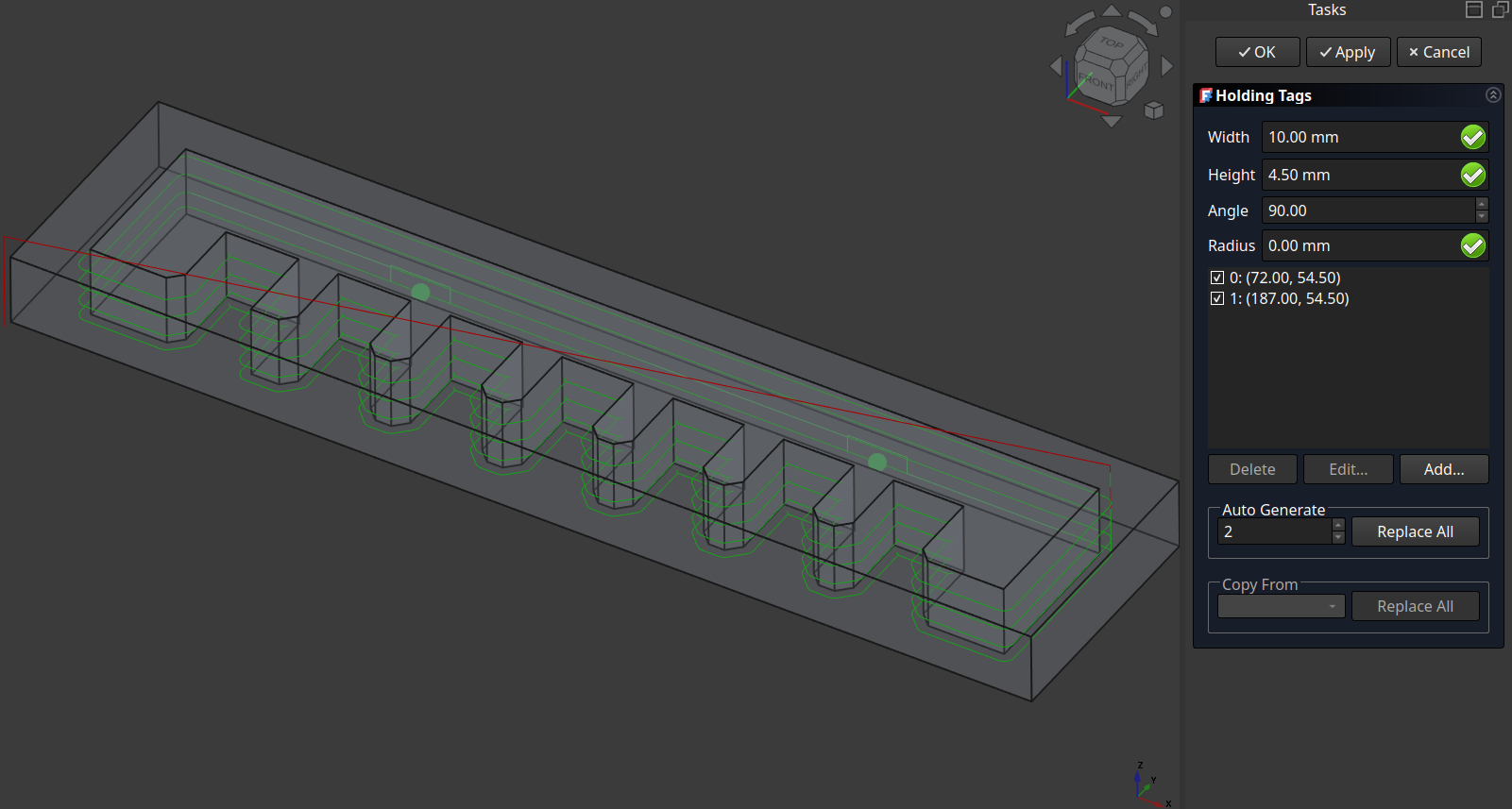

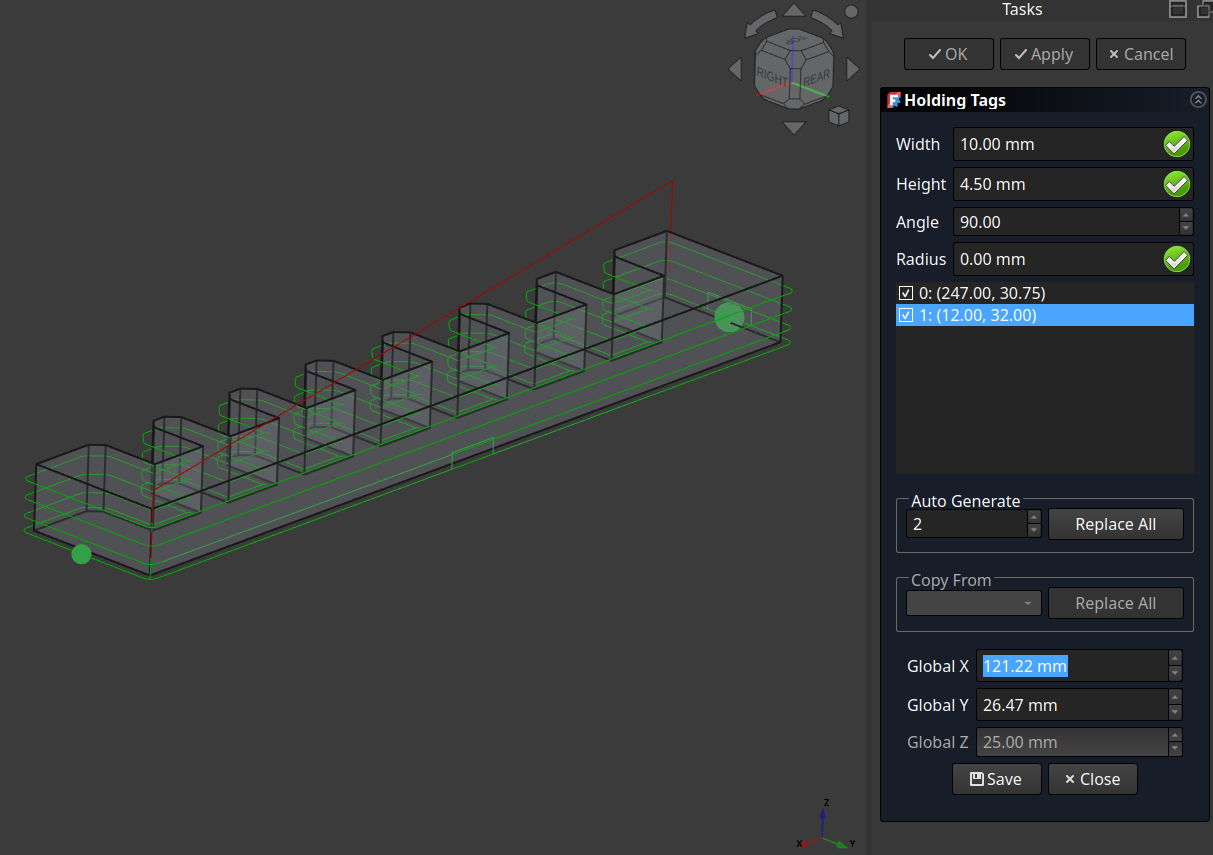

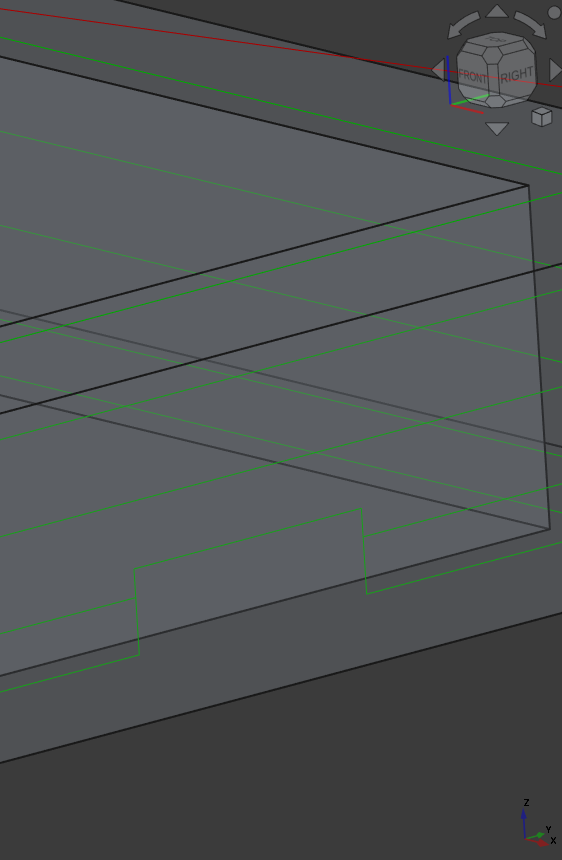

Bridges/Tags

Here you can add more bridges and also move them around:

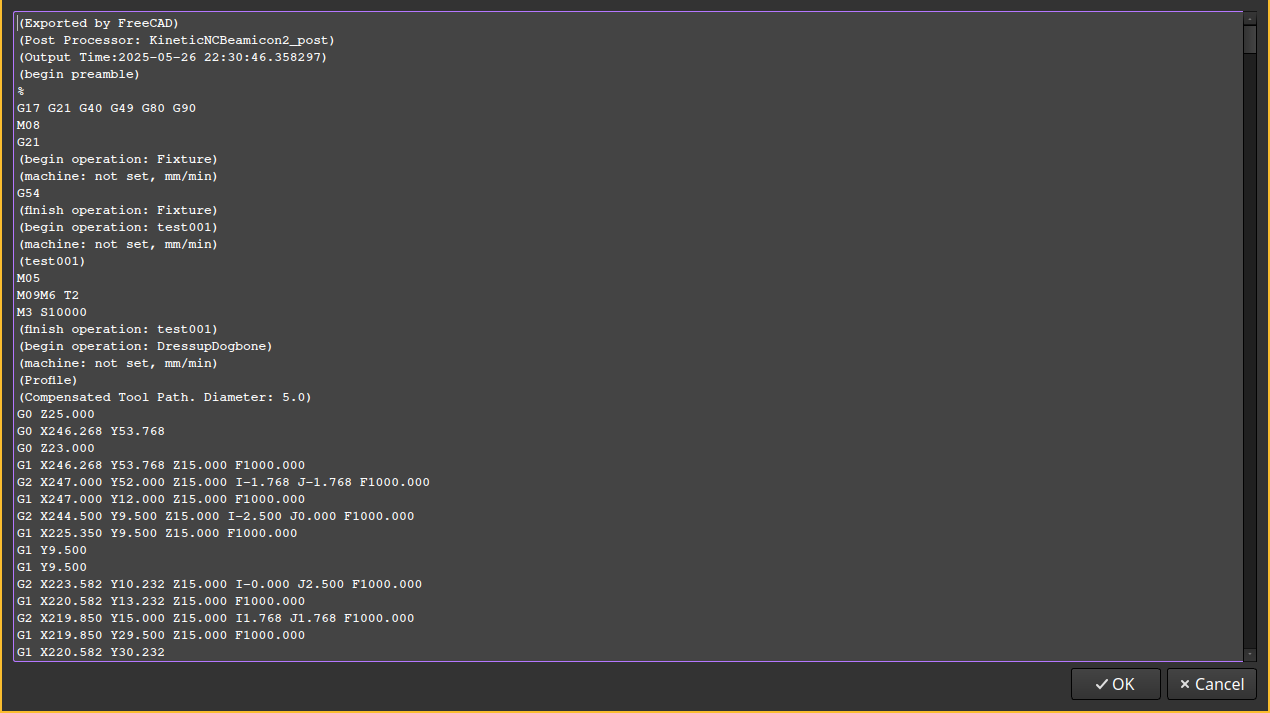

Then to Export, you choose Post Process:

Look at the G-Code and save the file.

Milling¶

First we clamped the wood:

The Powerswitch of the Carvera is on the back side.

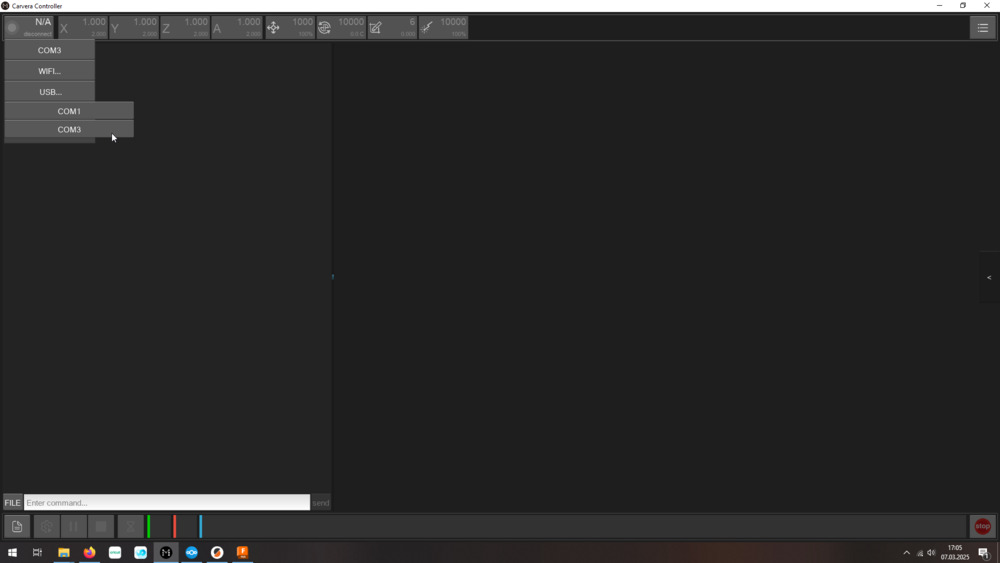

Then Start the Carvera Controller software and use the top left button to connect to the it (USB).

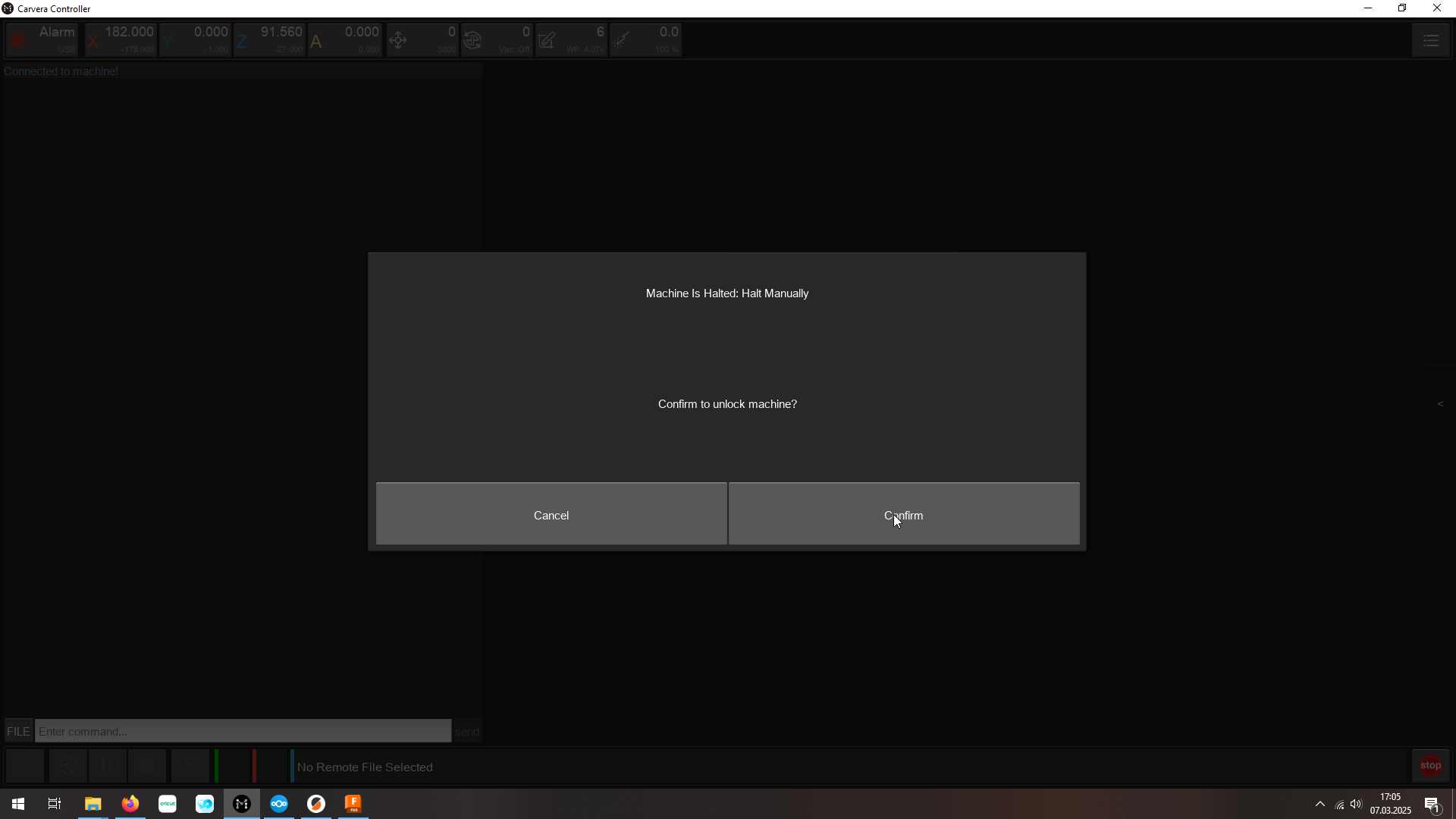

If the CNC was previously halted, you need to unlock the machine, so the motors can move again.

Tip

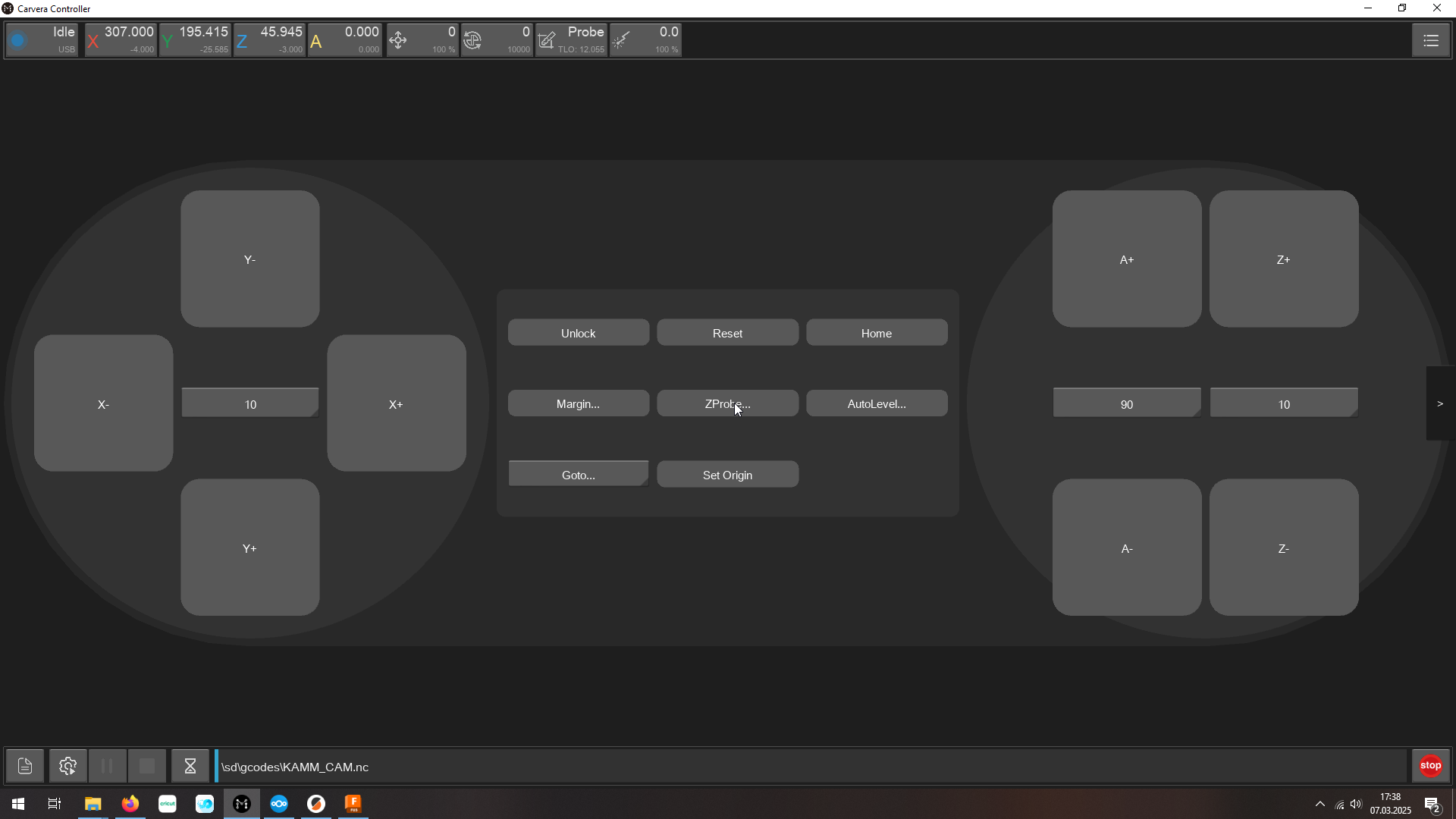

On the right side is the software-controller to drive the axis.

Then we used the probe end to find the bed zero. Therefor, because we used a different mill, we needed to change the end of the mill so it fits into the CNC Head.

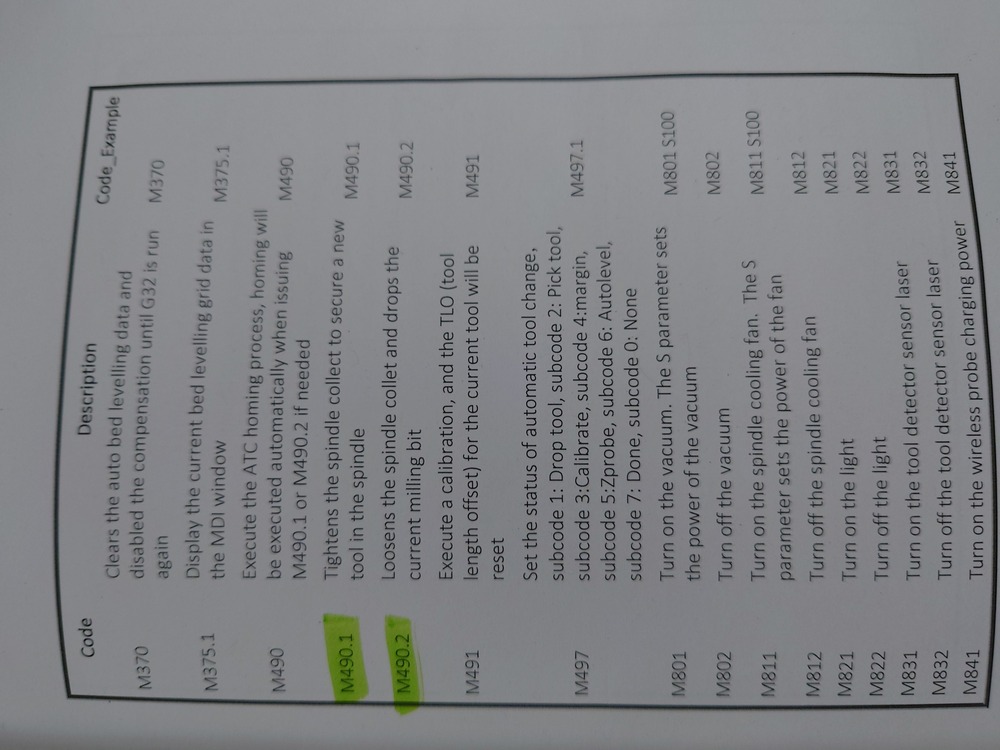

Gcode to tighten and lose the spindle shank.

And then use it to set the z zero.

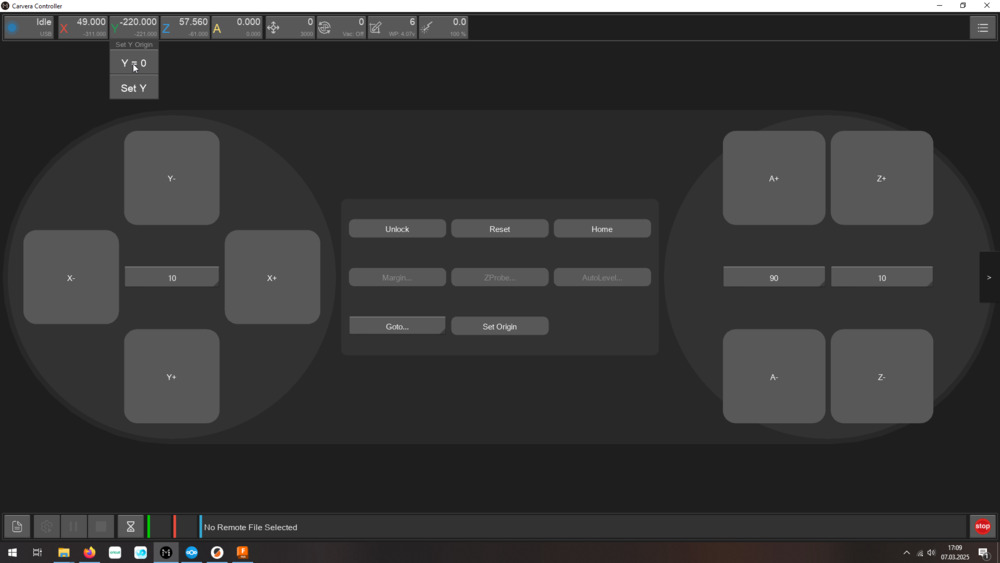

Then we set x and y to zero on the workpiece (by driving to a suiting point) where we wanted to start the milling.

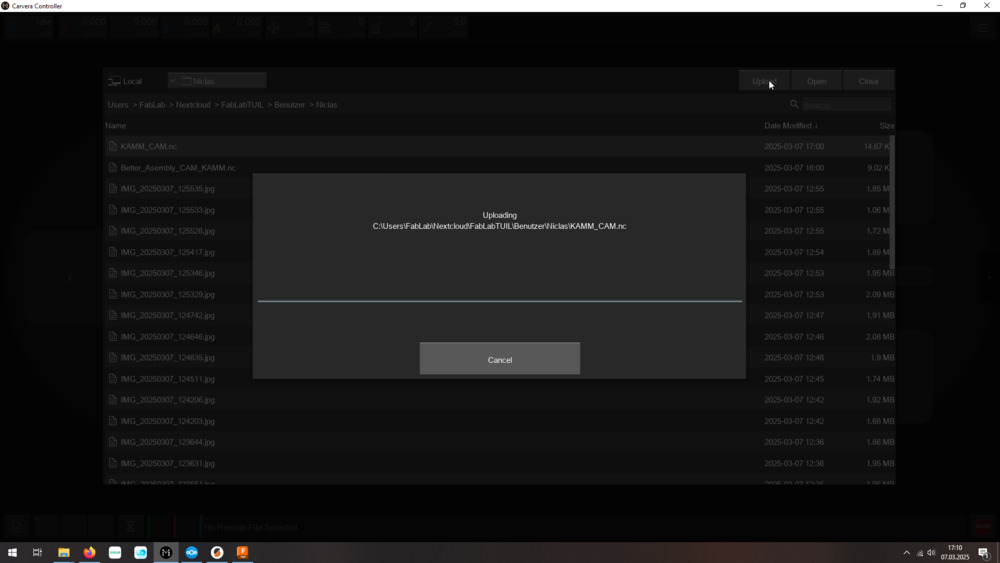

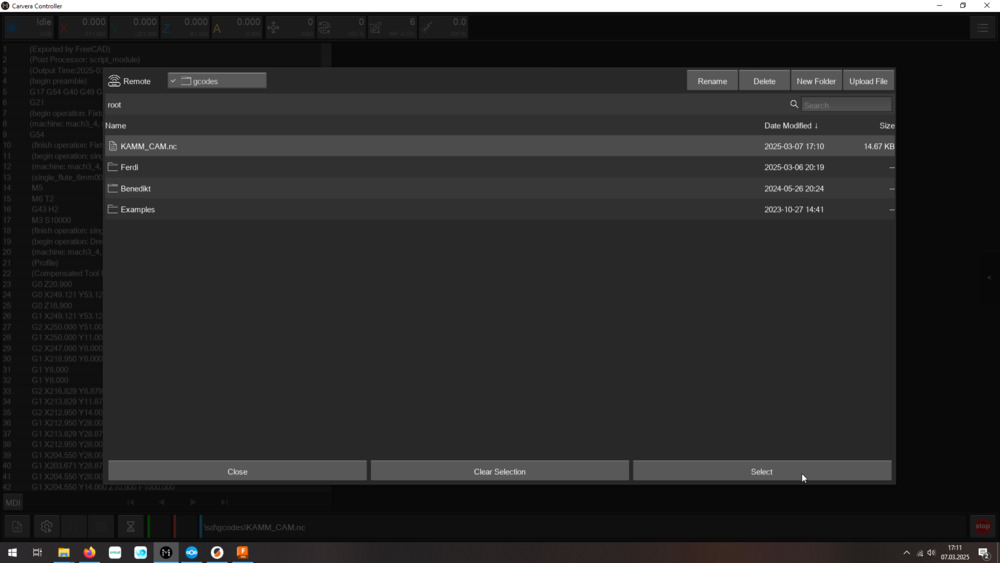

Then we need to upload the file to the machine and then select it again for milling.

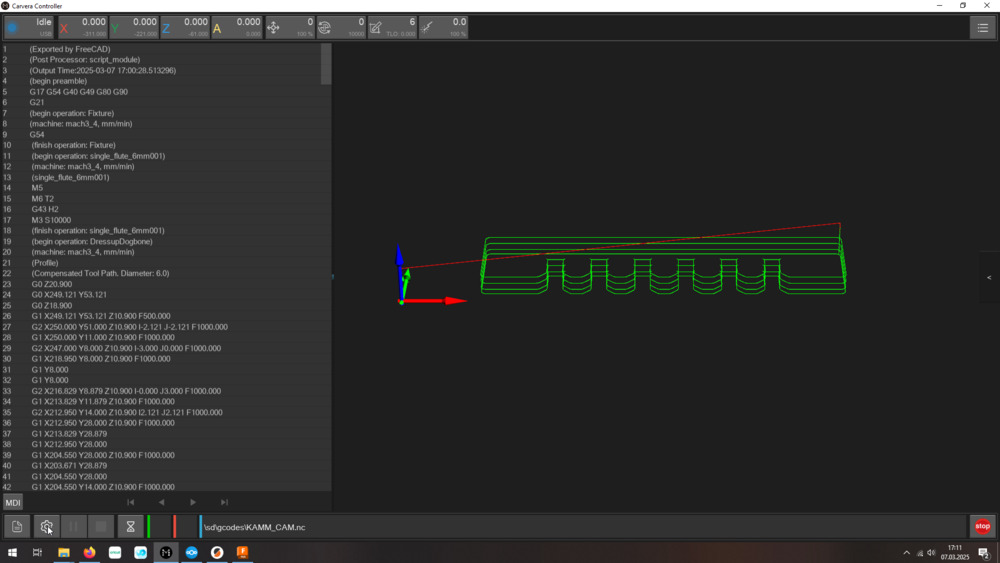

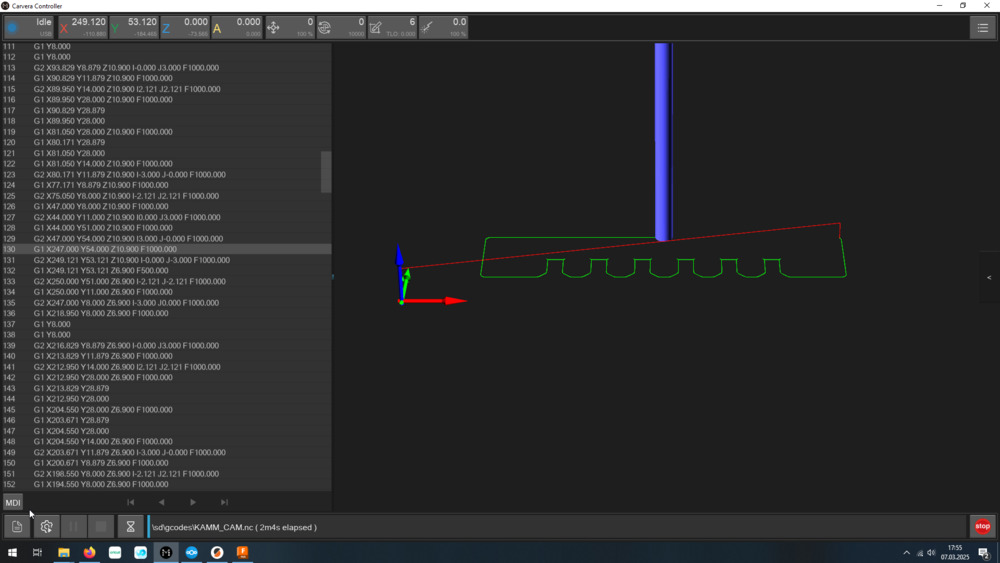

Loaded GCODE:

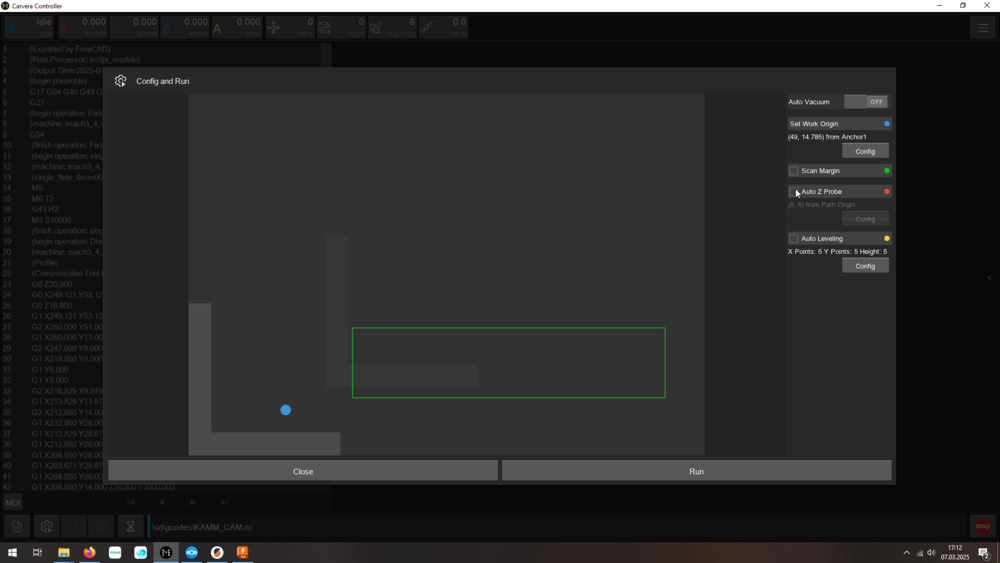

And then start milling, but deselect ‘Scan Margin’ and ‘Auto Z Probe’.

We just milled in the air to test out the G-Code (here I found out, that I forgot to set the RPM in FreeCAD).

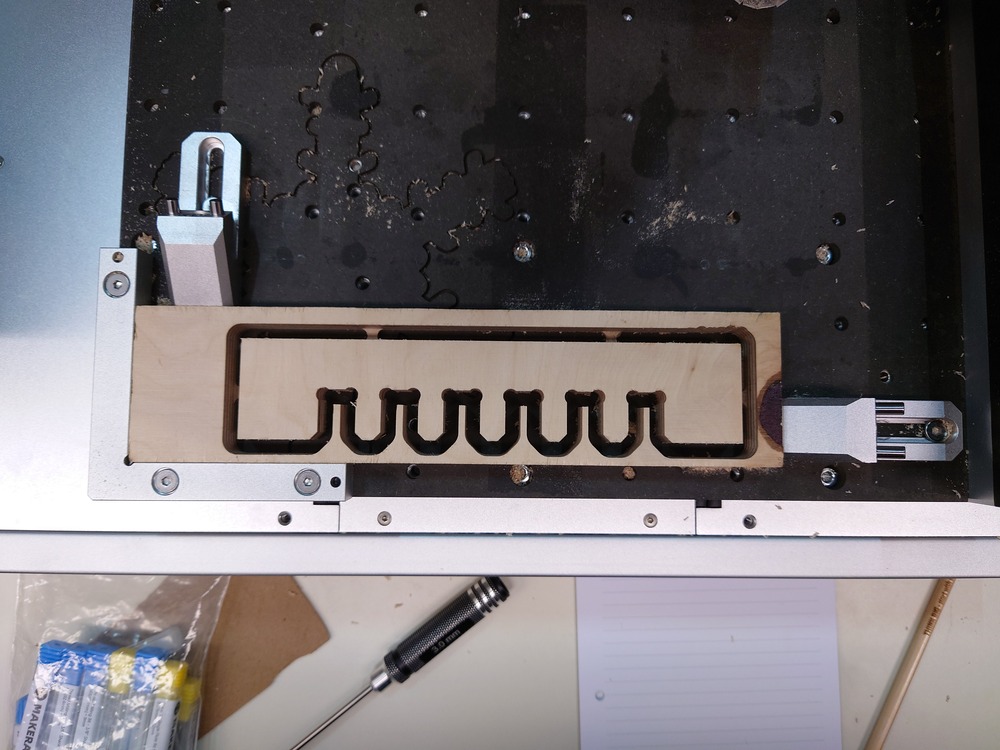

I corrected my mistake, we reset the Z value to the measured one and started milling:

Tool change:

Milling:

Finished:

So for this wood, the good fit was at 14.7mm.

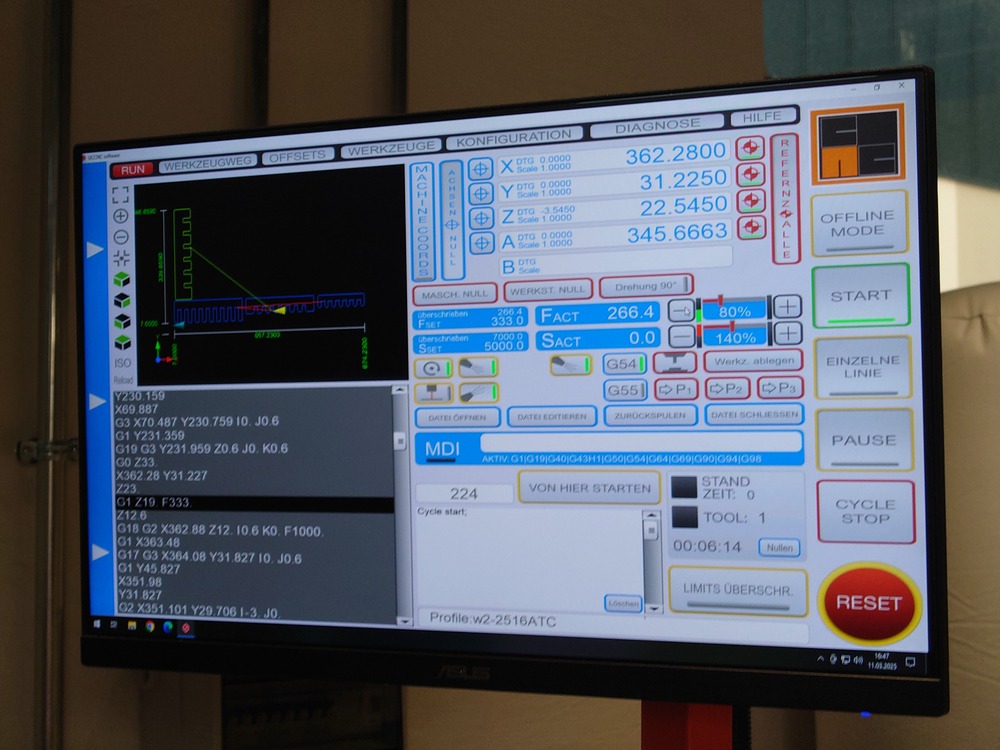

7.2.4.2. Custom CNC AC2513F from CNC-Multitool¶

We also here milled the comb on the actual material to test the fixtures:

To see more from the process, look into the Group Page.

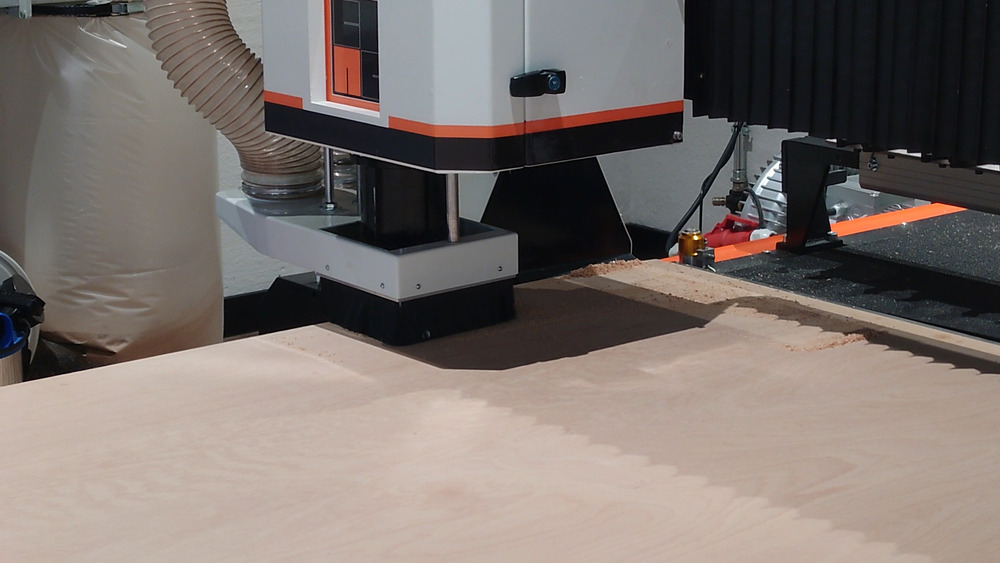

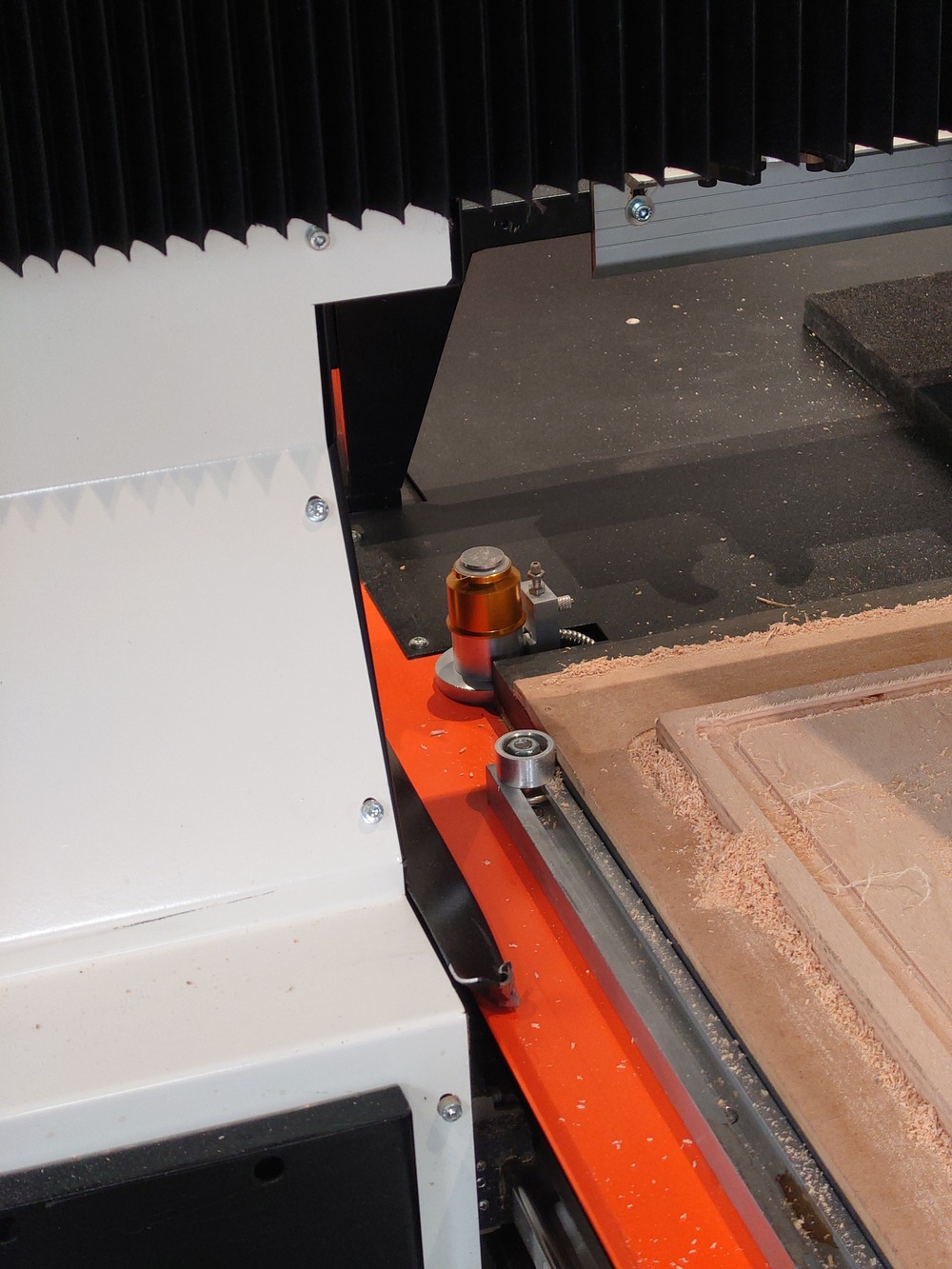

The CNC:

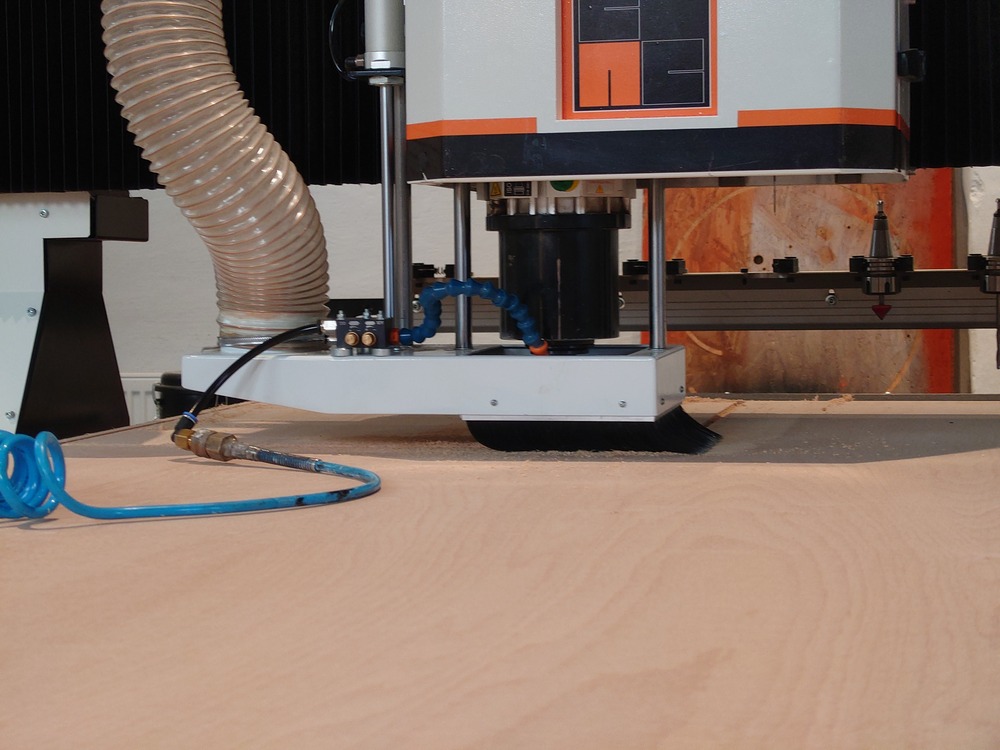

Milling:

The Comb:

Outcome

tabs where bigger then needed, 3mm sufficient

Fixtures where nice and tight at 17.8mm where the Material was somehow 17.6mm

-> 0.2mm more offset

7.3. Individual Assignment - Make something BIG¶

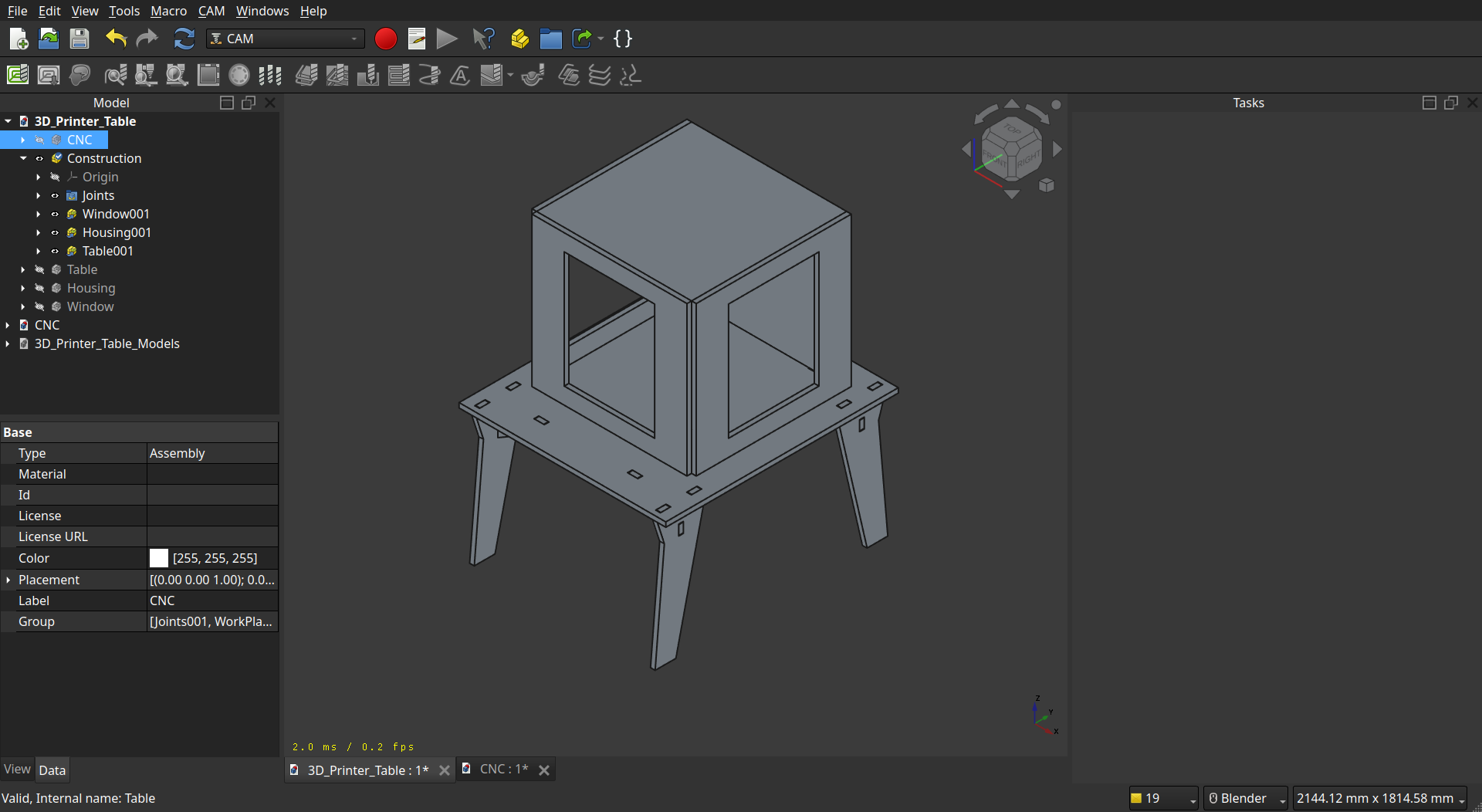

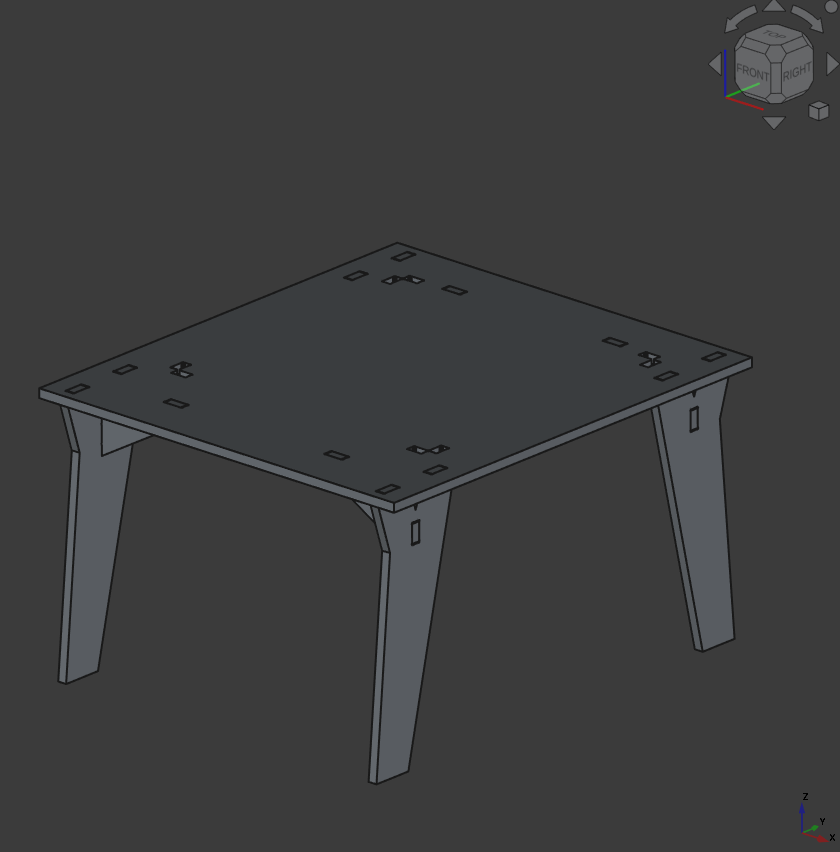

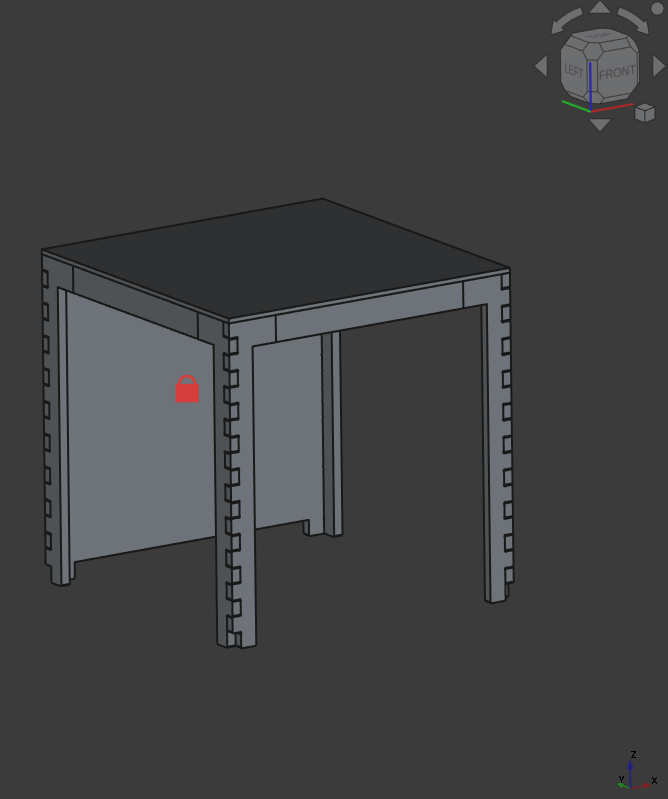

I’ve decided to build a Table with housing for my 3D-printer @home.

7.3.1. Design¶

It took me some time to get used to designing a parametric assembly (and also getting used to the CAD-style designing) and I had to restructure my files a few times. But now I think I’m more used to the workflow in FreeCAD now and I really like this kind of modelling.

I wanted to make an housing that is easily constructable (no fasteners) and don’t uses conventional doors and also want to have enough space to work on the 3D printer itself.

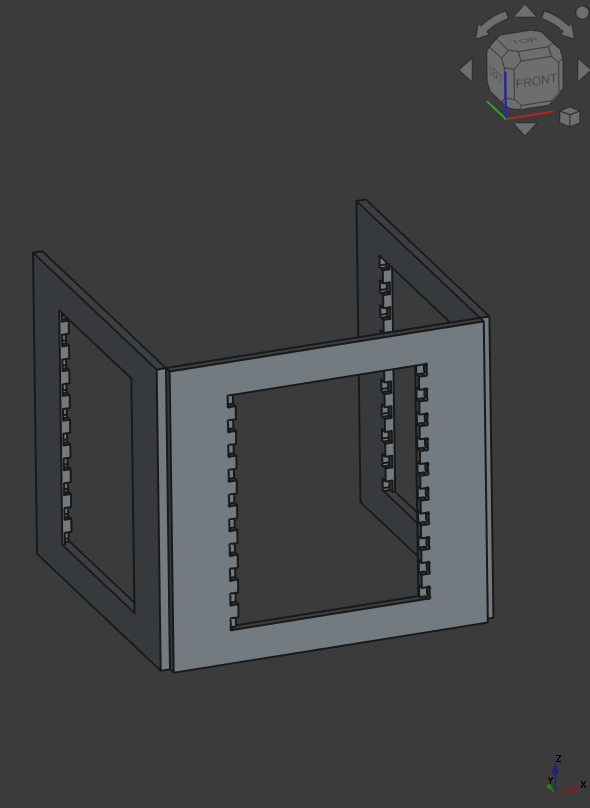

So the concept is to have a scaffolding, which is plugged into the table and the sealing window-sides are attached to the scaffolding via magnets, so I can remove the hole side.

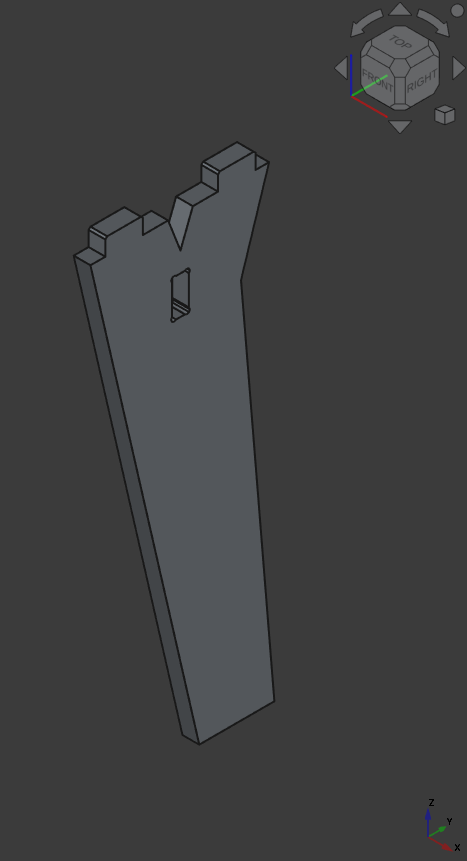

Table

Leg

Leg

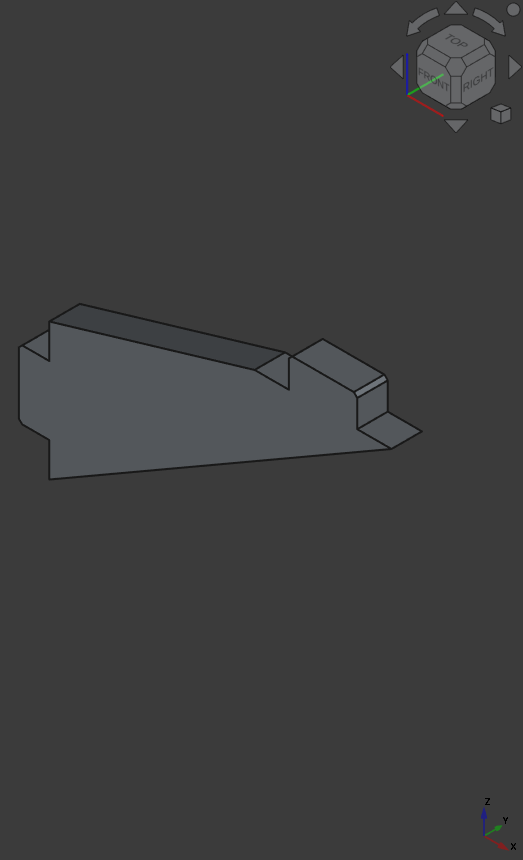

Support Angle

Support Angle

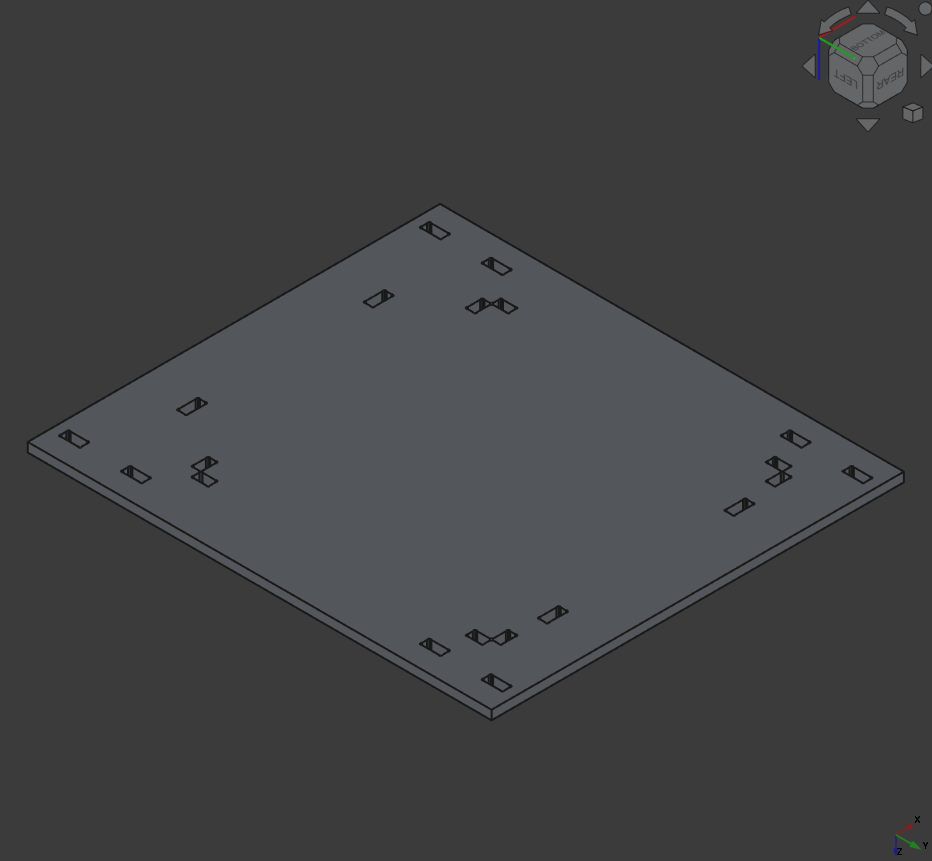

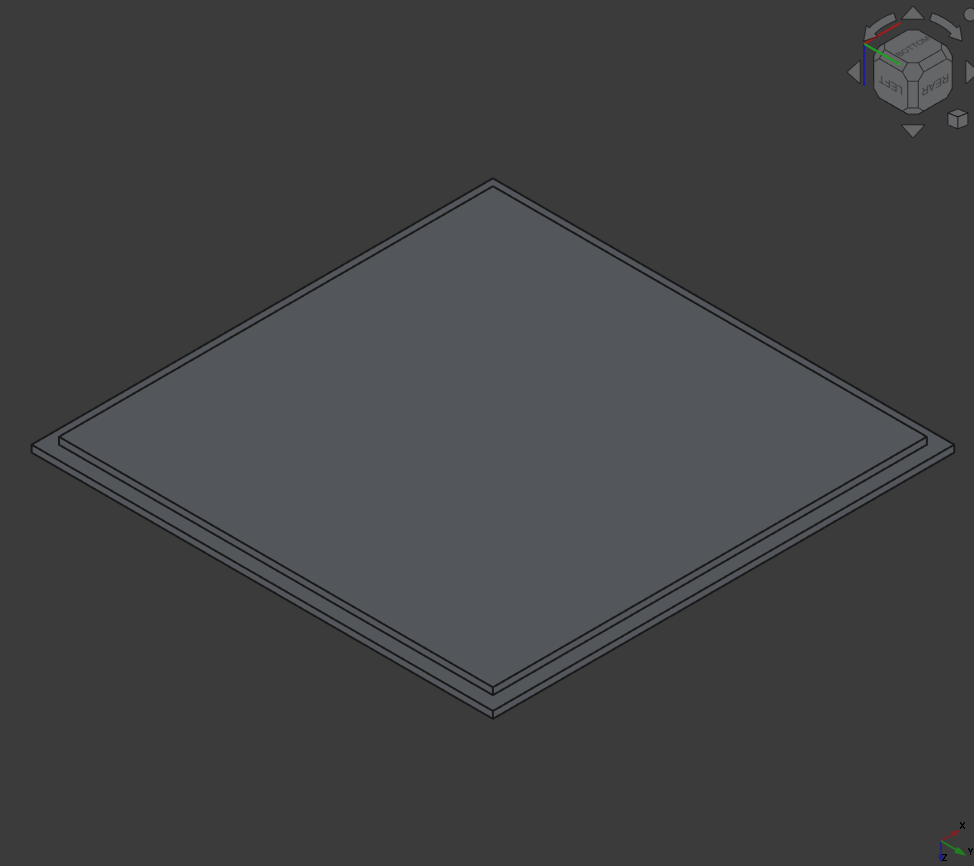

Table top with holes for the 3D housing

Table top with holes for the 3D housing

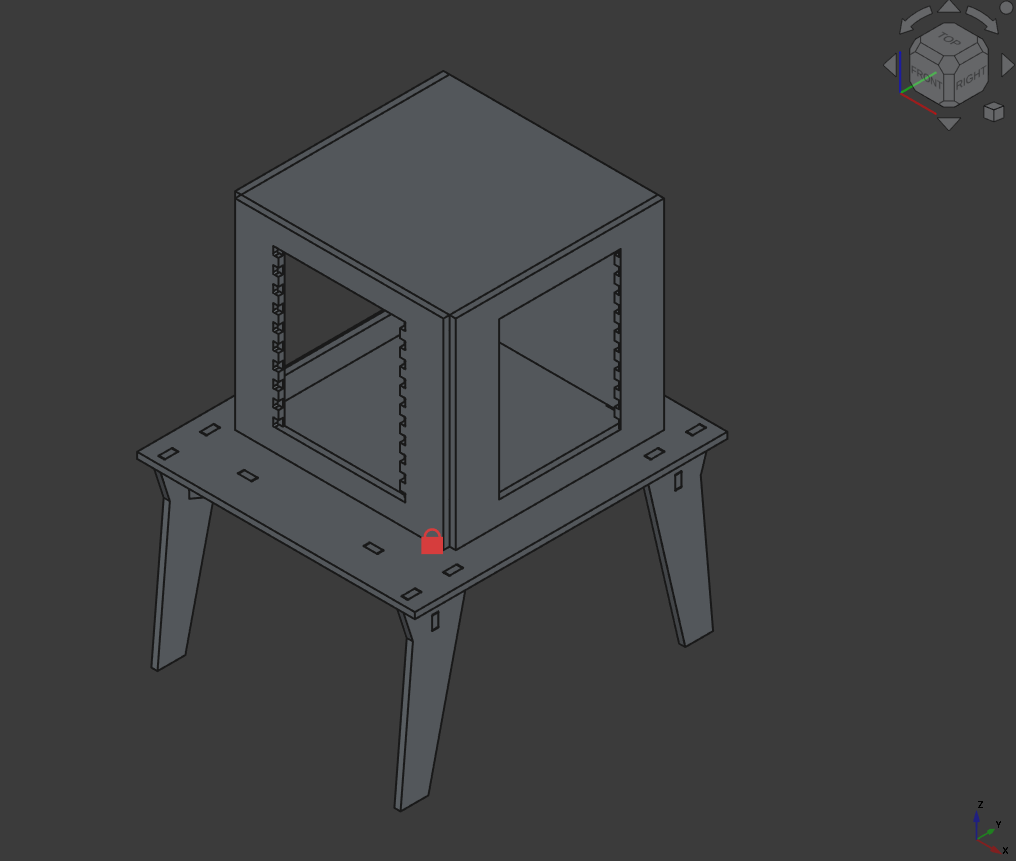

Assembled:

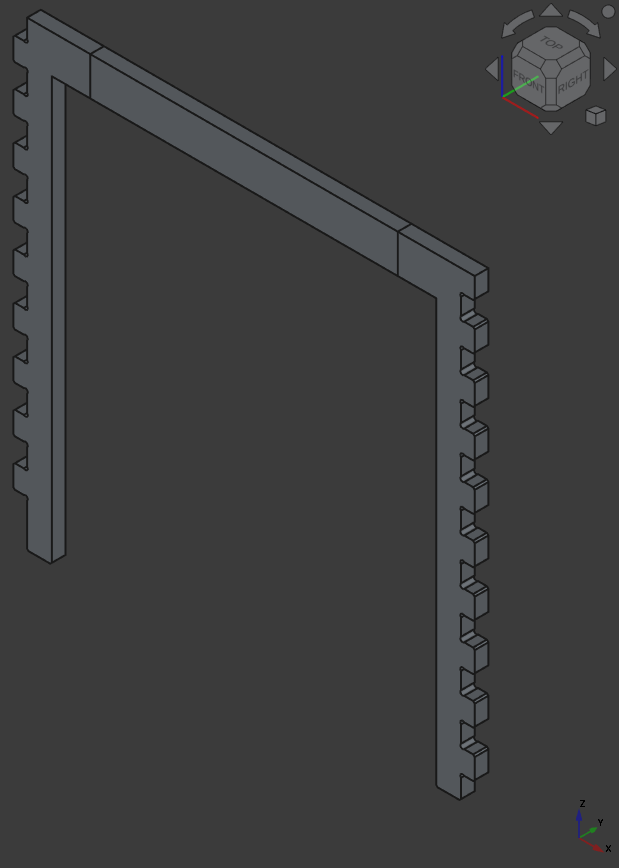

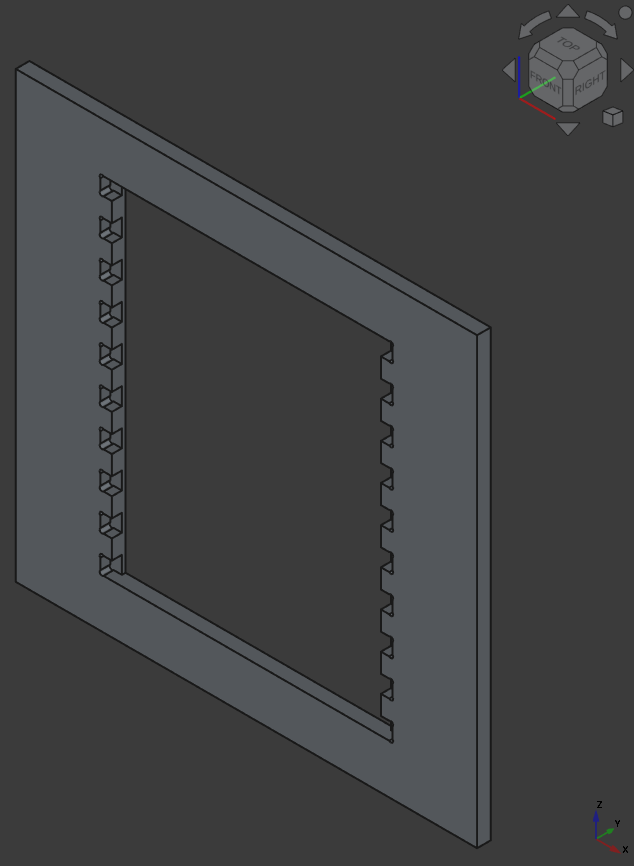

Frame

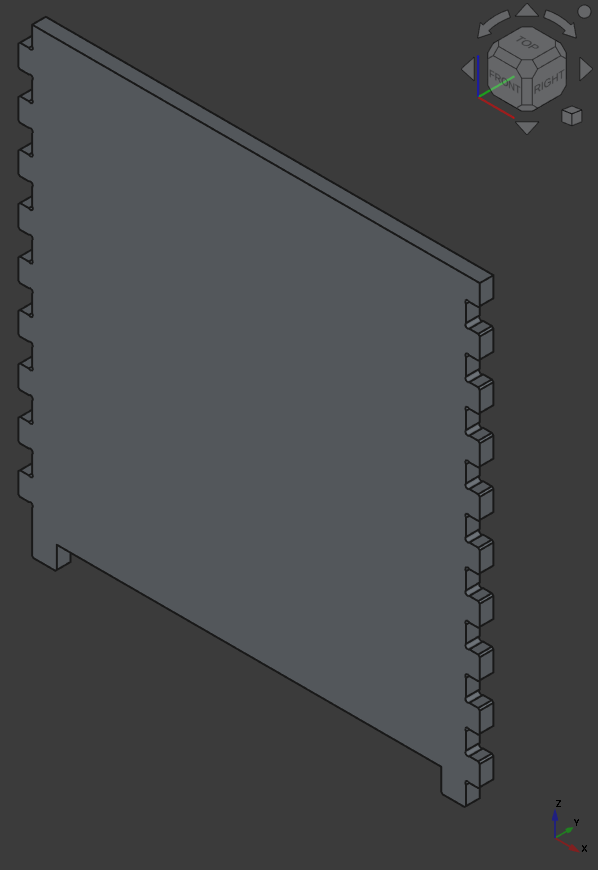

Side Frames

Side Frames

Back Side

Back Side

Assembled:

Windows

Assembled:

3D Print Table Assembly

7.3.1.1. Learnings¶

use ‘inheritance’ for better parameter handling (in this Case I used the baseplate for the backplate and the frames just with little adjustments) so when I can easily create a base object and just create a reference to it to make adjustments

use linear patterns for repetitive actions to not make your sketch to big

creating a good parametric design is hard -.-

7.3.2. GCODE-Generation¶

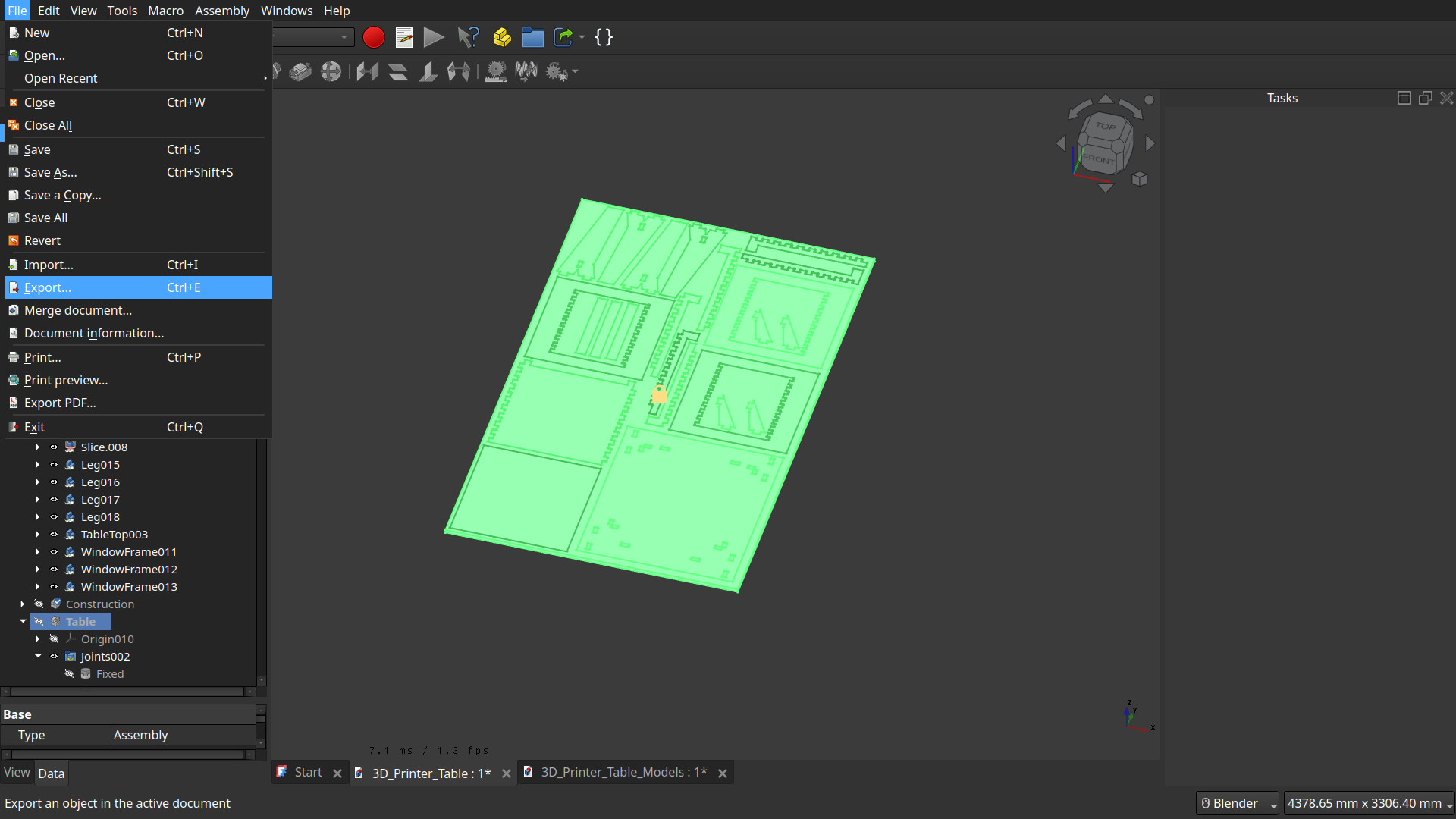

For generating the GCODE we used Solidworks Fusion360 because we milled at an external milling manufacturer and only got the generated code from fusion working properly.

So in my case to get the model of the CNC-assembled table I exported the model as STEP and imported it in Fusion, which worked perfectly.

Next I adjusted the Origin and had to align some parts to z==0 (because I messed that up in FreeCAD ._.).

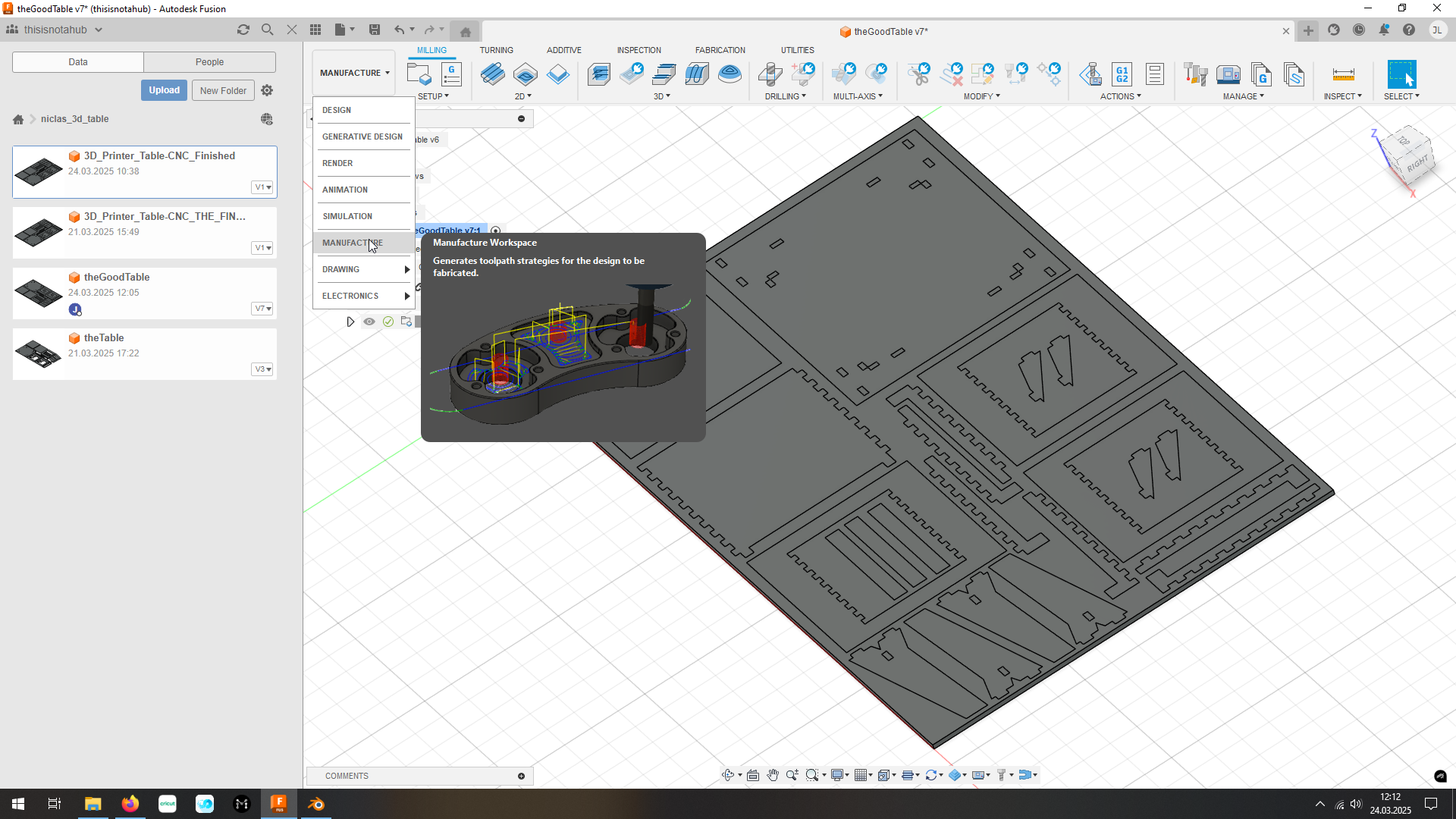

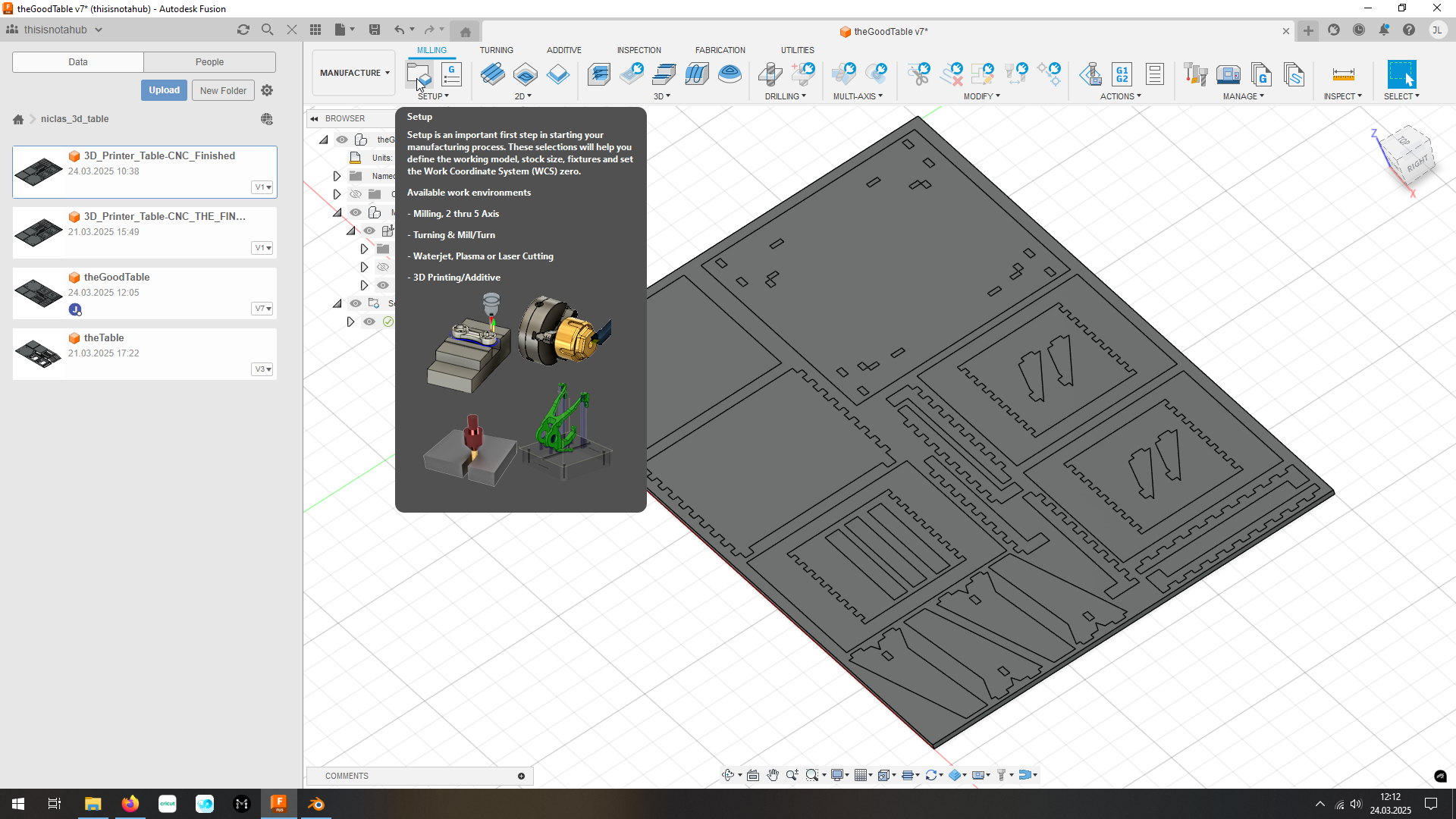

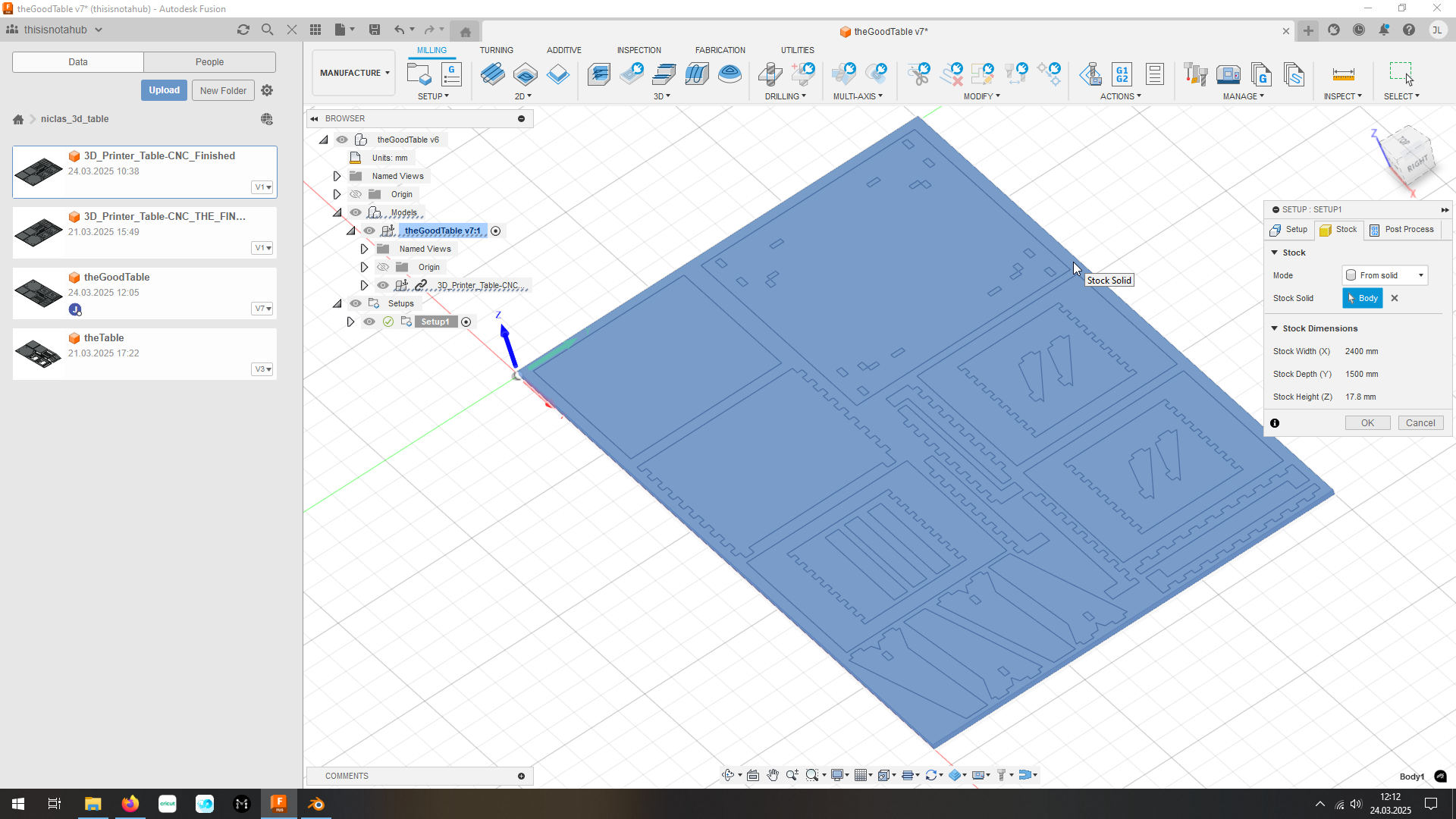

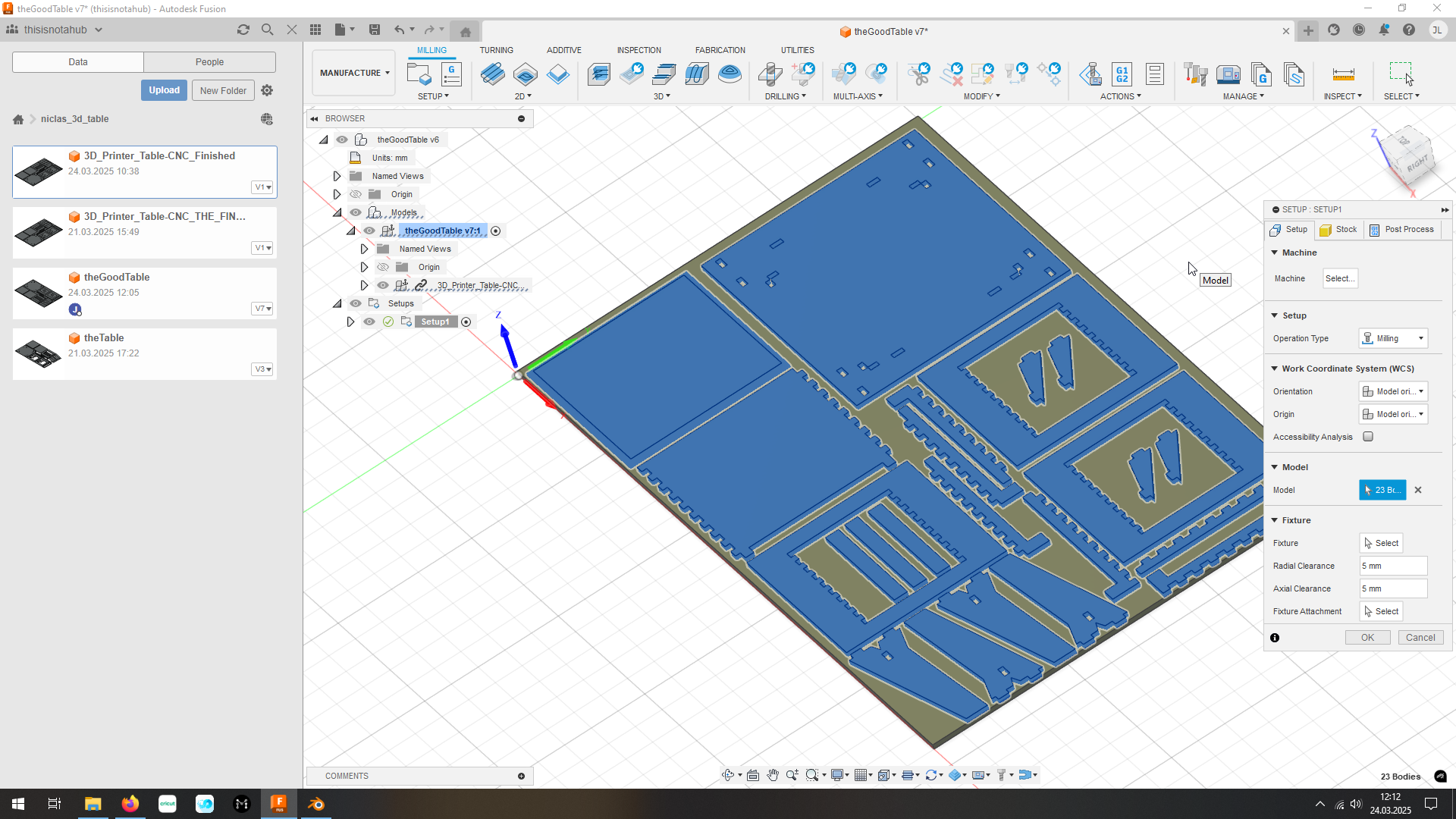

Then I changed to the ‘Manufacturing’-Workspace and created a new setup:

set the stock to the modeled workpiece

select all solids you want to mill

Important

Check the dimensions of the workpiece to match to the CNC (in our case 2400mmx1500mm) @CNC-Multitool the longer side of the workpiece should be on the x-axis!!

Setup a Manufacturing Process

Setup a Manufacturing Process

Choose the Stock

Choose the Stock

Initial Settings (like tool and Speeds/Feeds)

Initial Settings (like tool and Speeds/Feeds)

Choose the models to work on

Choose the models to work on

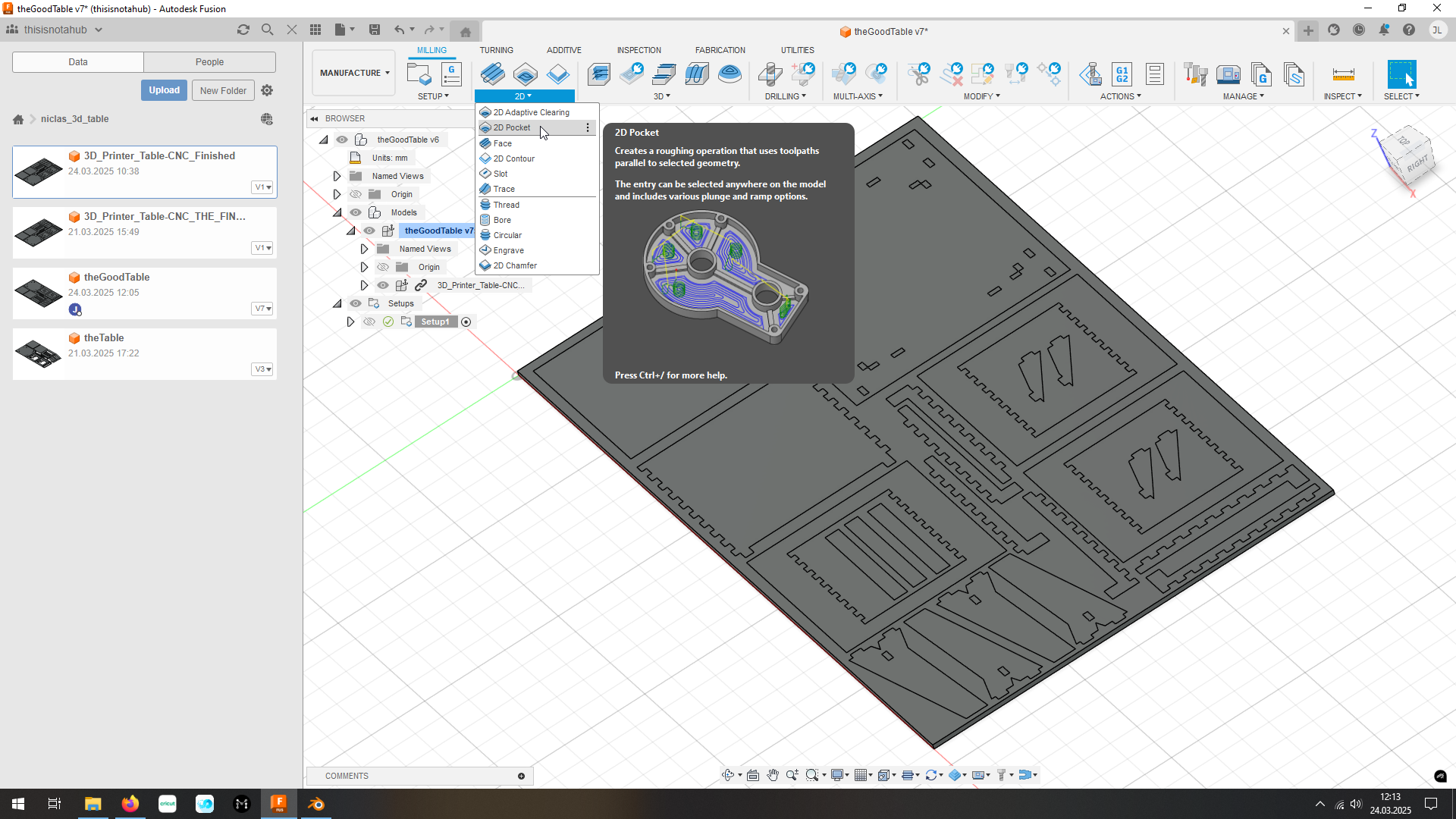

Now I can add ‘Jobs’ for different purposes, in my case I want to:

‘Pocket’ the holes for the scaffolding and angle, the fixtures for the windows and the outer part of the roof.

-> because a pocket-operation mills away everything of/to the selected part

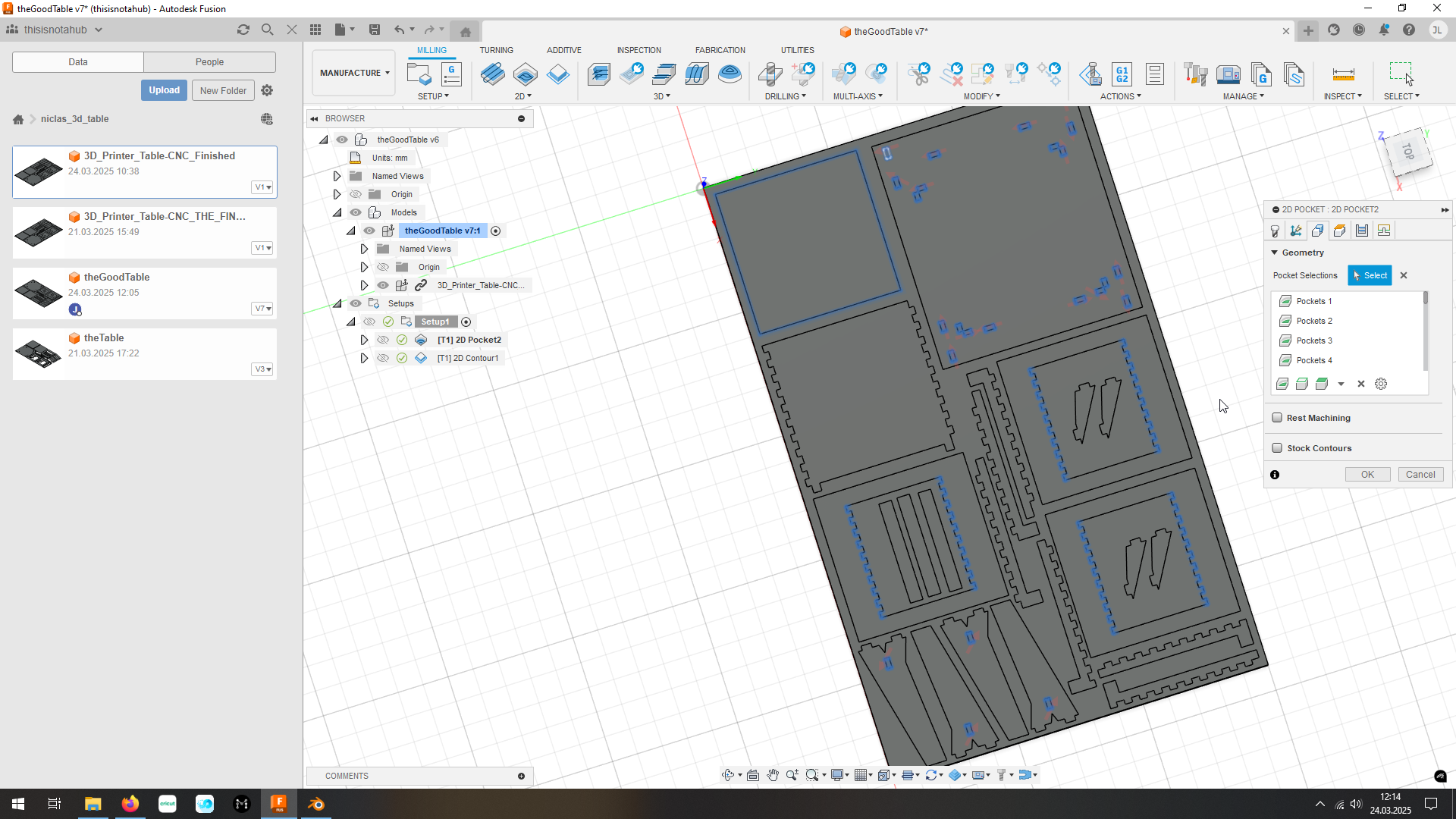

Choose the geometry you want to mill away

Choose the geometry you want to mill away

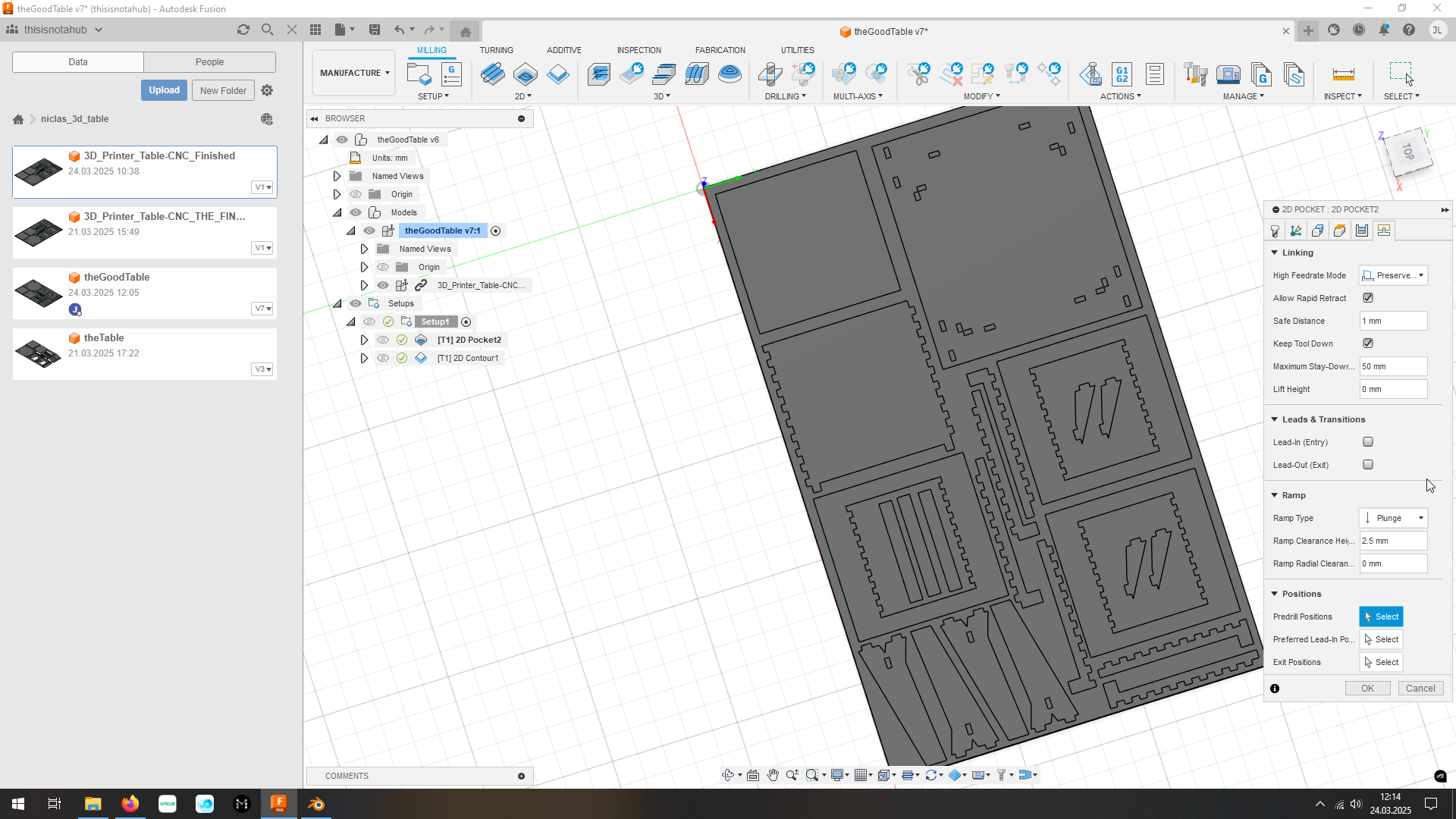

Disable lead in/out

Disable lead in/out

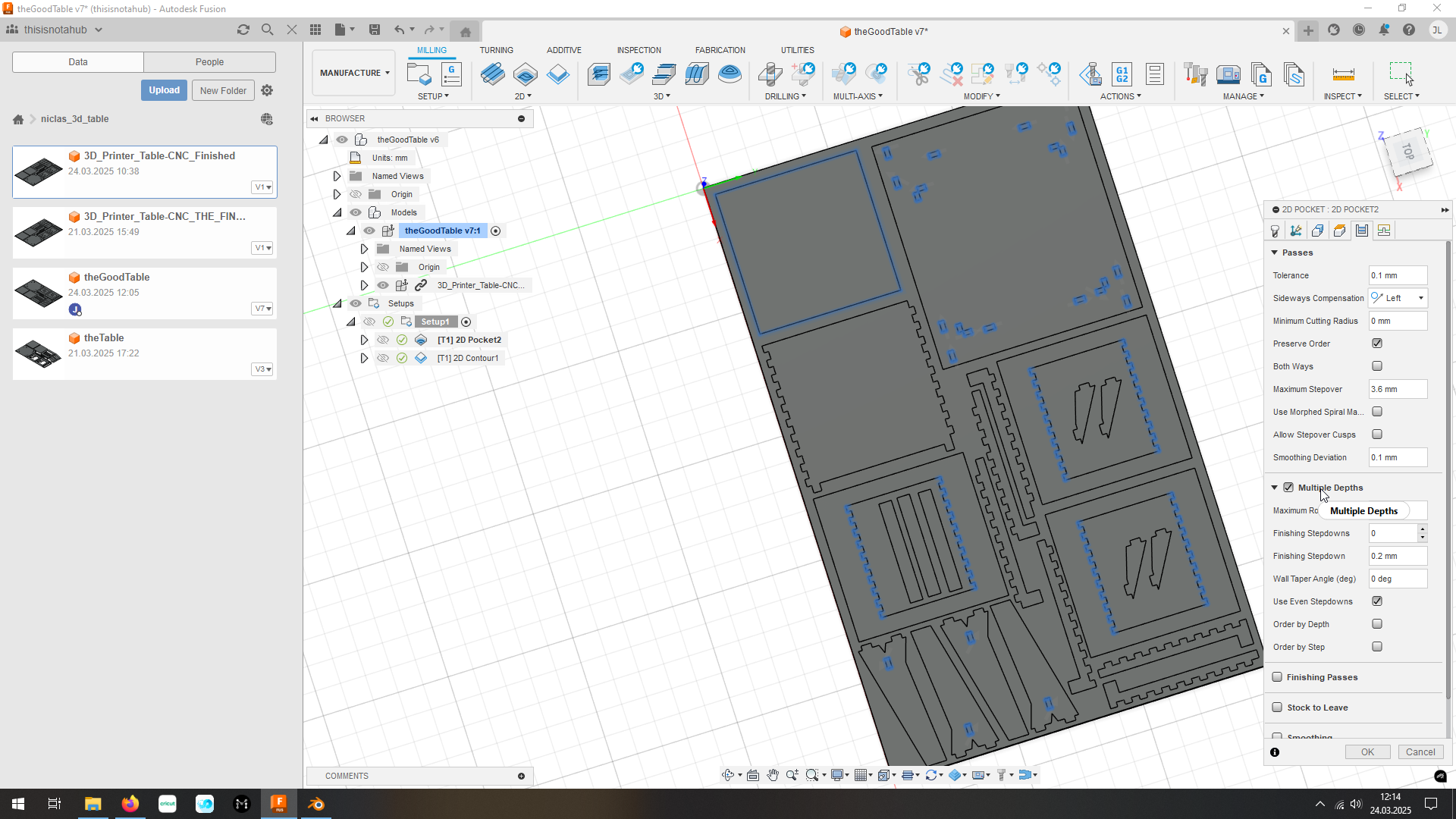

Enable multiple depths

Enable multiple depths

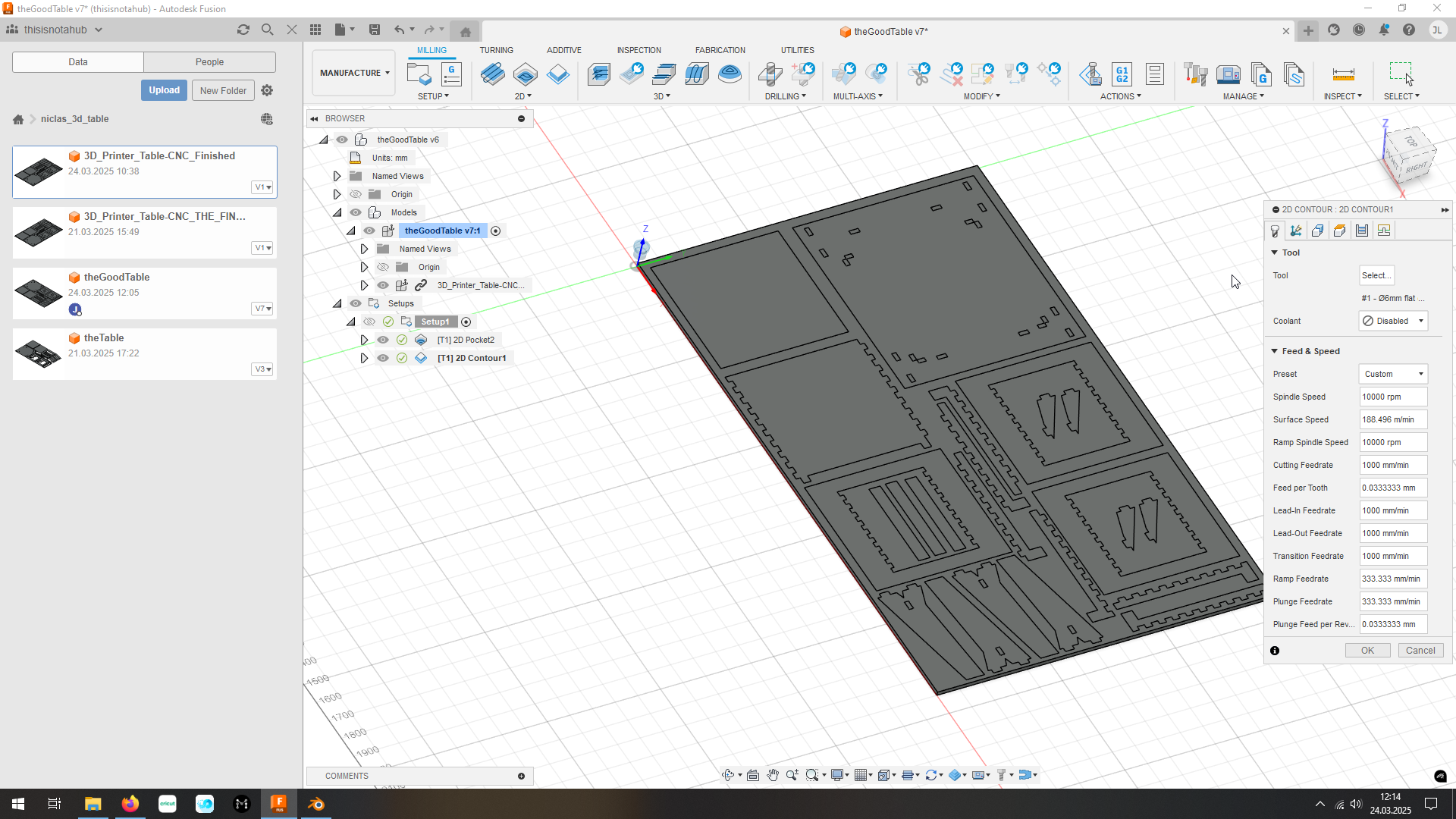

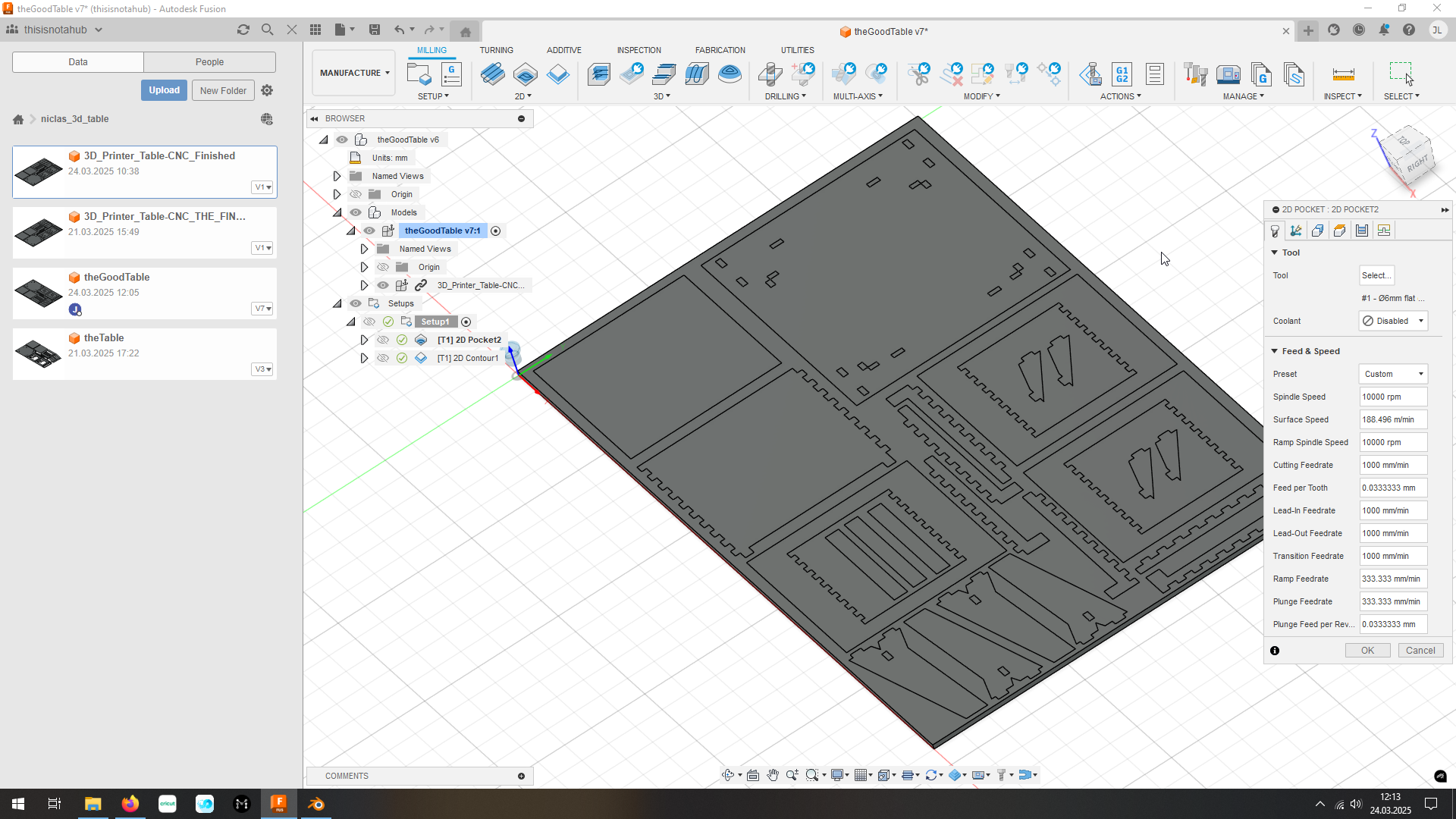

Configure Speeds and Feeds and tool

Configure Speeds and Feeds and tool

in geometry select the edges or faces to which everything should be milled away

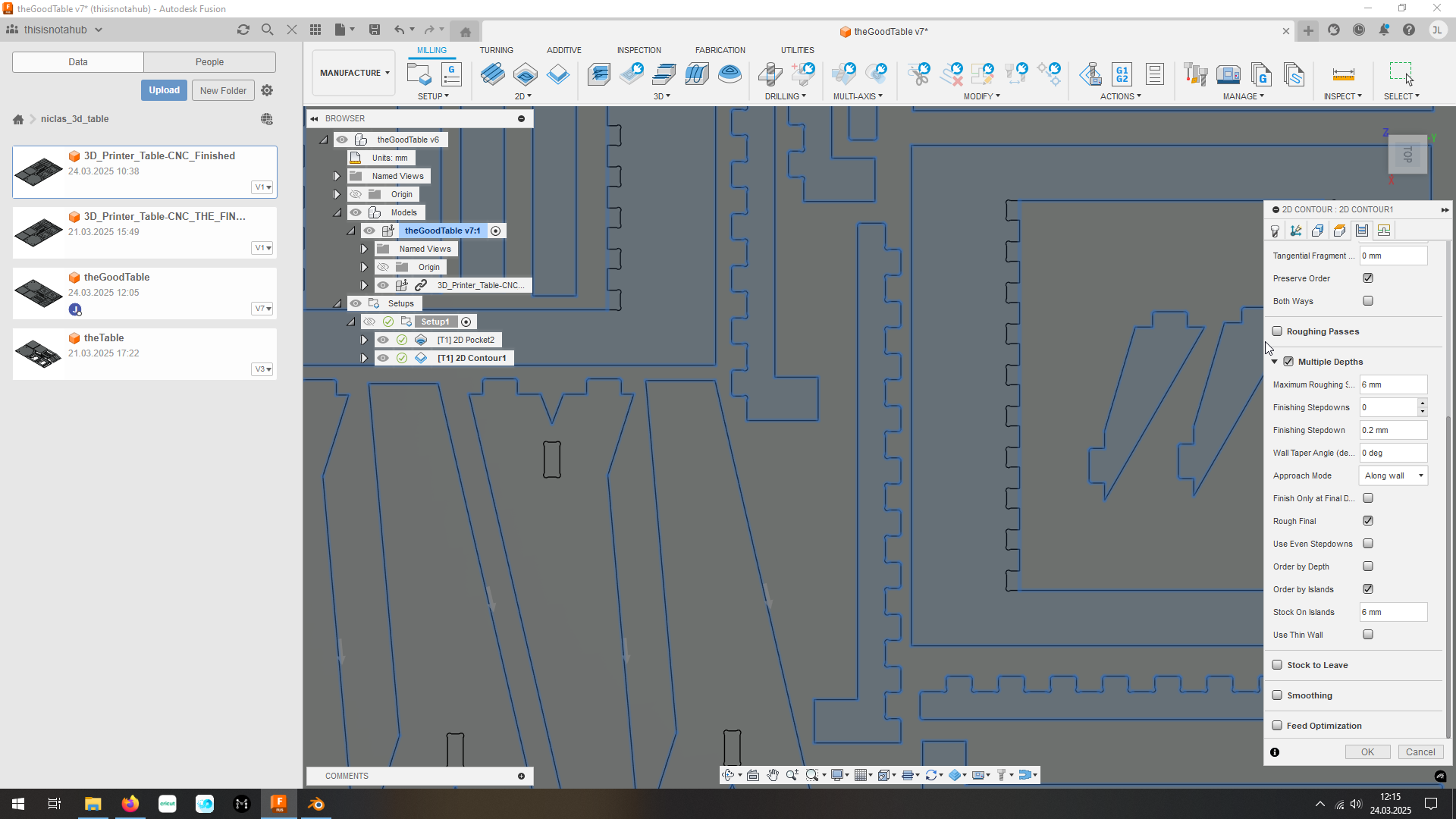

in the last tab, set ‘Multiple heights’ on and sett it to 6mm to ensure that the mill is not milling away to much at once

also in the first tab set the tool (in our case a 6mm flat endmill) and I set the RPM to 10000, which we tested our CNC with

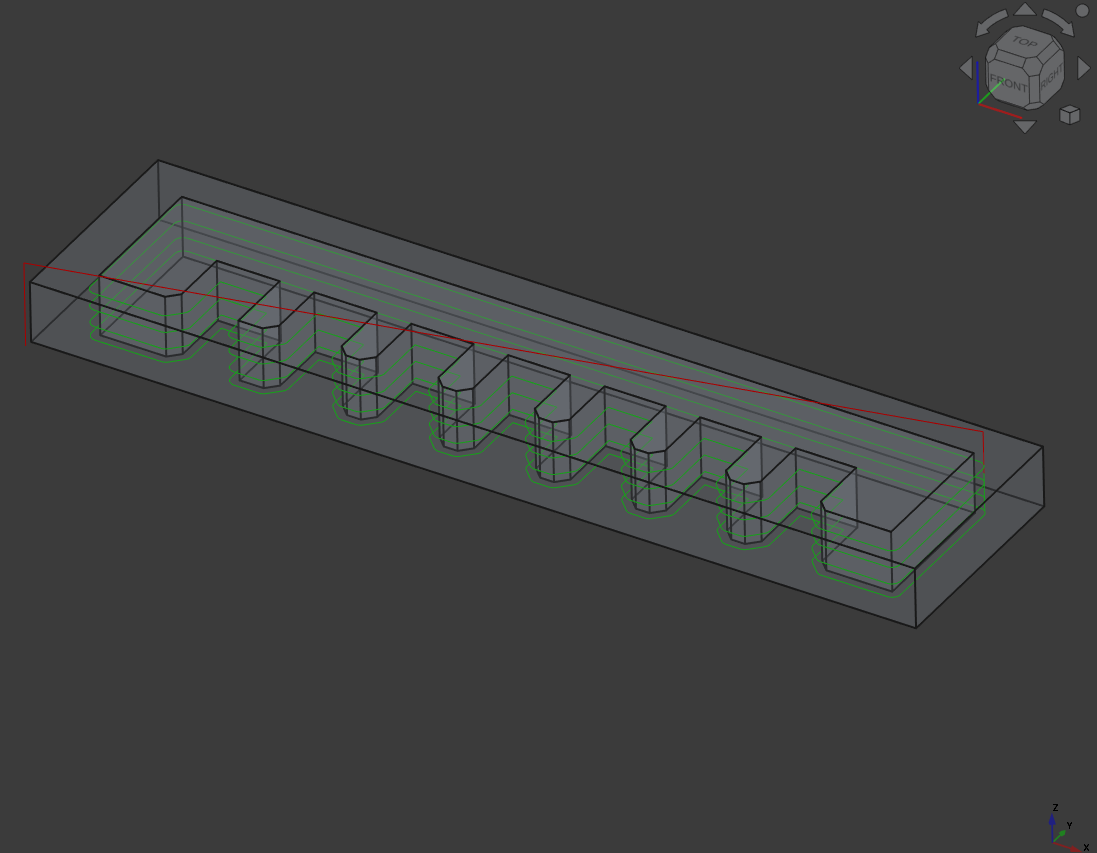

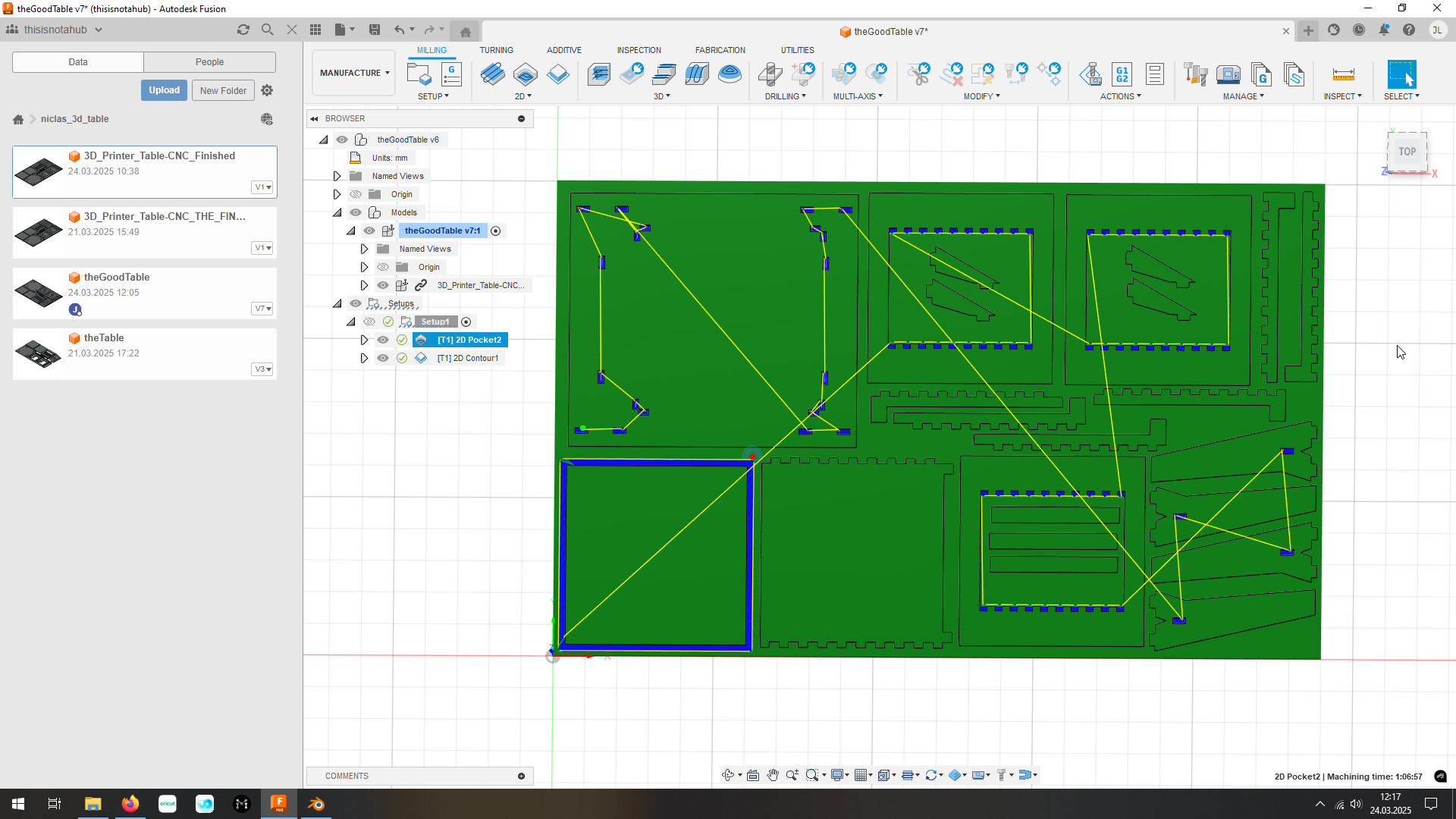

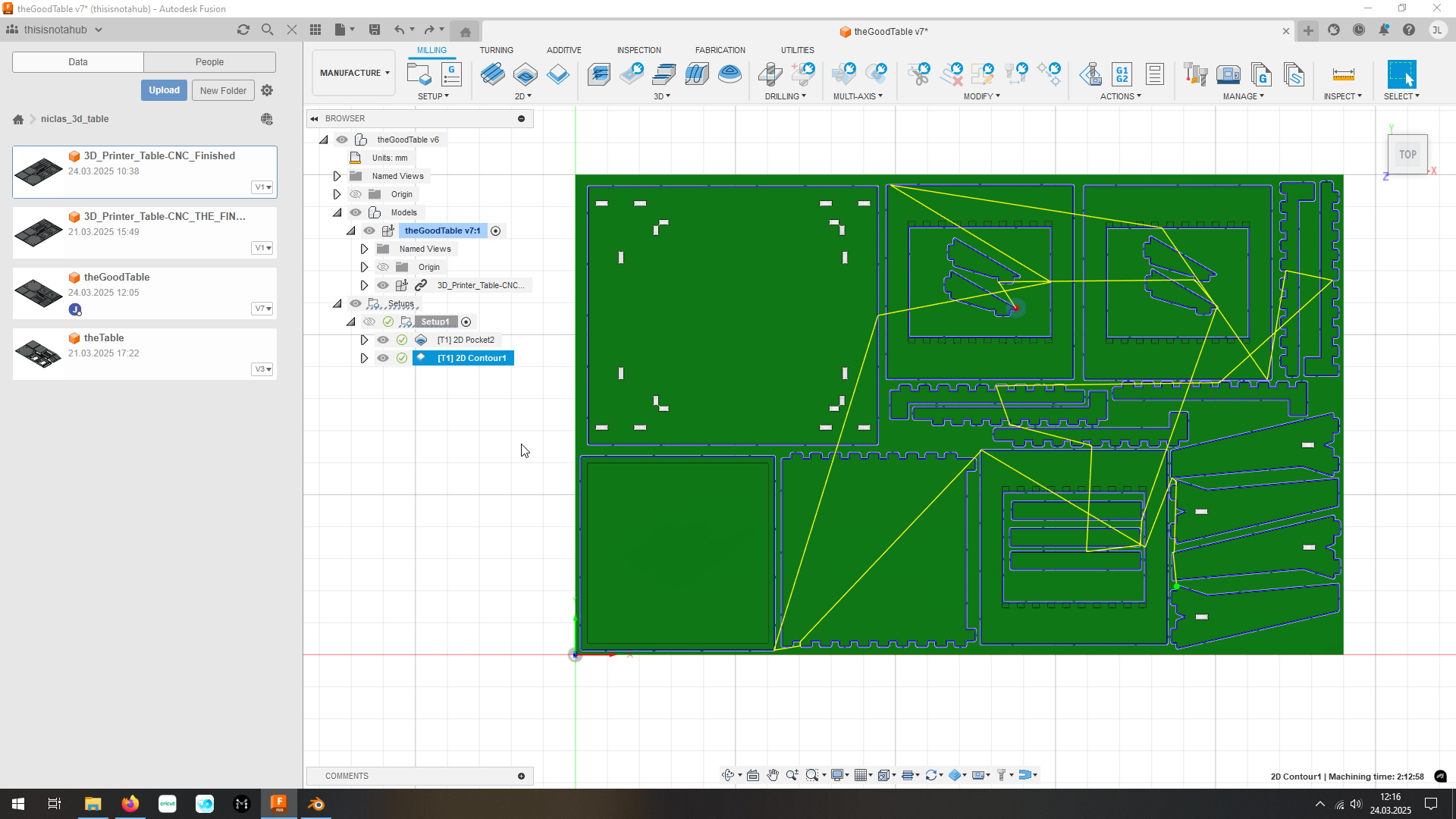

Path:

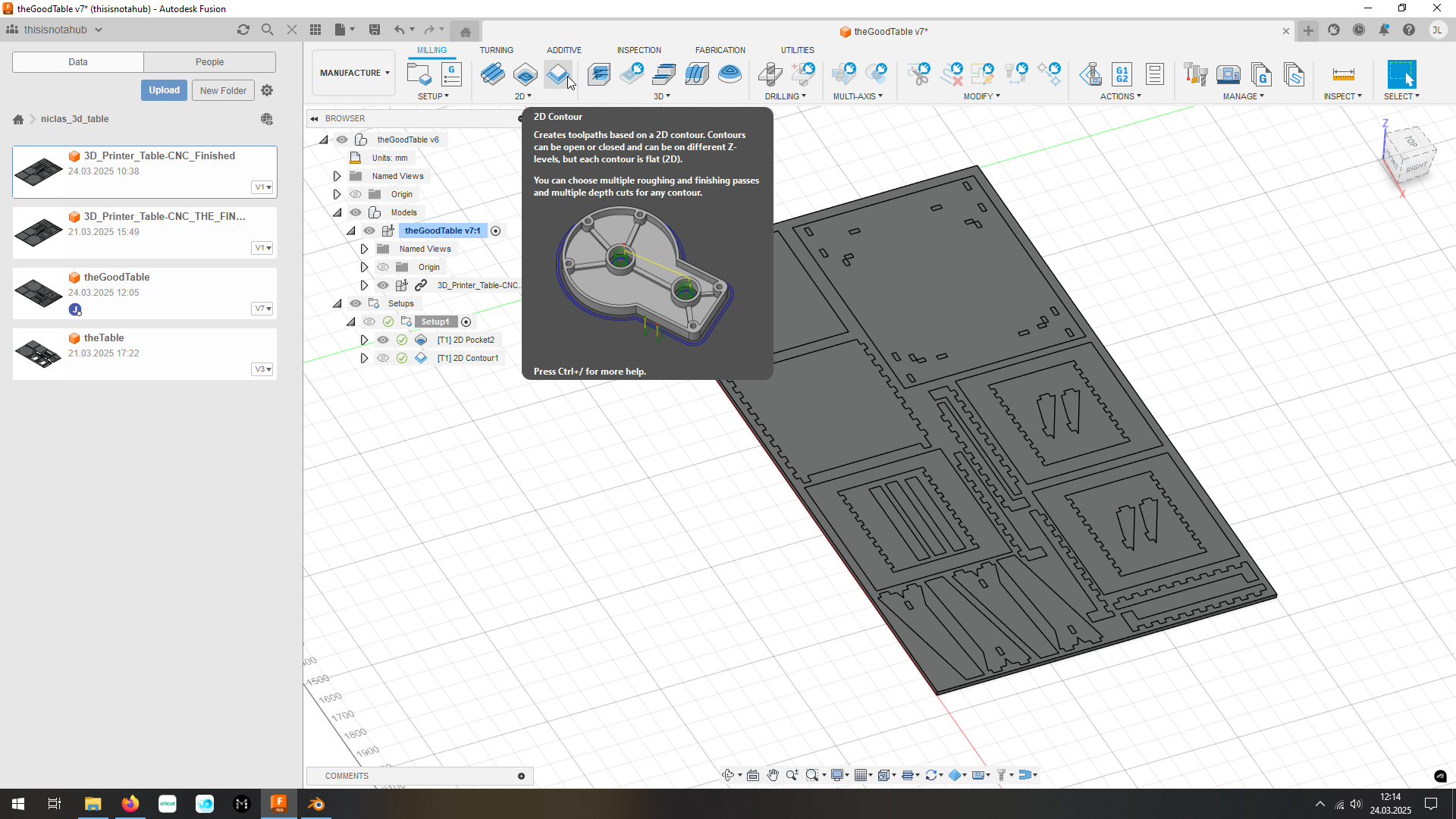

‘Profile’ the rest of the solids

-> because a profile-operation mills around the outline of the selected solid/face

Choose the geometry

Choose the geometry

Add multiple depth again

Add multiple depth again

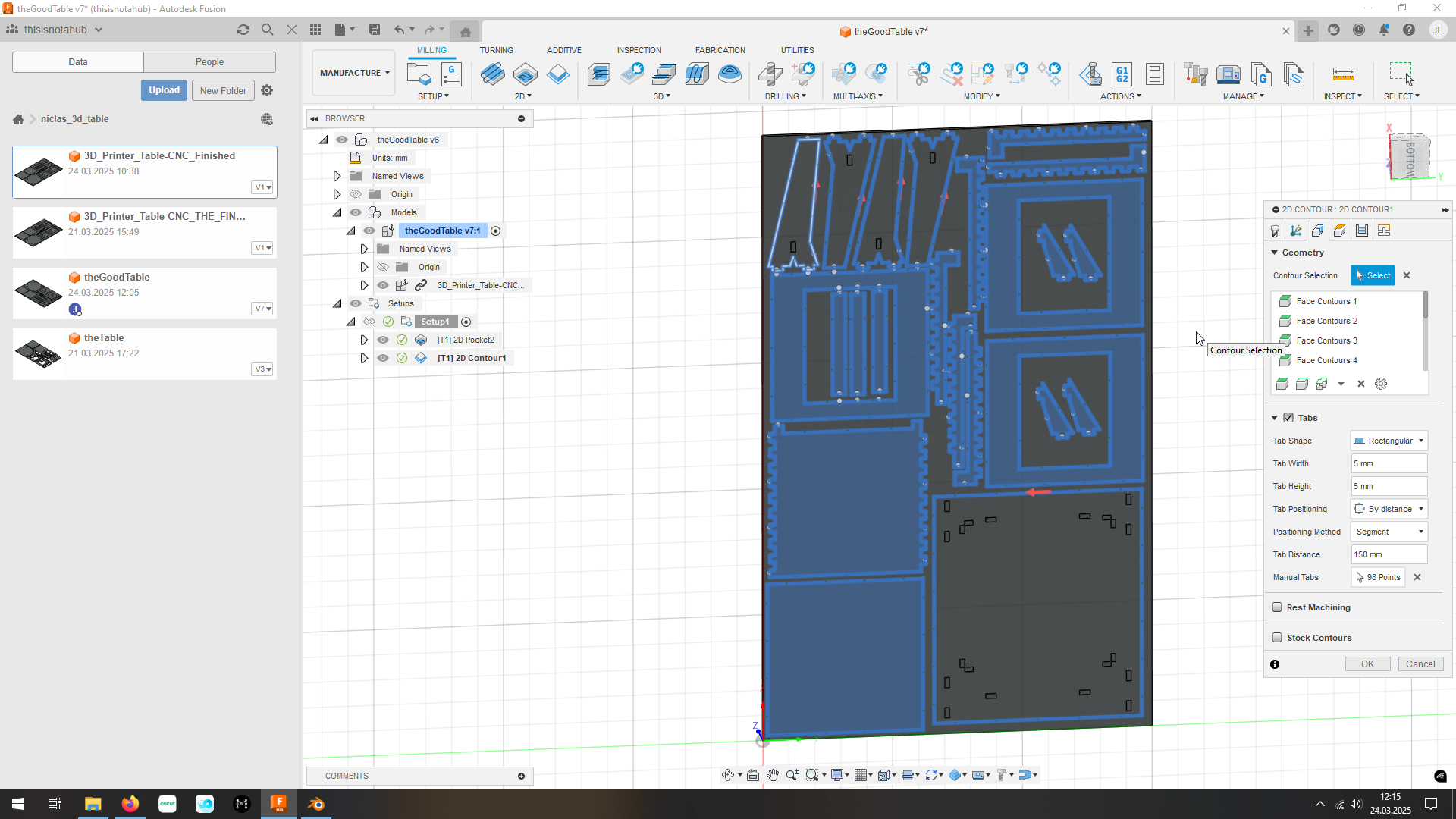

again on the geometry tab select every face/solid you want to mill out (recommendation, select from the bottom view)

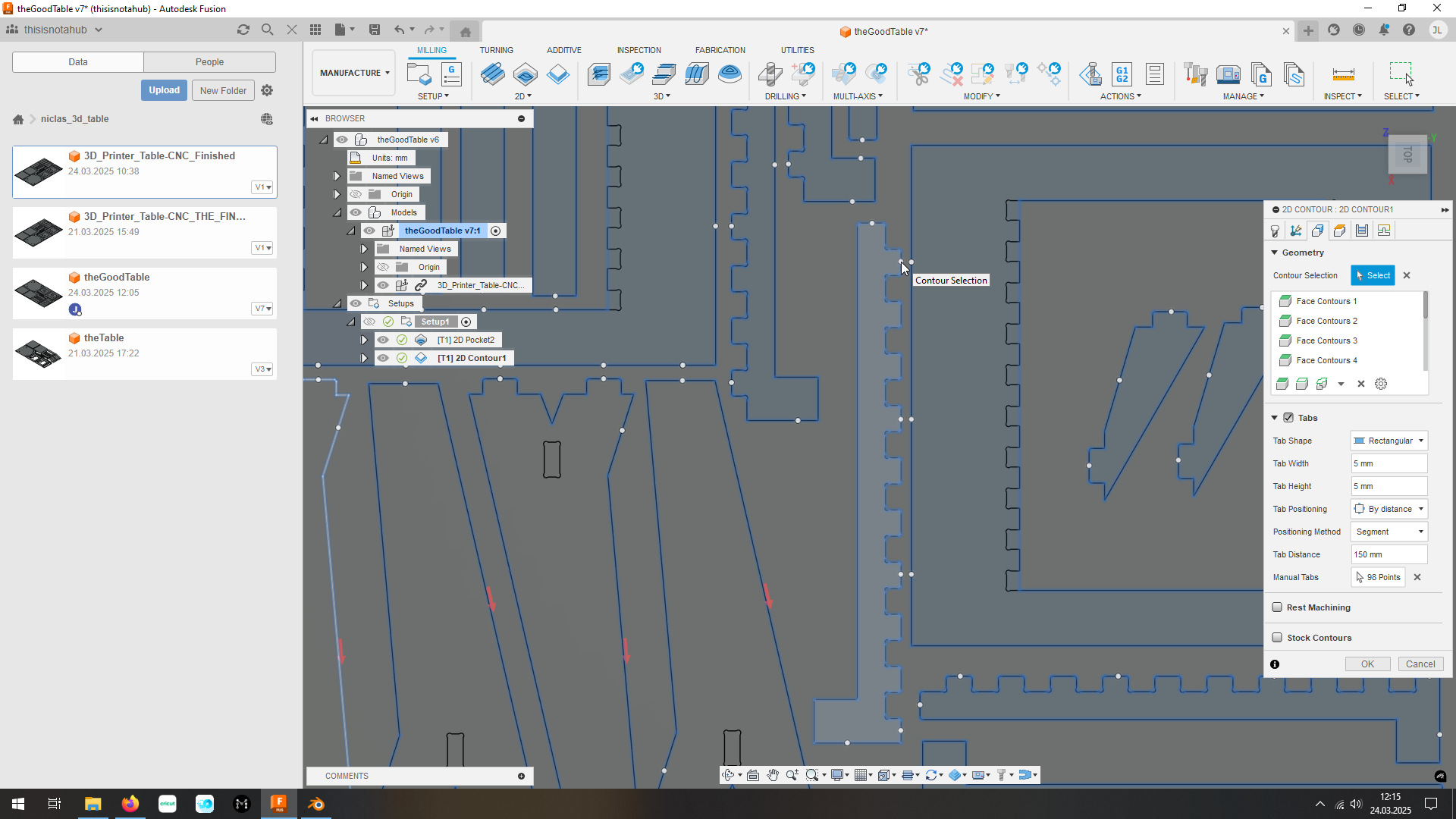

select tabs and this will auto-generate bridges so that the parts are fixed and cant fly away when milling the last pieces out

I don’t want tabs in my fixtures so I used following settings to only auto-generate at every straight line longer then 150mm

Path:

After looking over the generated path it’s also recommended to simulate (top right button ‘Simulate’) it to see, if the path is not strange in any way In the simulation I found out, that the CNC would drive unnecessary ways because of Fusion automatic-order of path I clicked

in the last tab of the operation I selected ‘manual order’ to change the order of generation to the order I selected the geometry

And if everything looks all right (also in the simulation), generate and export the GCODE (top right in ‘Actions’).

7.3.3. Manufacturing¶

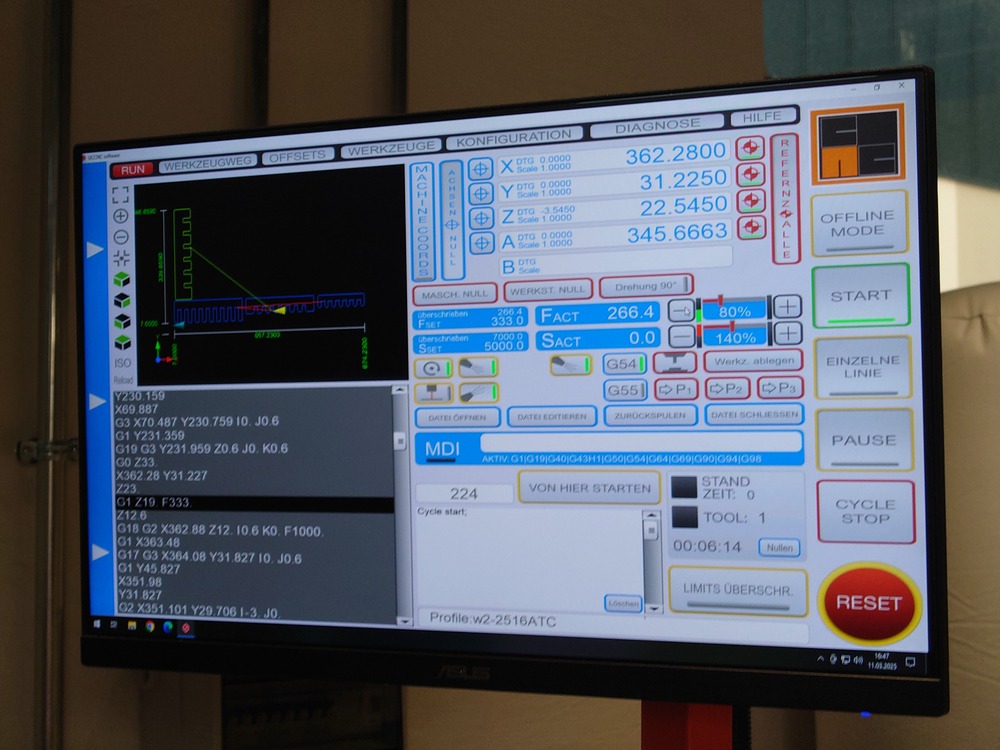

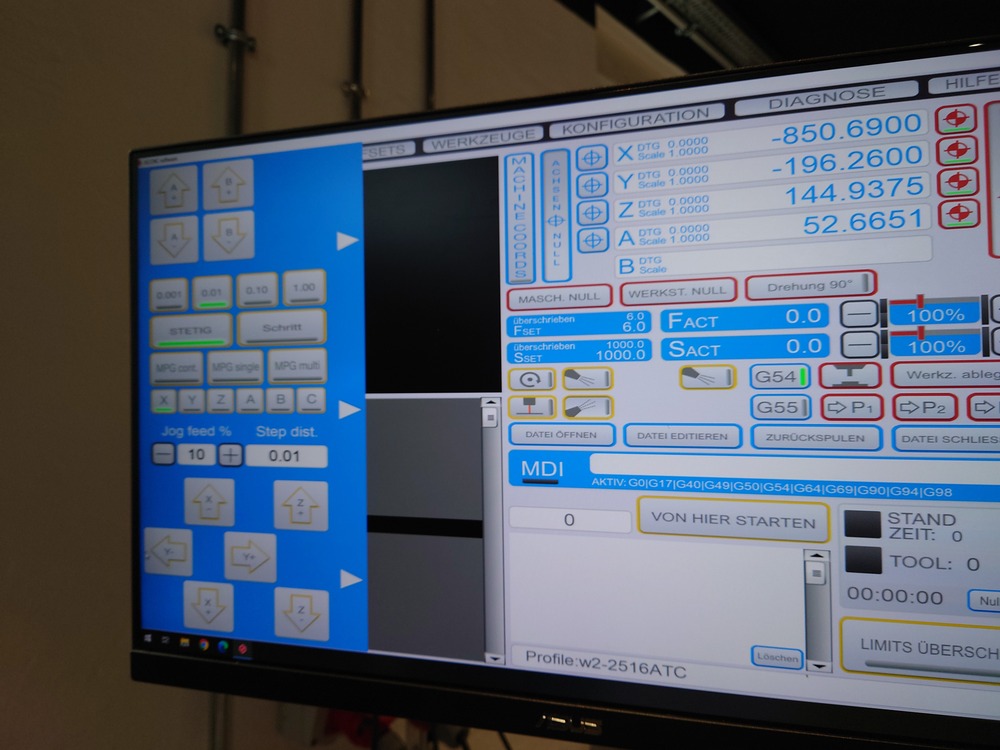

For starting the milling @CNC-Multitool, we need to turn on the machine controller and then turns on the PC.

The software

The software

The manual control panel

The manual control panel

Then Start the ‘UCCNC’ software and DON’T CLOSE THE SMALL POP UP WINDOW.

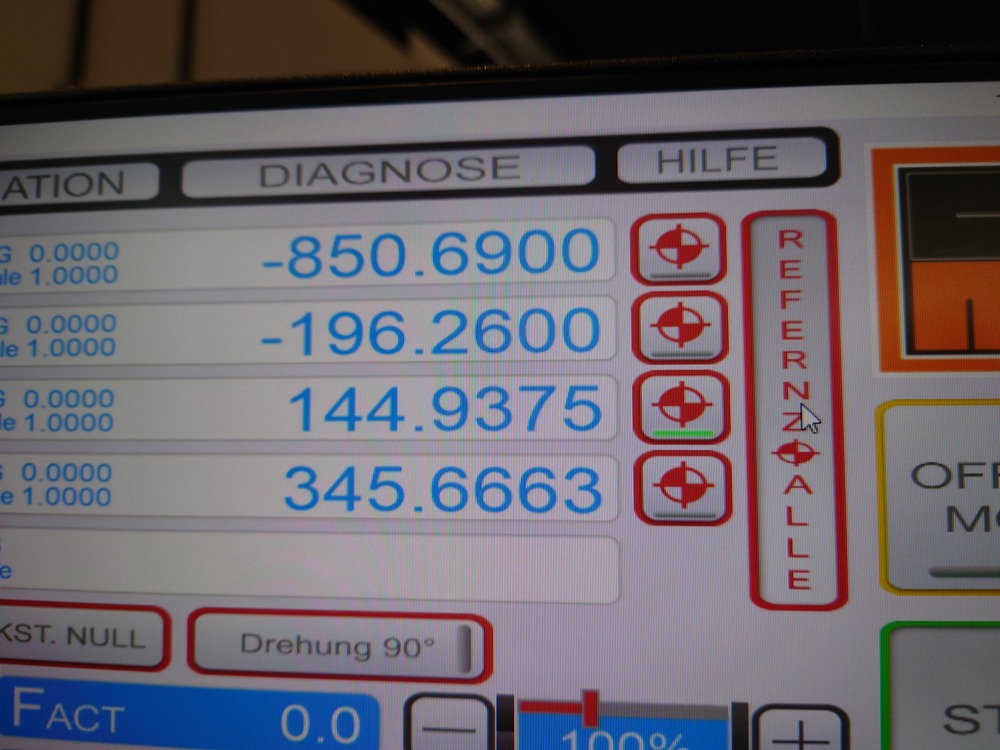

Now in the UI, use ‘Referenz Alle’ to Home the CNC.

Next Set the work-zero (the Cross Hairs next to the axis buttons).

Check, that the tool settings are like your settings in Fusion:

Before loading the GCODE, we need to measure the tool and like the Carvera, this CNC can automatically measure the tool-length and also activate all vacuums (table, suction).

Measure tool button

buttons on the side are for vacuum and suction.

Then open the GCODE File and start milling.

Note

In this case I also used pressured air to clean out the chips in the milling area because this helped with the edges afterwards.

The edges were not that clean (spiral ridge was on the edge of the wood) when the chips are in the way and the vacuum was not strong enough to clean out all the lose chips.

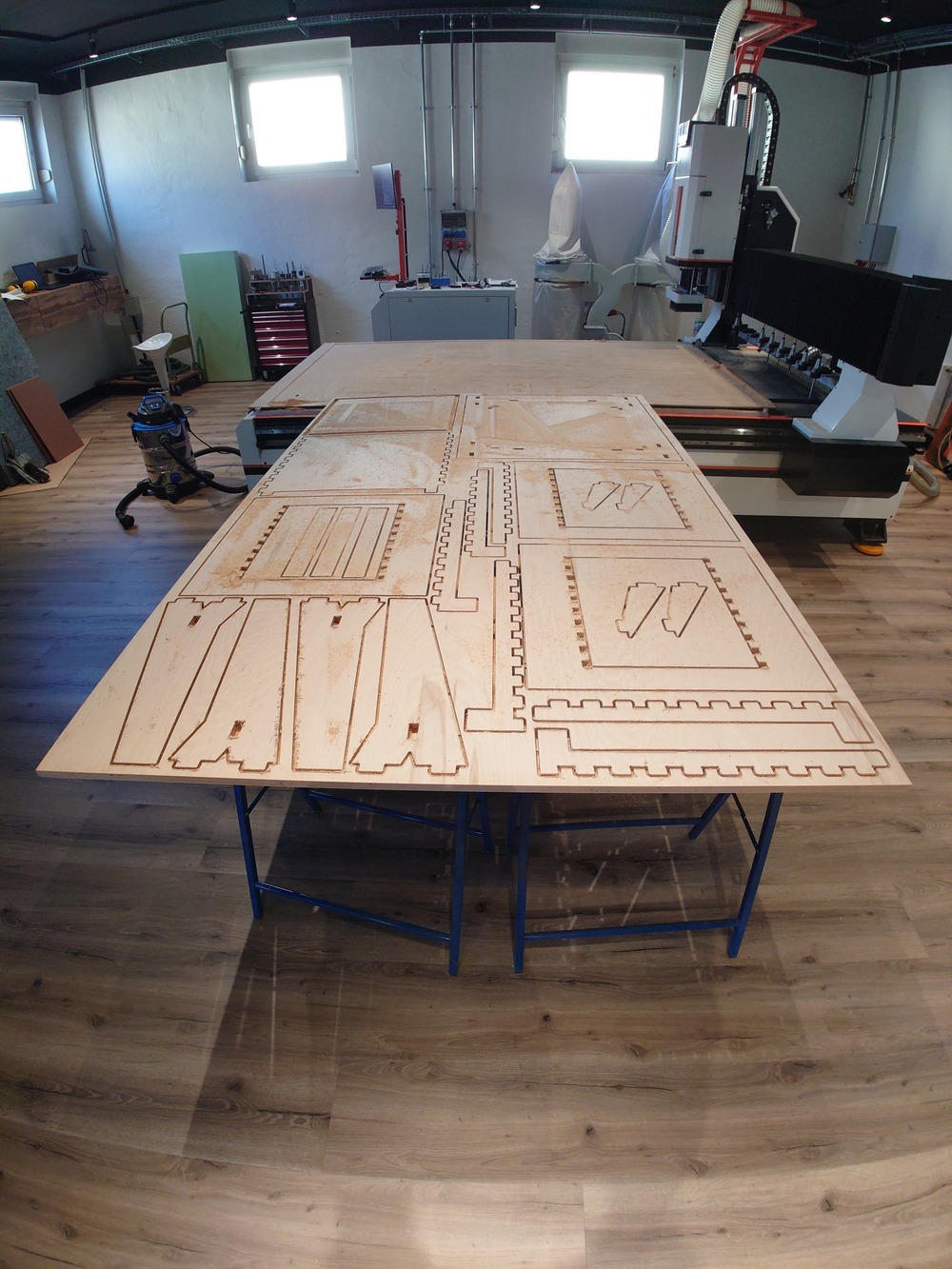

Result

And here the files from milling:

On this side, the wood was a bit thicker than I set in the model of the workpiece, but is was less then 1mm so it was no big problem.

The bigger problem was, that the press fit connections where a bit to hard to press into -.- …

And so I decided, that the Table is good enough unfortunately ._.

Post Process

In post-processing I used a router to make clean edges and sanded the surfaces:

Assemble

Assembling was now only to put the legs into the table with a wood hammer.

7.3.4. Result¶

7.3.5. Design Files¶

7.4. Notes¶

7.4.1. Tips¶

don’t forget dog-bones for fixtures

use minimal dog-bones -> place middle point of circle on a line 45deg. in the corner with its radius to the corner

plan screw in CAM - Programm

make a model in laser-cut

test-print joints

plan screw in CAM - Programm

For fixing:

(tape)

vacuum table (not for small parts)

tabs

straight flute also available

high chip load

easy to sharpen

the more cutting edges, the bigger the mill

posidrive vs philips head screw -> posidrive the sides are parallel -> philips the side is conical!

small parts screw down

clamping is very important -> clamp to far out -> wood may flex -> clamp to far in -> machine may drive into it -> take into account

wood is probably not exactly flat and has tension in it

screw

on tension -> may bend if cut -> more tabs, more screws

caliper -> don’t save money on them (helios-preisser in Germany)

chips on mill -> use something like WD40 on the mill against alu-particle -> also mill conducts heat better

7.4.2. Freecad¶

change units (mm, mm/s, etc.) left in the project itself when selecting the project

selecting material

7.4.3. FerdiAcademy¶

@ CNC-Multitool

7.4.4. Material¶

plywood

2500mmx1500mmx18mm

quality 1-2

6 mm milling bit

0.01 mm steps can depend for a good fit

wood not same thickness everywhere

z=0.0 auf der Unterseite (Empfehlenswert)

7.4.5. MAKE SOMETHING BIG¶

Andrew Klein - twin turbo wise - in-klein

magnetic vice

https://www.youtube.com/@sliptonic/videos

7.4.6. Mills an Drills¶

extra mill for roughing (with rills in flute)

depend on material cut

HSS (high speed steel) mill -> alu and wood, plastic

carbite mill (dark-ish) -> harder (steel, etc.)

flute length -> wegen abnutzung

strong ridgit

not just tip, as loong as needed

flute number

radius

as much material as possible

stability