15. Wildcard week¶

Group assignment:¶

None

Individual assignment:¶

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it.

hi, this week we’ve decided to do a project on the UV printer, we’re just going to print the image of our choice, preferably from our final project. hi, this week we’ve decided to do a project on the 3D Laser engraver.

so let’s move on to the presentation of our machine!

Introducing the 3D Laser engraver¶

3D Laser engraver. A 3D laser engraver is a device that uses a laser beam to engrave three-dimensional patterns on various surfaces. These machines combine the precision of lasers with the ability to work on curved or irregular surfaces, delivering high-quality results on a wide range of materials. This type of 3D crystal engraving machine uses an imported air-cooled laser system, which not only significantly increases engraving speed, but also produces a fine point of light. It cuts digital images with distinctive, high-quality features, offers good stability, and is easy to maintain. This machine is ideal for large shopping centers, tourist resorts and high-traffic areas, enabling the production of personalized portraits.

| Specification | |

|---|---|

| model | PE-DP-A2 |

| average life | > 20000 Hours |

| Max frequency | 5000 Hz |

| PMax engraving area | 400mm X 320 mm X 120 mm |

| Focal Length (standard) | 120 mm |

| Focal Length (Optional) | 120 mm |

| Accuracy | 20 μm ~ 40 μm |

| Max Speed | 300000 points / minute |

| Repeat Offsite | 10 ~ 20 μm |

| Power | < 350W 220V / 60Hz |

| Net Weight | 185 kgs |

| Cooling | Air cooling |

| Environment | Less dust and shock, Temperature 10-35°C, humidity < 85% |

| File Format | BMP JPG DXF OBJ WRL 3DS STL |

| Applicable Materials | Crystal, Glass, Acrylic and Other Internal Carvings and Mental Surface Carvings |

| Package Size | 1060 mm x 1060 mm x 1460 mm |

| Machine Size | Machine |

- In fusion 360, we exported the robot as a .stl

The Software introduction¶

You can open the manual Here

we are two softwares :

-

3D Crystal : Convert the 2D/3D model to Point Cloud with .cad format

-

Laser control : control the machine to engrave the image .cad into the crystal

follow these steps :

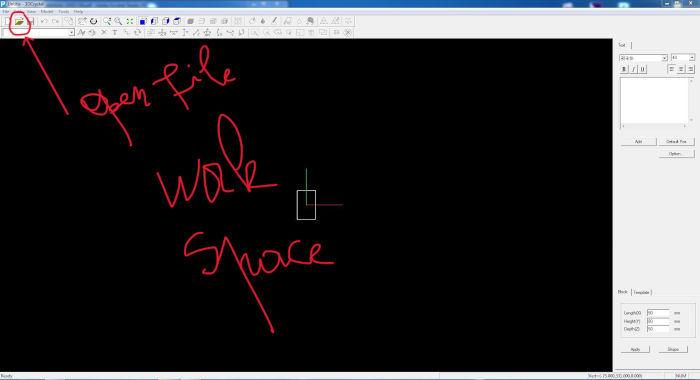

- Open the 3D model file

- Choose the file and click on open

we need to obtain the following :

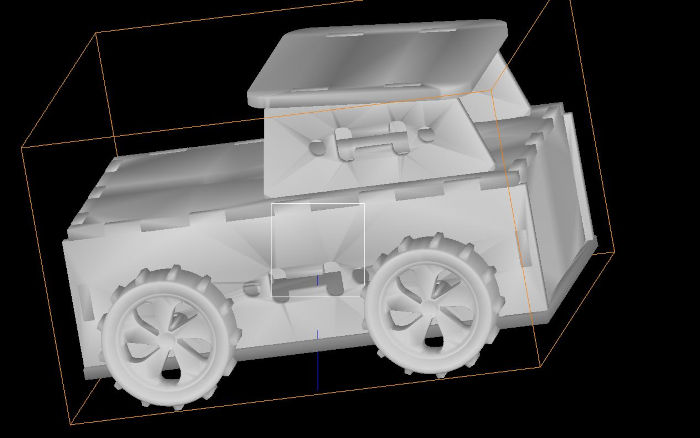

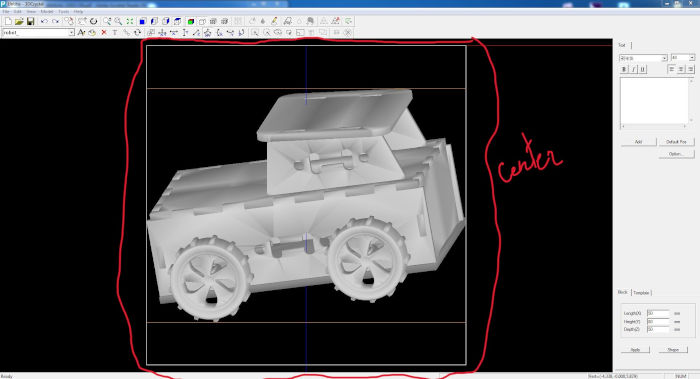

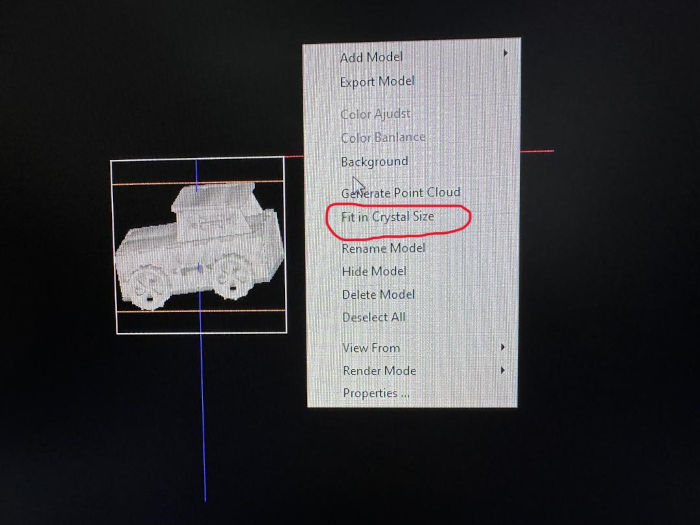

as we can see in the image, the file size is too large, it’s out of the crystal. To fix the problem, right-click and choose Fit in Crystal Size.

The orange color box is the size of the 3d model.

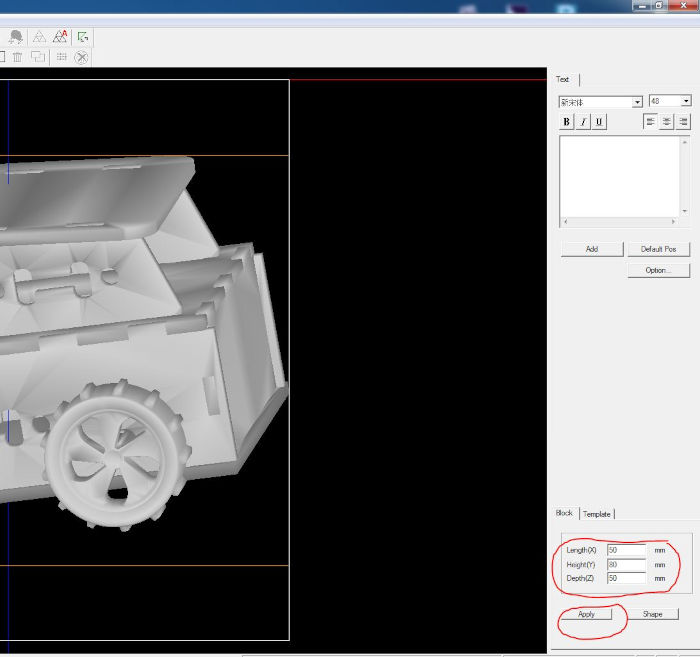

The white box shows the size of the crystal, we can change the crystal size by editing the block size. For example, we use the “558” size crystal just like in the picture below.

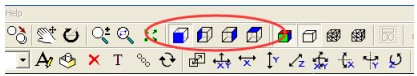

We can change the direction of the view by clicking the buttons in the picture

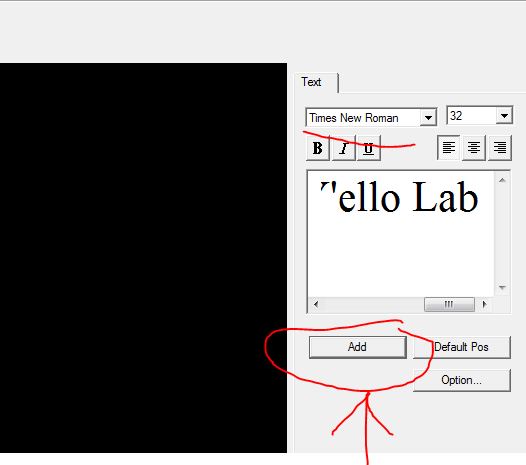

- Add the text

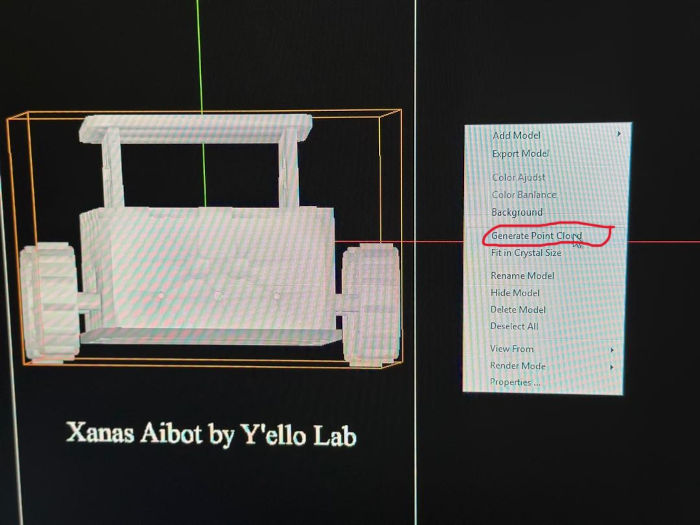

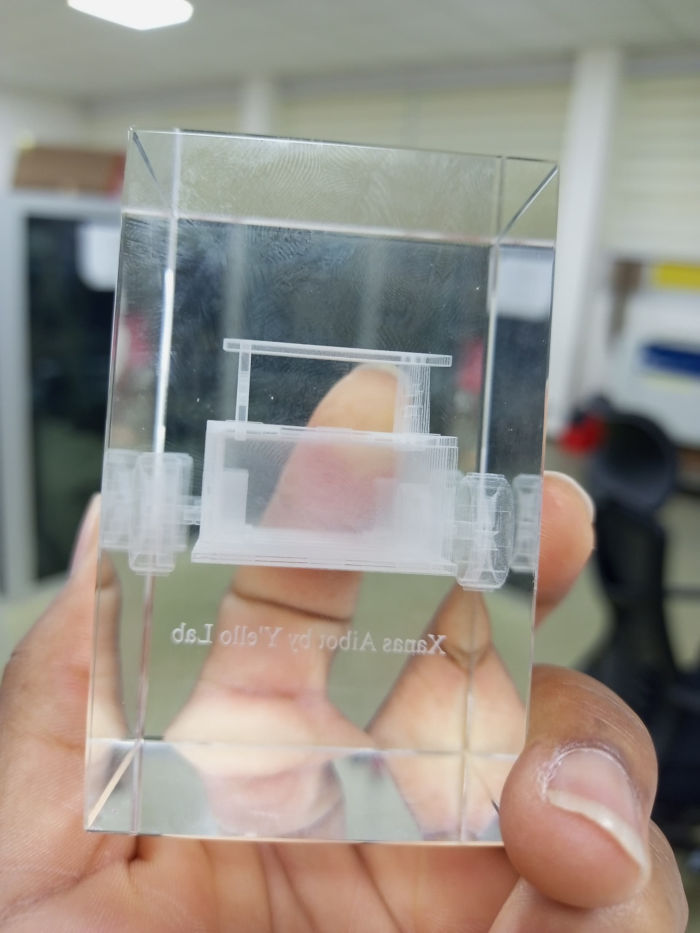

Type in Xanas Aibot by Y’ello Lab and then choose the size. For we : 32

Move buttons :

- Generate the Point Cloud

We will use 360-degree points for the 3d model, right click mouse and click Generate Point Cloud

Config the parameters:

- Combine the Model Points and Text Points

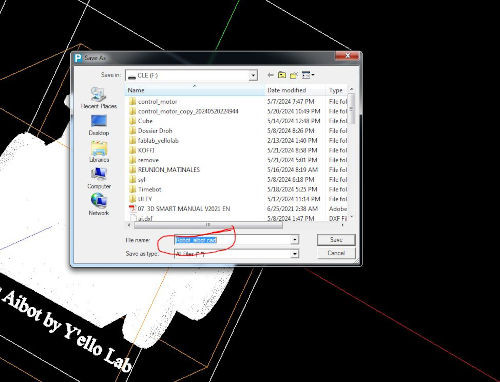

- Click on File > Export and give your file a noim by putting it in .cad format

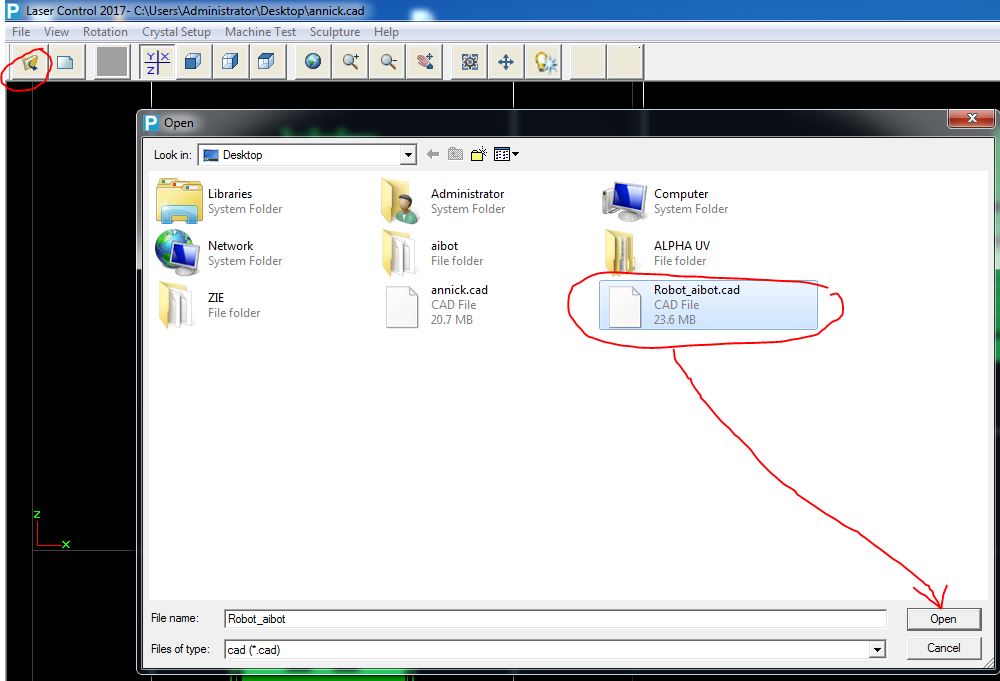

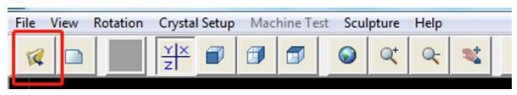

- Open Laser control software

open the file

Choose the file and click Open

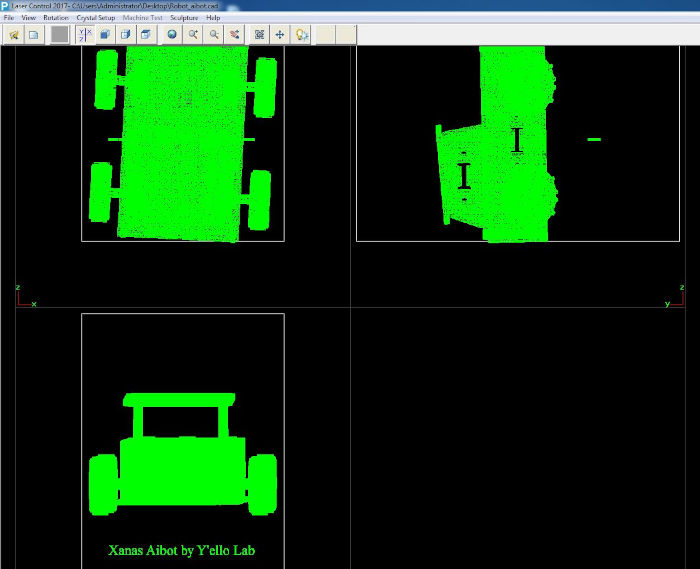

you must obtain the following

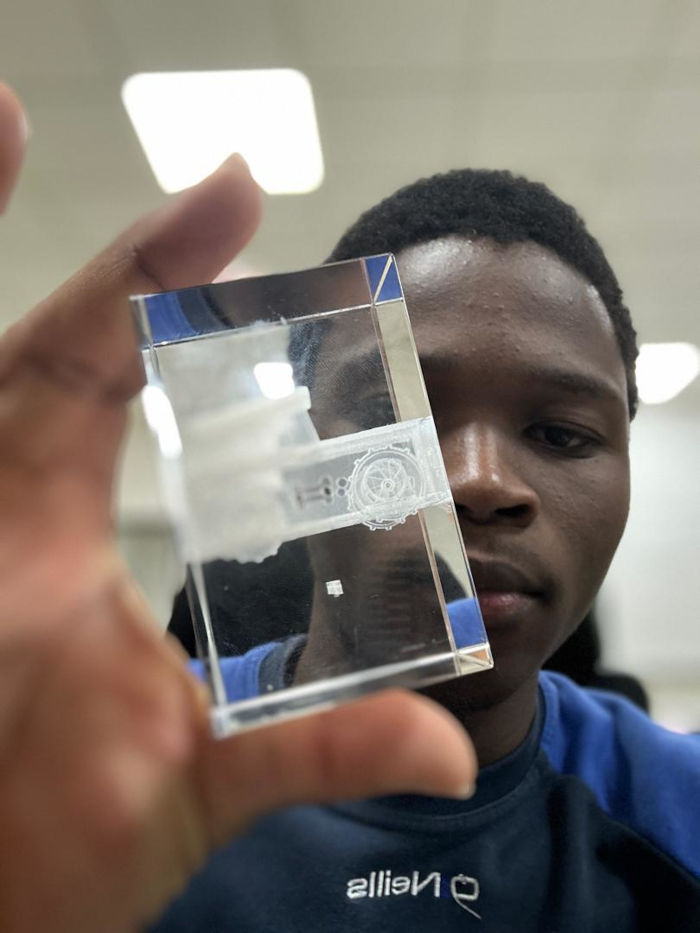

- We use 558 size crystal,press X/2 Y/2 Z/2 to set the center position.

Click the light button and press the Start

Movie

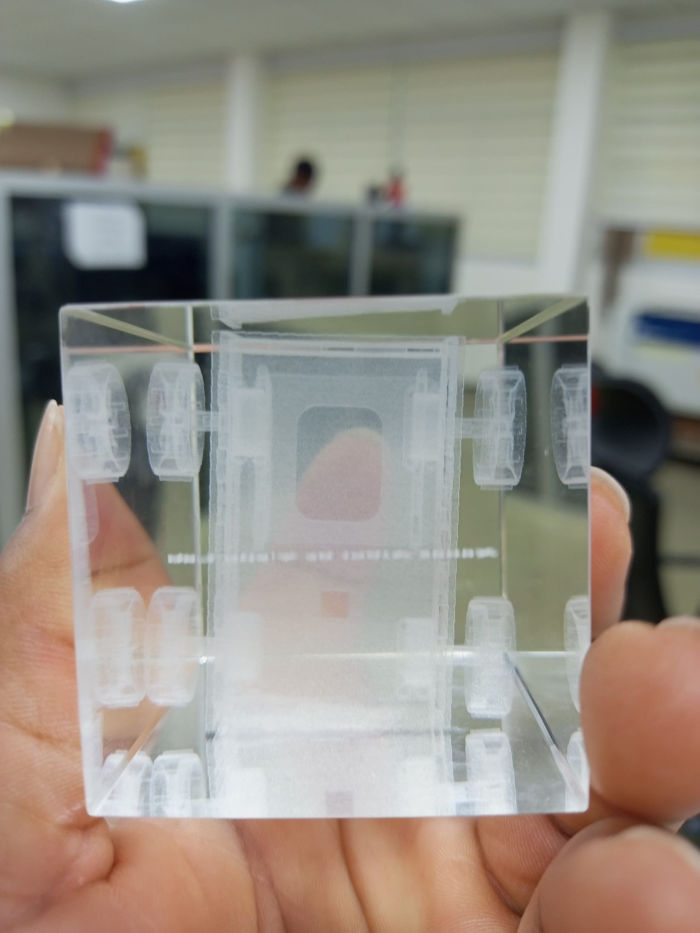

Photo of the hero¶

File¶

END