12. Molding & Casting¶

Group Assignment¶

Candlestick¶

So I thought for a long time what to do this week, since my original idea about the final project changed.But it so happened that one of my friends, who produces handmade candles, asked me to make a mold for a candlestick for her.

Design¶

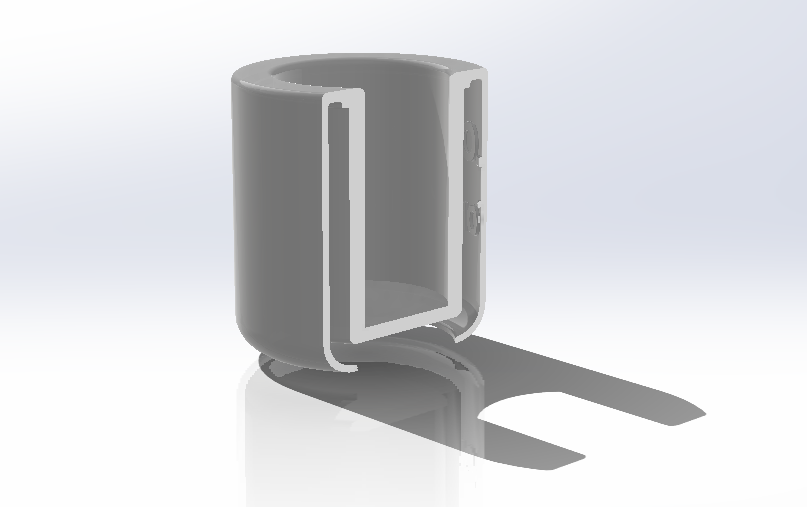

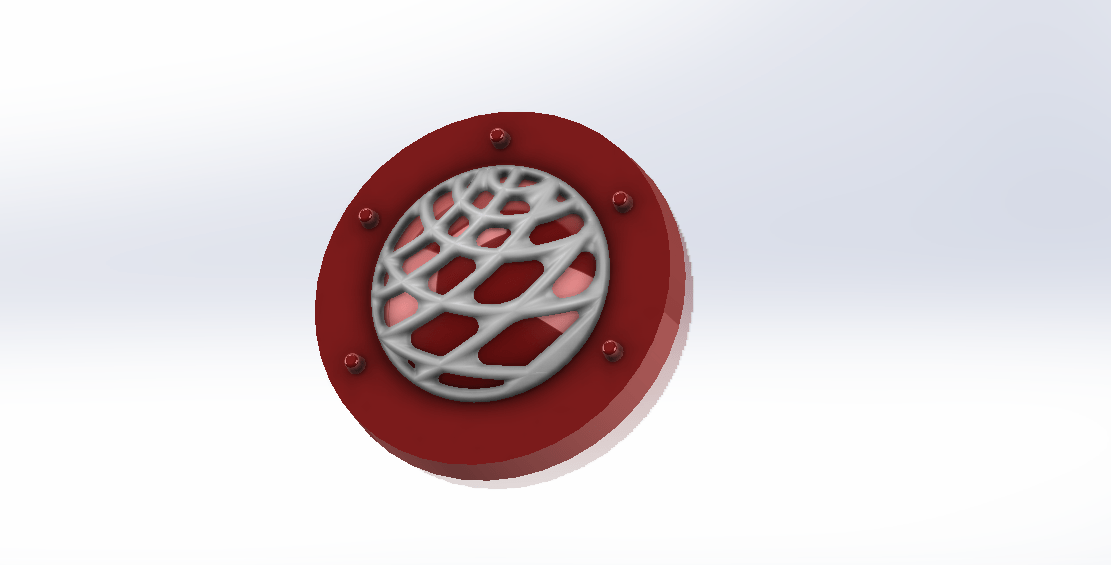

And so I started designing, first I made a model of a candlestick,

And so I started designing, first I made a model of a candlestick,

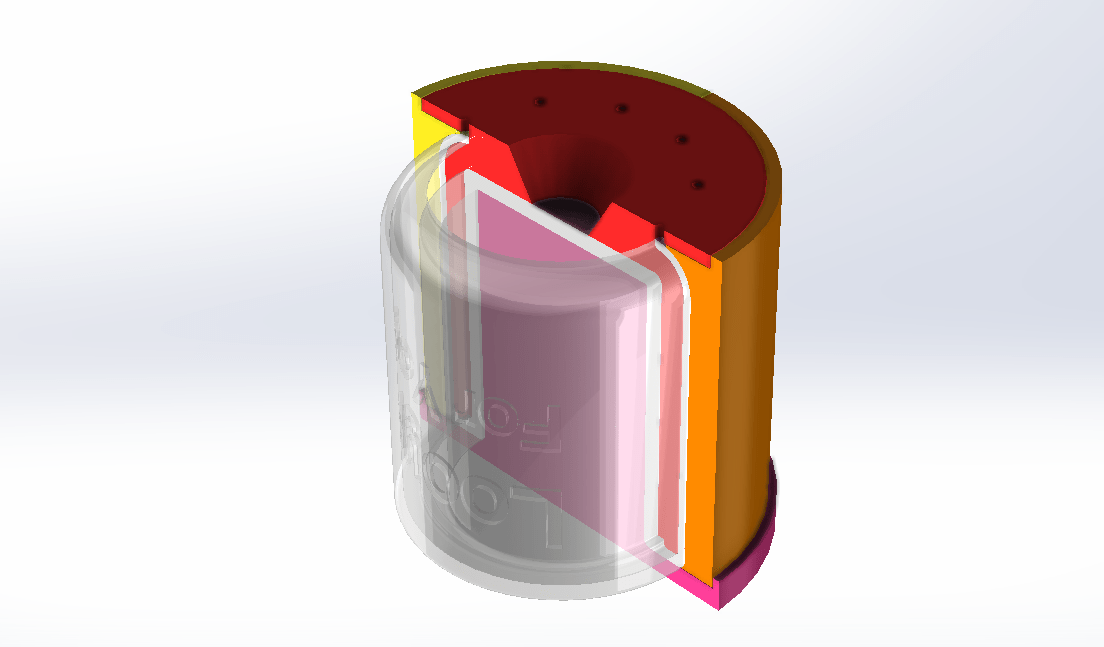

then based on this I designed a silicone mold,

then based on this I designed a silicone mold,

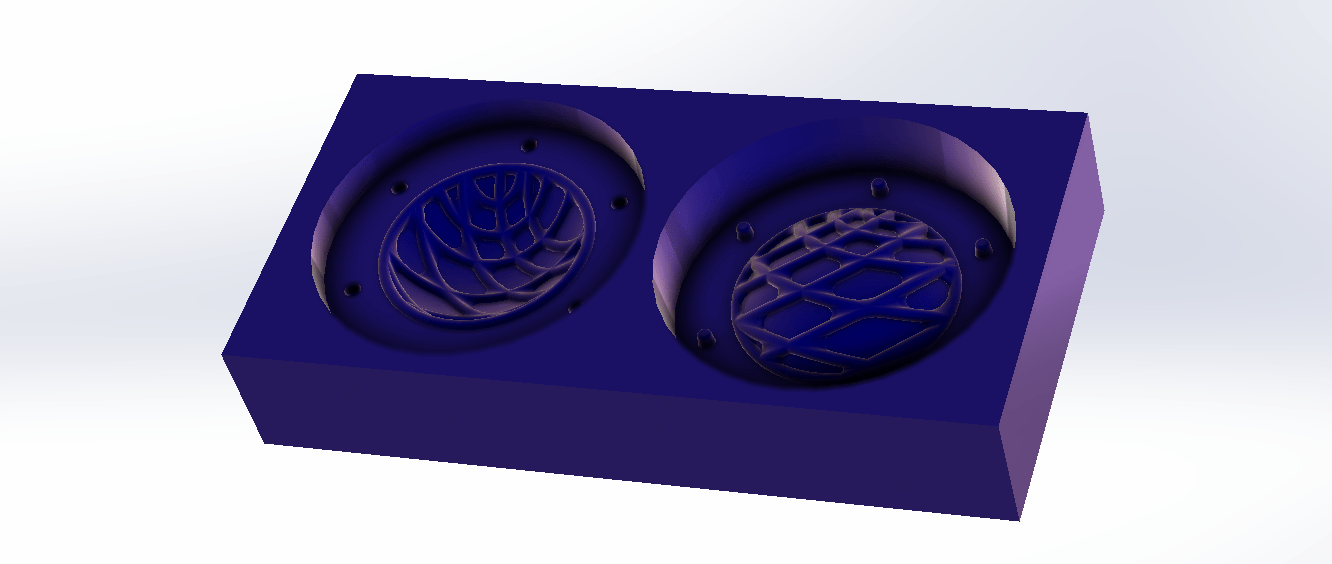

and since it was initially impossible to make it from silicone, I also designed a mold for silicone, which I will print on a 3D printer.

and since it was initially impossible to make it from silicone, I also designed a mold for silicone, which I will print on a 3D printer.

Mold’s 3D Printing¶

I then sliced it using the Cura slicer and printed it.The print came out good on the first try.

So I have a 4 piece mold.

So I have a 4 piece mold.

Casting of Silicone Mold¶

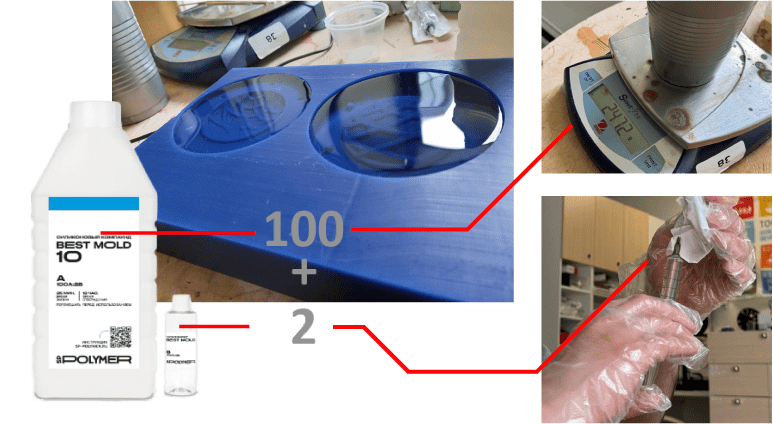

Then I started the process of casting the mold with silicone.

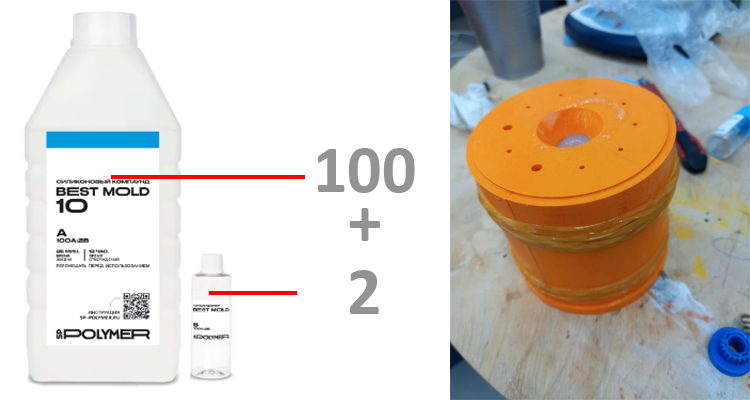

For casting I used BEST MOLD 10 silicone with the highest elasticity

So, to use this silicone, you need to mix component A with component B in a ratio of 100 to 2.

So, to use this silicone, you need to mix component A with component B in a ratio of 100 to 2.

Conclusion¶

In general, you saw the result. It didn’t work out very well for me because this mold is intended for silicone of lower viscosity, you can pour liquid plastic into it and it will work perfectly. And with this material you need to either leave thicker walls with larger holes for pouring or use another technique for pouring, for example indentation. In the future, I will design a new mold more convenient for silicone.

Jewelry¶

Design¶

Mold Milling- from Wax¶

Toolpath Creating¶

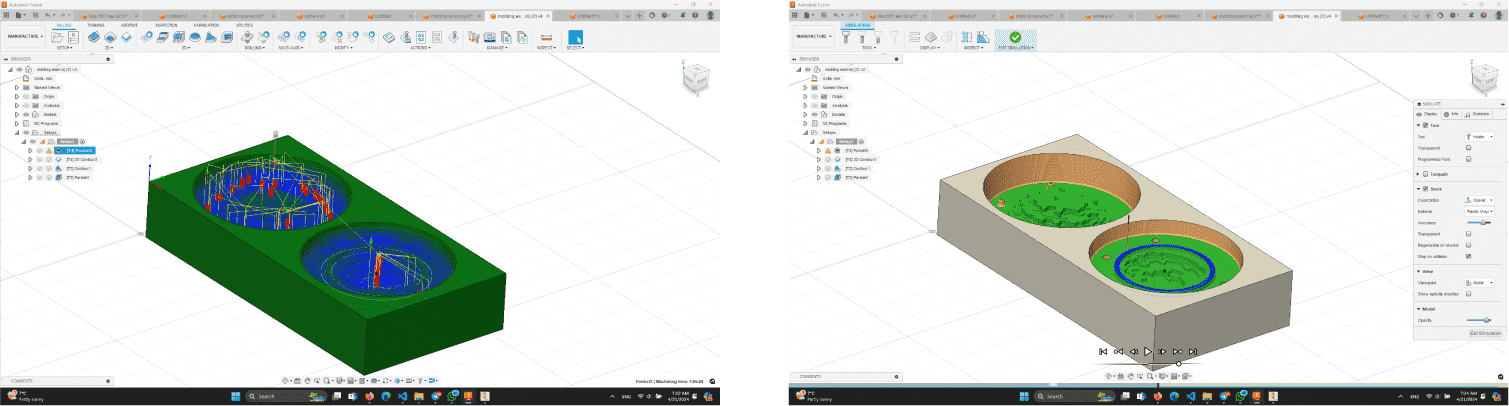

I created the toolpaths in Fusion 360.

Rough Milling

FInal milling

In final cutting I used the 1/8” 4 Flute Solid Carbide Ball Nose Long for flat surfaces.

And for small rounded surfaces i use the 1/32” 2 Flute Solid Carbide Ball Nose

I went a little overboard with the rough milling, but I liked it, so I left it that way.

I went a little overboard with the rough milling, but I liked it, so I left it that way.

Mold’s Casting- from Silicone¶

Final casting - From liquid plastic.¶

Casting - From Wax.¶

So this wax had a large shrinkage and this was visible with the first pour, about five percent.

The second attempt was more successful because I not only put wax into it, but also pressed it with the second mold.

So this wax had a large shrinkage and this was visible with the first pour, about five percent.

The second attempt was more successful because I not only put wax into it, but also pressed it with the second mold.

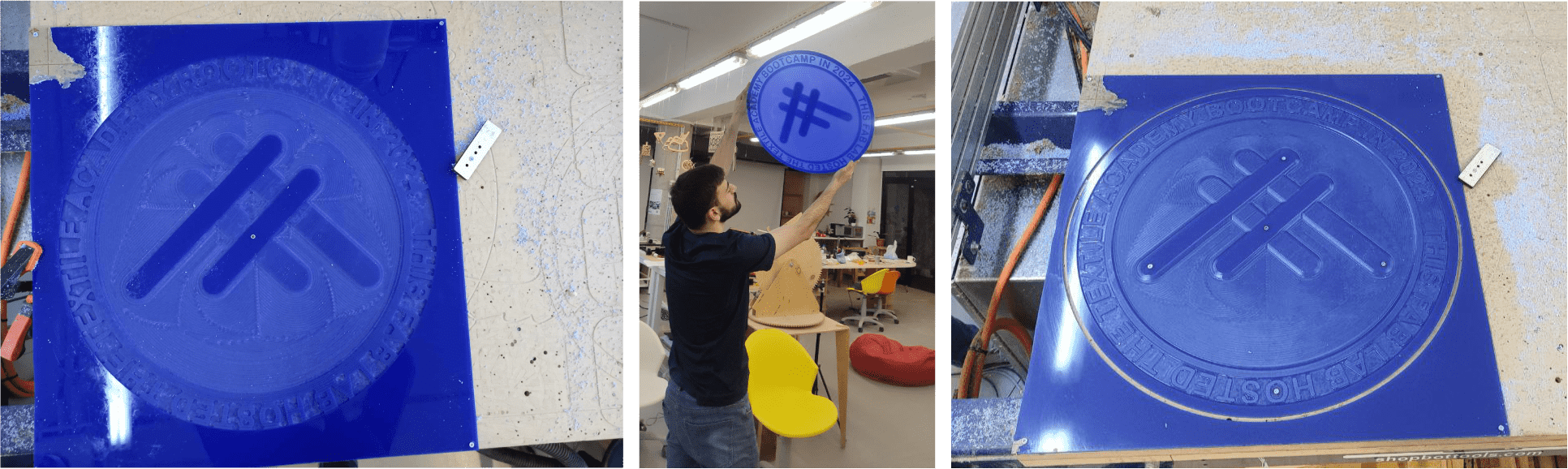

Manhole¶

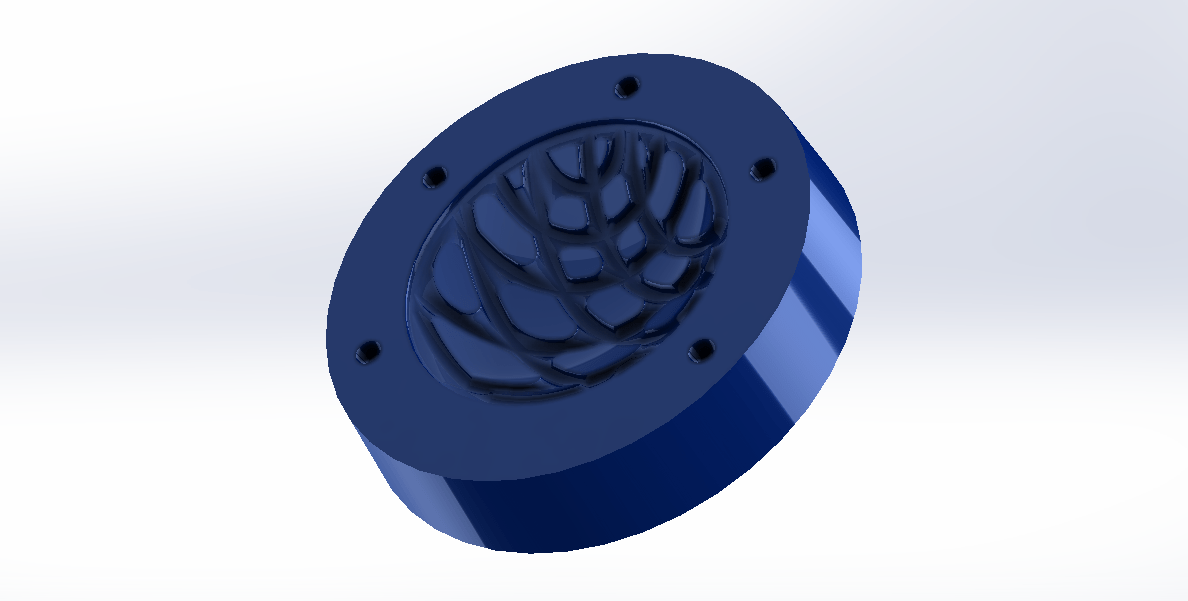

Design¶

Model Milling- from Acrylic¶

Sand Molding¶