Week 10: Machine Building

We decided to build a machine that has an ultrasonic welder attached, so it can melt plastics together - to simplify the making of inflatables.

|

|

The two pictures above were not taken by me, and are from our group assignment page.

The whole process is documented on our group assignment page, which can be found here.

Individual contribution

I helped out with building the Acre 1010 machine set based on the instructions from OpenBuilds. I also explored the OpenBuilds CONTROL software (Figure 3).

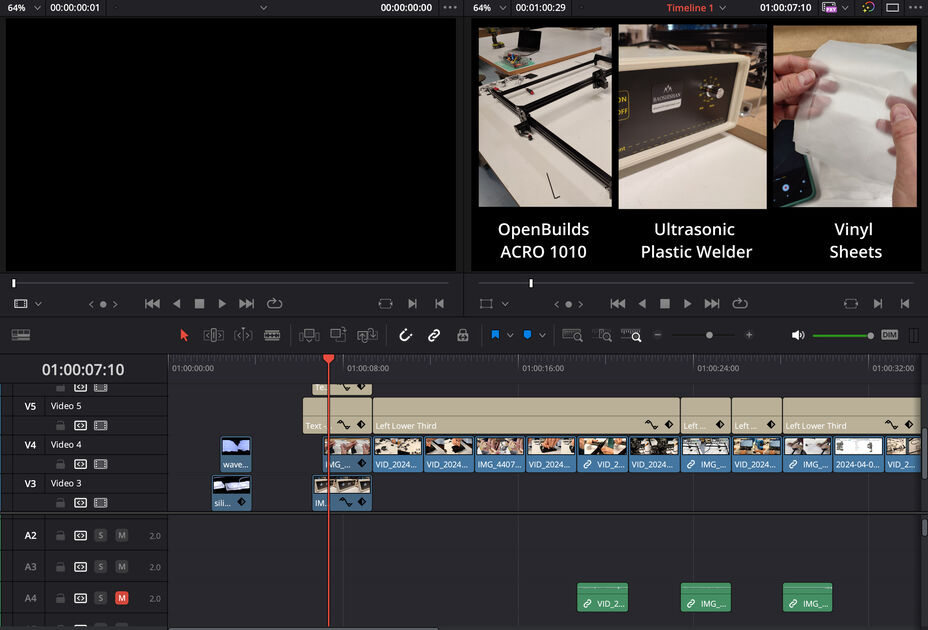

I partially documented the progress and I made the final video presented during Global lecture. It was made using DaVinci Resolve (Figure 4). It was my first time using this specific software, and I really liked it -> it was quite intuitive, free and there were many cool features!

After we built the acre part of the machine, we left it on for a bit while doing something else. After a while, we started to smell burned plastic - I touched stepper motor and burned myself. We then measured how hot they are, and it was something like 98 degrees - they were overheating! After reading online for a bit, it seemed like there is too much current going through them. Thankfully the OpenBuilds have this current regulator on their BlackBox (on Figure 5). We adjusted current on most of the stepper motors, so now they don’t get hotter than 45 degrees. We didn’t notice any change in performance of the machine.

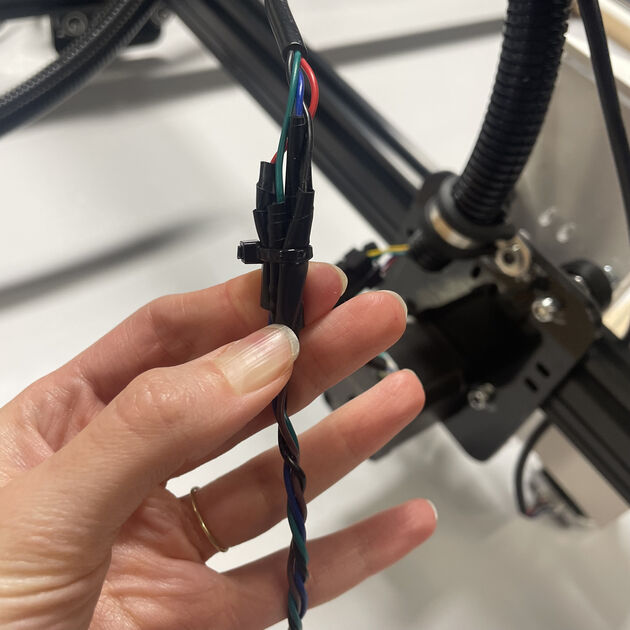

I also soldered a long cable for the extruder motor.