Week 6: Electronic design

group project: use the test equipment in your lab to observe the operation of a microcontroller circuit boardindividual project: design a development board to interact and communicate with an embedded microcontroller

extra credit : try another design workflow

extra credit : make a case for it

extra credit : simulate its operation

- For our Lab, the group Assignments can be found:

- The individual assignment for this week happened as follows:

- Installing the software that does the PCB design.

- Choice of the microcontroller unit to interact with.

- Designing the schematic for the circuit.

- Converting the Schematic into the Board.

- Programming the interaction i would have with the MCU.

- Interacting with the circuit in the simulator.

INTRODUCTION TO PCB DESIGN

CIRCUIT GENERATIONS:

FIRST GENERATION - WIRED CONNECTIONS

SECOND GENERATION - PRINTED CIRCUIT BOARDS

THIRD GENERATION - IC DESIGNING (VLSI)

First Generation description:

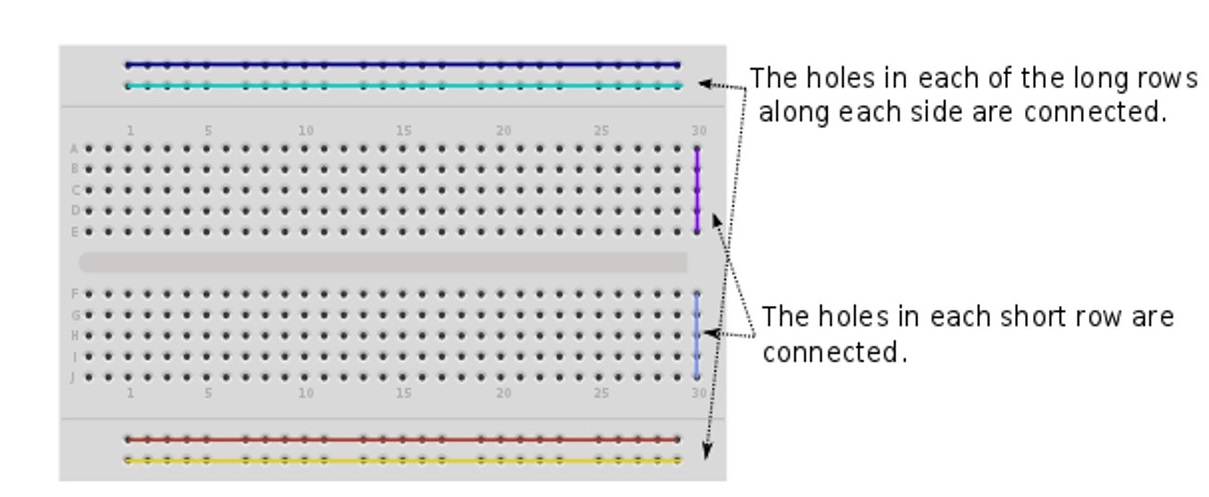

the breadboard's internal orientation and CONNECTIONS:

the breadboard's internal orientation and CONNECTIONS:

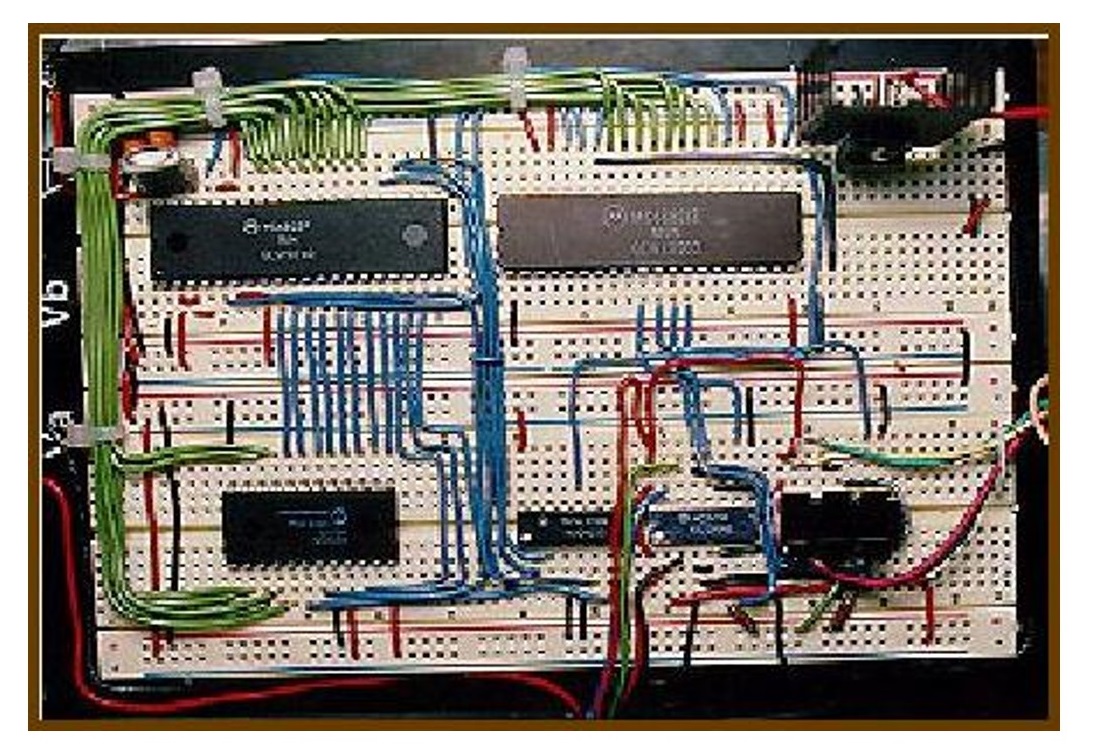

However, this carries a limitation in how many components it can host, also wires make a mess. Not to mention that over the time,

connection holes wear out and become loose.

However, this carries a limitation in how many components it can host, also wires make a mess. Not to mention that over the time,

connection holes wear out and become loose.

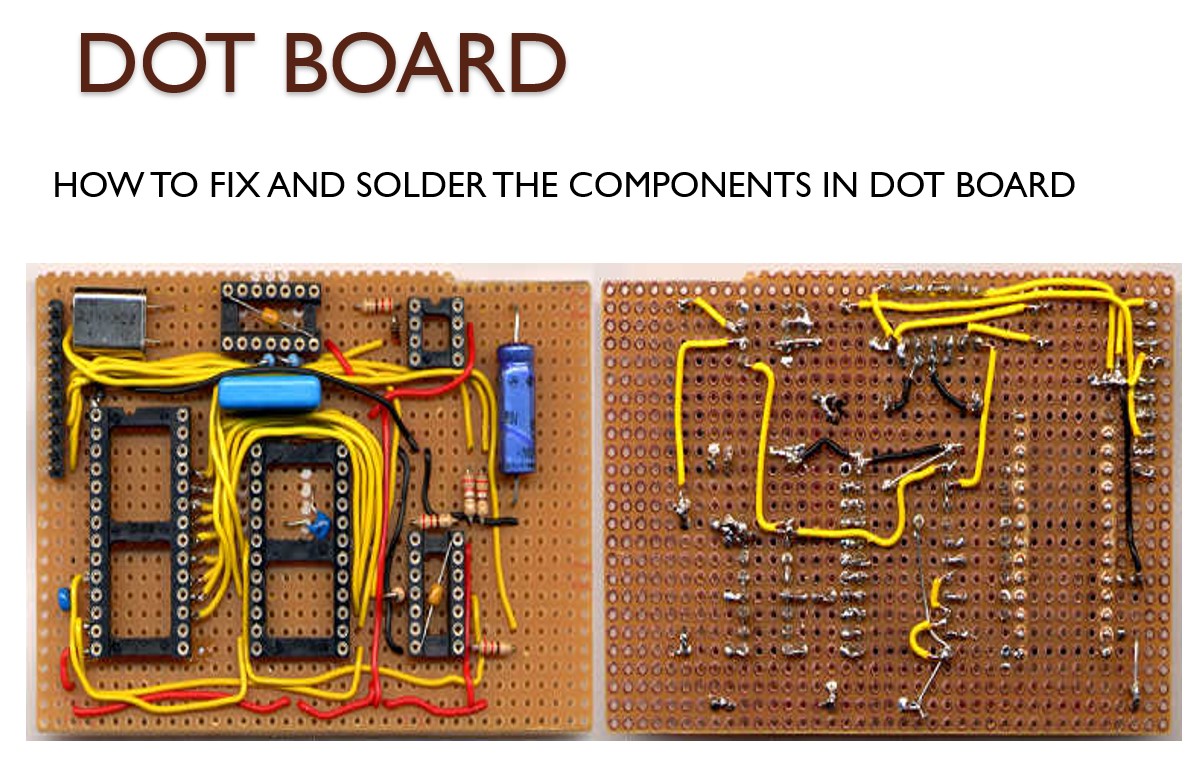

the Dot matrix was no different in terms of complexion adaptability

the Dot matrix was no different in terms of complexion adaptability

SECOND GENERATION description

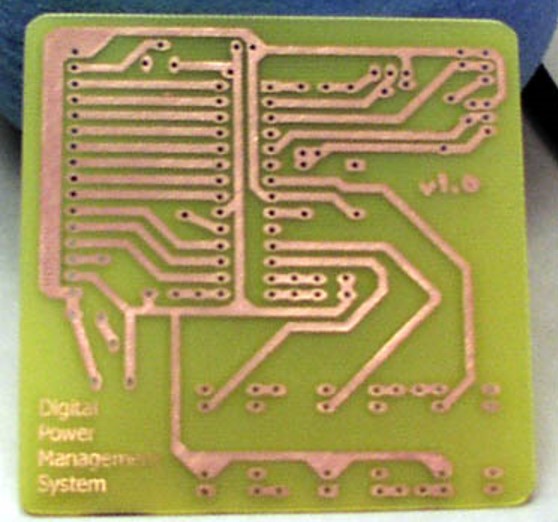

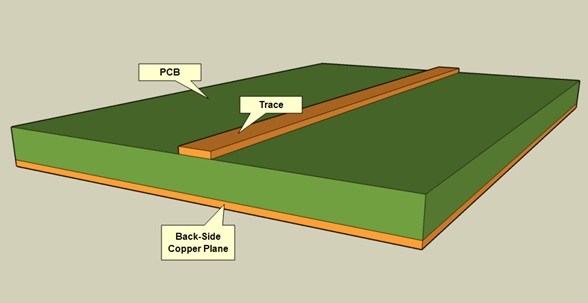

PCB: A flat plate or base of insulating material containing a pattern of conducting material (Copper) in it

SECOND GENERATION description

PCB: A flat plate or base of insulating material containing a pattern of conducting material (Copper) in it

Now a days, we are using different software to design PCB

EAGLE

ORCAD

FREE PCB

EXPRESS PCB

PROTEL

TINA

KiCad

proteus ISIS professional and many more,...

Now a days, we are using different software to design PCB

EAGLE

ORCAD

FREE PCB

EXPRESS PCB

PROTEL

TINA

KiCad

proteus ISIS professional and many more,...

ADVANTAGES:

- many circuits can be etched simultaneously,

- Compact circuit design can be achieved,

- Wire connections are not necessary,

- Easily understandable circuits.

DISADVANTAGES:

- Once designed and etched, we can not change the circuit easily

Have to redesign and to etch the new circuit in different copper board

- Harmful chemicals are used for PCB manufacturing

GLASS EPOXY BOARD (SILK SCREEN BOARD):

Glass epoxy board is fixed back to copper plate.

This board is preferred while design circuits that carry large currents.

Types of PCB:

SINGLE LAYER PCB: Components are mounted on one side of the board and the conductor pattern on the other side.Suitable for simple circuits only

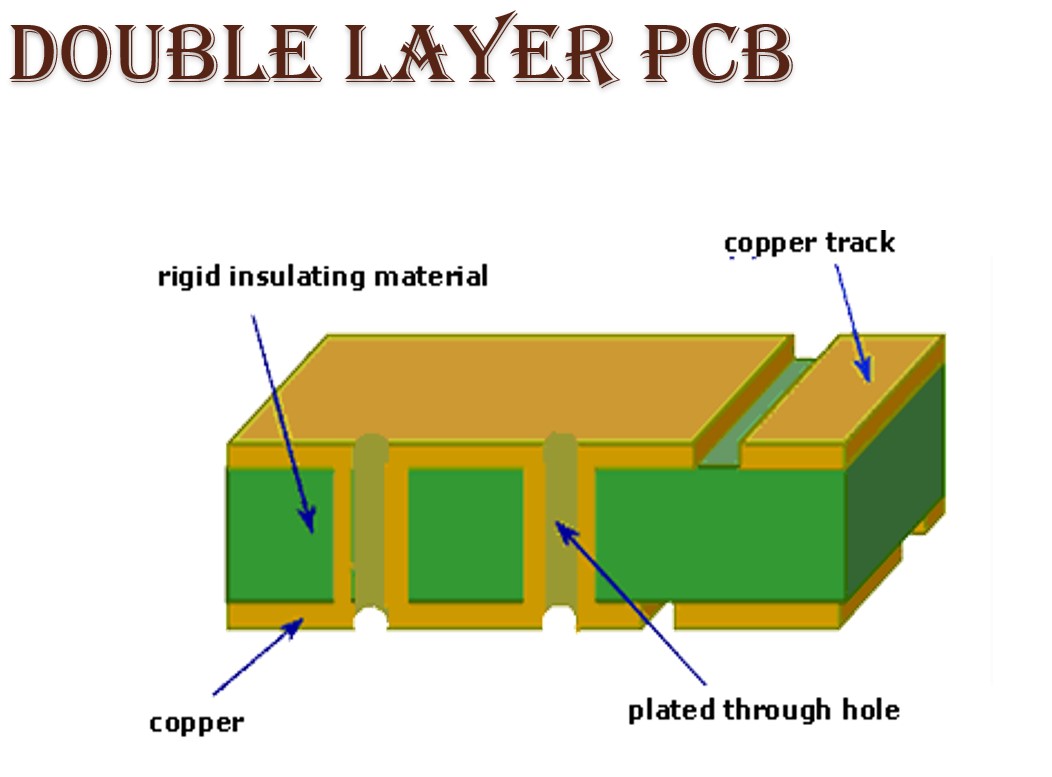

DOUBLE LAYER PCB:They have twice the area for the conductor pattern compared to single-sided PCBs

Having conductor pattern on both sides of the board

Top layer conductor pattern and bottom layer conductor pattern are connected by vias

The vias described in Double-sided PCBs always penetrate the whole board.

Types of PCB:

SINGLE LAYER PCB: Components are mounted on one side of the board and the conductor pattern on the other side.Suitable for simple circuits only

DOUBLE LAYER PCB:They have twice the area for the conductor pattern compared to single-sided PCBs

Having conductor pattern on both sides of the board

Top layer conductor pattern and bottom layer conductor pattern are connected by vias

The vias described in Double-sided PCBs always penetrate the whole board.

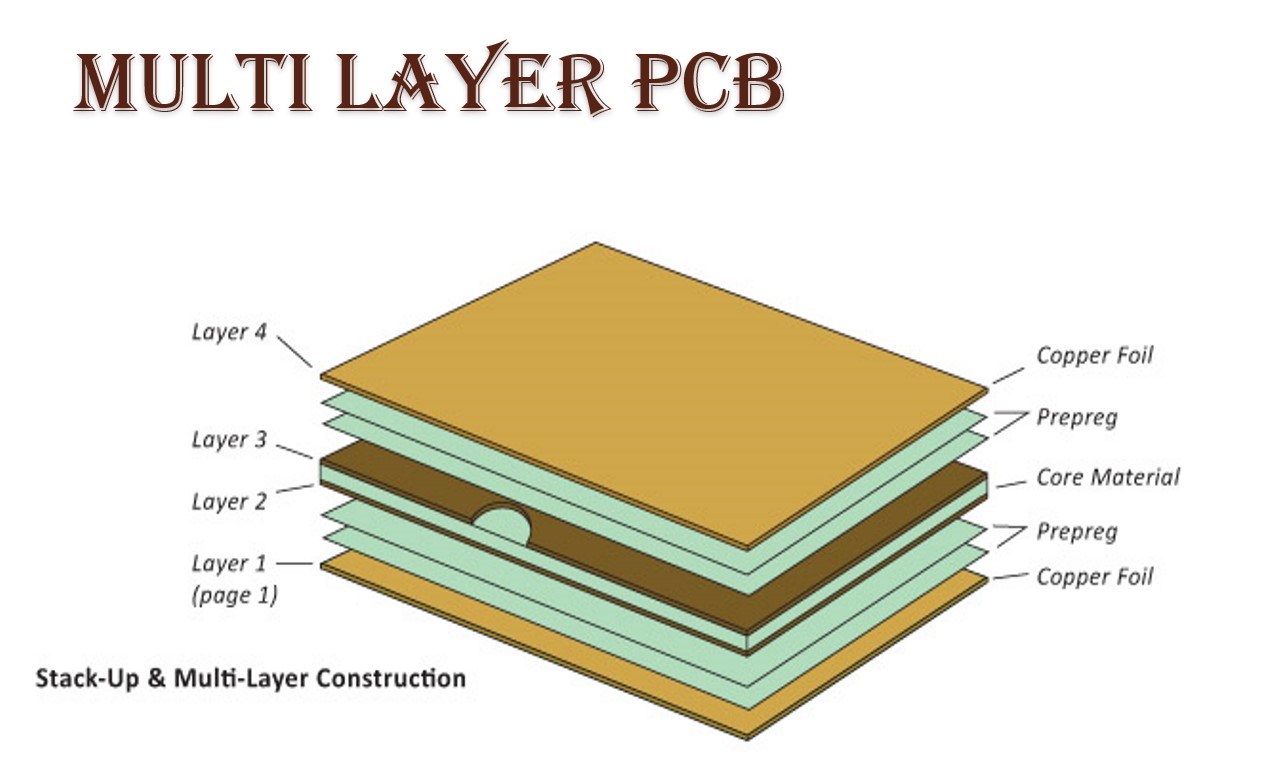

MULTI LAYER PCB: Having more than two conductor pattern inside the board

To minimize the PCB board size

They are made by gluing (laminating) several double-sided circuit boards together with insulating layers in between.

FACT: Almost 100 layers can be made

MULTI LAYER PCB: Having more than two conductor pattern inside the board

To minimize the PCB board size

They are made by gluing (laminating) several double-sided circuit boards together with insulating layers in between.

FACT: Almost 100 layers can be made

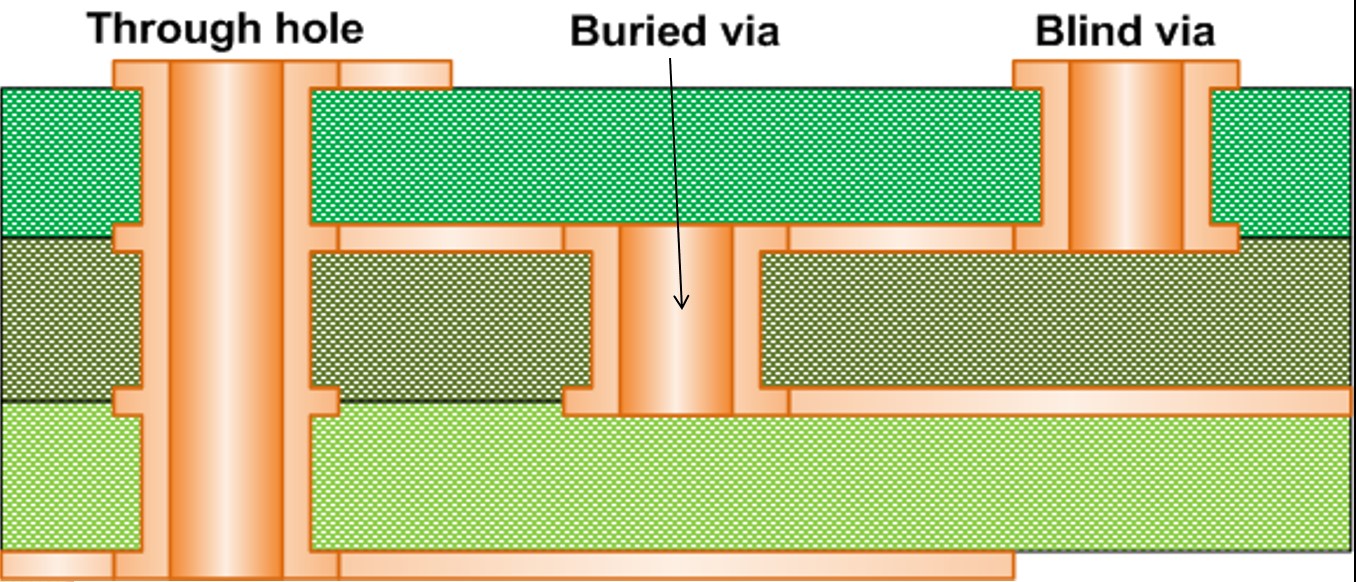

The vias described in multi layer PCBs do not penetrate the whole board, all the time.

Blind vias connect one or more of the inner layers with one of the surface layers, without penetrating the whole board.

Buried vias only connect inner layers so you can’t see them by looking at the surface of the PCB.

The vias described in multi layer PCBs do not penetrate the whole board, all the time.

Blind vias connect one or more of the inner layers with one of the surface layers, without penetrating the whole board.

Buried vias only connect inner layers so you can’t see them by looking at the surface of the PCB.

Now to the assignment's question one:

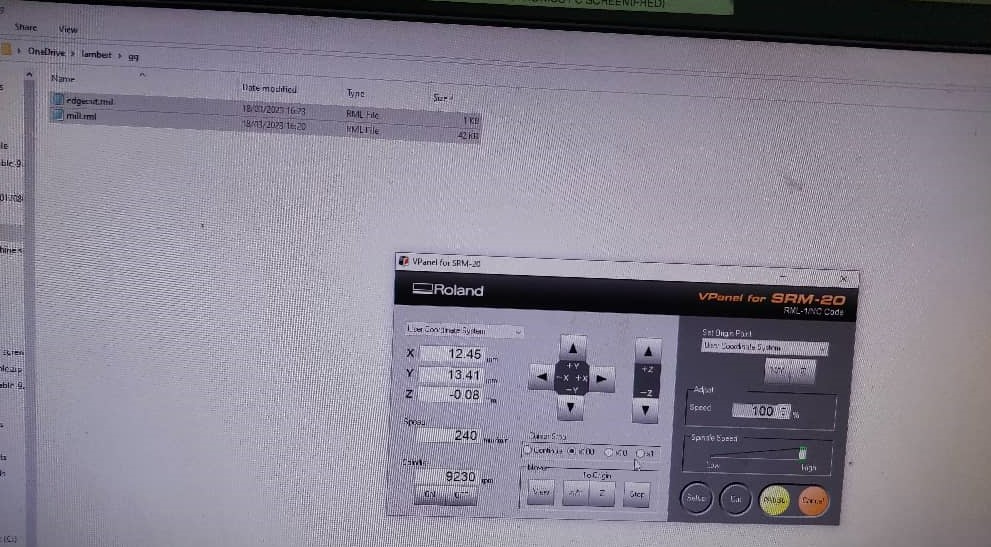

STEP1: Installing the software that does the PCB design.

Now to the assignment's question one:

STEP1: Installing the software that does the PCB design.

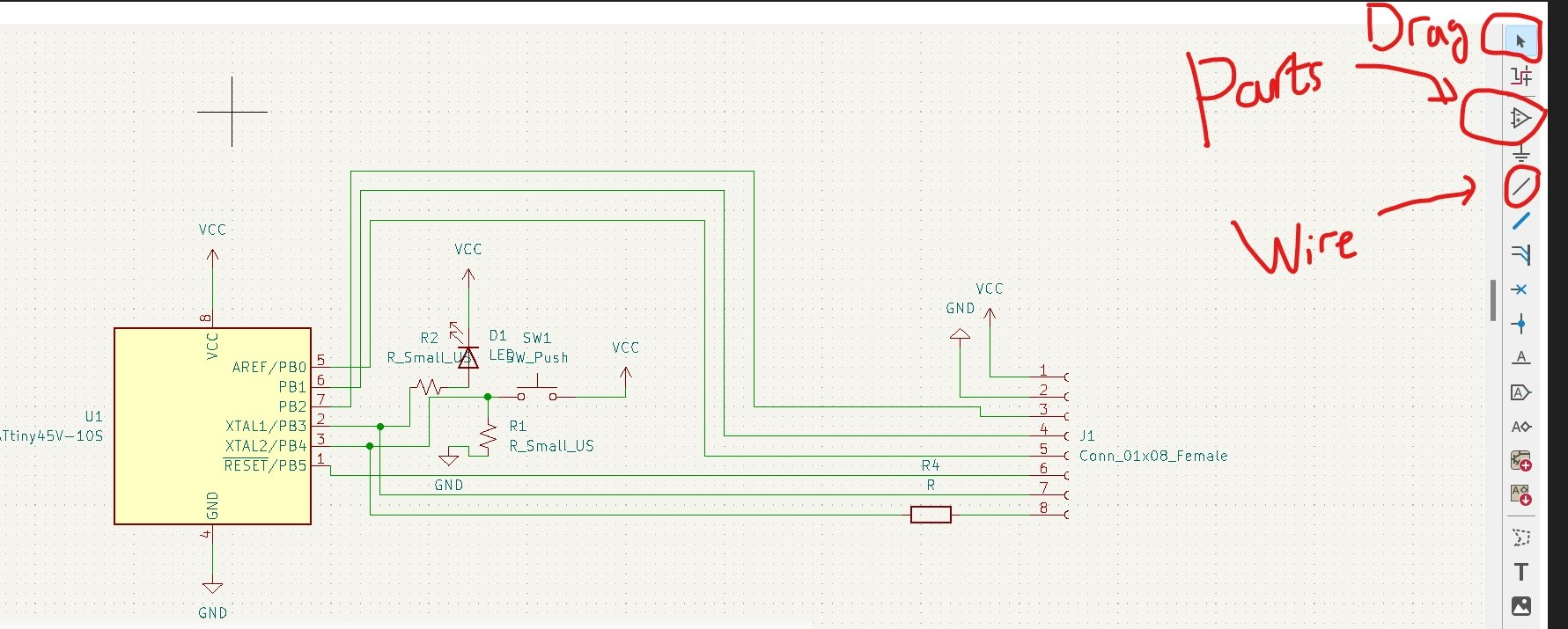

INTRODUCTION:I considered using many other software, especially those recommended in the class like Eagle PCB.

However, since there is a licence issue i chose to use KiCad that is free. I will demonstrate how i intalled it below:

- I downloaded the installation file from: kicad.org/download/windows/

- After unziping and installing, i straight went to opening Kicad File>New Project>nameit

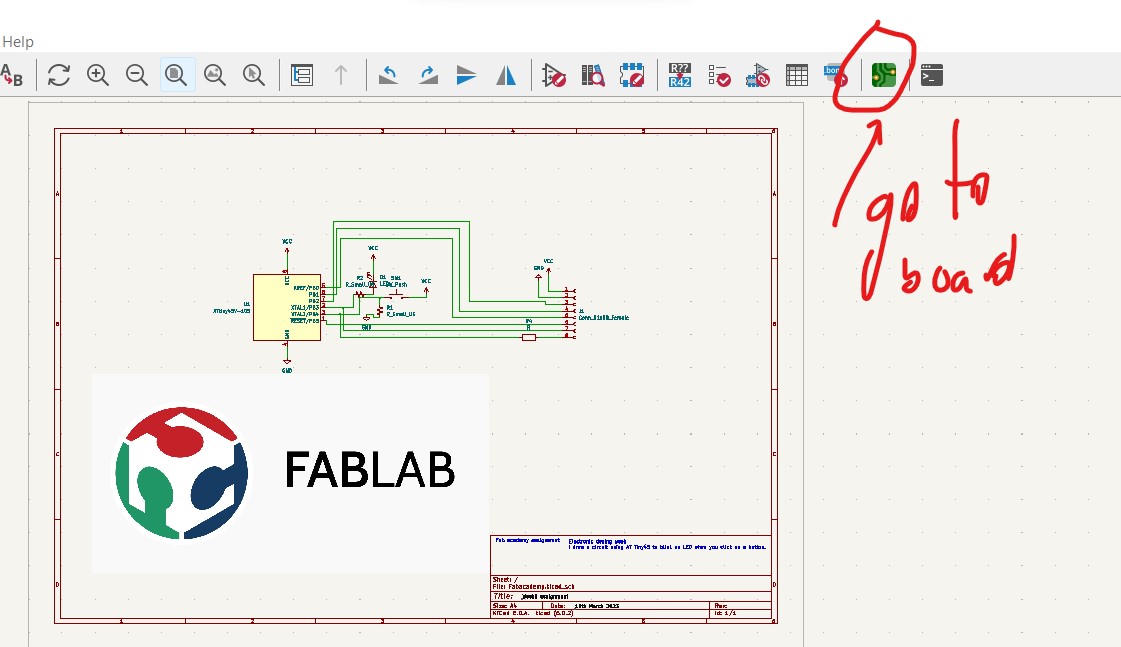

- I started with a schematid diagram

- i went on by fancying the design and edited the lablel

GOING TO THE BOARD AFTER ERROR CHECKS

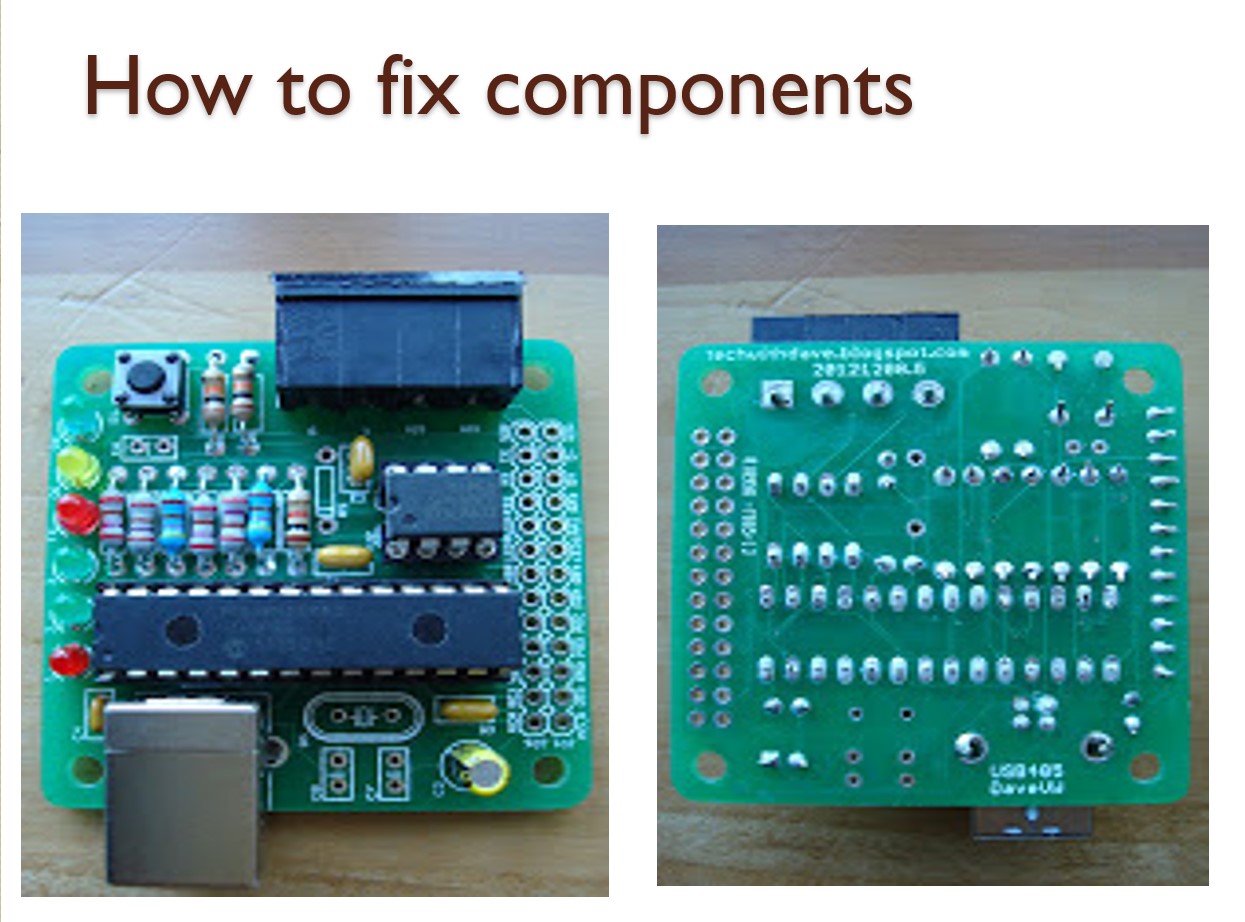

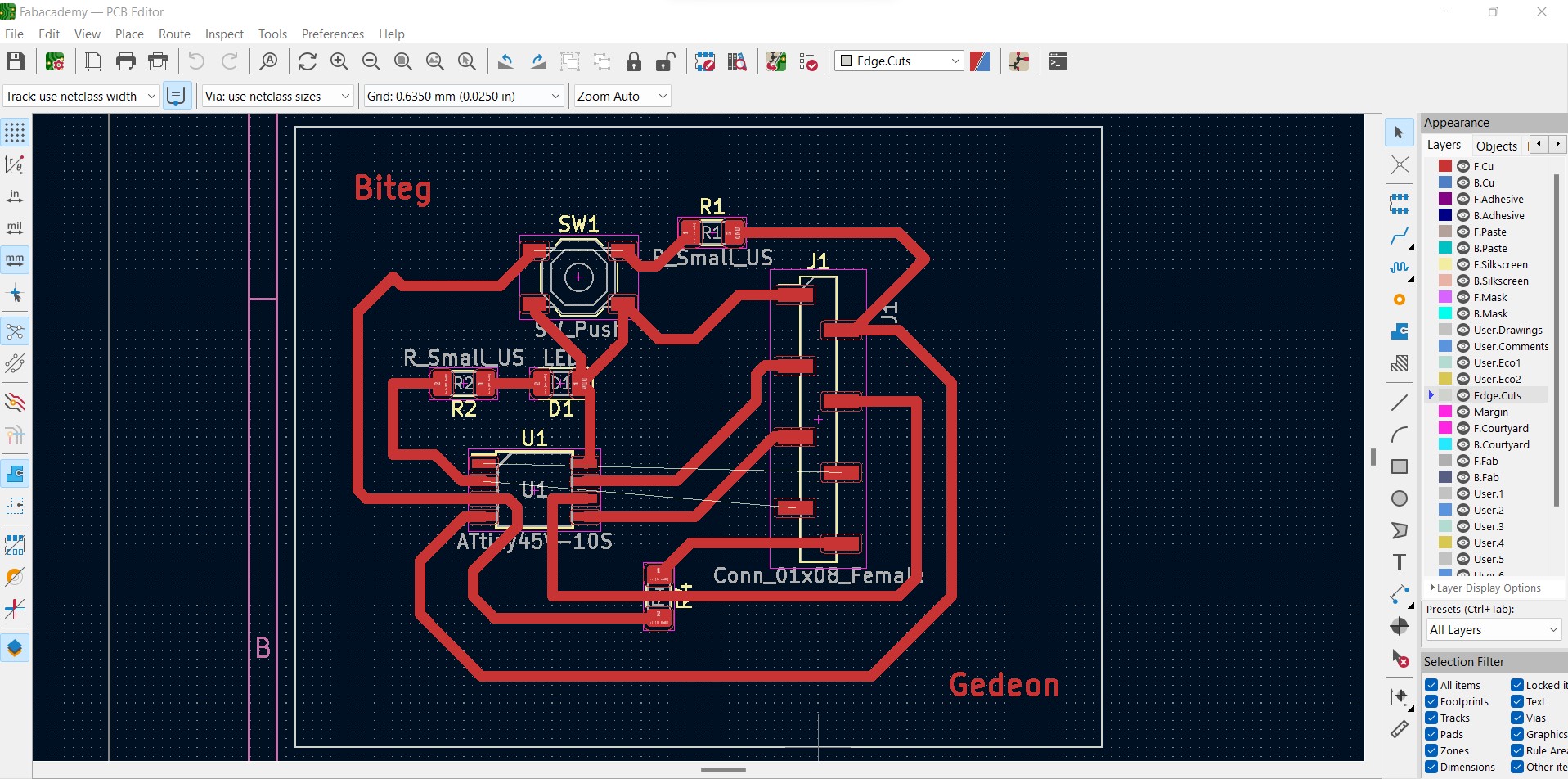

Click on the switch to board, drag and drop componets into the given space.

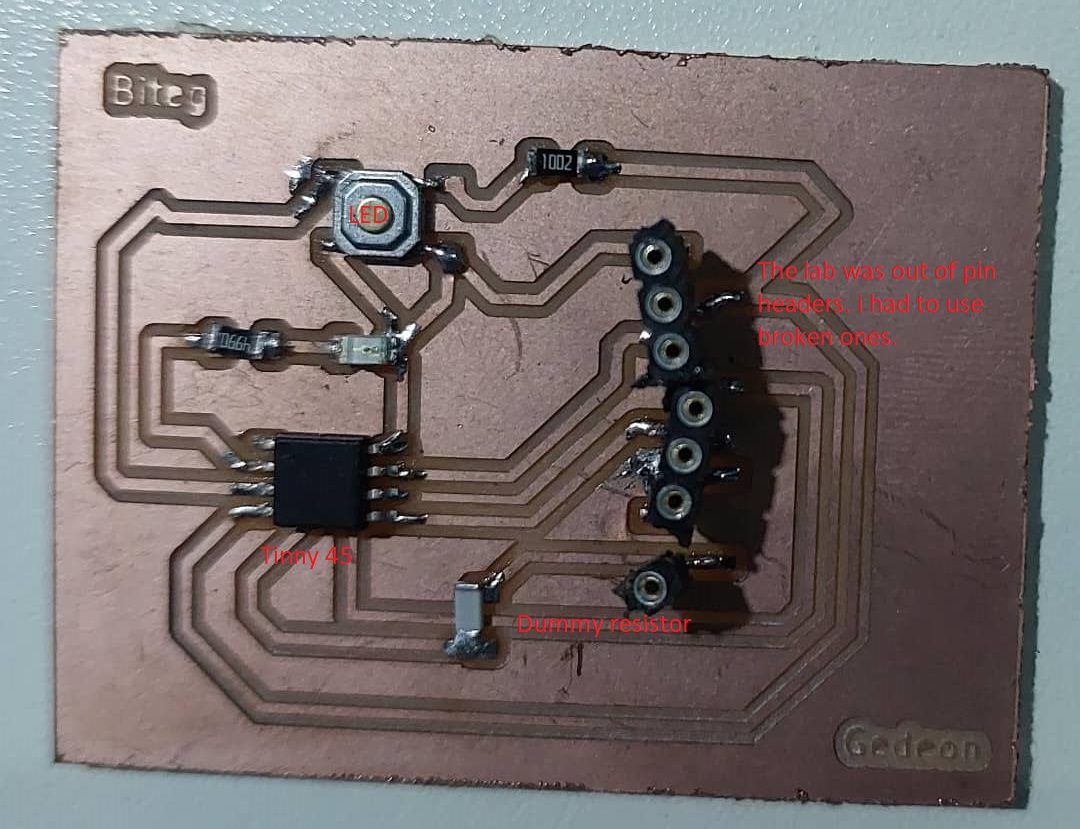

Since the Kicad software does not encourage the auto-trace way of doing things,

i had to manually route(add a wire) to each path.Plus we are supposed to use one side of the board.

As a consequence, there were two lines i couldn't wire without causing an error.

The trick is to add a 0Ohm resistor (dummy resistor) to allow crossing over the other line.

Setting the wire thichness also is importance as it results in the capacity to conduct electricity (resistance)

I uses 0.75mm as the thichness

Since the Kicad software does not encourage the auto-trace way of doing things,

i had to manually route(add a wire) to each path.Plus we are supposed to use one side of the board.

As a consequence, there were two lines i couldn't wire without causing an error.

The trick is to add a 0Ohm resistor (dummy resistor) to allow crossing over the other line.

Setting the wire thichness also is importance as it results in the capacity to conduct electricity (resistance)

I uses 0.75mm as the thichness

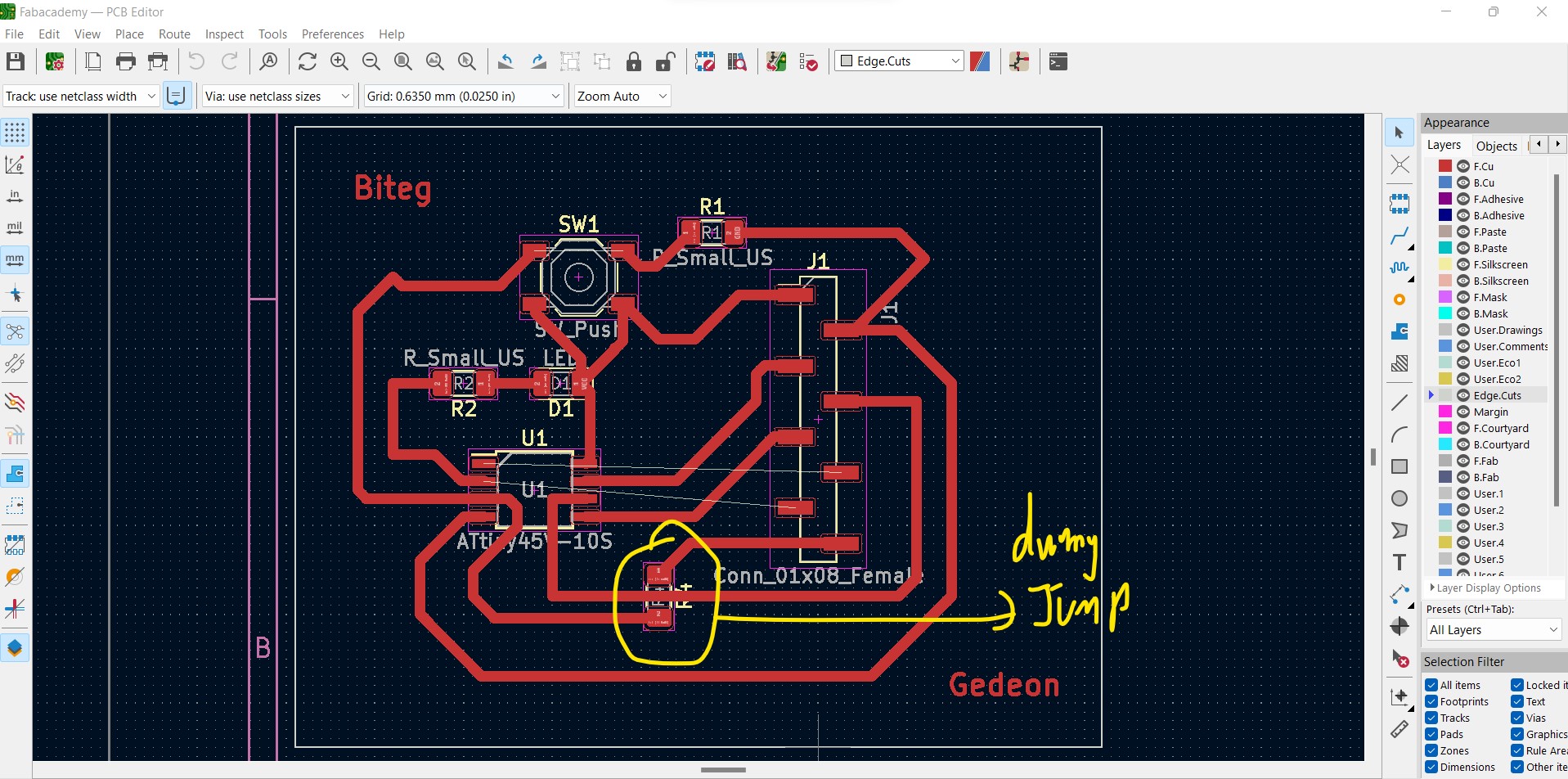

Here i show which resistor is dummy

Here i show which resistor is dummy

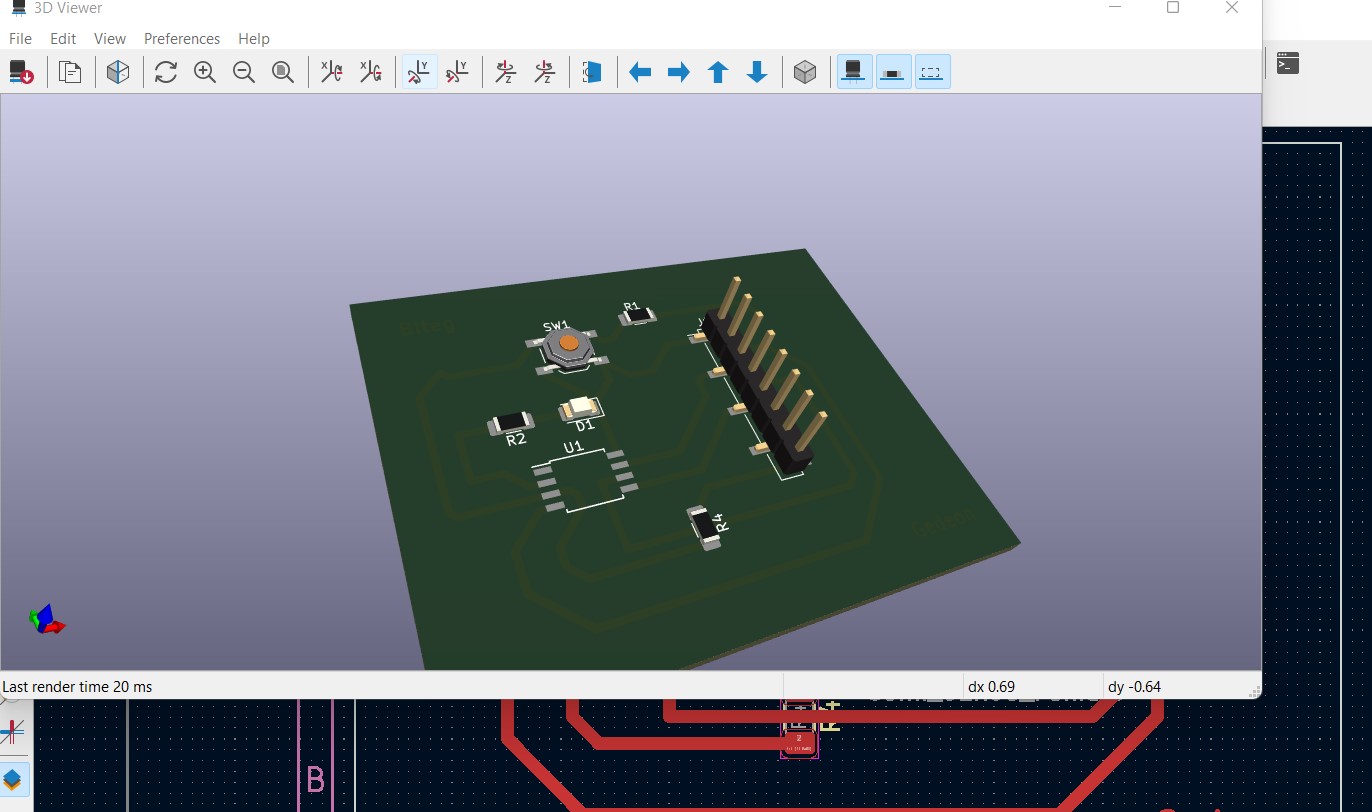

The 3D View of the expected PCB:

The 3D View of the expected PCB:

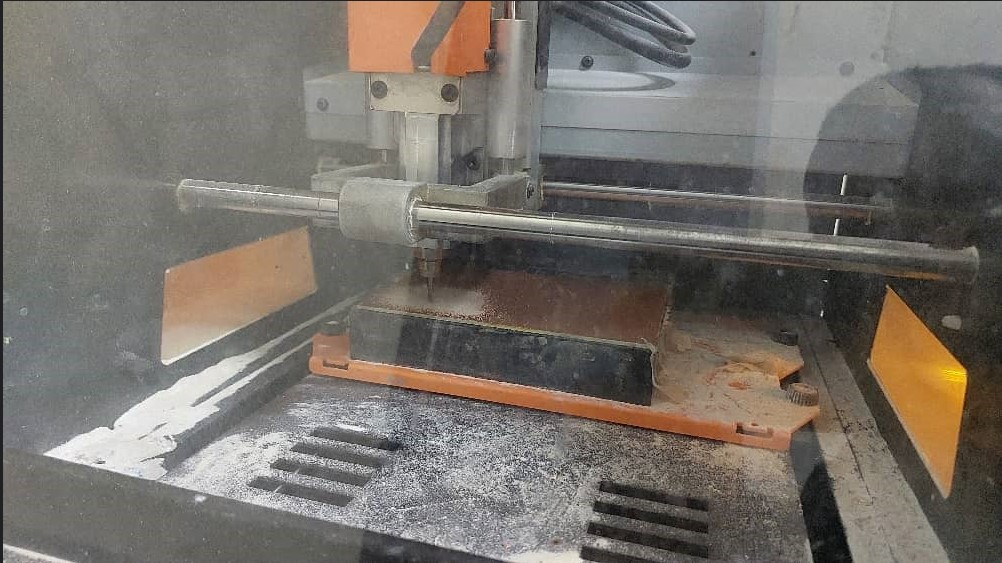

The next steps:

Setup the machine

The next steps:

Setup the machine

Print the board

Print the board

Clean it

Clean it

Solder components on and operate.

Solder components on and operate.

The details of the last few steps are in the assignment of Week8_Electronic_production

The details of the last few steps are in the assignment of Week8_Electronic_production

Files used

Schematic

Board

Traces in svg

Edge cuts in svg