Week 5: 3D Scanning and 3D printing

Group Assignments: https://fabacademy.org/2023/labs/rwanda/Group_Assignment/3D_Scanning_and_Printing.html or just click Here

Individual assignment:

- design and 3D print an object (small, few cm3, limited by printer time)

that could not be made subtractively

- 3D scan an object (and optionally print it)

Our local instructor advised us to design something with parts that move yet still connected.

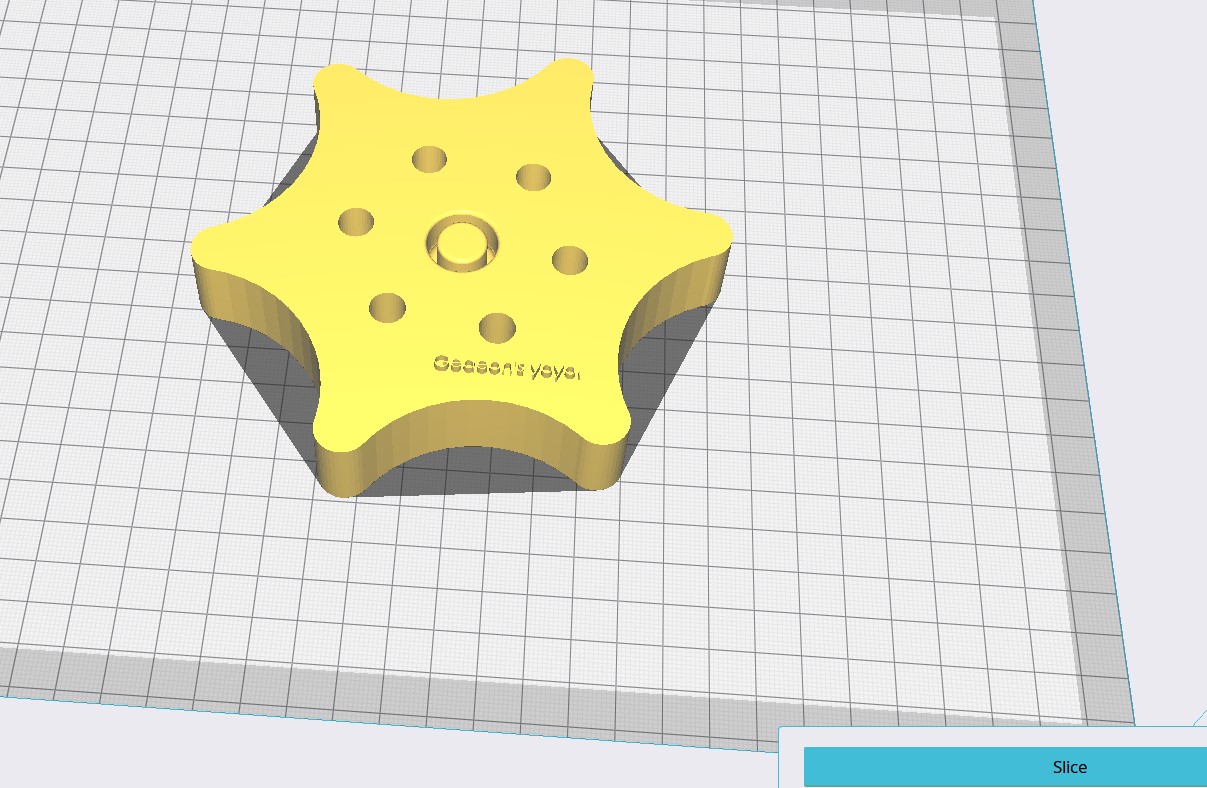

with the idea of a yo yo, i made something that has a central part which will move, rotated.

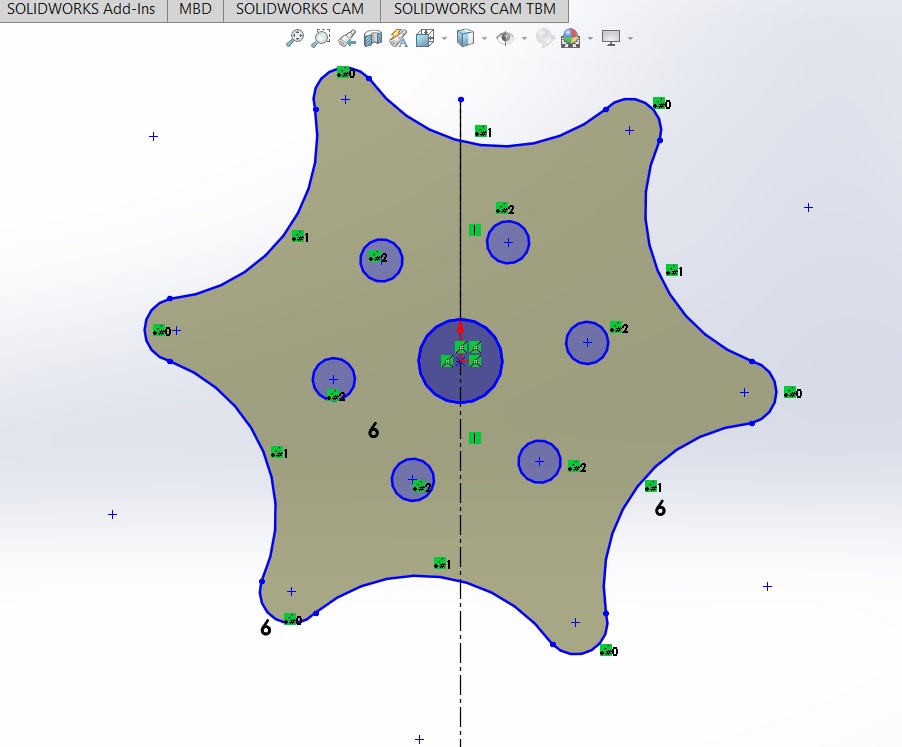

On the top plane, I started by sketching a circle, a 3point curve around the cicle,made it a circular partern (6).

Then i joined two curves with another curve and made 6 circular partern of that curve.

I made another (to be cut) circle and multiplied it by 6.

Then i extruded bross.

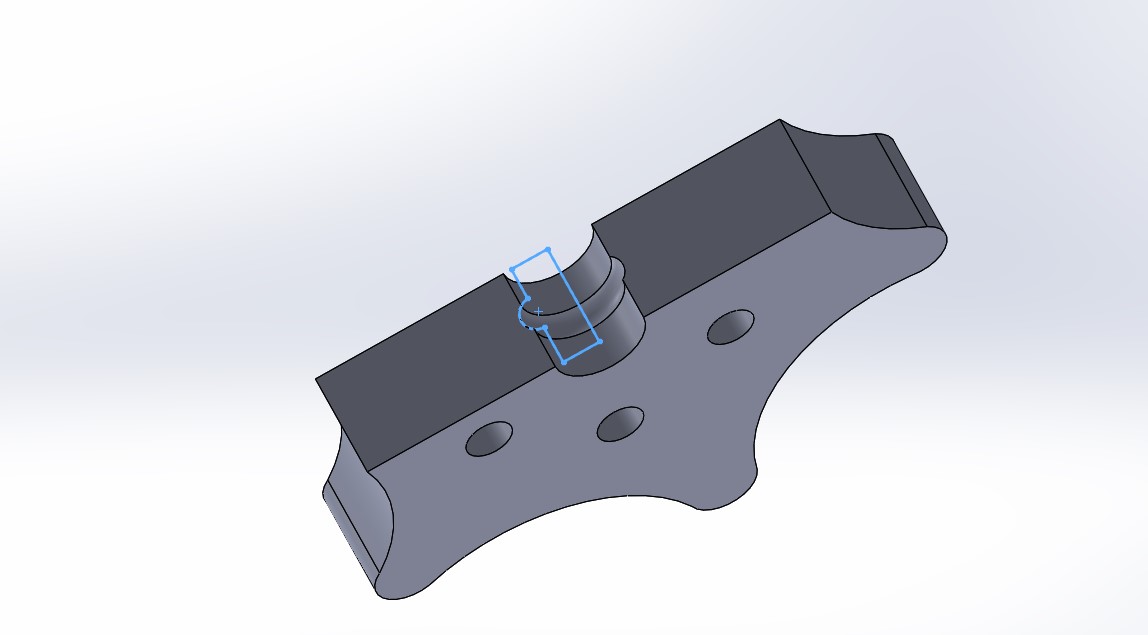

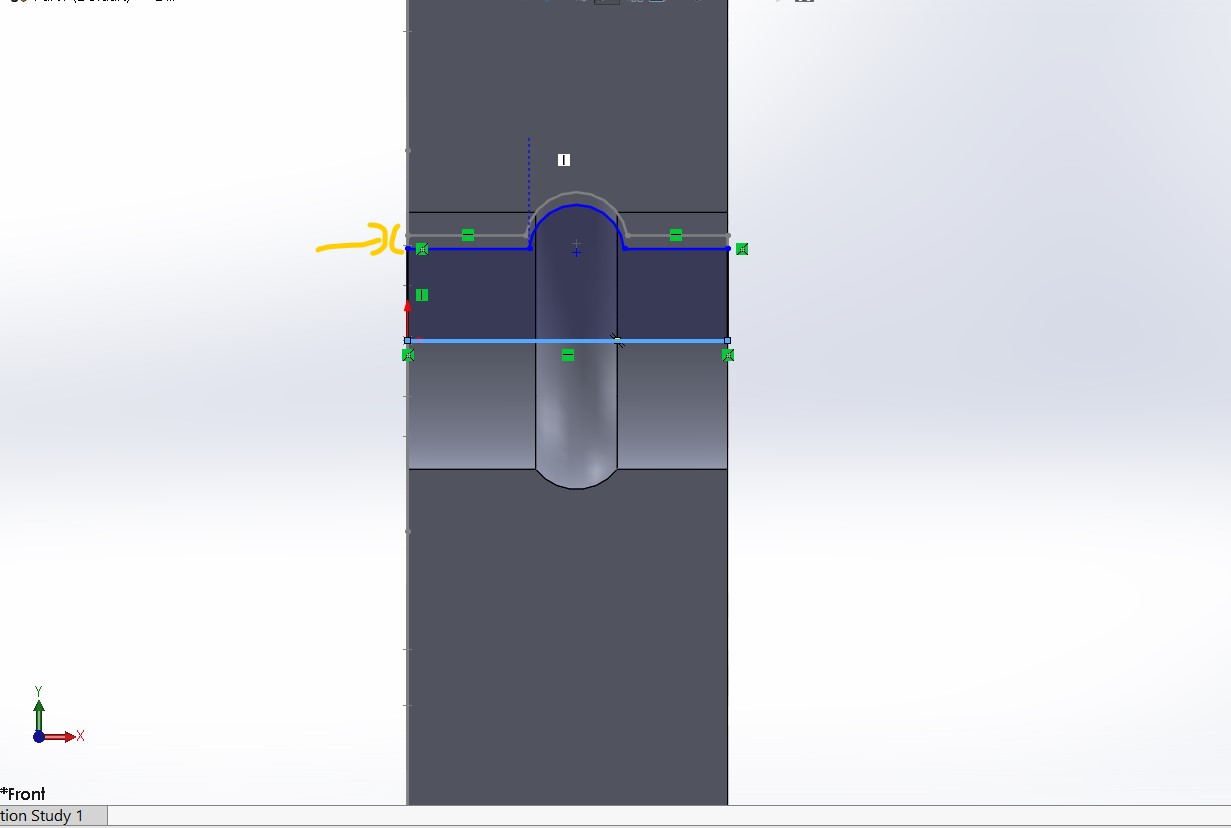

On the front plane, drew a center line, and sketched the contour that, when revolve-cut, will extract the trail of the inside peace.

Then i extruded bross.

On the front plane, drew a center line, and sketched the contour that, when revolve-cut, will extract the trail of the inside peace.

Then i drew a similar shape with a little bit of clearance.

Then revolve extruded the inside.

Then i drew a similar shape with a little bit of clearance.

Then revolve extruded the inside.

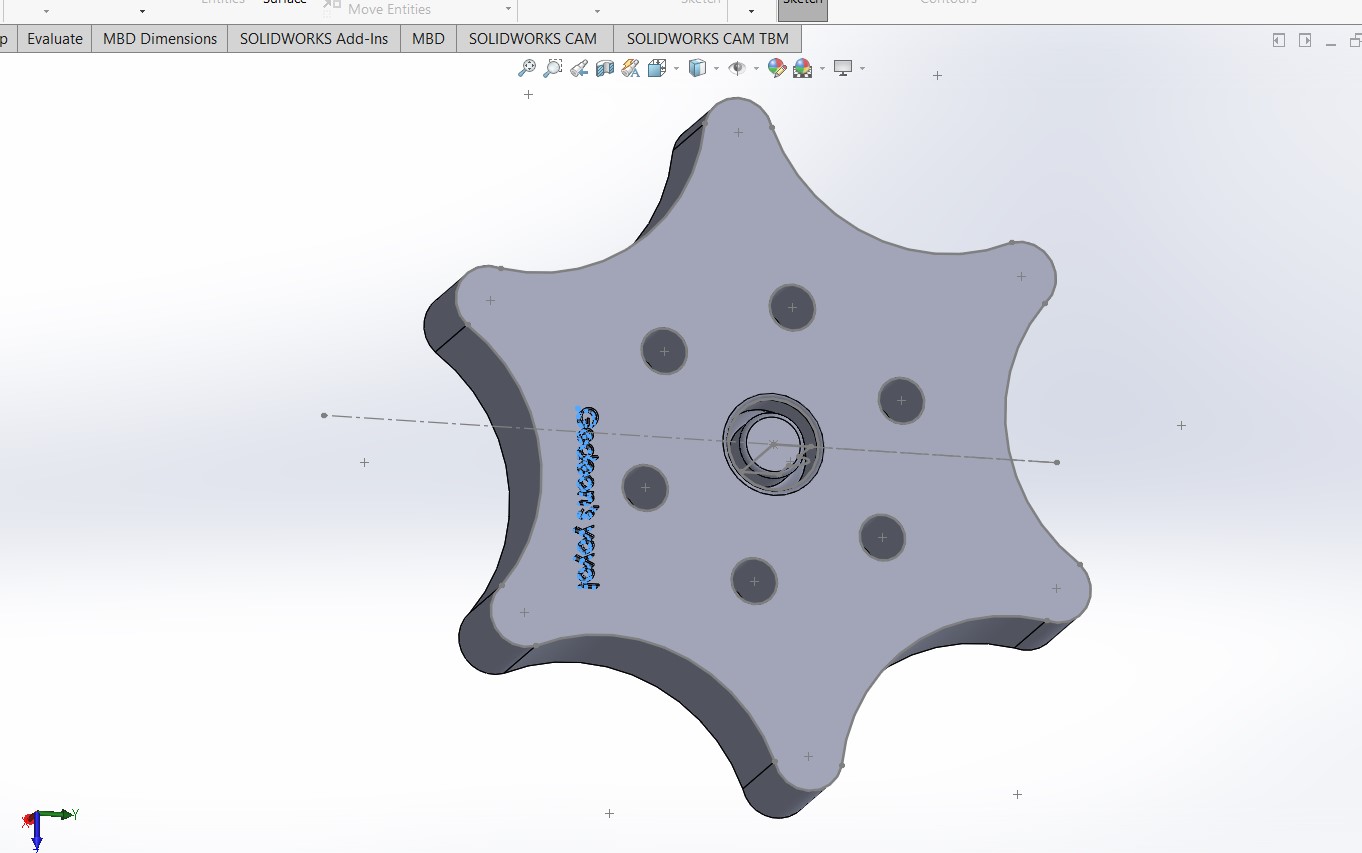

The final piece looked like this:

I tried to add text on top of the piece as well.

The final piece looked like this:

I tried to add text on top of the piece as well.

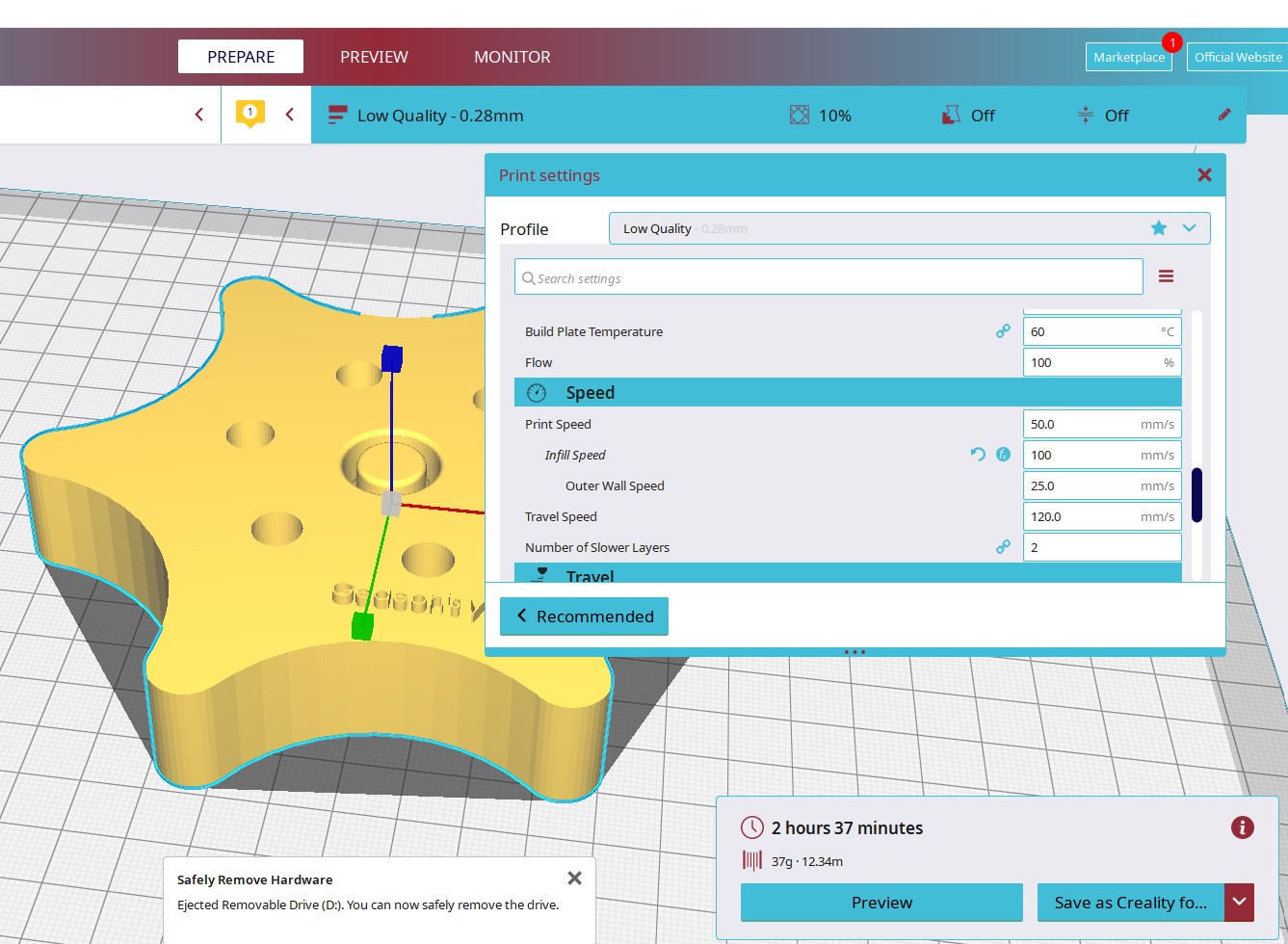

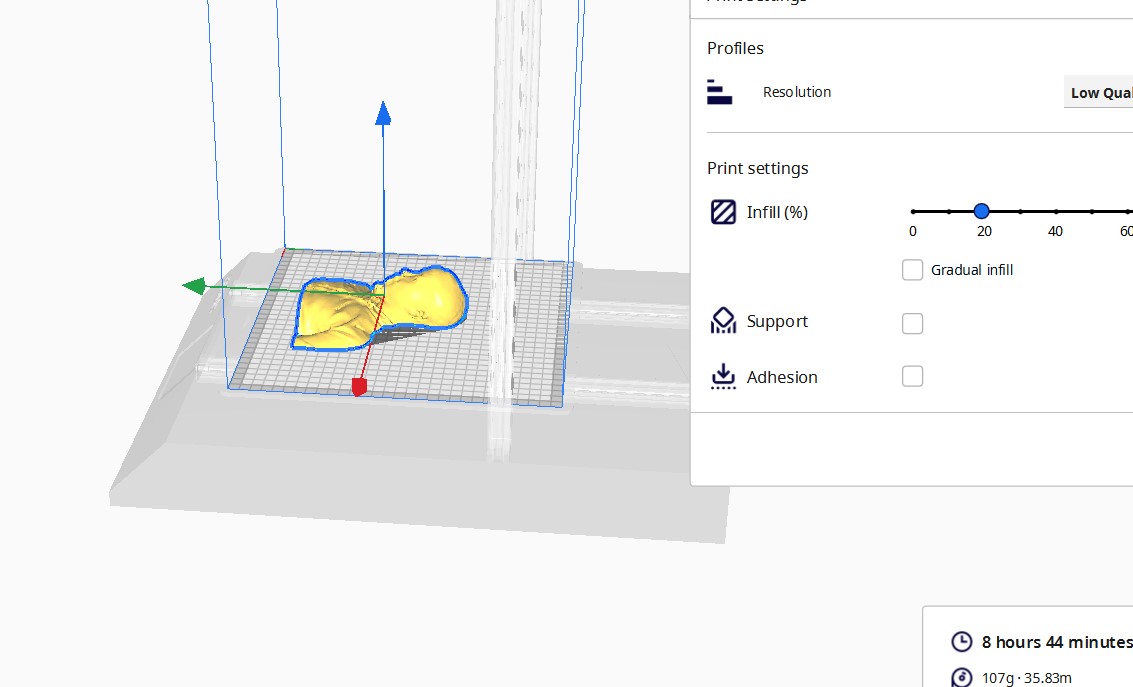

After exporting the stl format from solidworks, i opened the piece in creality slicer.

After exporting the stl format from solidworks, i opened the piece in creality slicer.

I did open in creality slicer, because the machines in our lab is creality. Cura may have other parameters that are similar,

However i preferred using the same model, to avoid inconsistances.

I did open in creality slicer, because the machines in our lab is creality. Cura may have other parameters that are similar,

However i preferred using the same model, to avoid inconsistances.

I eddited some quality, infill percentages, bottom and top layer traces, to reduce the printing time.

I eddited some quality, infill percentages, bottom and top layer traces, to reduce the printing time.

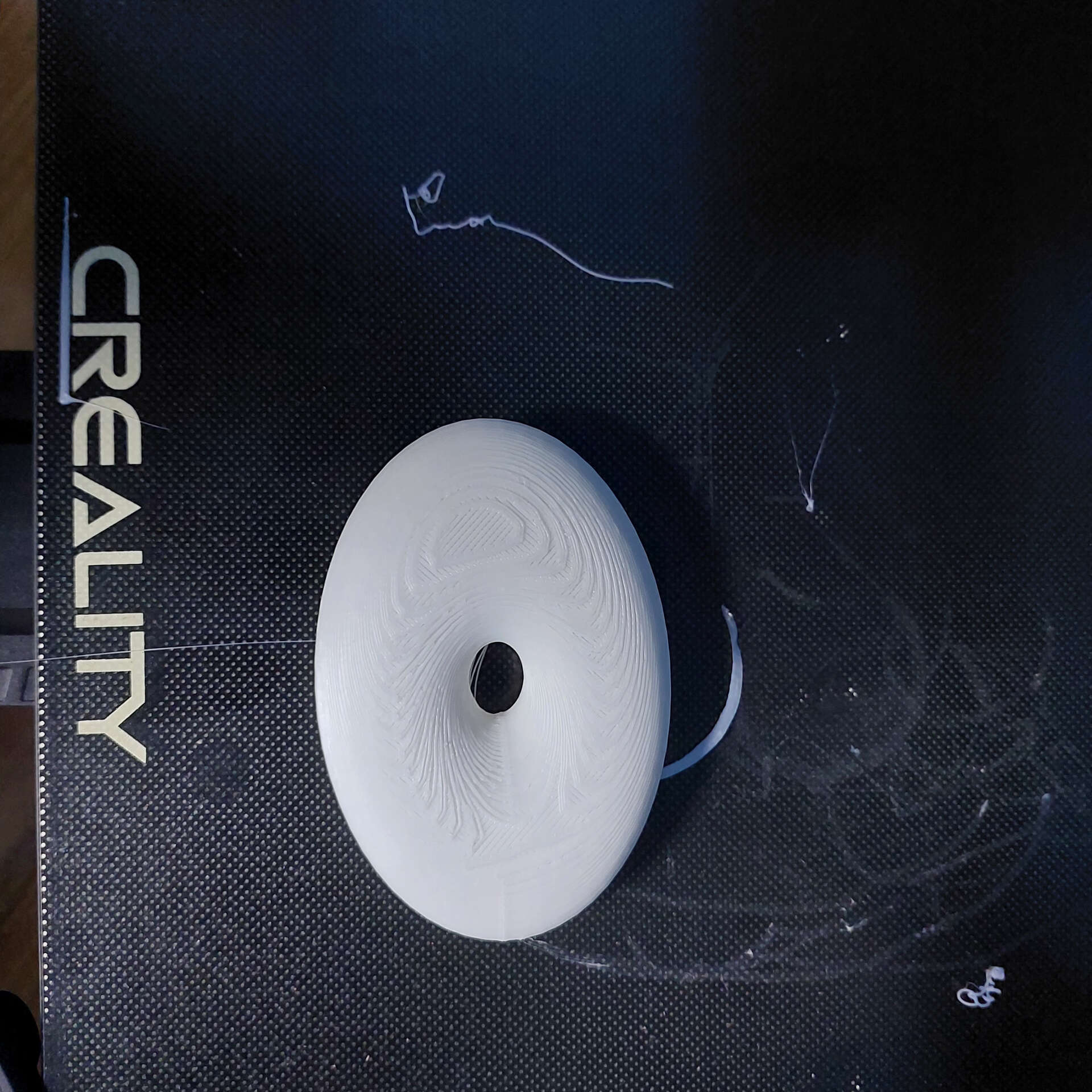

It took more than 2 hours but the print went well.

It took more than 2 hours but the print went well.

The final peice came out but the letters i had put on the top did not get printed well.

Probably because they were too small.

The final peice came out but the letters i had put on the top did not get printed well.

Probably because they were too small.

The final piece looks like this:

The final piece looks like this:

The video on how it is used is embedded

The video on how it is used is embedded

.jpeg)

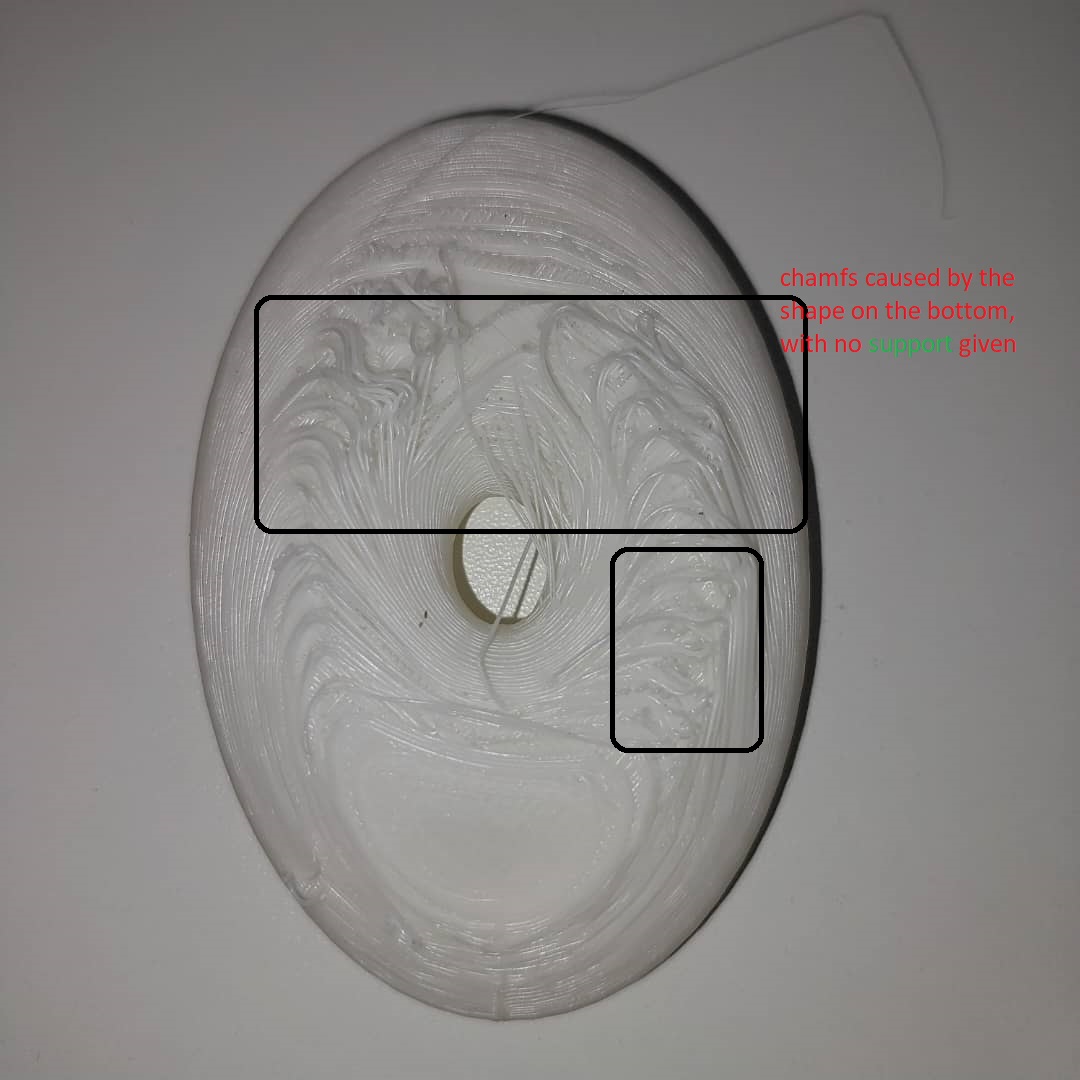

A dognut shape that is not well layed on the bed of the printer comes out with a good top but a bad bottom!

Another rotating jointADVANTAGES OF 3D PRINING

- LOW COST PROTOTYPING

- EASY TESTING OF Mechanical/ PHYSICAL STRUCTURES

- INHOUSE/ PERSONNAL FABRICATION MADE EASY

- CUSTOM PARTS ARE EASILY MADE

LIMITATIONS OF 3D PRINTING

- SMALL SIZES

- LONG TIME OF PRINTING

- SOME PARTS REQUIRE SUPPORT TO COME OUT NICELY

- COMPLEX MODELS ARE SOMETIMES HARD TO PRINT

A flat surface supported by the perimeter, looks good on the top but the bottom may have issues.

3D scanning:

In my lab i have a leTMC-520 scanner

i am figuring out how to use the device, there is potential in what does.

I admit the cura sense 3d scanner is much better I had to go to the local fablab and use it for this assignment, since i have used it before.

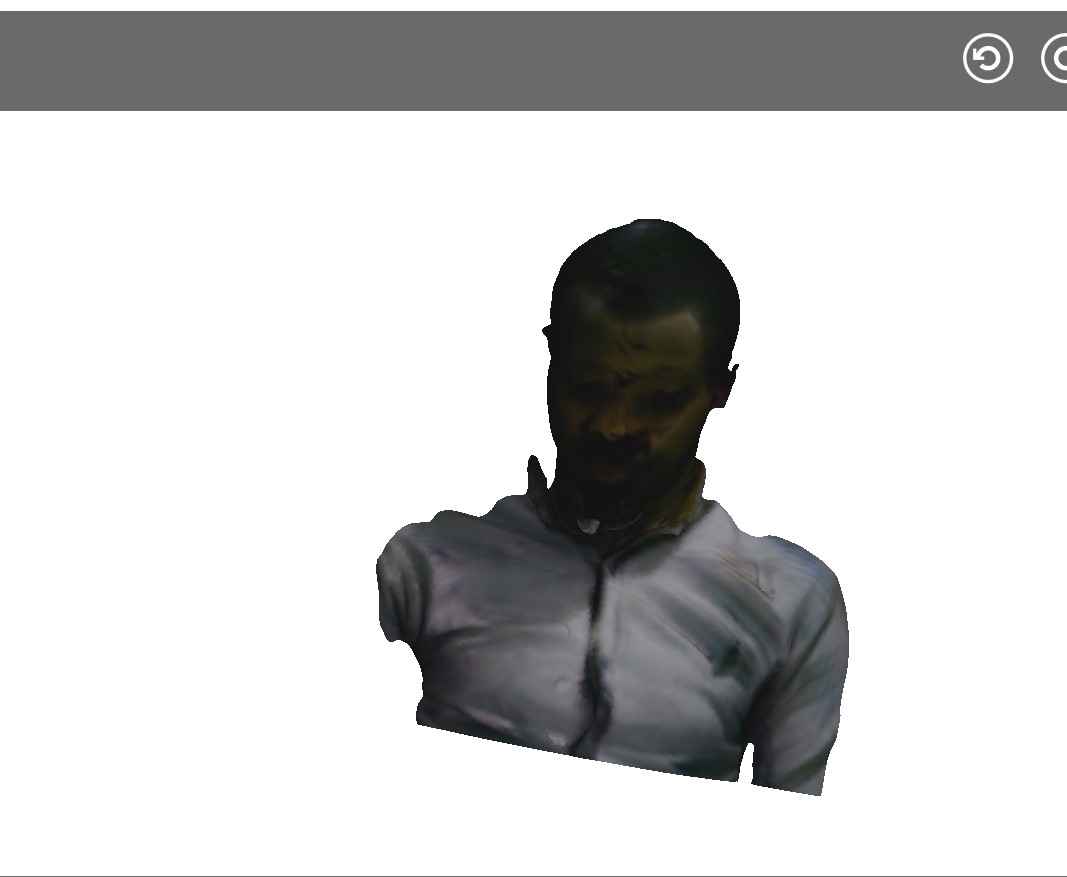

The front came out like:

The back came out flat!

The back came out flat!

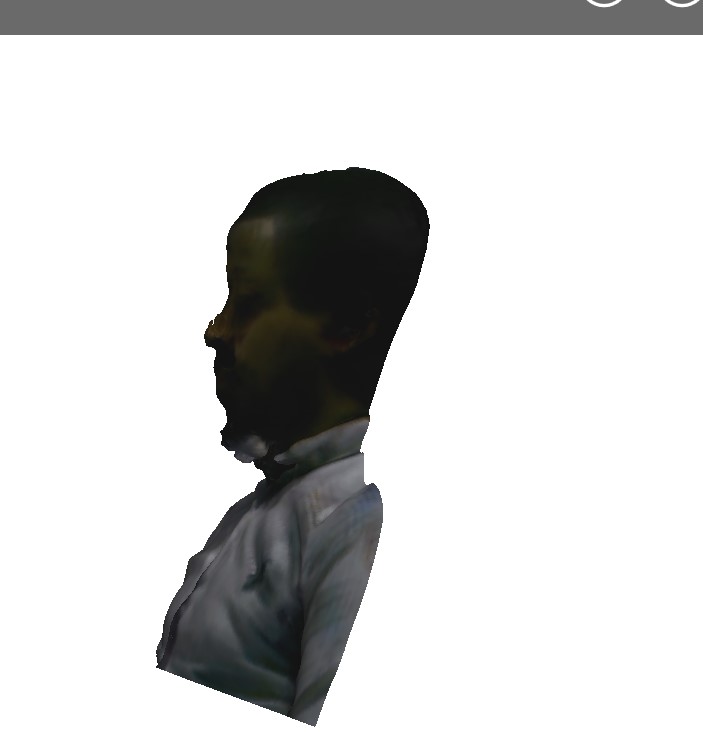

the side was like:

the side was like:

Then I opened the scan into the slicer

Then I opened the scan into the slicer

The deigns i used in this assignment can be found here:

The deigns i used in this assignment can be found here: STL of the yoyo

Solidworks part for the yoyo

The scanned stl of my face