Wildcard Week

Wooo ! The much awaited wildcard week is here.

I think I really went wild with this one.

Processes attempted :

- Waterjet metal cutting

- Metal laser cutting

- Vacuum forming

- Papier mache

- Resin-fabric wetlaying

What I also wanted to attempt but didn't :

- Origami in rigid materials

- Curved origami

- Biofabrics

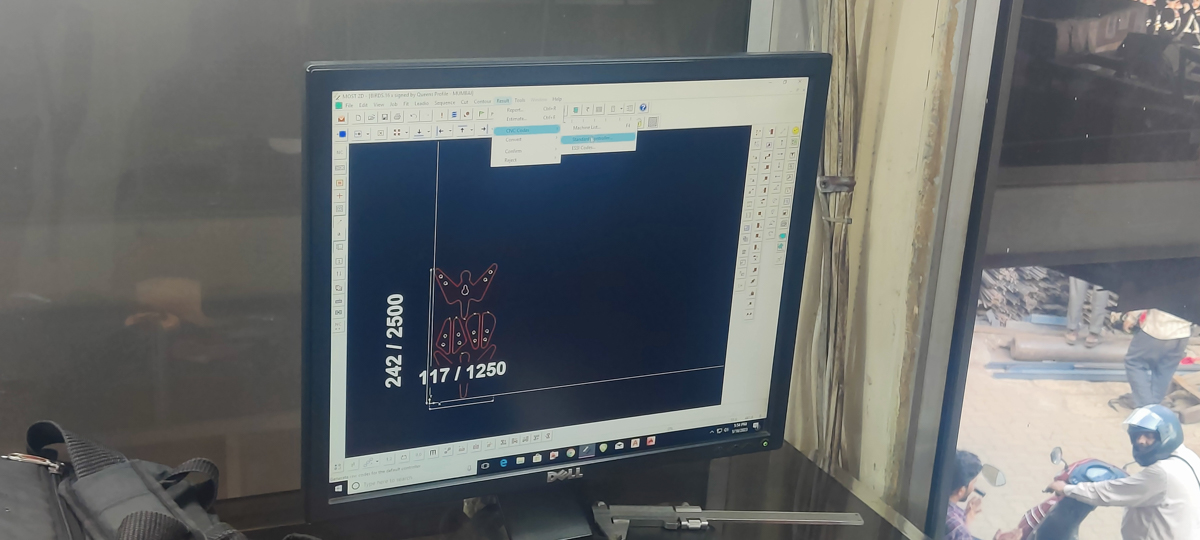

Waterjet cutting

Test cuts before going to metal

Waterjet cutting is a process usually used for thicker materials that lasers can't work with - thicker metals sheets, glass, etc. The process involves a jet of water loaded with abrasive garnet particles cutting through a sheet of material.

We do not have a waterjet cutter as part of the lab, but I had met a commercial operator on a recent field visit. Since I teach Product Design, I will require their services at some point for myself as well as my students, so this was a good reason to figure out the workflow, limitations and characteristics.

Characterisation :

Kerf loss : 1.5 mm

Minimum hole diameter : 12 mm

Metal Laser cutting

Metal lasercutting usually involves a fiber laser that produces enough power to cut through metal sheets. The same vendor had metal lasercutting facilities as well, so I got some of the same pieces cut on that.

Characterisation : Kerf loss : 0.5 mm

Learnings : Waterjet to Laser comparison

- The Metal laser can cut at a finer scale, and so is more suitable for intricate patterns compared to the Waterjet.

- The waterjet can cut through thicker metals, as well as glass, so the range of materials and thicknesses is more.

- The waterjet produces a far cleaner edge than the metal laser, whose pieces do need some sanding and deburring.

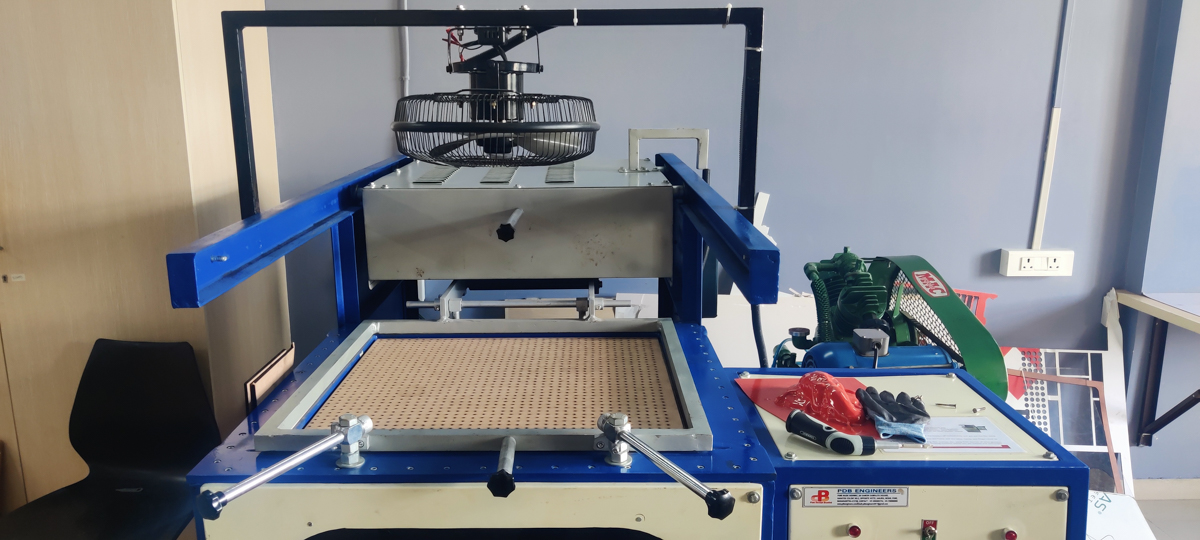

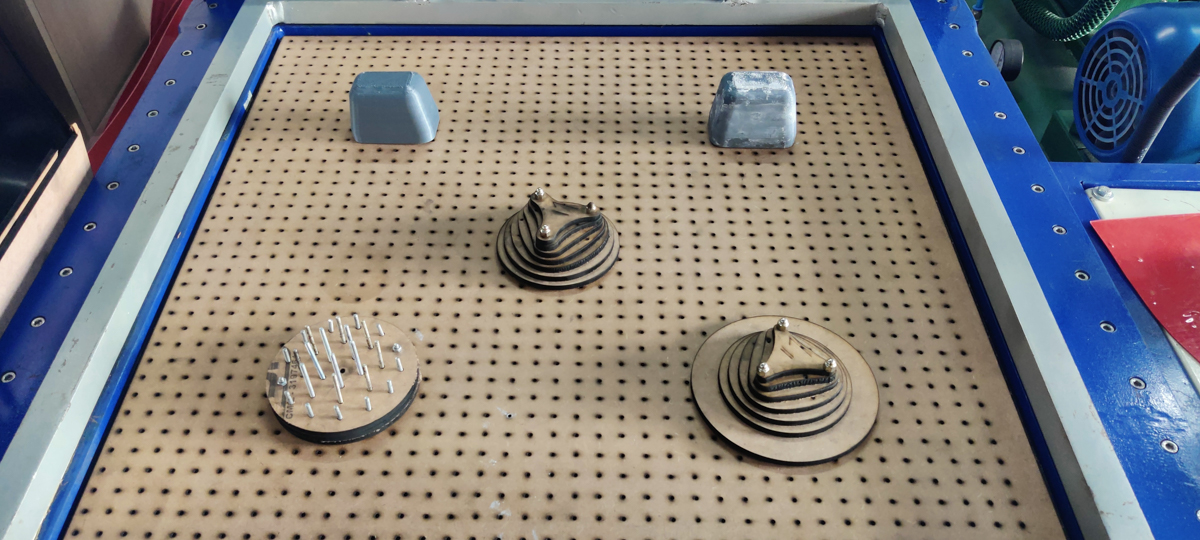

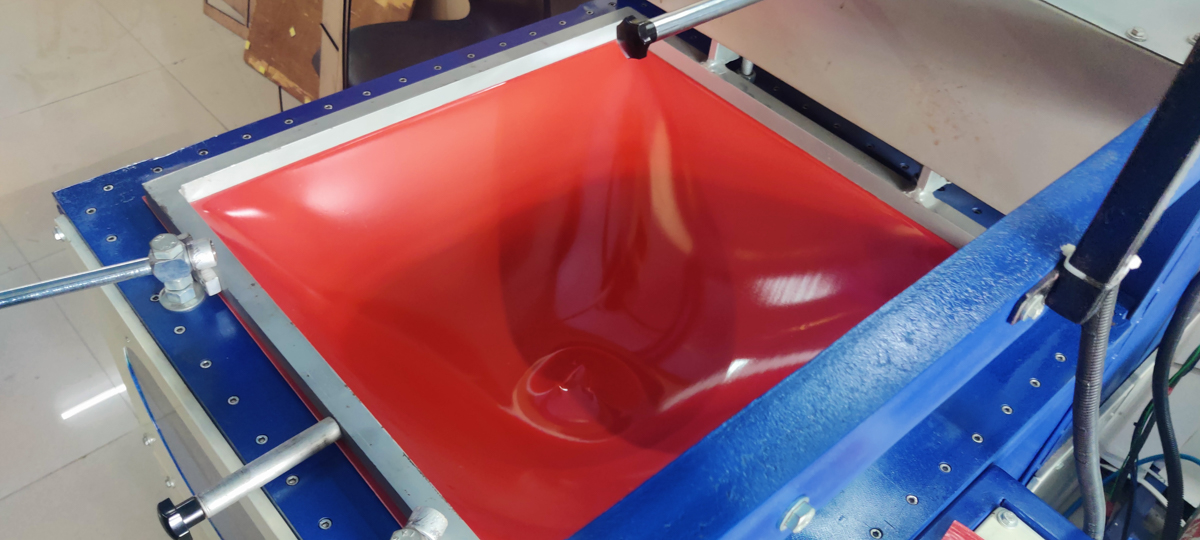

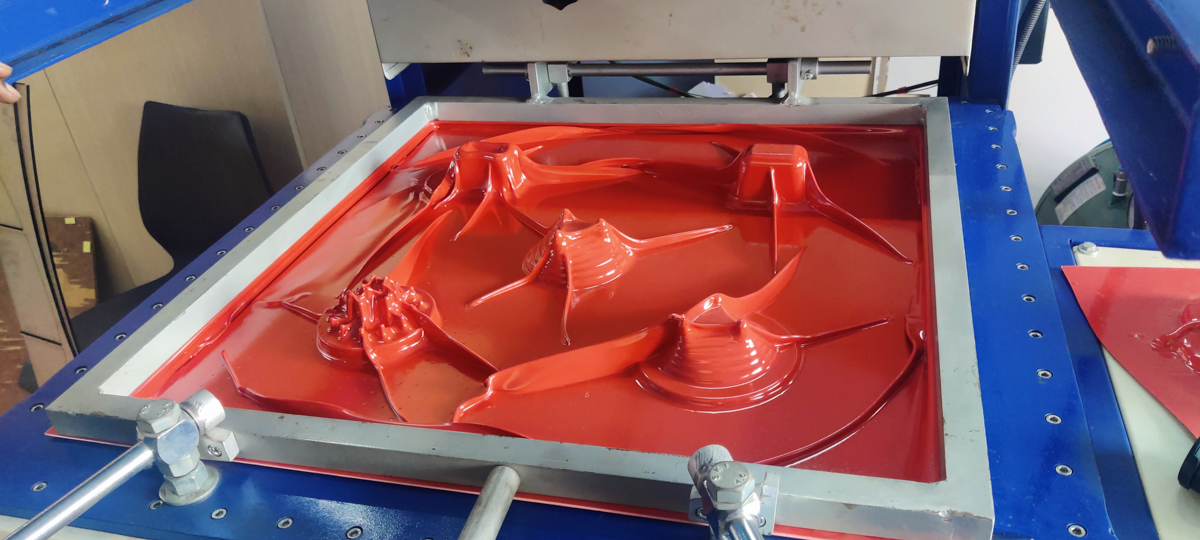

Vacuum forming

I cut out a series of slices and stacked them up to form the vacuum forming core, to make various containers, etc. We let the PVC sheet heat for too long - it stretched out quite a bit and that resulted in a lot of wrinkles and creases overall.

Learnings

- Do not let the sheet soften up too much ! It wrinkles.

- 3D Printed cores which are empty shells do not work on their own - they soften in the heat and sag, but..

- 3D Printed cores with a bulk filler, like Plaster of Paris, filled inside, work just fine

- Lasercut mdf slices work fine

- Core bottoms should have a deeper indentation or space on the base to hold them and pull them out easier

Papier Mache Molding

I am quite familiar with papier mache, but I have never cast it, only built it up in layers. I was 3D printing molds for resin wetlaying, and I decided that trying out paper mache was also worth trying. It's a 3 part mold, with a core, a base and openable walls.

I soaked and pulped up some newspaper, and later added white glue to the mix as well. To speed up the process of soaking and breakdown, I microwaved the mix for 120 seconds (before adding the glue).

For the first layers on the base as well as the core, I used tissue paper and water to get them to stay in place. I did not use glue since this layer would help separate the mold from the casting. Once the tissue layup was done, I filled up the mold with the soaked pulp, and pressed the core piece in. This squeezed out a lot of the water, which was caught by the laid up newspapers. I then clamped the two halves together with G clamps to further compress the mold.

Since white glue needs to air dry, after a while, I opened up the mold and removed the core. This piece is currently air-drying.

Learnings

I still think 2-part molded papier mache has it's possibilities, and I'll work it out in the future. But layering papier mache on a single part mold seems a far faster and simpler means to achieve a 3D form for now.

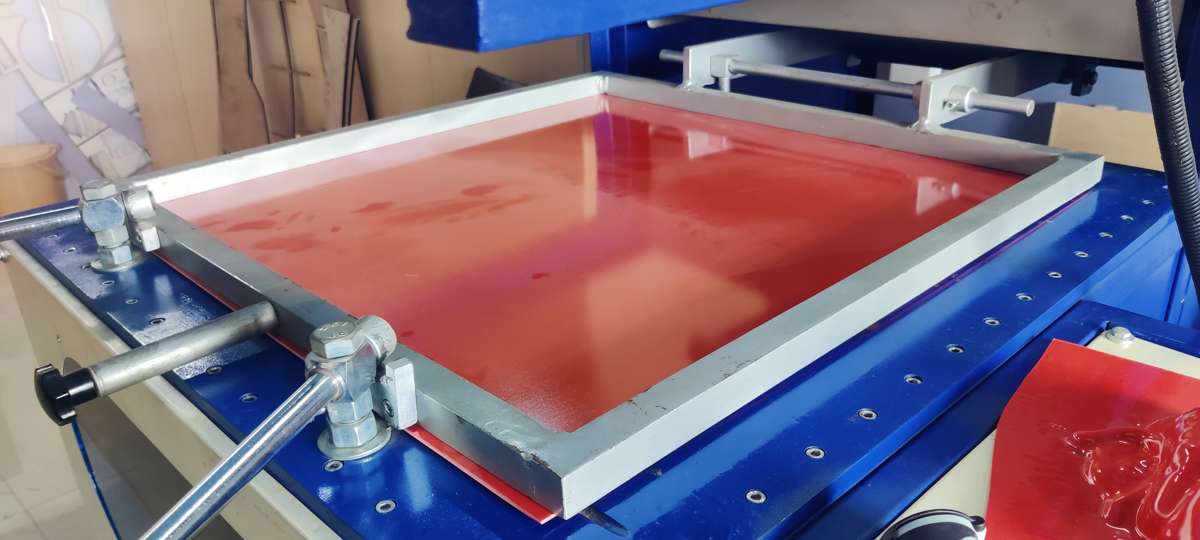

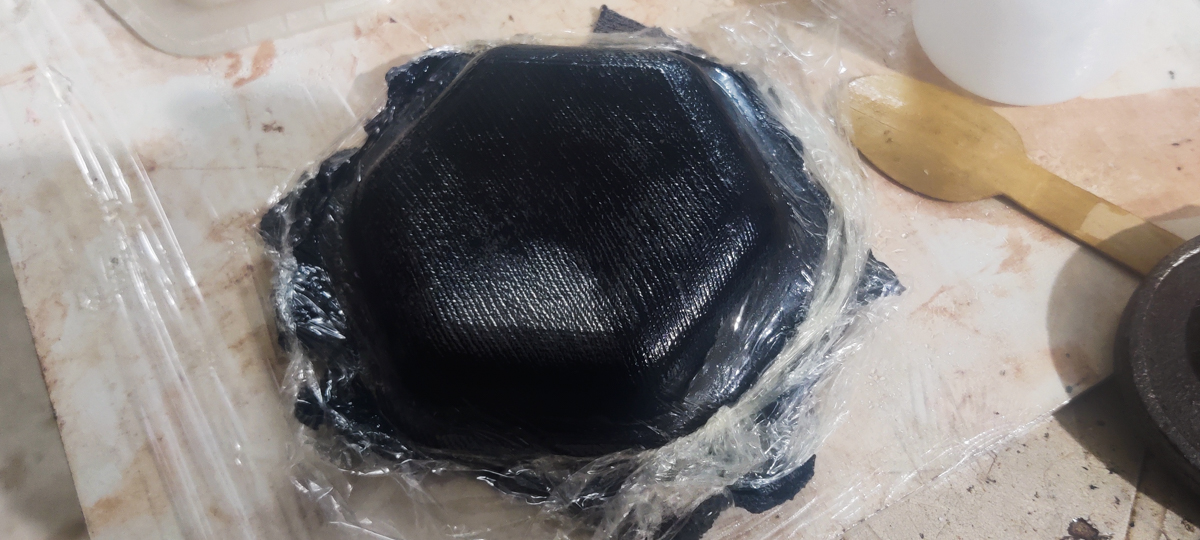

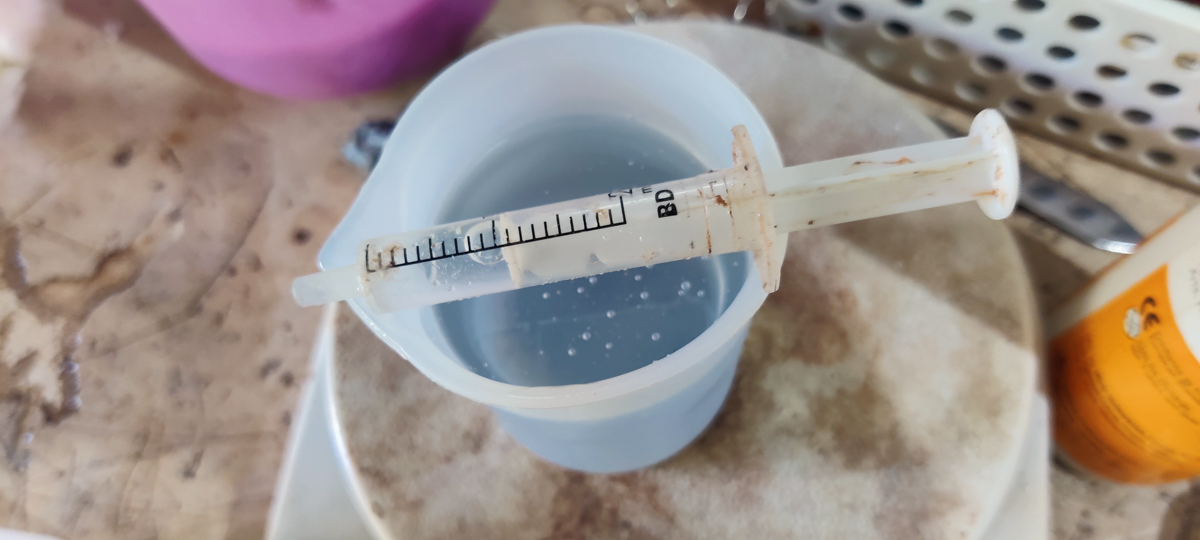

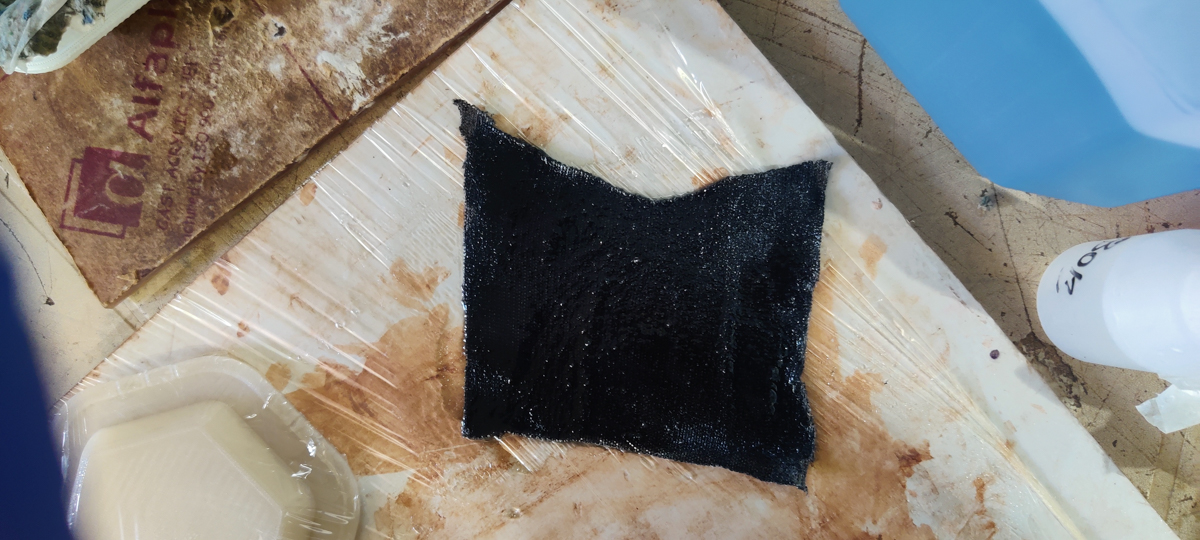

Resin Wet-laying

I realised that the papier-mache mold was rather deep and printed a shallower mold for the resin-wetlay. The mold parts were encased in clingwrap to prevent resin from adhering to them. The "fibre" component is just squares cut from old socks. Once the preparations were done, I poured out the resin and added the hardener. Some of the mix was applied to the inside of the mold to wet it. Then the squares were laid out and more resin was applied. The wetted fabric was then laid into the mold. This was repeated with multiple squares, until I realised this was taking too much time and the resin would start to harden. Hence, after the first few layers for good finish, I basically dunked out a lot of resin and the fabrics and closed the mold. Again, clamps were applied and this was let to set.

Prep :

Action :

Clamp and wait :

Learnings :

This was a surprisingly good result for something that I have never done before.

- Preparation is key, everything should be ready to go before you start, and certainly before you mix the resin.

- Lots of newspapers, clingwrap, etc protection of the surroundings and work surface is essential

- Safety, gloves, ventilation, paper towels - literal and figurative lifesavers

- Thinner cross sections will probably work (I started off with 8 mm thick surfaces, which, on seeing the results, is overkill, and difficult to manage)

To Do

- Clean up the edges of the wet-lay object

- Bend the metal cut pieces as needed to make the cubes and the hooks

- Bolt or rivet the hooks, drill mounting holes

Files

Metal LC and Waterjet f3d and dxf

Resin Wetlay f3d and stl

PapierMache f3d and stl

Vacuum Forming f3d, sliced cdr and dxf

Acknowledgements

Many thanks to Hafeezbhai for discussing the nuances of the waterjet and metal laser cutting as well as a stellar job of operating and executing the pieces.

Also to Mr Maitreya and Pranav for help with the Vacuum forming.