Moulding and Casting

Materials and Processes Explored

For Mother-mould :

- CNC Milling

- 3D printing

For mould Making :

- Silicone

- Alginate

- Plaster of Paris

For Casting :

- Silicone

- Plaster of Paris

- White Cement

Ratios I've collected over frequent use :

- Alginate : Water - 1:2

- Plaster of Paris : Water - 2:1

-

White Cement : Water - 3:1

-

Silicone : Hardener - 5% 1000 gm Silicone - 50 ml Hardener 20 gm Silicone - 1 ml Hardener 100 gm Silicone - 5 ml Hardener

-

Clear Commercial Resin : Hardener - 15% 1000 gm Resin - 15 ml Hardener You can use 10 ml for a slower set or if it is a hot day.

Terminology :

I don't know if there is a formalized terminology around this, but many years ago, I was working with a client on rapid prototyping pottery moulds, and came up with the following so we were always on the same page.

- M0 - The actual positive that is the required part

- M1 - The mould that will create the M0; A mould as commonly understood in terms of cake moulds and injection moulds and pottery moulds. This can be a single object for simple bodies, or a 2 part, 3 part moulds depending on complexity.

- M2 - The encasement that will create the M1 moulds

Exercises :

- Einstein Tile - 1 part Alginate mould with Plaster Cast, starting with CNC milled Wax block mould

- Einstein Tile - 1 part silicone mould with cement cast, starting with 3D printed M2 mould

- Sphericon - 2 part silicone mould with Plaster cast, starting with 3D printed M2 mould

- Braid - Plaster mould with Silicone Cast, starting with actual object, a string braid

- Airplane - Starting with actual object, a model plane

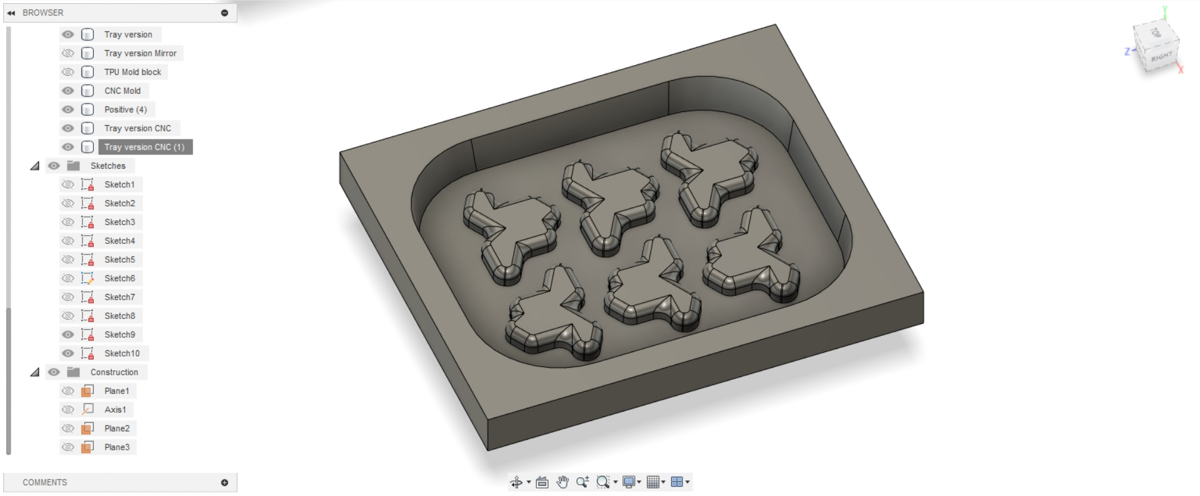

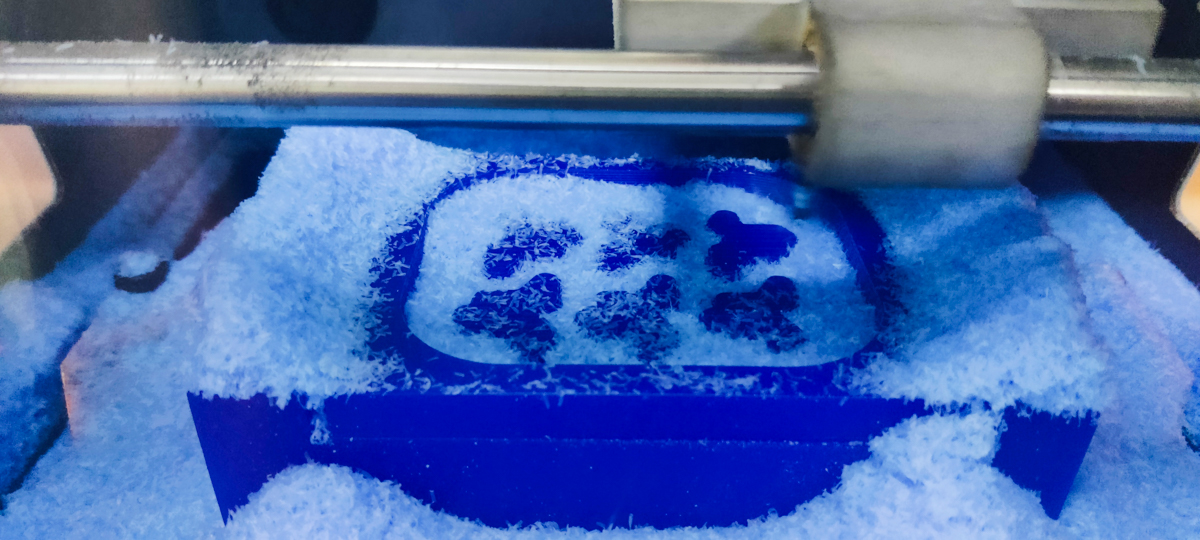

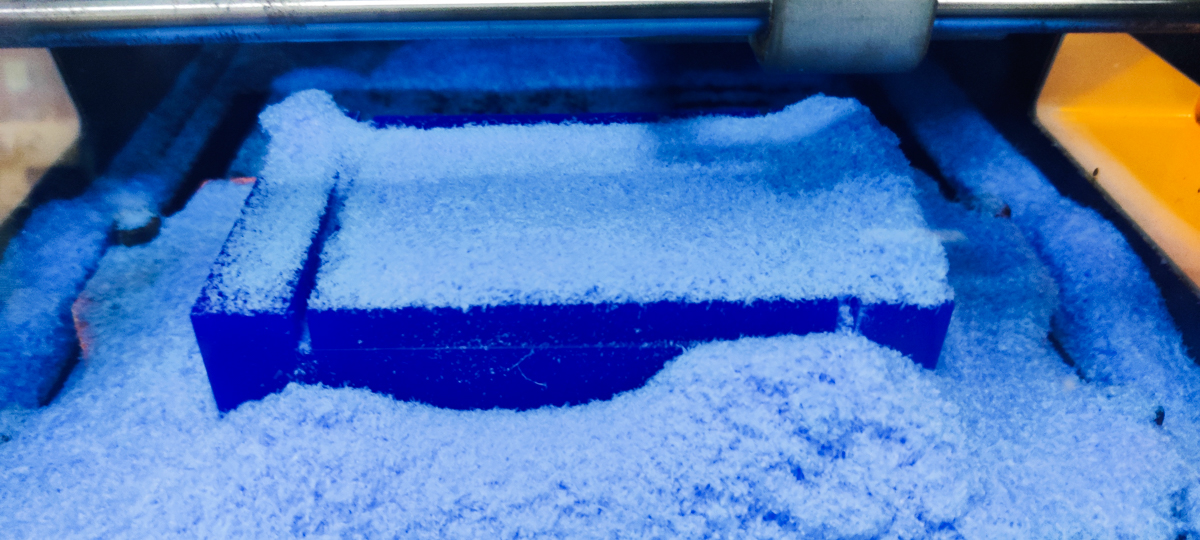

Einstein Hat 1 - CNC milling of Wax Block

The Einstein Hat shape is recently discovered aperiodic tiling unit. Since I have always been interested in tessellations, and this discovery came up on my radar sometime last month, I've been meaning to try something with it. Lasercut tiles was the first choice, but since it requires a large number of similar pieces, it seemed an ideal candidate for moulding and Casting.

This was the last of the exercises I did on this page, but the most technically involved one.

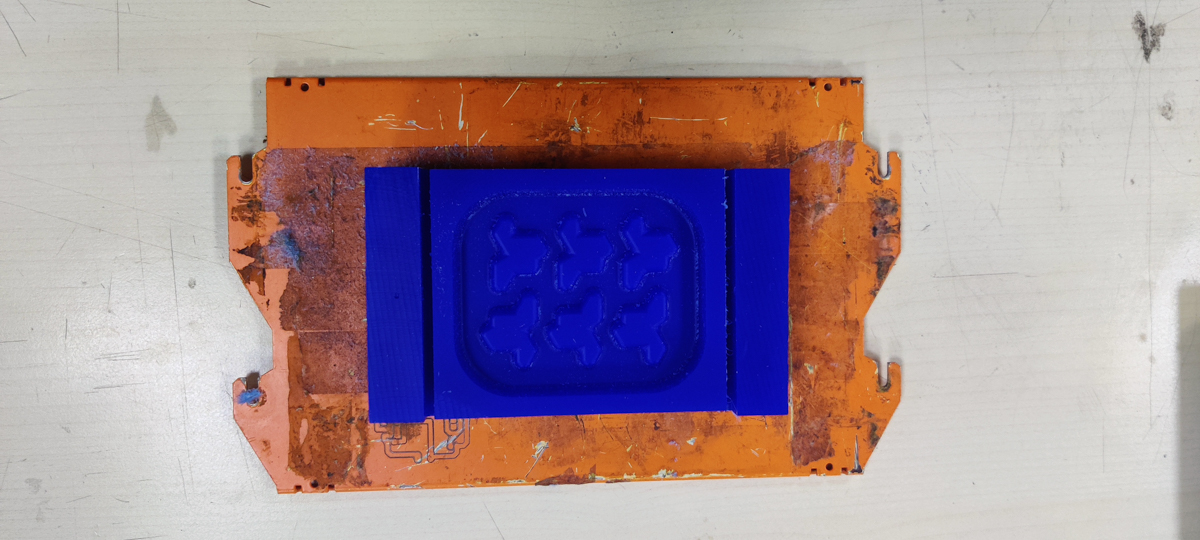

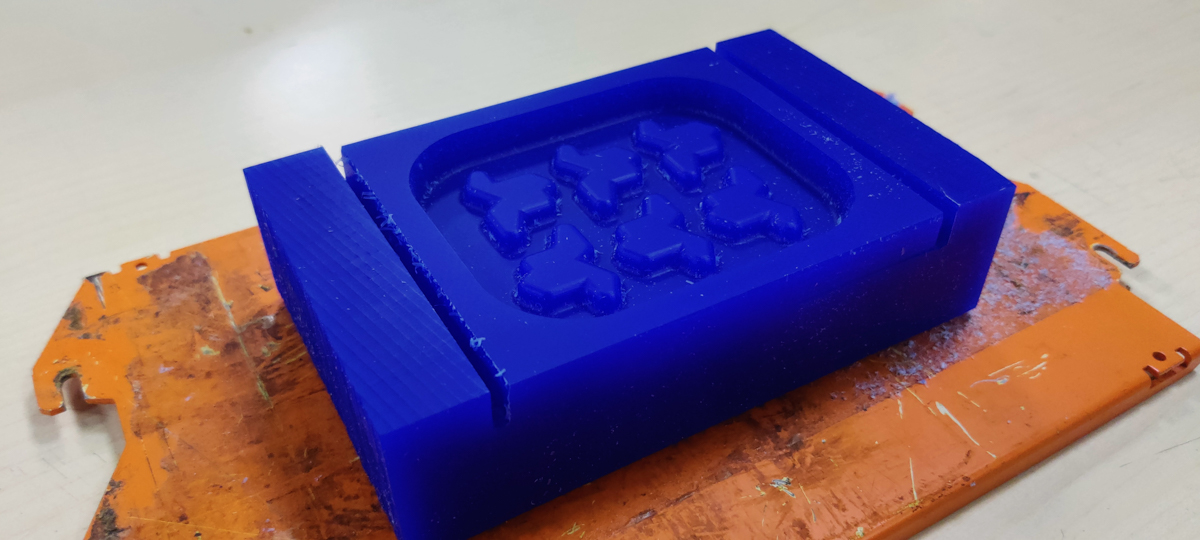

A block of wax was carved with a CNC milling machine, the Roland SRM20, to have a cavity. I filled this cavity with Alginate (and later I plan for Silicone) to make a mold for the Einstein Hat tile I had been playing with in previous exercises.

CAD

The model was exported from Fusion as an STL file

The model was exported from Fusion as an STL file

Milling Setup

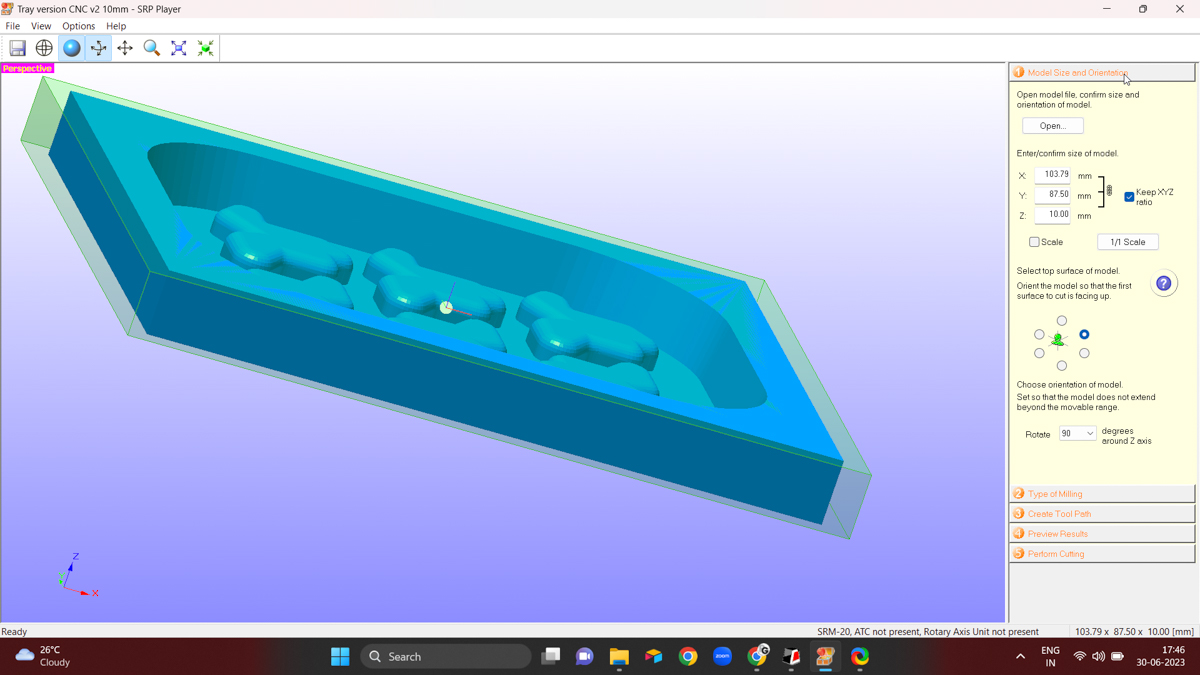

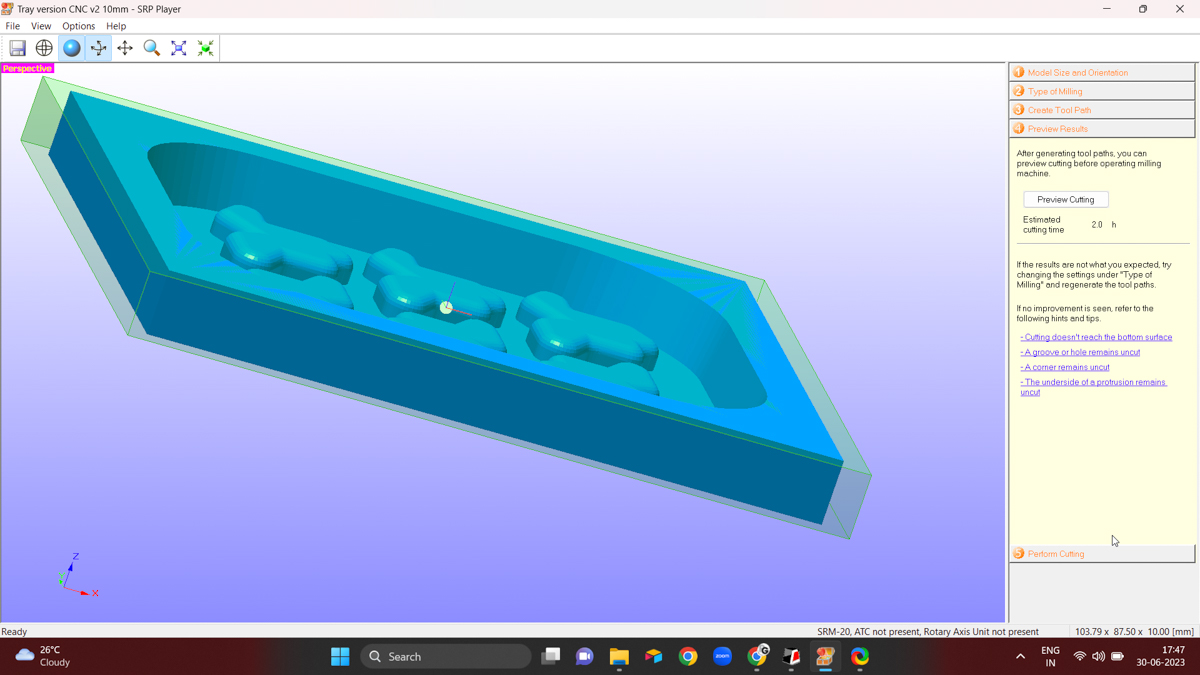

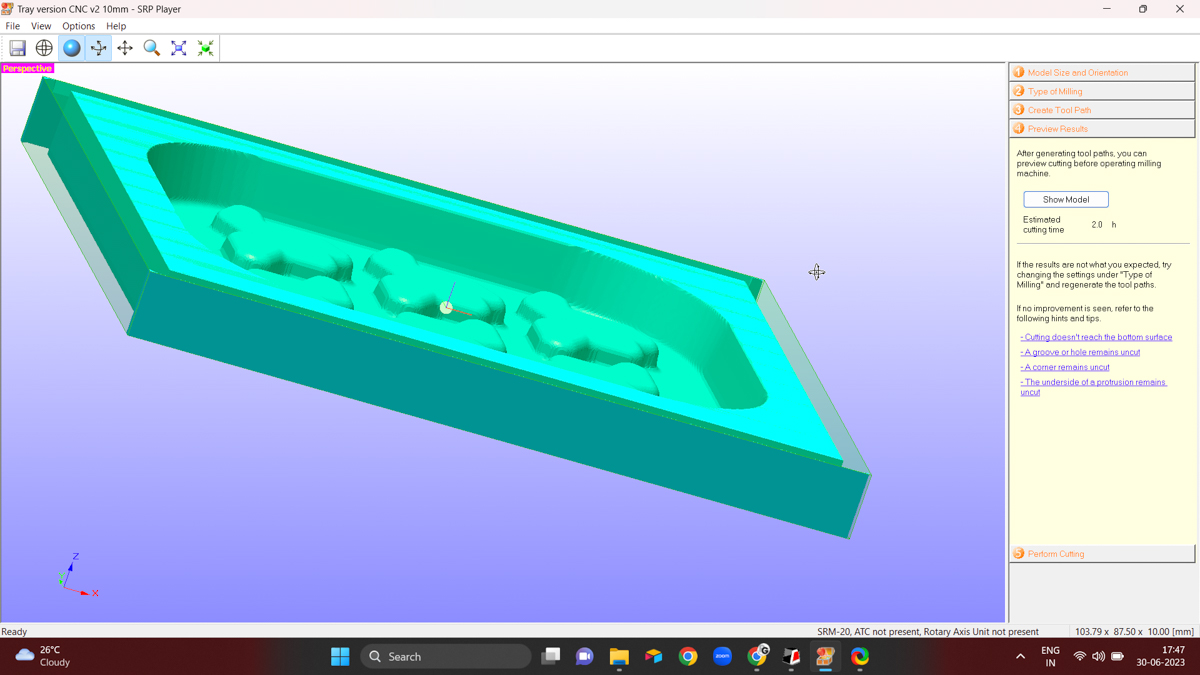

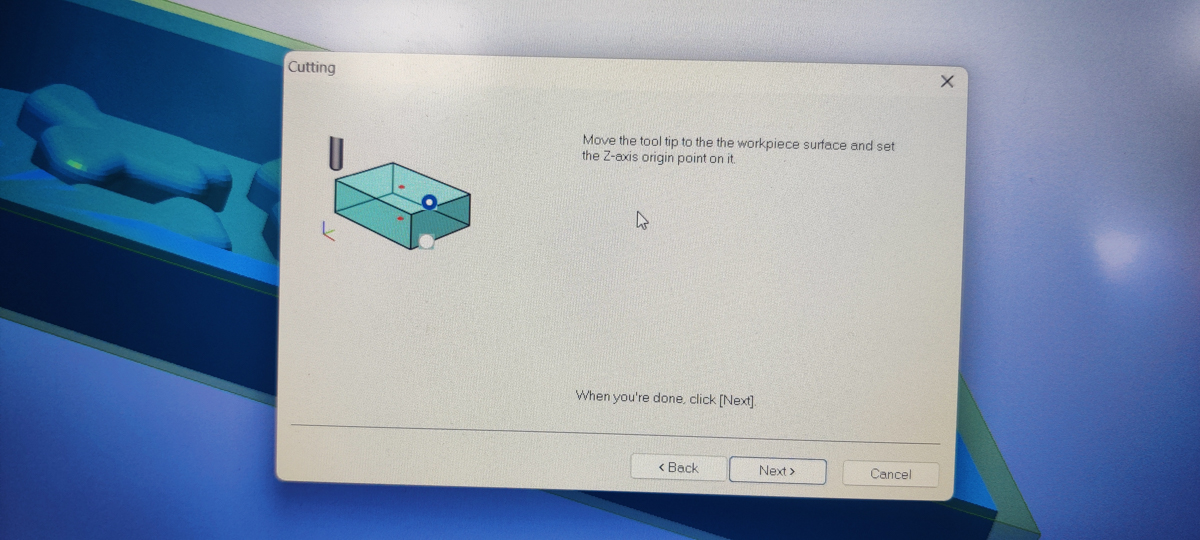

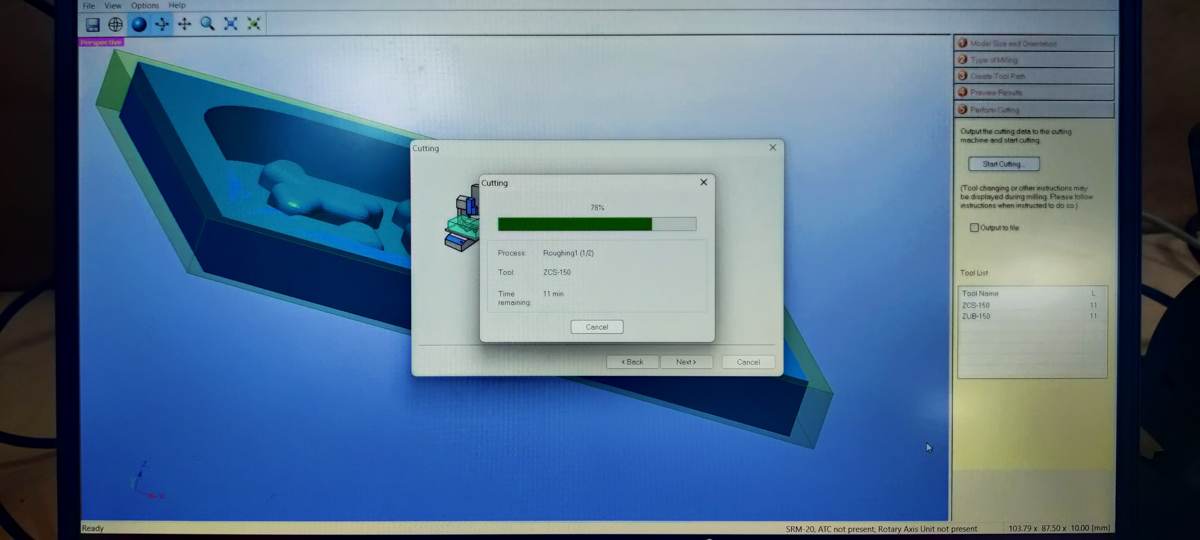

This was loaded into SRP Player.

This was loaded into SRP Player.

SRP Player is the app that controls the toolpath generation as well as the milling machine on the whole. VPanel is the other software that directly engages with the SRM20 to move the axes around, manage the origins, and other options.

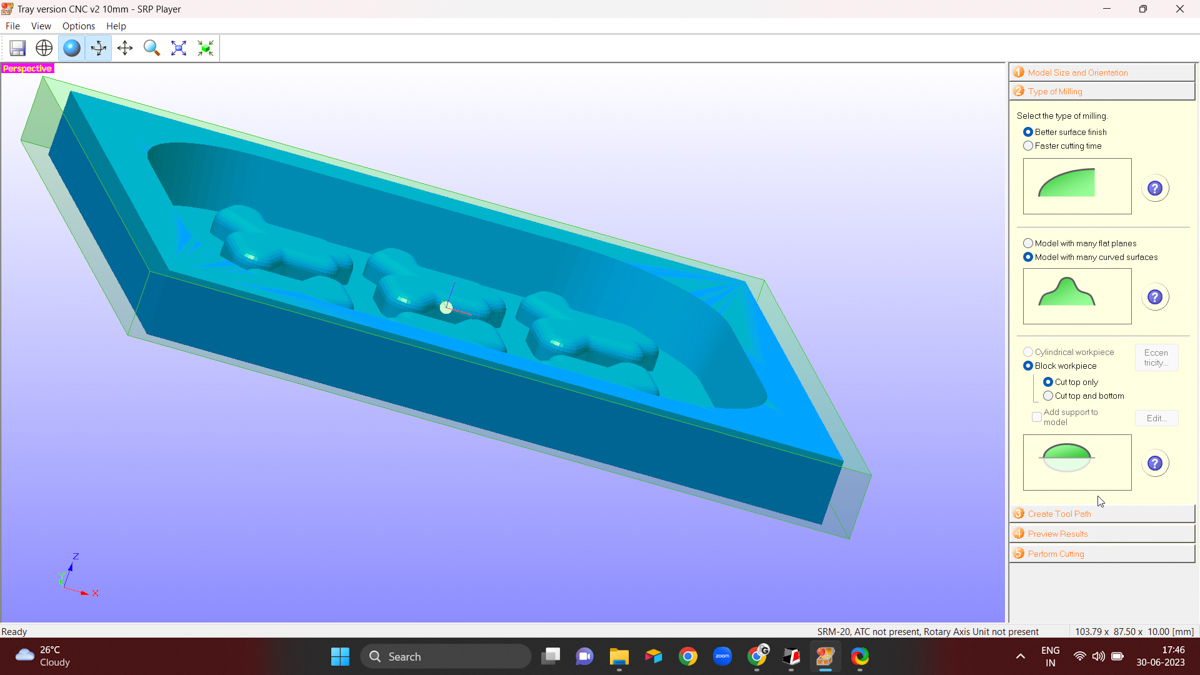

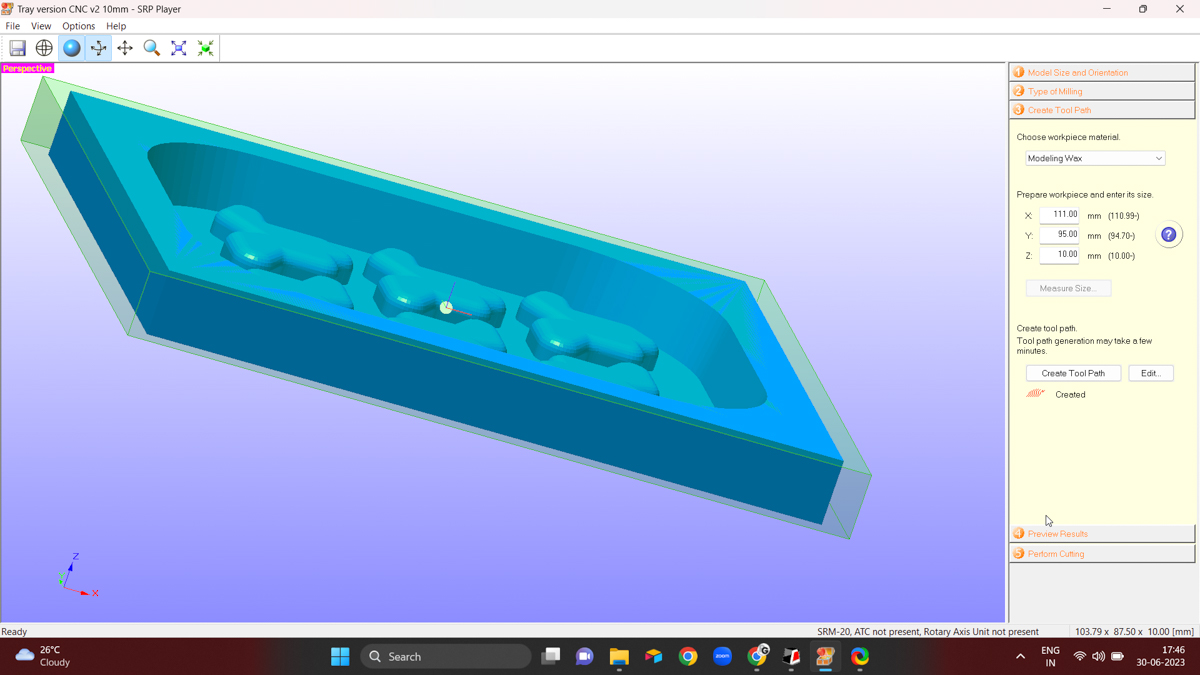

The different kinds of settings were adjusted as needed in the right-sidebar.

Model Size and Orientation

Type of Milling

Type of Milling

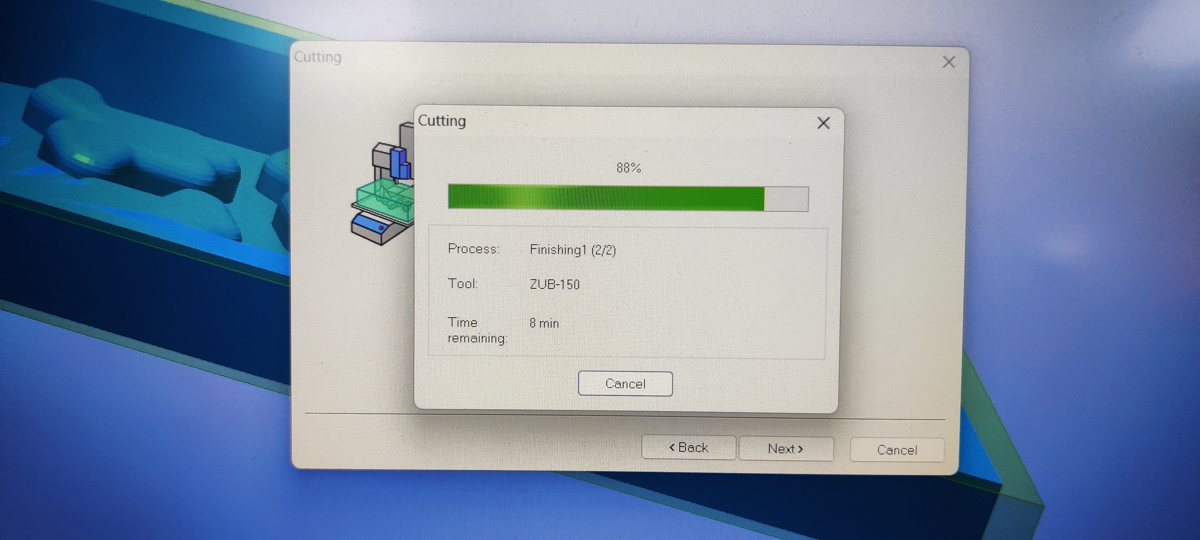

Create Tool Path

Create Tool Path

Preview Results

Preview Results

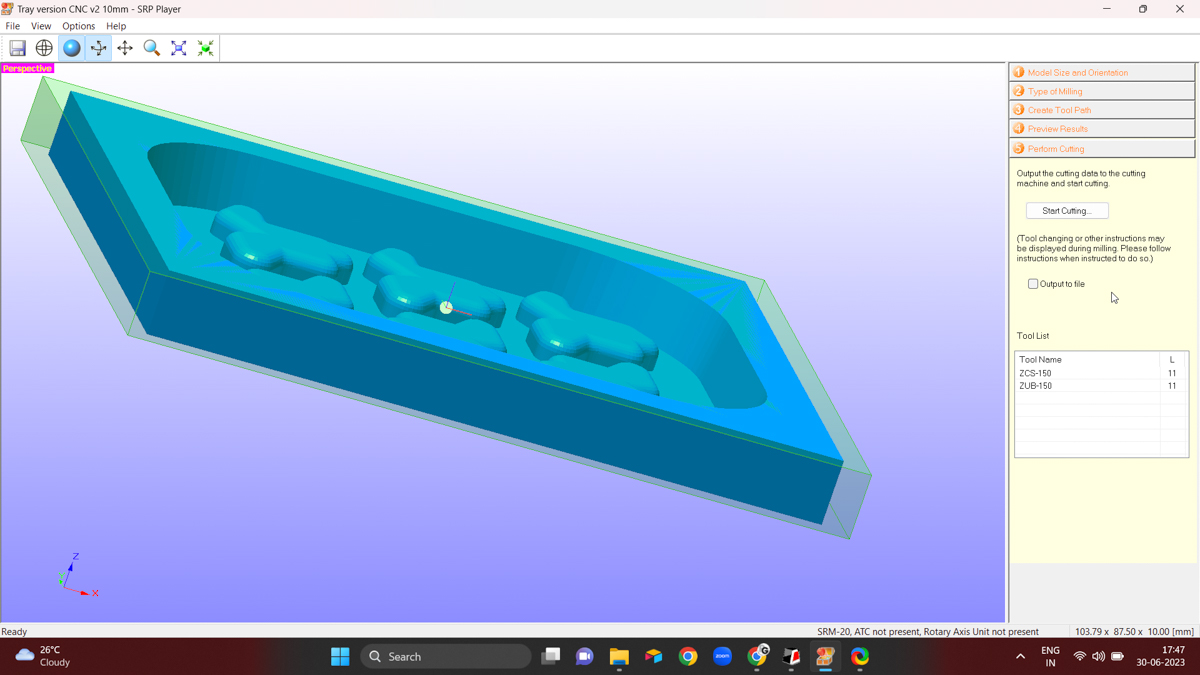

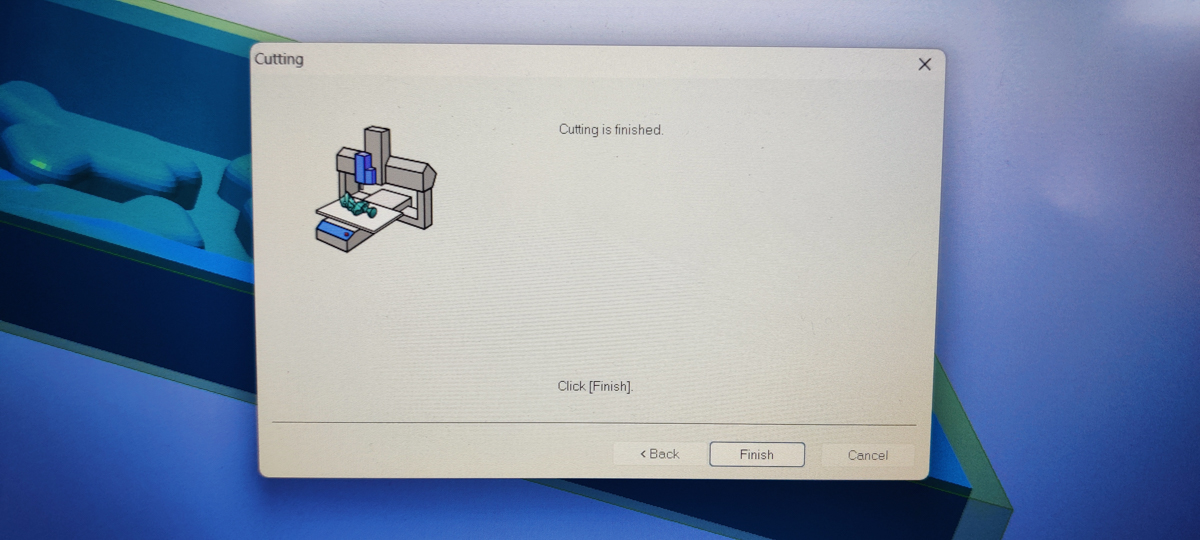

Perform Cutting

Perform Cutting

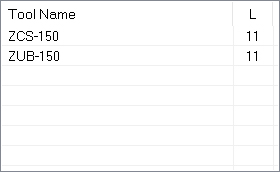

Milling Bit list that was setup to use in SRP Player

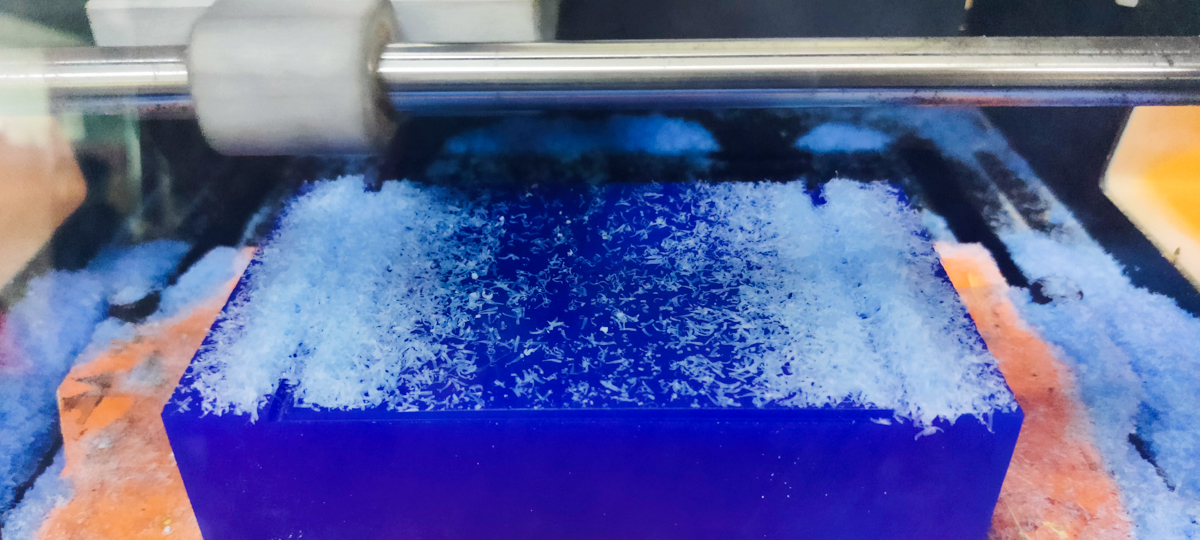

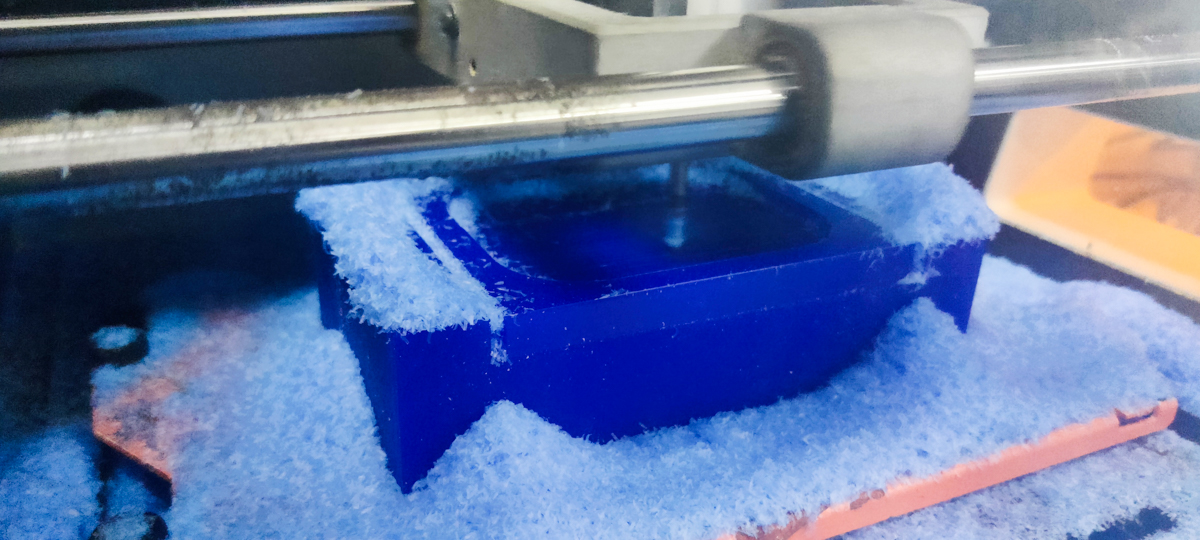

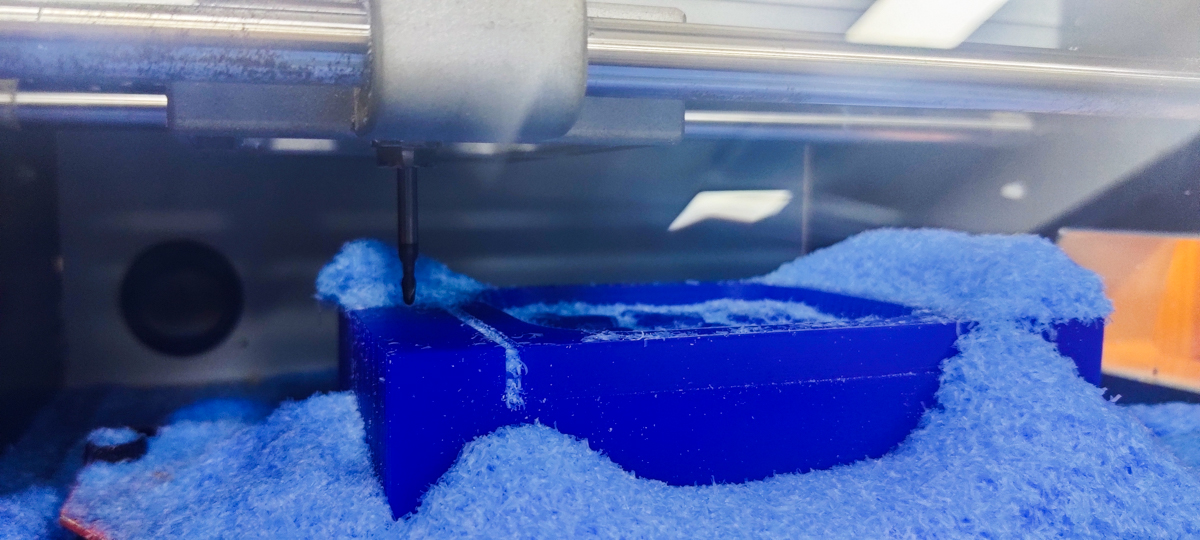

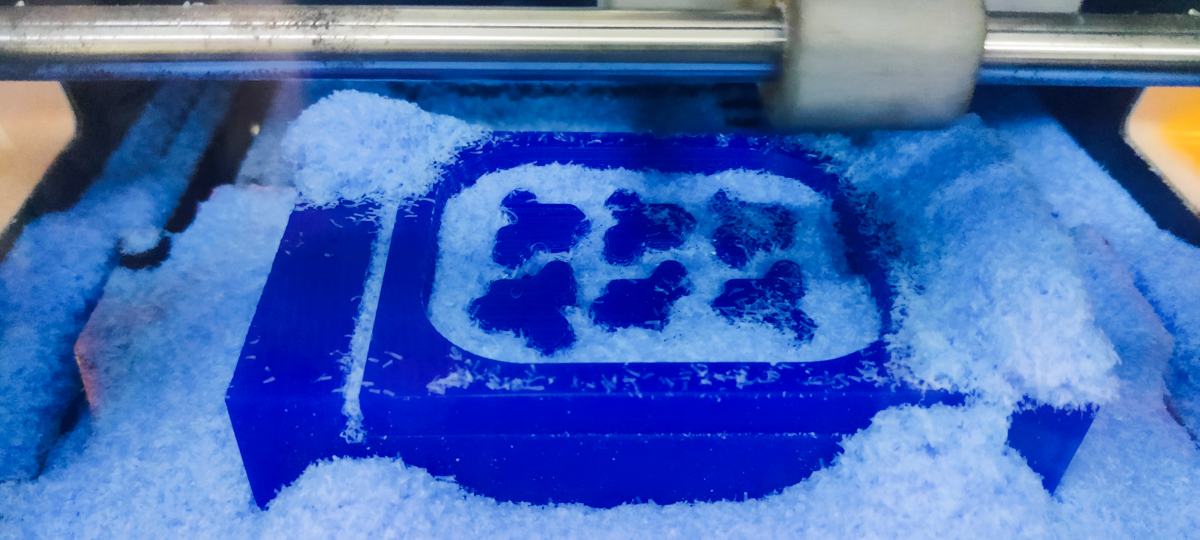

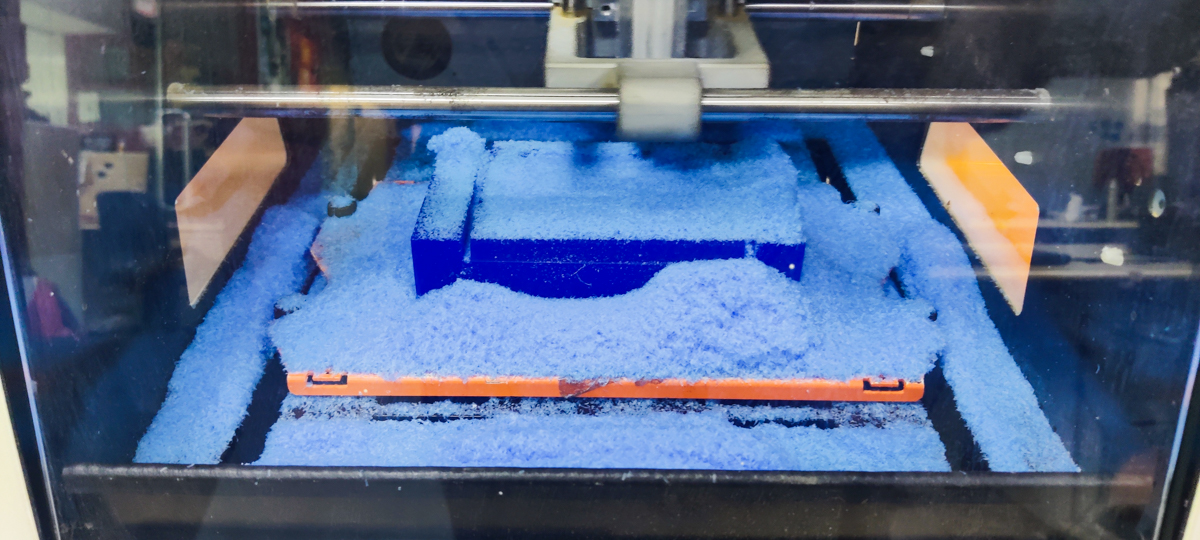

Milling in the Roland SRM20

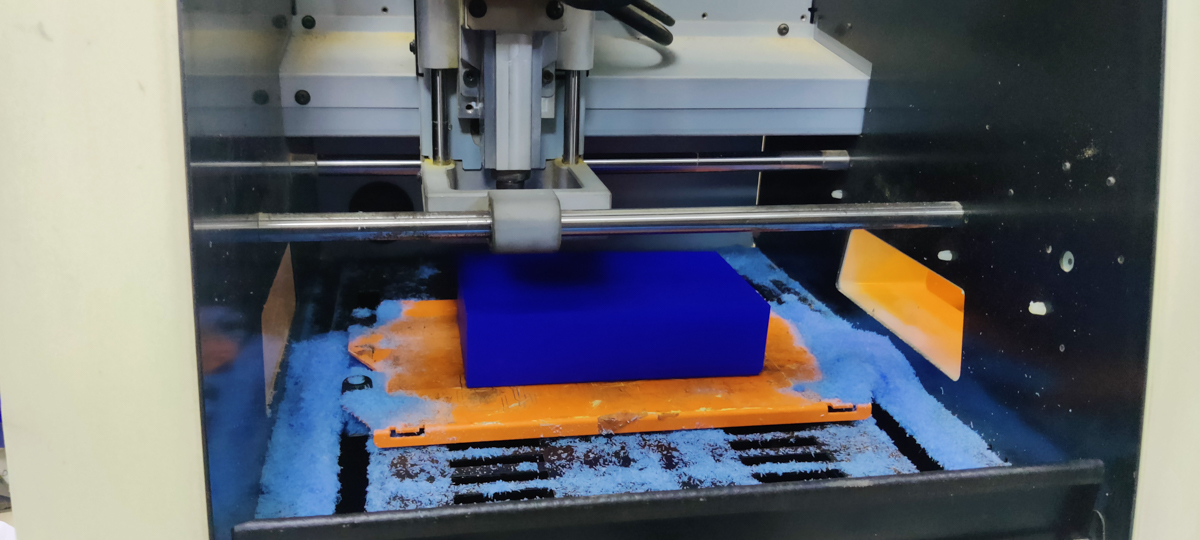

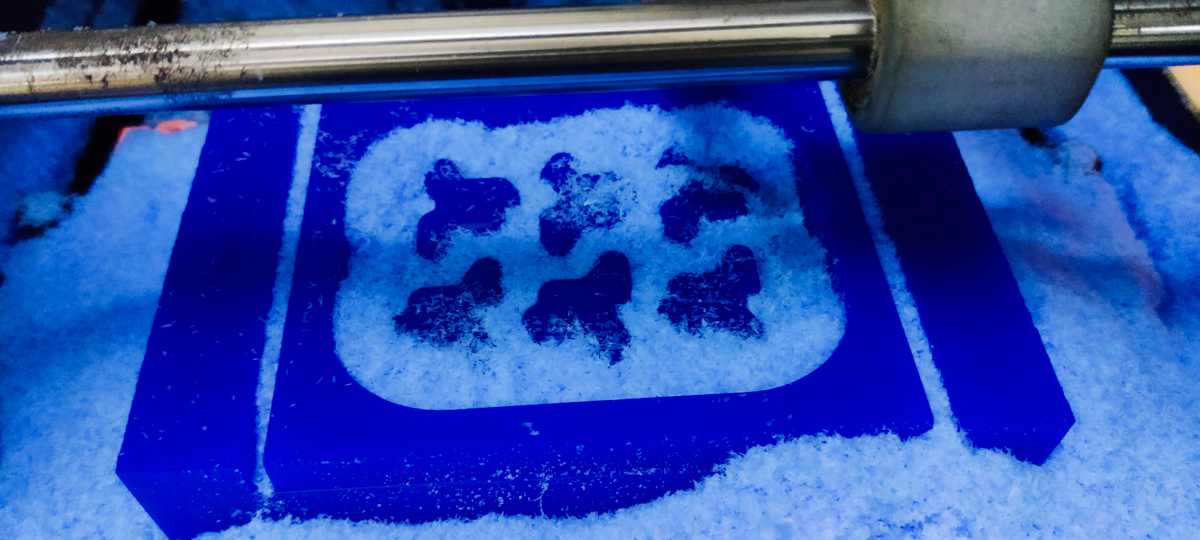

Two bits were used - 3 mm shank diameter, 10 mm depth End Mill and Ball mill

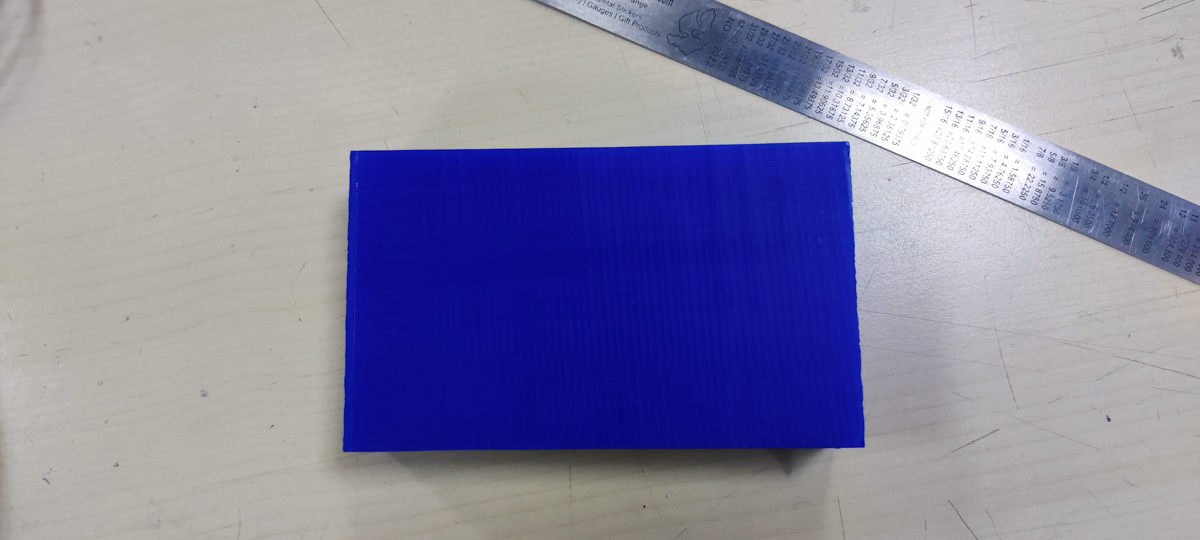

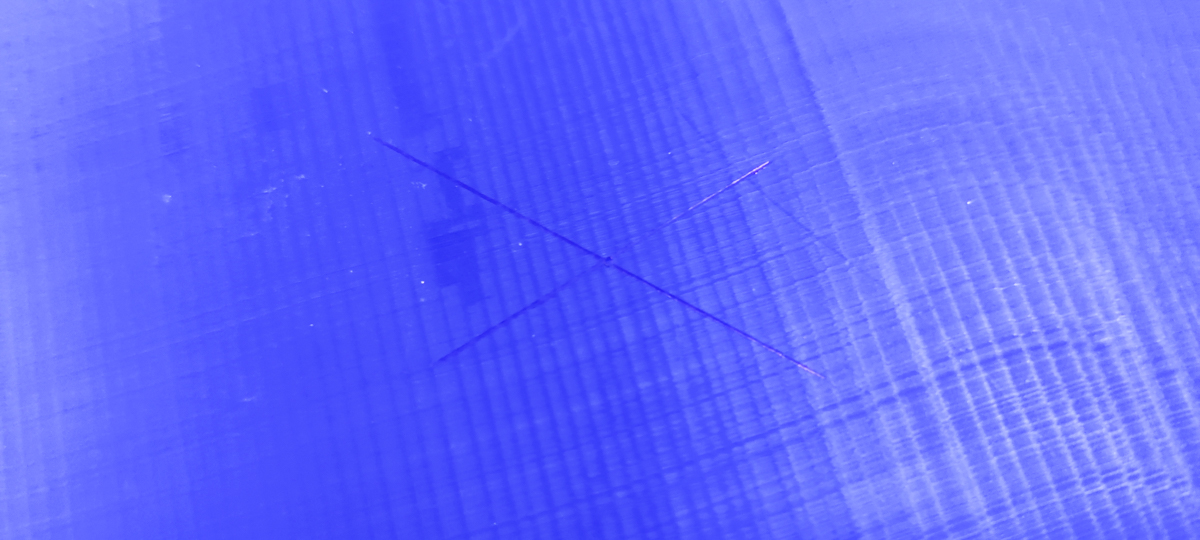

The centre of the block was marked to use as the origin.

The block was taped to the base plate of the SRM20 using double sided tape.

The block was taped to the base plate of the SRM20 using double sided tape.

After setting up the Origin using VPanel, the milling was started.

The initial roughing round of milling was about 50 minutes.

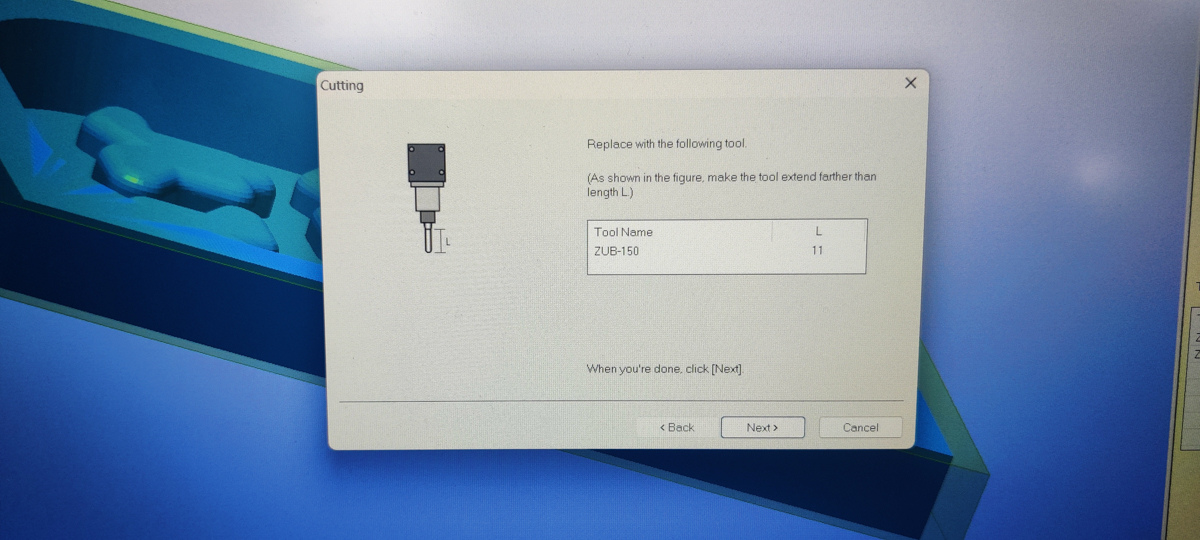

Once the Roughing was done, the Ball Mill was put into the machine. Once again, VPanel was used to move the milling head. While the XY origin of the setup would not change, due to vertical offset of the new bit, the Z origin had to be reset.

For this, the head was moved to the side where the original block top surface was still present for reference. Once the Z origin was set, the XY origin was applied and the head returned to the correct starting position.

For this, the head was moved to the side where the original block top surface was still present for reference. Once the Z origin was set, the XY origin was applied and the head returned to the correct starting position.

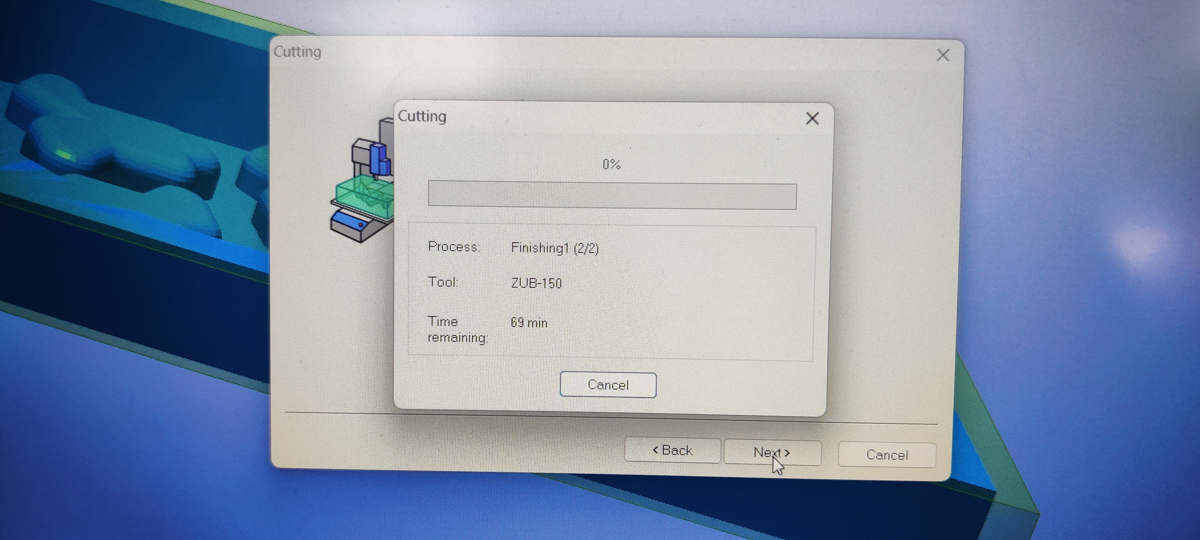

The fine-cut milling was for 69 minutes.

Finally the Finishing round was also over.

The base plate was taken out of the machine and I wrestled the block off it.

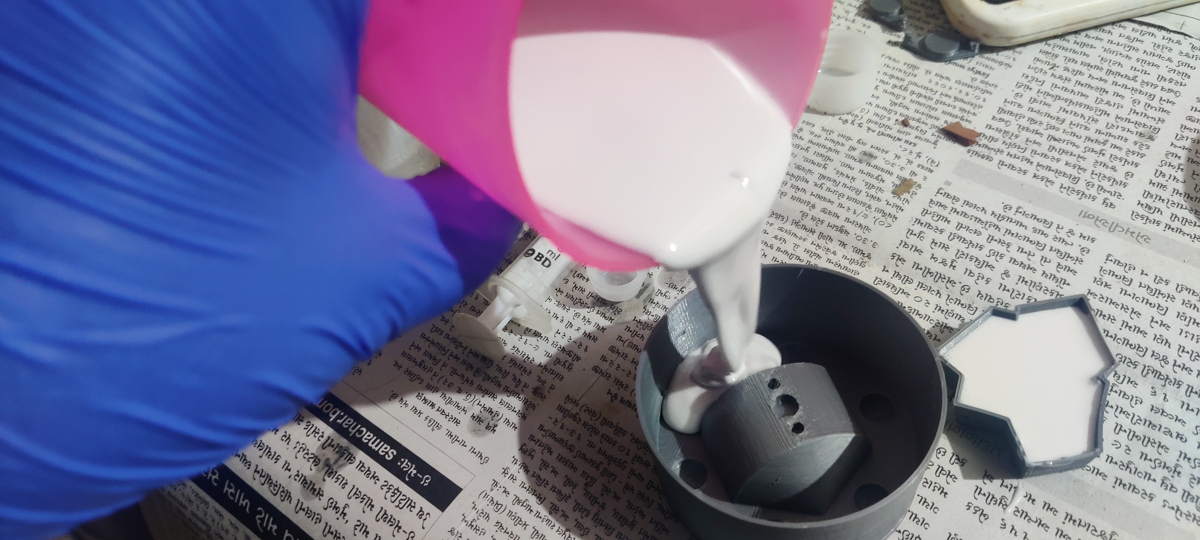

Pouring the Alginate

Using the Wax M2 mold to create the M1 Mold

I made a mix of Alginate and poured it in.

It sets in about an hour (30 mins but I was being safe) after which I removed it from the block

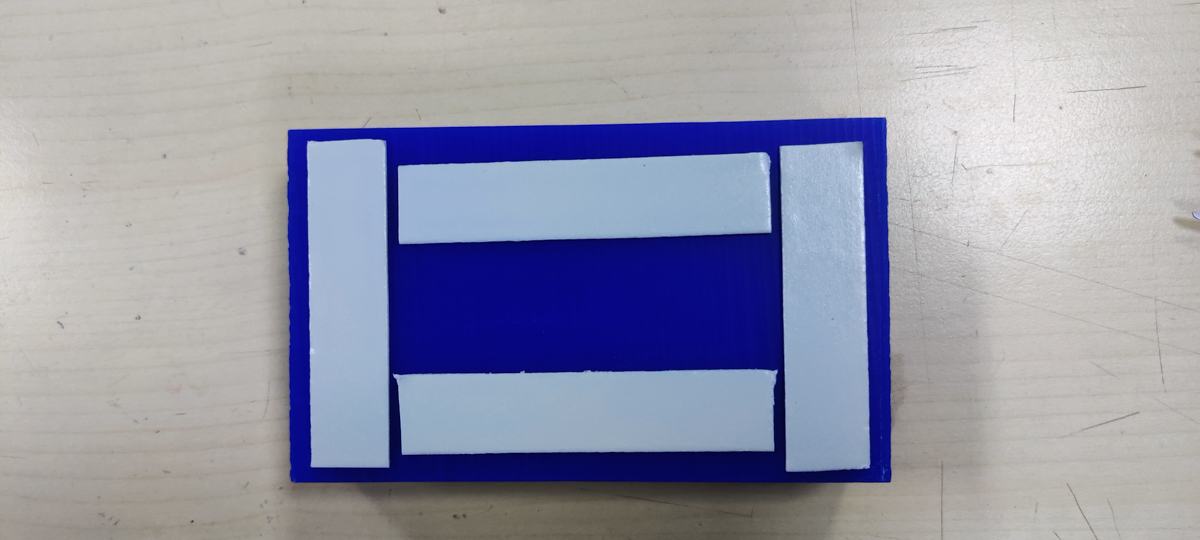

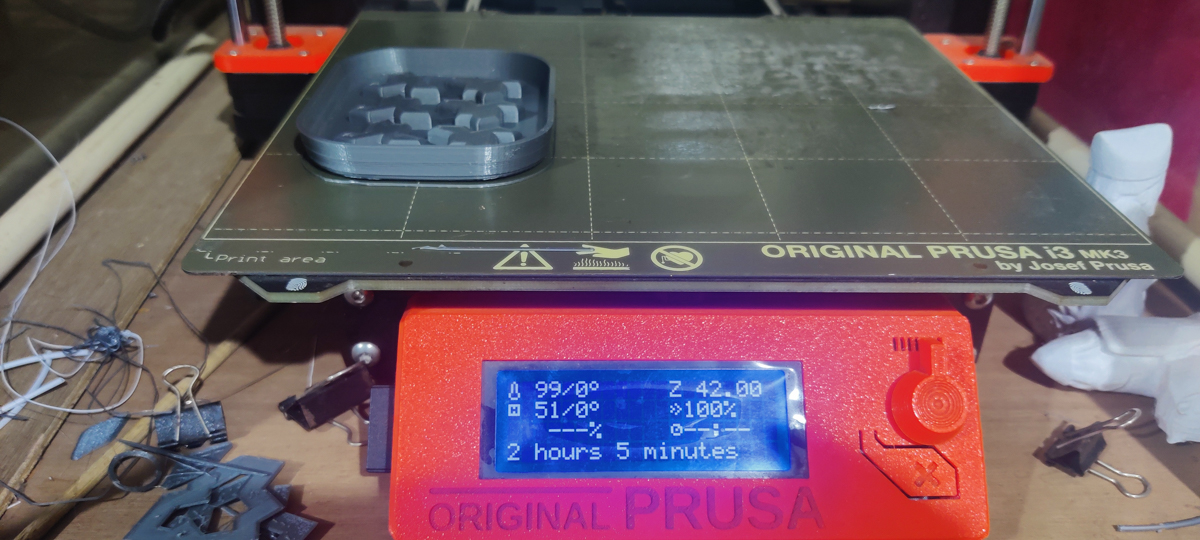

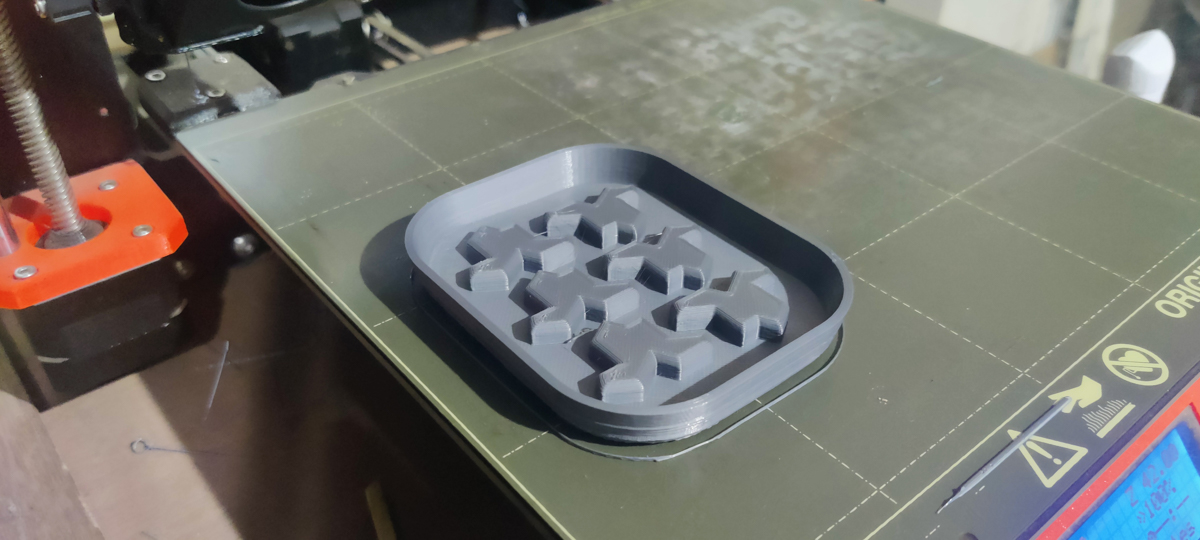

Einstein Hat - 3D Printed Mould

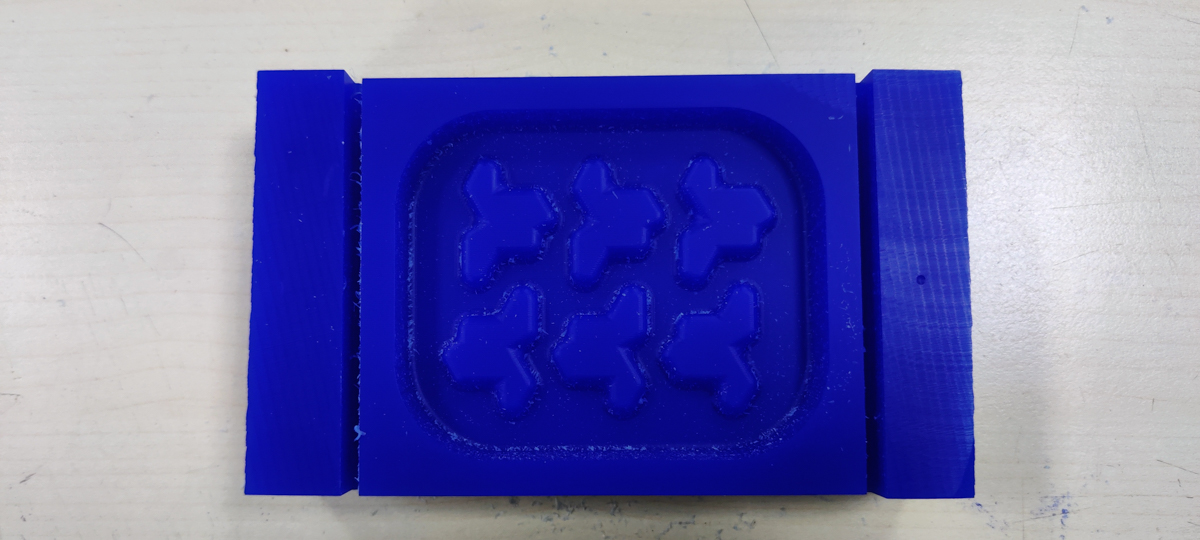

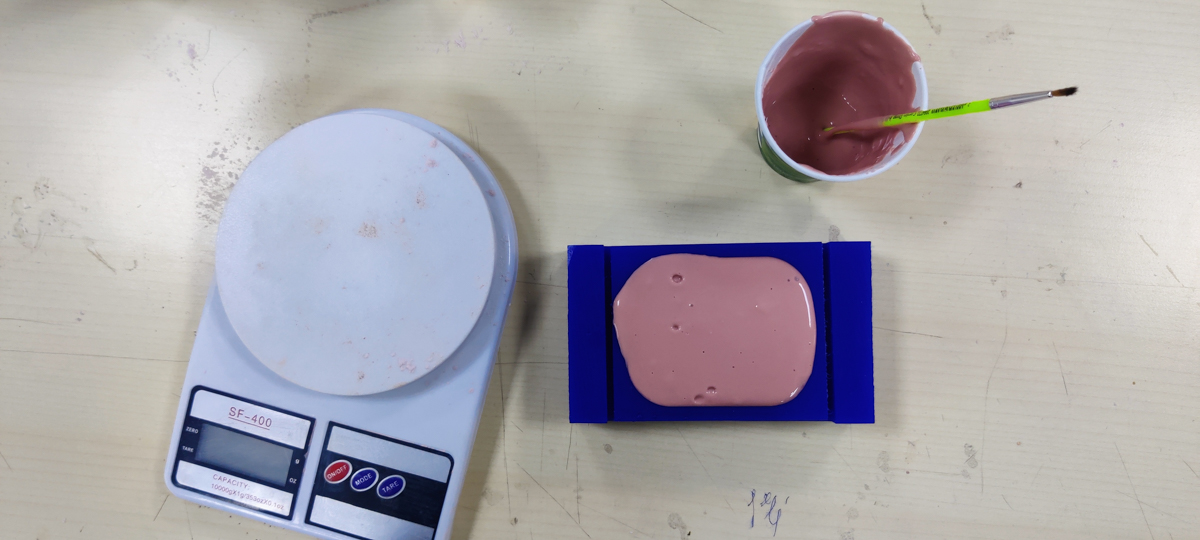

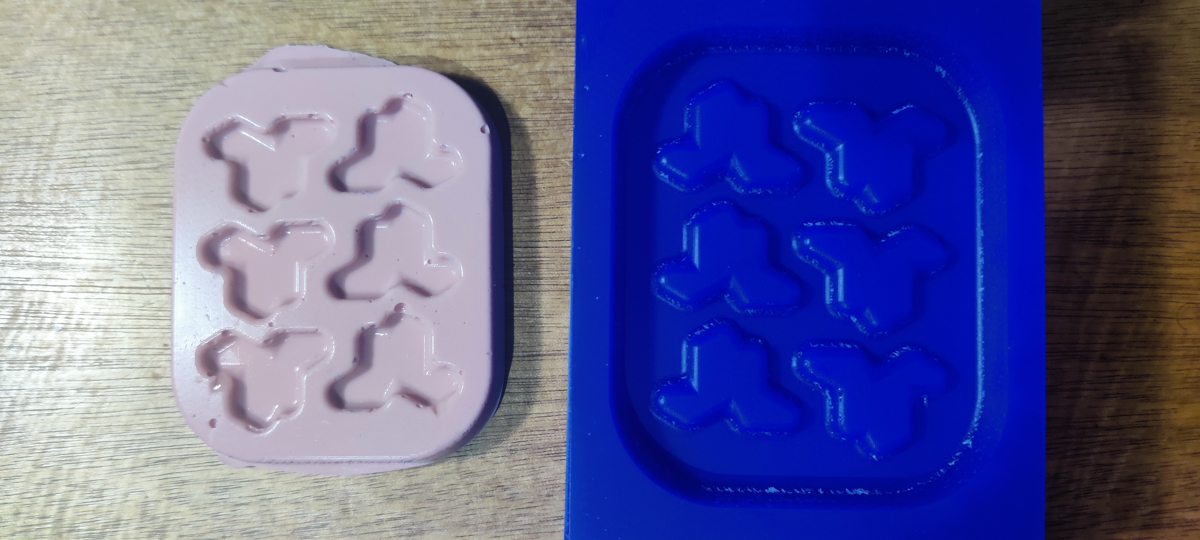

I created the M2 mould by 3D printing it, then poured Silicone in it to create the M1 mould, and then cast white cement to make the tiles.

A little powder goes a long way when wearing gloves.

Doing this is in a well ventilated place in the Mumbai summer evening means you are actually dripping with sweat, and it's dripping over your glasses and going into your eyes, and your silicone hardener soiled gloved hands are not the best idea to wipe your eyes with ! :P

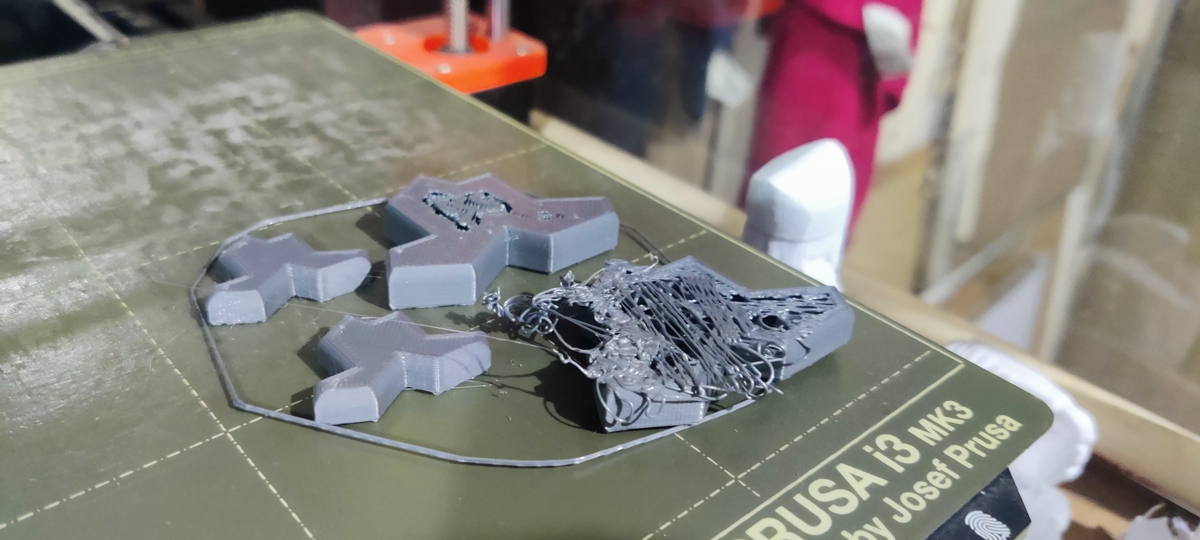

After doing this for a single piece, I created an array of 6 so I could produce tiles faster. A mirror image was also created because the complete tessellation requires some reflected shapes.

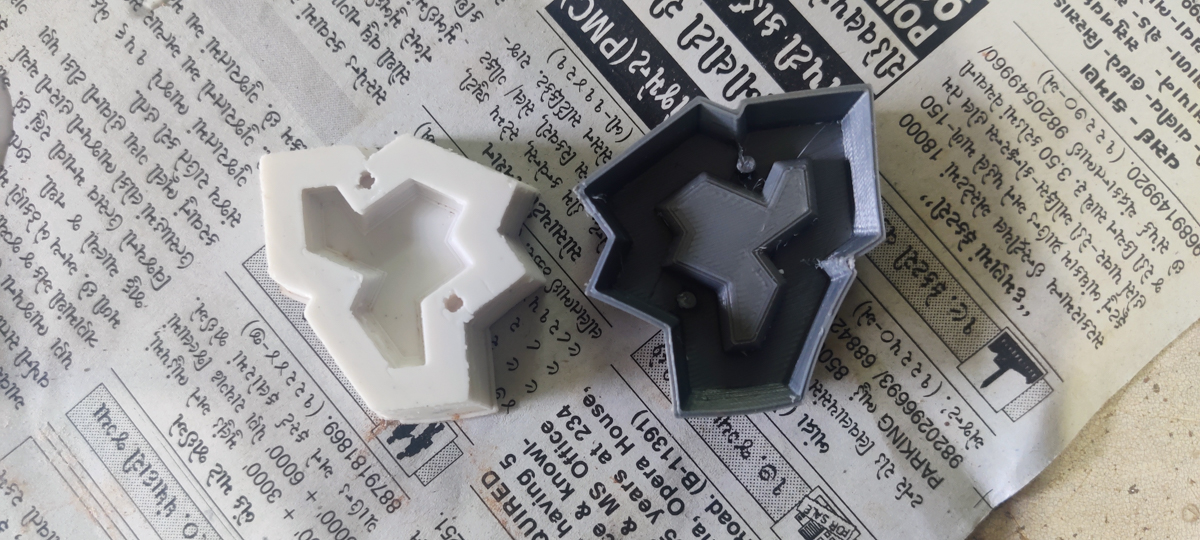

A third version, I tried to print the M1 mould directly in TPU instead of silicone, and cast cement in it. I want to explore the possibility of TPU, being flexible, in its ability to make a direct mould for hard materials.

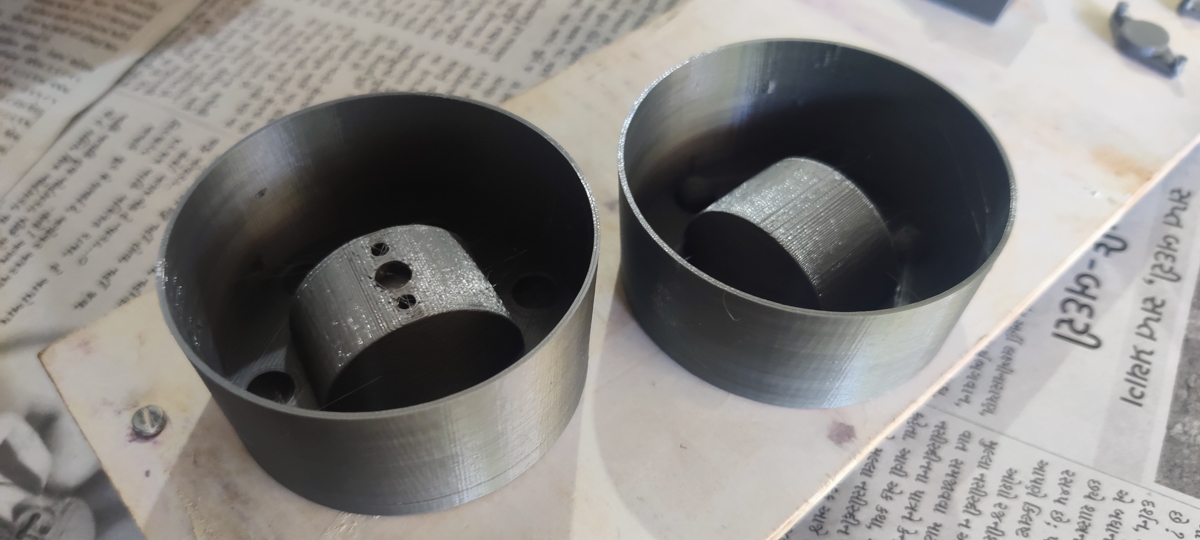

Sphericon

The Sphericon is a rolling shape that follows a generally linear but actually wavy path when rolling without slipping on a surface.

I have always been fascinated by them in various forms, so decided to make some. This time, it required a 2 part mould - 3 parts if you consider the separate insert for the gate that fits into the gap on the surface. The process was similar - 3D print the M2, and M1 in silicone. I cast the final object in Plaster of Paris but the gate is too tiny for PoP to flow, and I'll do a round of resin casting in this after cleaning it up.

Braid

The Braid is an experiment in reversing the hardness. A hard PoP mould to capture the details of a knotted braid that I created with paracord, with silicone poured into it as the casting material to create a flexible replica.

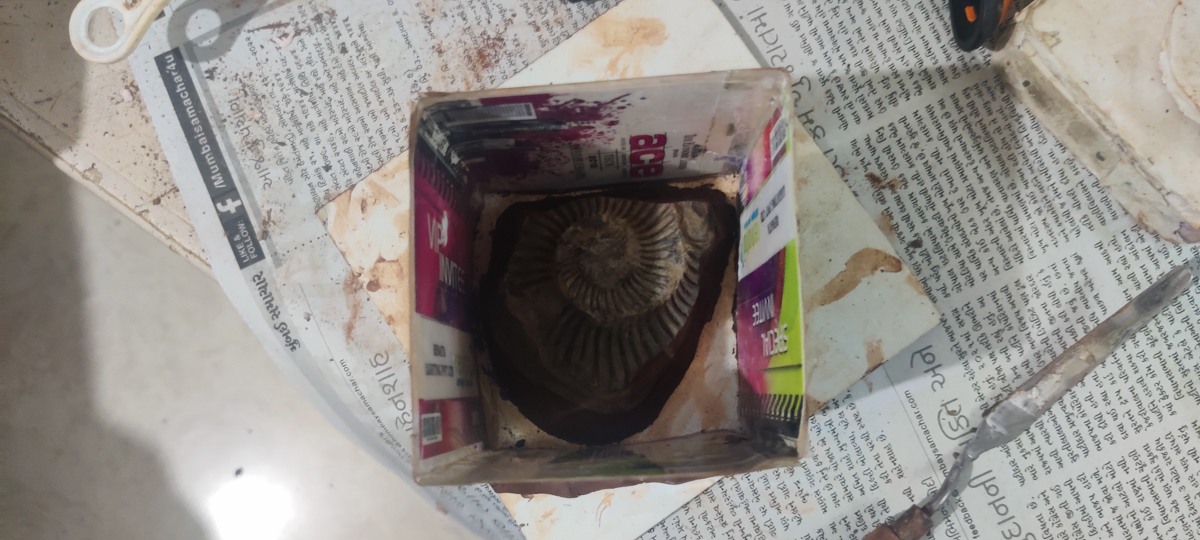

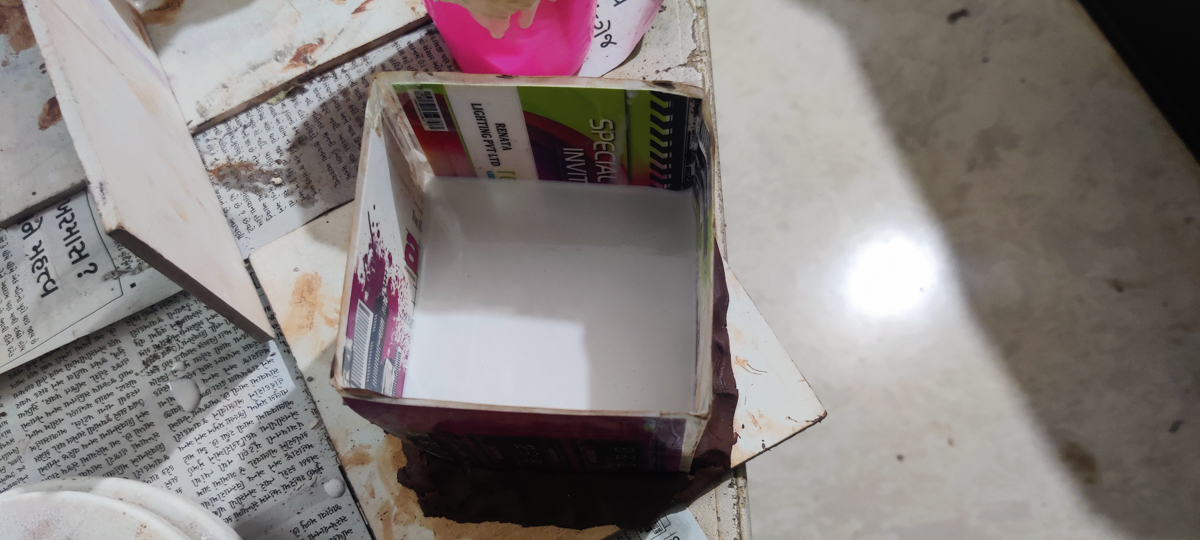

Ammonite Fossil

The Ammonite fossil was something I got back from a recent trip to the mountains. I was reluctant to expose it to anything stronger than water but I figured silicone would be quite neutral.

A simple 4 sided mouldboard encasement was created, and brown terracotta used to fill the undercuts beneath the rock. The silicone was poured to create a basic mould. The fossil was extracted without any obvious harm, so that's a relief. Cement was cast into the mould to create a replica.

I intend to use this replica to create a sand casting of Aluminium later. I am hoping the talcum powder trick helps fill up the details, which is part of the reason I chose this object.

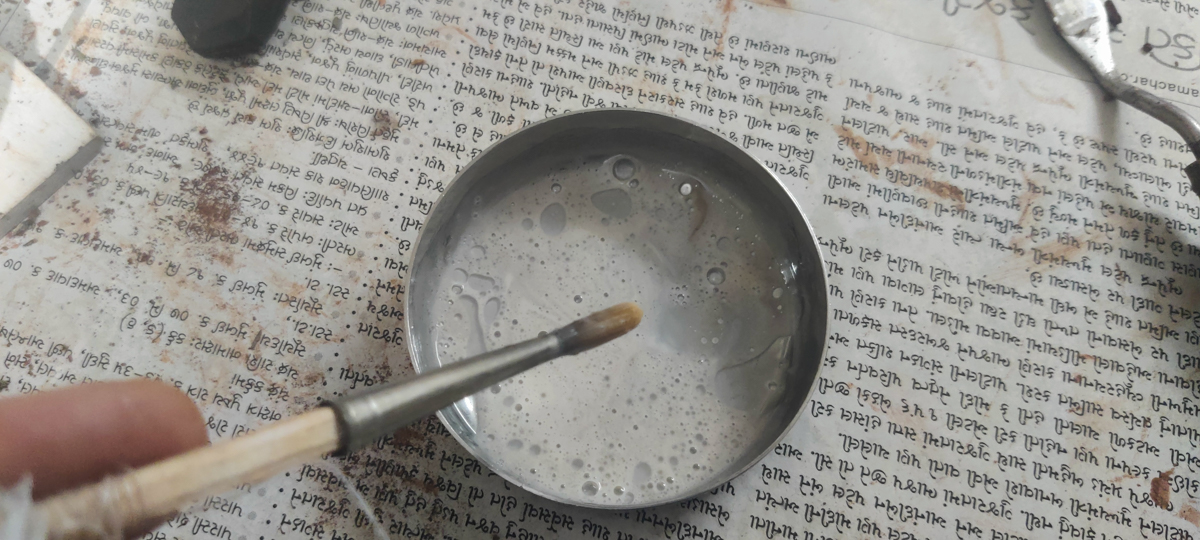

Airplane Model

The Biplane model was actually an old project left halfway that I revived since casting was the flavour of the week. It's a 2 part mould, and one part had already been created. I cleared up the terracotta filler and cast the second half. Unfortunately, and to no surprise, everything has moved and is shaken a bit, and the drying of the terracotta layer didn't help. So the second half of the mould is a little shabby fit. Cast with white cement, and while I left a largish gate and air vents, I don't think this is going to come out well. Again, I'll try resin for it's ability to flow better.

I used a mix of 1:1 oil and hand soap to create a brush-on de-moulder to keep the silicone halves from fusing to each other.

To Do

Use the cement casts of the Ammonite fossil to cast Aluminium ?

Similarly for the Einstein Tiles

Use a furnace to melt the Al

Use a mini induction heater coil for small quantities ?

With Machined moulds, try multipart moulds similar to the tesseract.

Files

Fusion File for all versions of the Einstein Hat Tile

Hat Einstein Tile Mold v7.f3d

Hat Einstein Tile Mold v11.f3d

CNC files and STL

Tray version CNC v2 10mm.stl

Tray version CNC v2 10mm.spj

Other versions of the Einstein Tile as STLs

Mold - Hat Einstein Tile.zip

Mold - Hat TPU version.zip

Mold - 6x tray.zip

Sphericon Mold

Sphericon mold v6.f3d

Mold - Sphericon.zip