Computer Controlled Machining

Individual Assignment:

1- Make (design + mill + assemble) something big

extra credit: don't use fasteners or glue

extra credit: include curved surfaces

Group assignment:

2- Do your lab's safety training

Link

3- Test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

1- Make (design + mill + assemble) something big

The Design

To start off with design I searched the internet and tried to get few ideas on what should I make, and the most simple thing for me turned out to be a chair, I tried to incorprate the extra credit on the design(curved object and not using any fastners) and here are sources that inspired my design.

Here is how I did it in fusion360, started by drawing a sketch and trying to get the shape as close as possible to sources available using arcs and curved lines.

Next I added a rectangle which will form the seat of the chair

To create a smooth chair seat I used the circular pattern tool and selected the curve/arc as a center point.

select the arc

Increase the quantity of the rectangles until you can get a smooth seat looking structure.

Delete the extra rectangles that are not needed

Here is the result after removing the rectangles

Next I applied the same steps fot the other arc

making little modifications to insure smooth seats

This is how it turned out in the end

adding extra modifications around the edges

and this is how it turned out like

sketching extra rectangles to make the chair more rigid

and this the final sketch of the Chair

after that I redrew the seats of the chair

and extruded them

And this how it turned out

After to test the model I had cut in the laser cutter to make sure there are no design flaws. note that this version is had flaws which i fixed later.

Laser Cut

CNC Machine

before Cutting its important to set up the design files correctly, we do that using the Shopbot Vcarve pro software

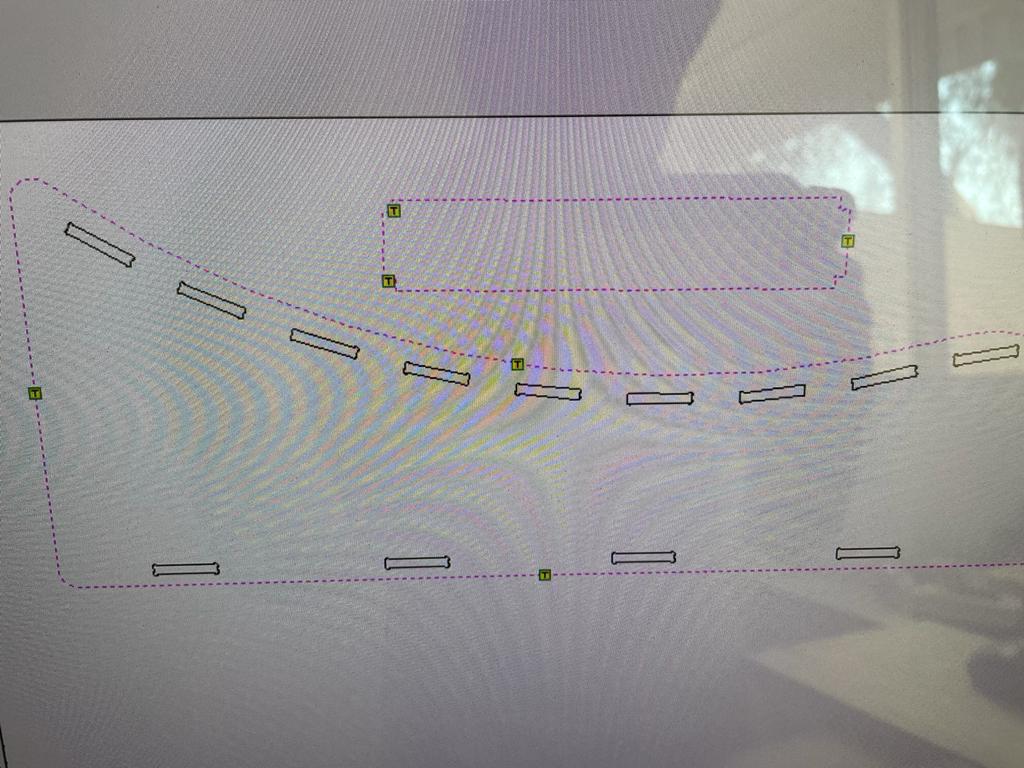

Adding the drawing to the software

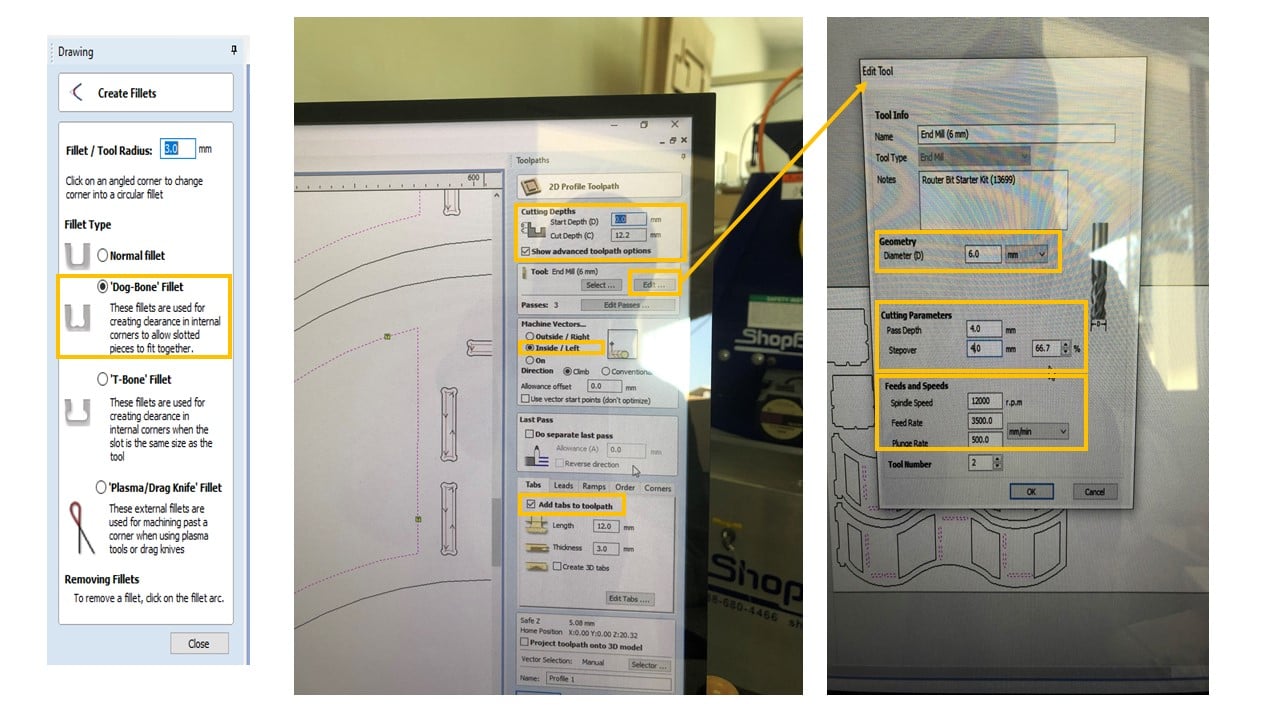

setting up the tool paths of the drawings

Adding tabs to insure that the cut piece stays stable and dosen't fly away mid cut

Setting Up the Feed rate and Speeds

Setting up the machine

To start cutting its important that select the correct endmill that is suitable for the material, this case plywood.

Also its very important to make sure the surface you are cutting on stays flat not like this

CNC cutting

CNC'ed

Group assignment:

2- Do your lab's safety training

3- Test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

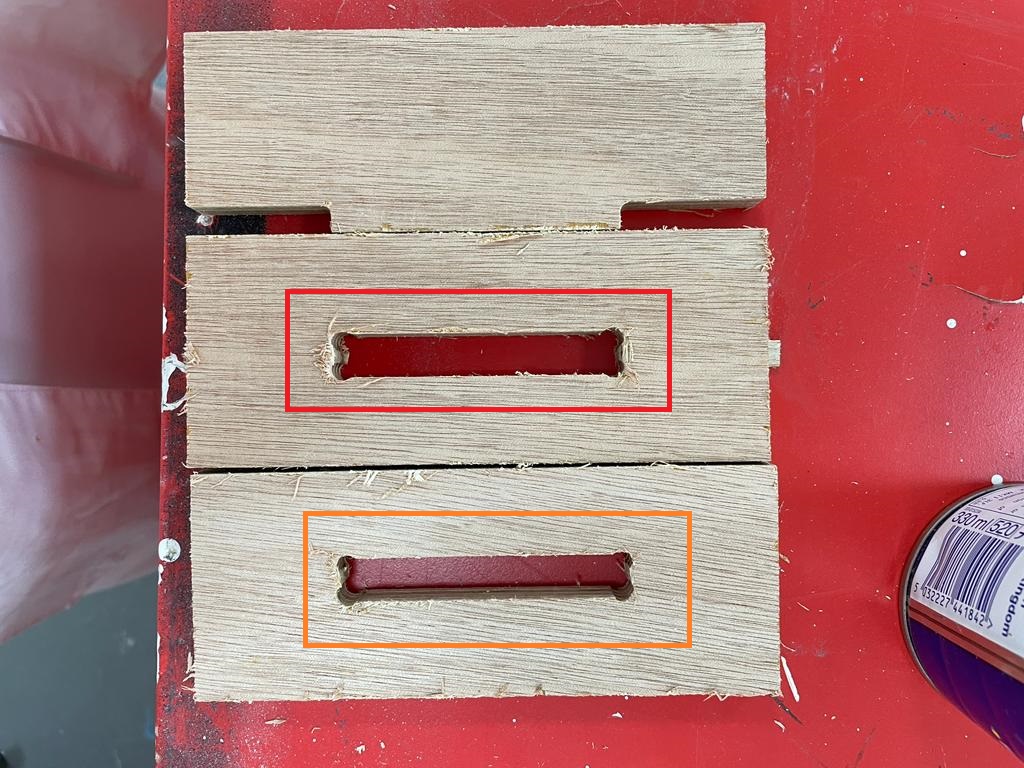

For the group assignment I choose the slot to test the machine,

so I sketched the slot and then cut it with the shopbot machine

As seen in the sketch one of the slots has width of 12mm while the other has width of 11.8mm this is to test the which is more tighter fit.

Files

ArmSide

Male slot 12mm

Female slot 12mm

Female slot 11.8mm/