4. Computer controlled cutting¶

This week I worked on designing a Parametric Press-fit Construction Kit and use Vinylcutter to cut something. In addition, I tried to make a sonic knife for cutting experiments.

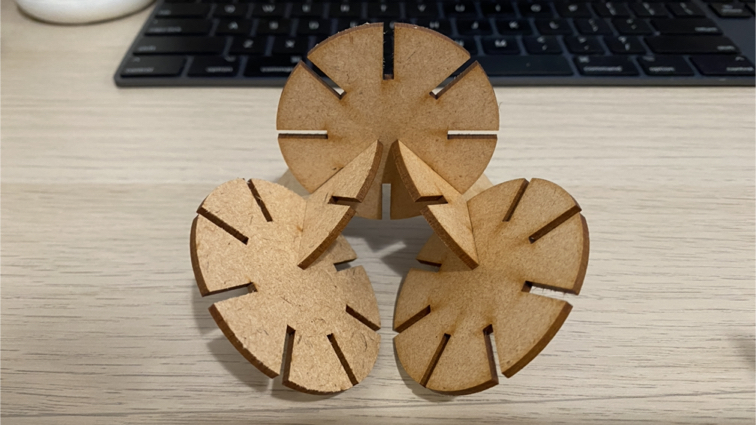

This week Hero shot!¶

This week checklist¶

- [✓] Linked to the group assignment page

- [✓] Explained how to parametrically designed my files

- [✓] Documented how to made my press-fit kit

- [✓] Documented how to made my vinyl cutting

- [✓] Included my original design files

- [✓] Included hero shots

Group assignment¶

This week, I work with my teammate Terry, Darren together to characterize our lasercutter’s focus, power, speed, rate, kerf, and joint clearance. Please click here to see more details of our group assignment.

Individual assignments¶

Vinyl Cutter¶

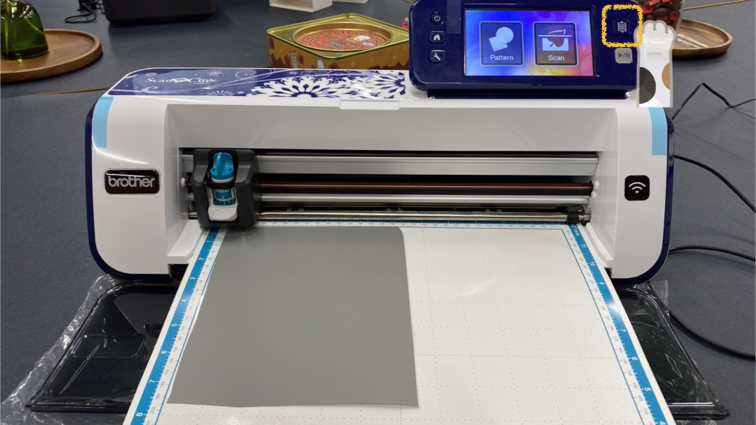

I’m using Brother ScanNCut CM900 to explorer Vinyl Cutting. It provide Scan-to-Cut, Direct-to-Cut, Fabric Cut, and Pen Draw function.

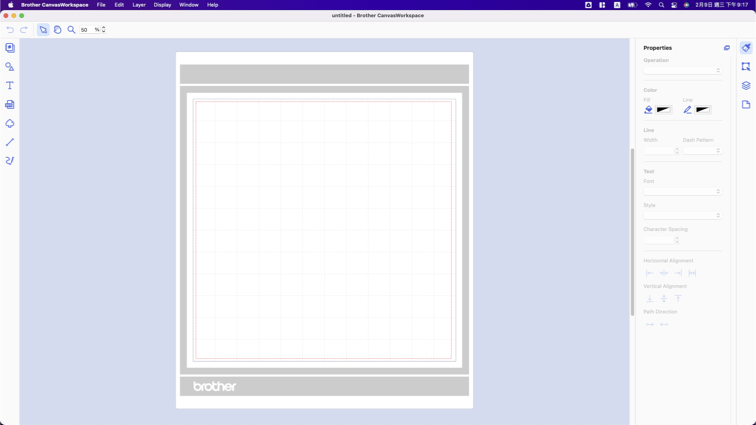

Brother ScanNCut CM900 bundle a software call CanvasWorkspace. You can create original cutting and drawing data for your ScanNCut machine. This platform is able to add SVG file into Canvas Workspace. You may download it here.

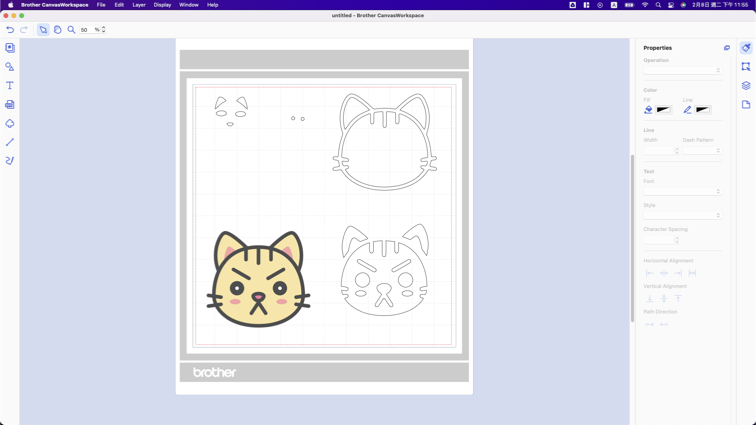

▼ I’m import png file to Canvas Workspace first.

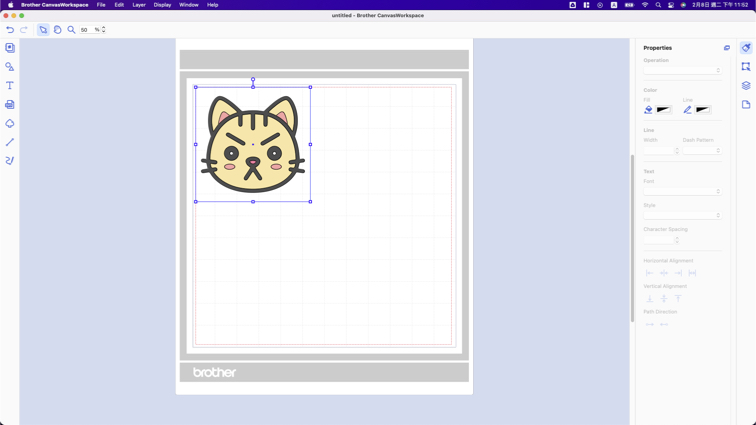

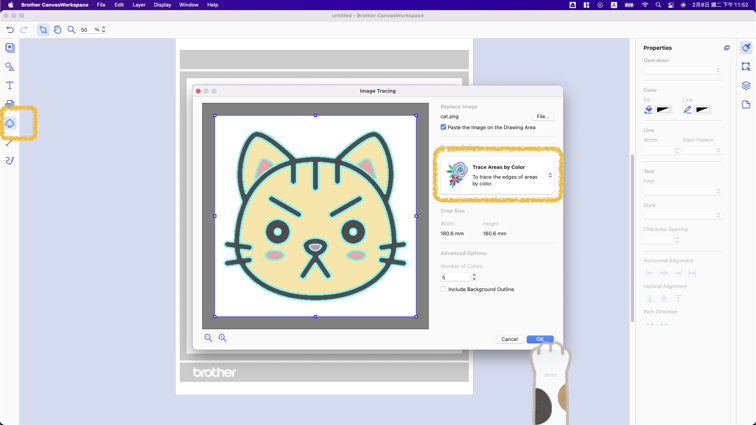

▼ Canvas Workspace have a great fuction is Images Tracking. It can convert many bitmap type image file (png, jpg, bmp) to vector type image (svg). Why convert to vector file? Because this kind of cutting needs to be done according to the vector.

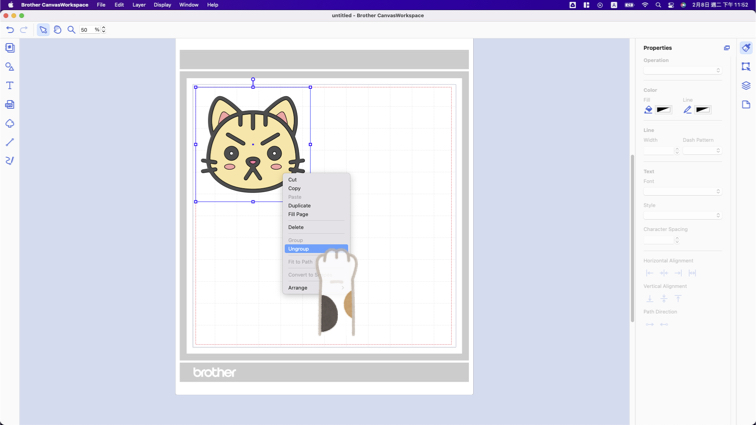

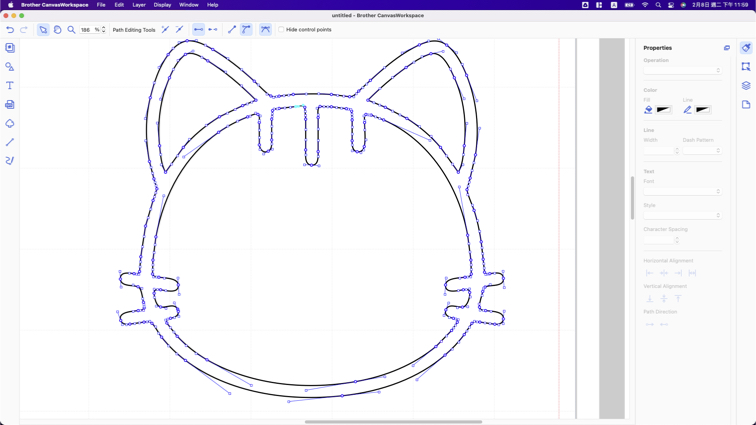

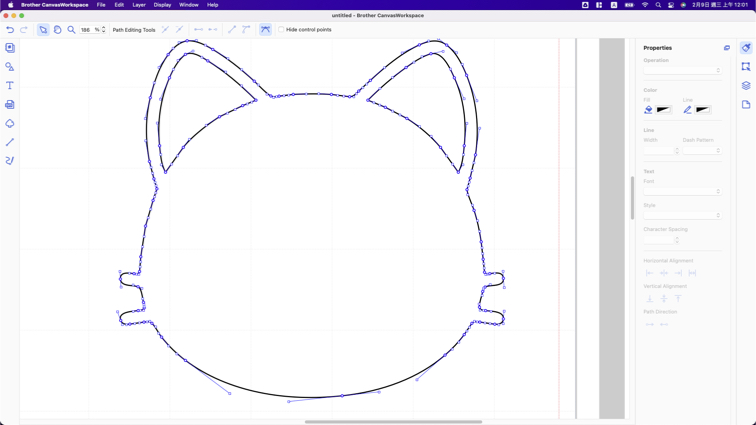

▼ Image converted to vector image after images tracking, then I upgroup curve from vector image.

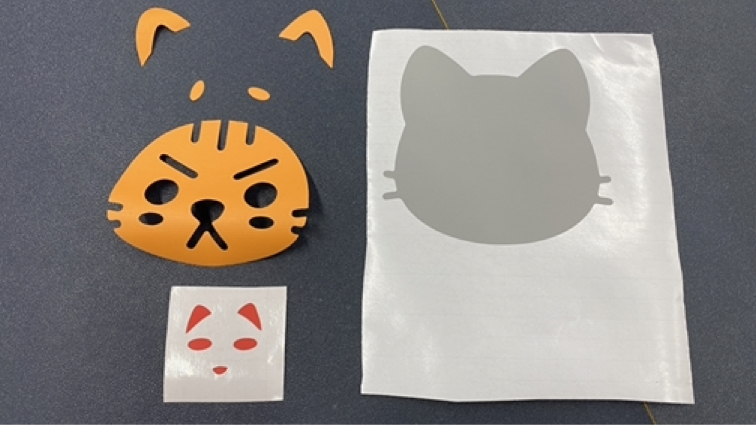

▼ I will cut with three colors of tape.

▼ I can edit or erase curve by double click.

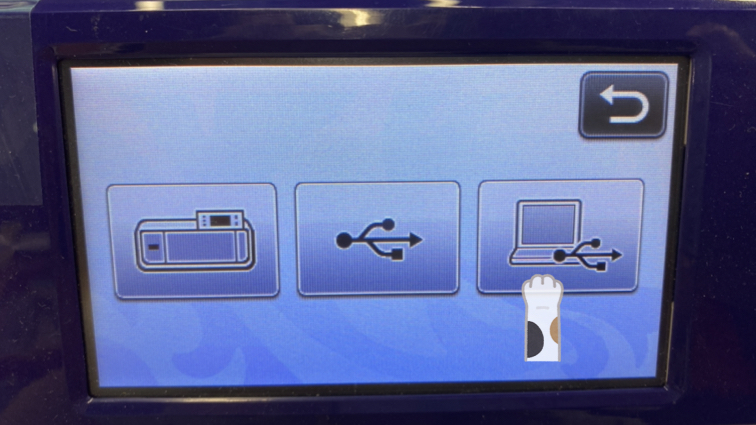

▼ When ready for cut, connect Computer with ScanNCut through USB cable, then Export FCM File to ScanNCut’s USB drive.

▼ It’s time to operate the machine, press the load button to load the cutting mat first.

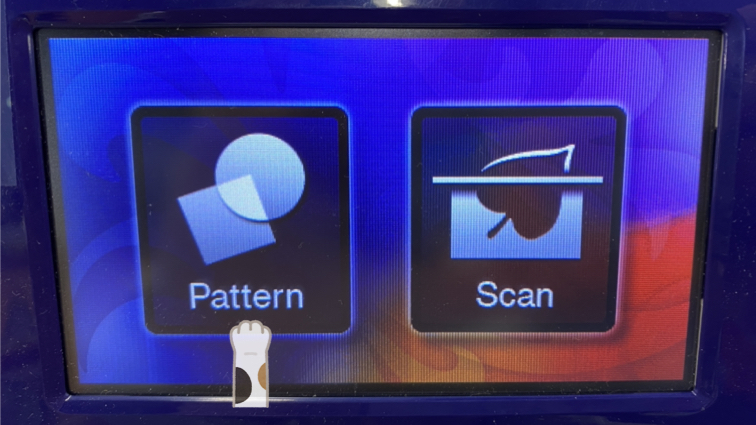

▼ Press Pattern to cutting.

▼ Press Saved Data to select cutting file from ScanNCut’s storage.

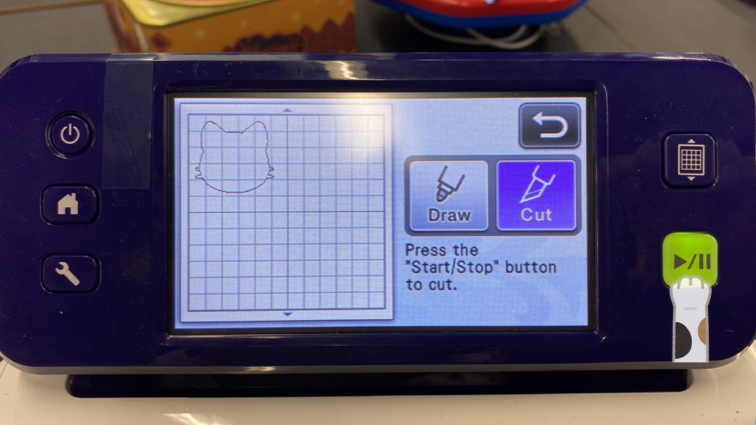

▼ Press Cut and Start button.

▼ When finish, press Load Button to unload the mat.

▼ Repeat the operation to cut other colors.

▼ Finally, I put all stickers in place.

▼ This is a Hero Shot for my sticker.

DIY Sonic Knife¶

After seeing vinyl cutter and ultra sonic knife, I also want to make a knife that can be used to cut styrofoam without heating.

The benefits of sonic knife are

- No heating to deform or discolor on object

- Not need too much force to control the knife, making cutting easier and more capable of cutting complex lines

I tried to make a sonic knife, the material is a sonic toothbrush, a art knife and a connector that I draw with fusion 360 and printed with a 3D printer. Total cost less than USD$ 40.

▼ The following is a test video of my Sonic Knife.

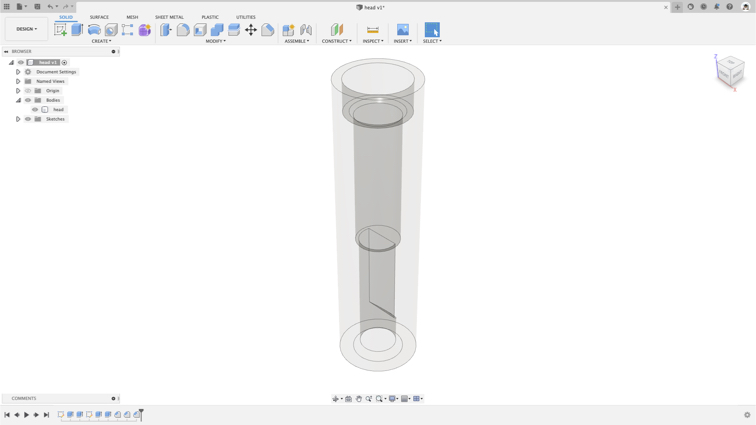

Parametric Press-fit Construction Kit¶

I would like to make a craft animal as the Parametric Press-fit Construction Kit, and try to use laser cutting machine.

▼ I draw a parts of my craft animal first.

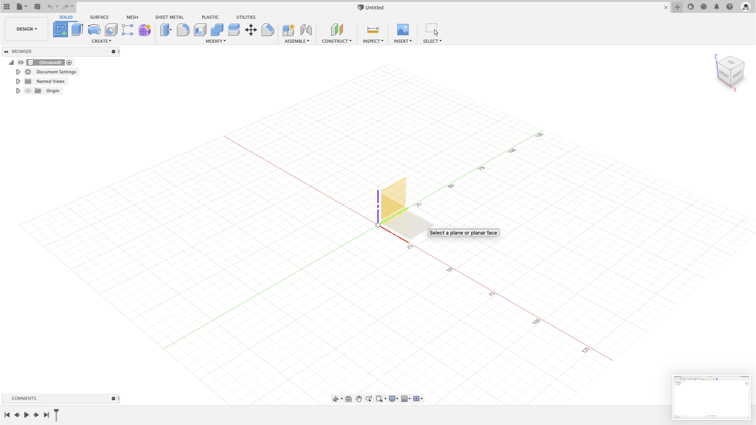

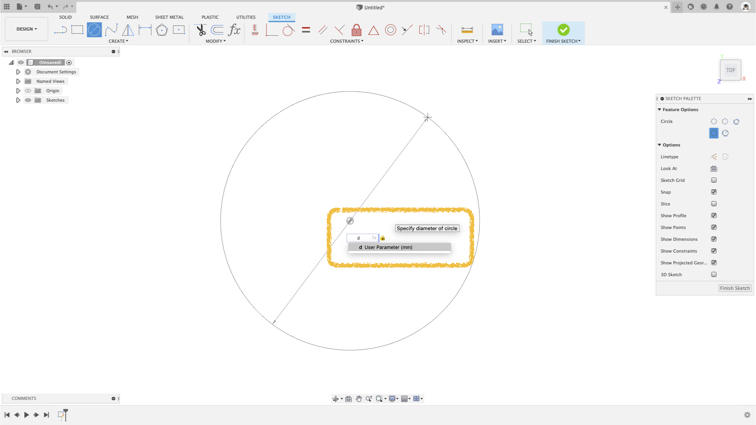

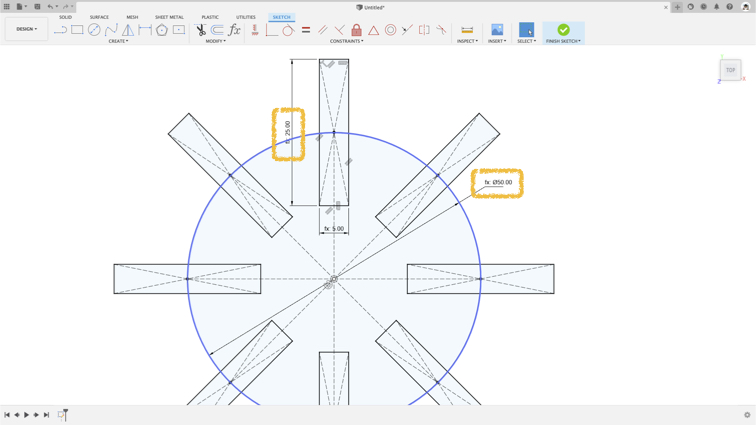

▼ Create user parameters.

▼ During the drawing process use parameters to fill in the dimensions and thickness of MDF.

▼ I can change parameters any time.

▼ If I need change to use 5mm thick MDF material, just change parameter t to 5mm, all dimensions about material thick will change automatically.

▼ All dimensions about material thick have been changed.

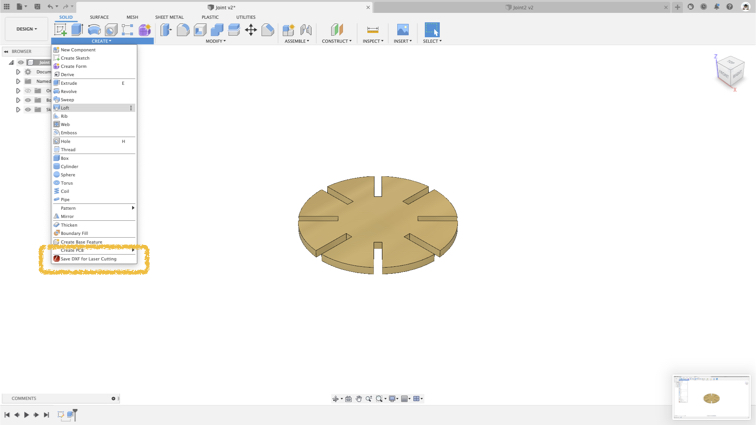

▼ Before output to Laser cutting machine, I need export to DXF format file first, I use a Add-in DXF for Laser to output a DXF file for laser cutting.

▼ After install DXF for Laser, we have new function Save DXF for Laser Cutting here.

▼ Select face you want to export, also you can set Kerf of your laser cutting machine.

▼ Now is time to use Laser cutting machine.

▼ This is air filtration, used to filter and discharge the air generated during cutting.

▼ This piece of glass protects our eyes by filtering light of specified wavelengths.

▼ This is the key for switch laser output.

▼ This is Emergency Stop Button, Press immediately when there is something abnormal about the machine.

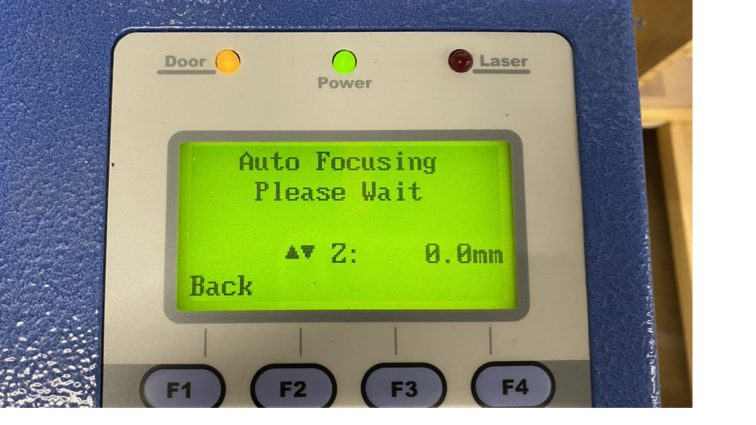

▼ Auto focus when change material.

▼ Don’t forget check the lens.

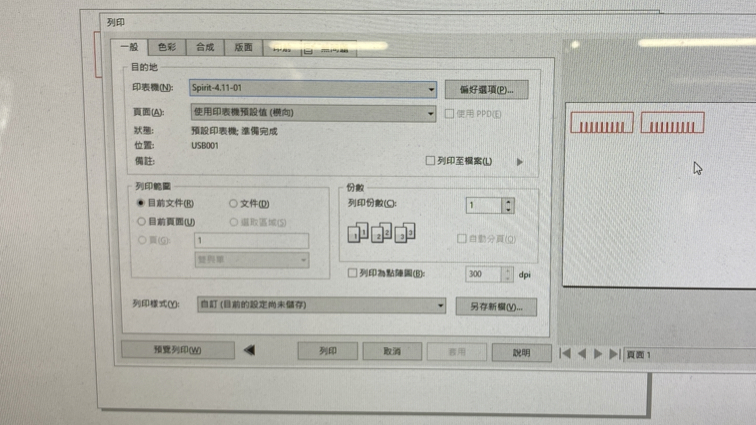

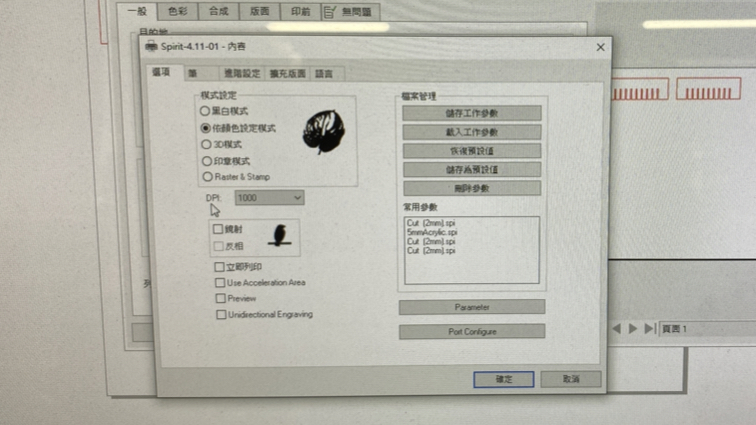

▼ Our FabLab using GCC laser cutting machine, it’s very simple to use, if you want to cut or engrave somthing just print out form vector graphics software to there printer driver. According to the manufacturer’s suggestion, we can choose CorelDraw or Adobe illustrator.

▼ GCC Laser cutting machine very easy to use, I just like using printer printout my picture to laser cut machine.

▼ Start cutting! I feed very excited!

▼ Final test for joint, It’s very fit!

▼ This is a Hero Shot for my MDF craft animal.

Downloads or share for this week.¶

Parametric Press-fit Construction Kit

Sonic Knife

Useful links¶

There are useful links for this week