16. Wildcard Week¶

This week Hero shot!¶

This week Checklist¶

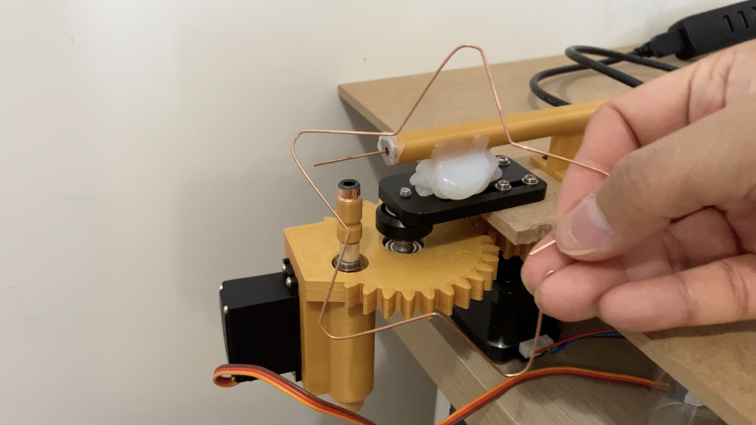

This week I want to make some copper wire artwork produce by machine, but I did’t have machine to make it, so I will try to make a wire bending machine to make copper wire artwork.

- [✓] Documented how I made my creation

- [✓] Described problems and how I fixed them

- [✓] Included my design files and hero shot of the result

Research¶

I have searched a lot of videos/instructions and this is what I think is most likely to be achieved with the resources on hand.

Arduino 3D Wire Bending Machine

Hands-on¶

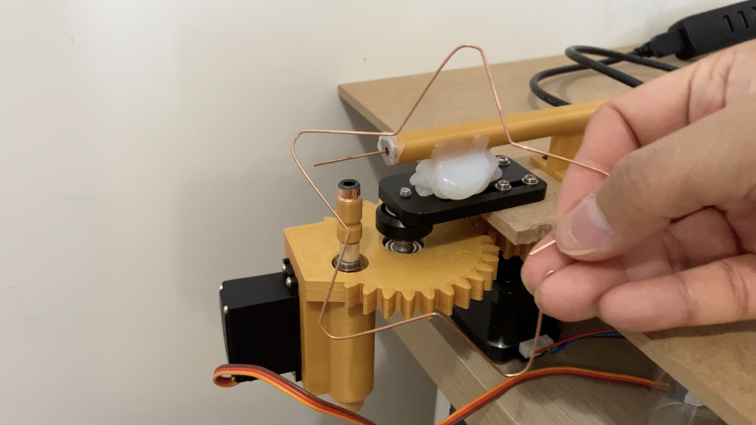

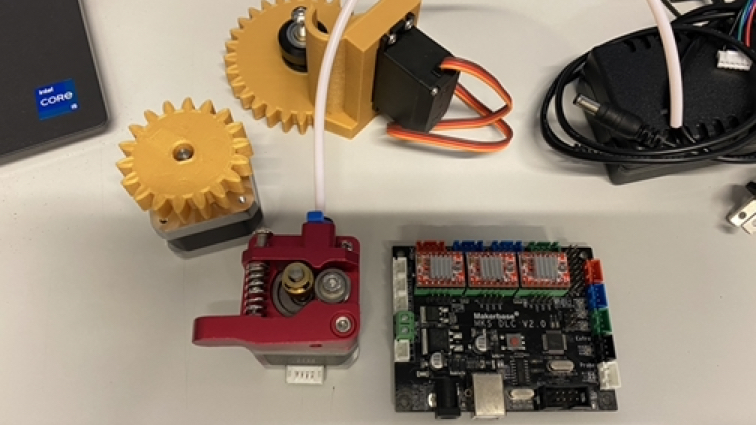

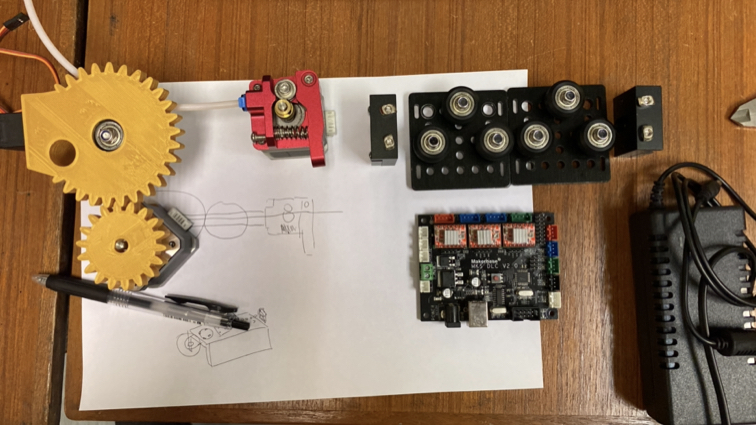

▼ Print out 3DP gear components first, and collect mechanical and electronic parts from old machines.

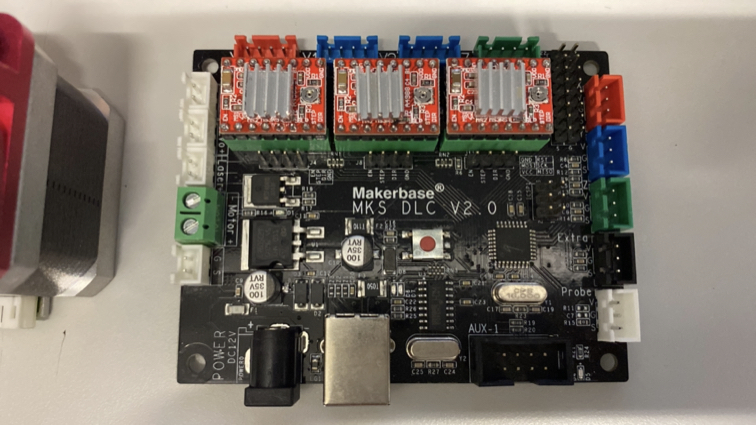

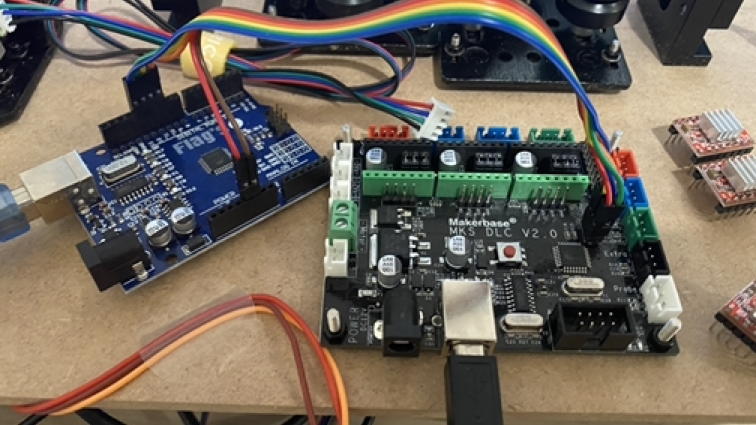

▼ I choose to use this board - Makerbase MKS DLC V2.0, because it can be programmed using the Arduino IDE.

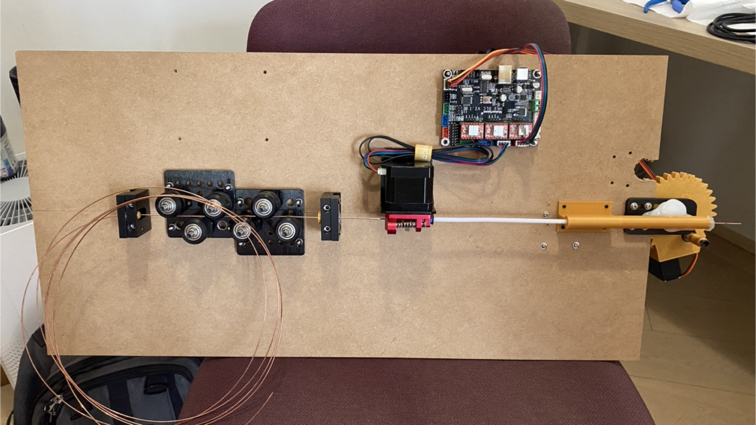

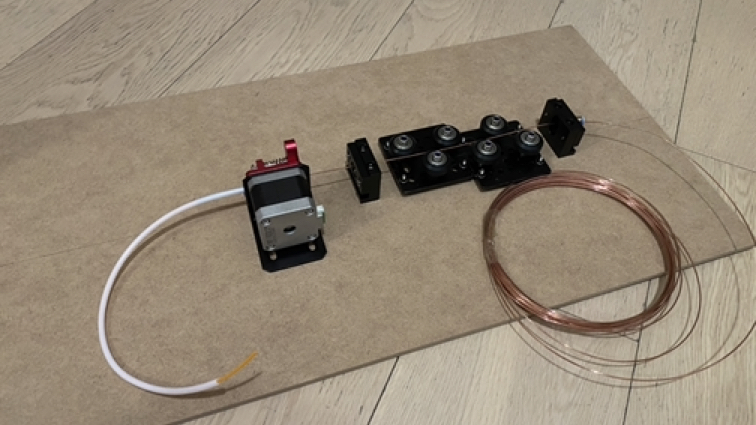

▼ Measure and arrange parts.

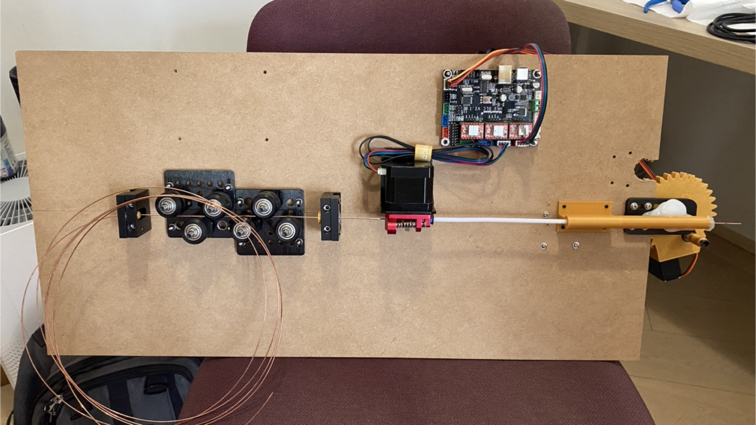

▼ Mount to MDF board.

▼ Hardware part of the wire bending machine is roughly completed.

Problems¶

█ 1. Stepper motor too hot!

When the machine is running about 10 minutes, one of the steppers will be very hot, and the servo motor will continue to vibrate slightly. I modified the program so that the motor will stop power supply when it reaches the desired position, to prevent the motor overheat.

In addition, I adjusted the maximum current of the motor driver board according to the advice of the instructors, and now there is no problem of overheating.

█ 2. Control board out of order…

▼ I’ve tried everything I can think to try to repair it, but still not work, In the end I decided to buy two more control boards.

▼ The video below is one of the testing before the control board broke down.

Coding¶

#include <Servo.h>

const int servoPin = A5;

Servo myservo;

#define enPin 8

// stepper motor X

#define stepXPin 2

#define dirXPin 5

// stepper motor Y

#define stepYPin 3

#define dirYPin 6

#define stepsPerRevolution 200

#define delayms 1000

void setup() {

Serial.begin(115200);

pinMode(servoPin, OUTPUT);

pinMode(stepXPin, OUTPUT);

pinMode(dirXPin, OUTPUT);

pinMode(stepYPin, OUTPUT);

pinMode(dirYPin, OUTPUT);

pinMode(enPin , OUTPUT);

digitalWrite(enPin, HIGH); // disable Stepper

action001(); // make a star shape

delay(3000);

}

void loop() {

}

void feed(int distance) {

digitalWrite(enPin, LOW); // enable Stepper

digitalWrite(dirYPin, HIGH);

for (int i = 0; i < stepsPerRevolution * (distance / 2); i++) {

digitalWrite(stepYPin, HIGH);

delayMicroseconds(delayms);

digitalWrite(stepYPin, LOW);

delayMicroseconds(delayms);

}

delay(500);

digitalWrite(enPin, HIGH); // disable Stepper

}

void turn(boolean direction, int angle) {

digitalWrite(enPin, LOW); // enable Stepper

digitalWrite(dirXPin, direction);

for (int i = 0; i < stepsPerRevolution * angle; i++) {

digitalWrite(stepXPin, HIGH);

delayMicroseconds(delayms);

digitalWrite(stepXPin, LOW);

delayMicroseconds(delayms);

}

delay(500);

}

void header(boolean position) {

myservo.attach(servoPin);

if (position) {

myservo.write(20);

} else {

myservo.write(110);

}

delay(1500); // delay for 1.5 second

myservo.detach();

}

void action001() {

header(false); // ⬇ true = high position, false = position

feed(30); // feed 25mm

for (int j = 0; j < 5; j++) {

header(true); // ⬆

turn(HIGH, 4); // ▶ to +4

for (int i = 0; i < 4; i++) {

feed(5); // feed 5mm

turn(HIGH, 1); // ▶

} // ▶ to +8 尖角轉彎

turn(LOW, 6); // ◀ to 2

header(false); // ⬇

feed(25); // feed 25mm

header(true); // ⬆

turn(LOW, 5); // ◀ to -3

turn(HIGH, 2); // ◀ to -1

header(false); // ⬇

feed(30); // feed 25mm

turn(HIGH, 1); // ▶ to 0

}

}

Downloads¶

Arduino program for wire bending machine (Makerbase MKS DLC 2.0 board)

week16.ino